engine FORD E SERIES 1999 4.G 7.3L Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1999, Model line: E SERIES, Model: FORD E SERIES 1999 4.GPages: 39, PDF Size: 0.46 MB

Page 13 of 39

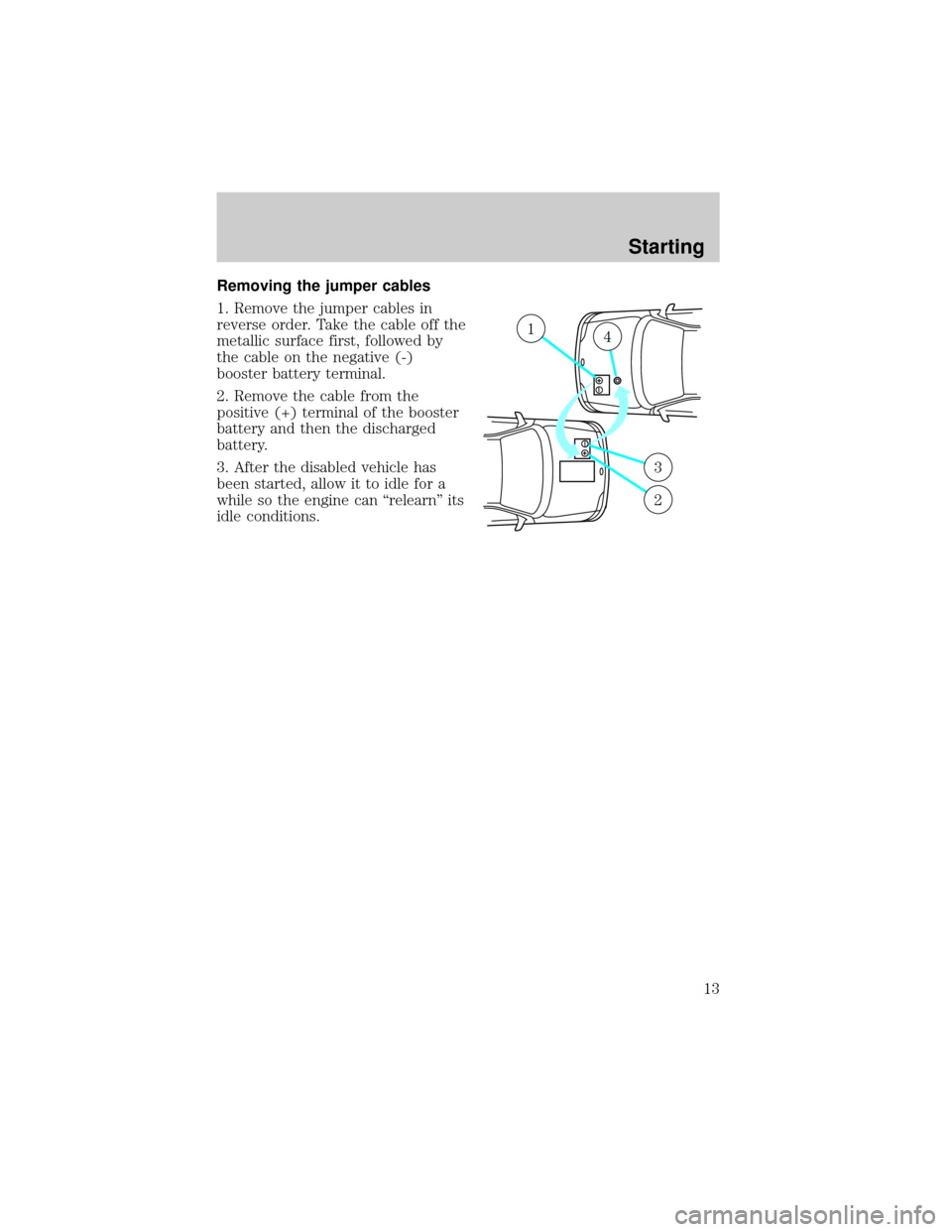

Removing the jumper cables

1. Remove the jumper cables in

reverse order. Take the cable off the

metallic surface first, followed by

the cable on the negative (-)

booster battery terminal.

2. Remove the cable from the

positive (+) terminal of the booster

battery and then the discharged

battery.

3. After the disabled vehicle has

been started, allow it to idle for a

while so the engine can ªrelearnº its

idle conditions.

+–

+–

14

3

2

Starting

13

Page 14 of 39

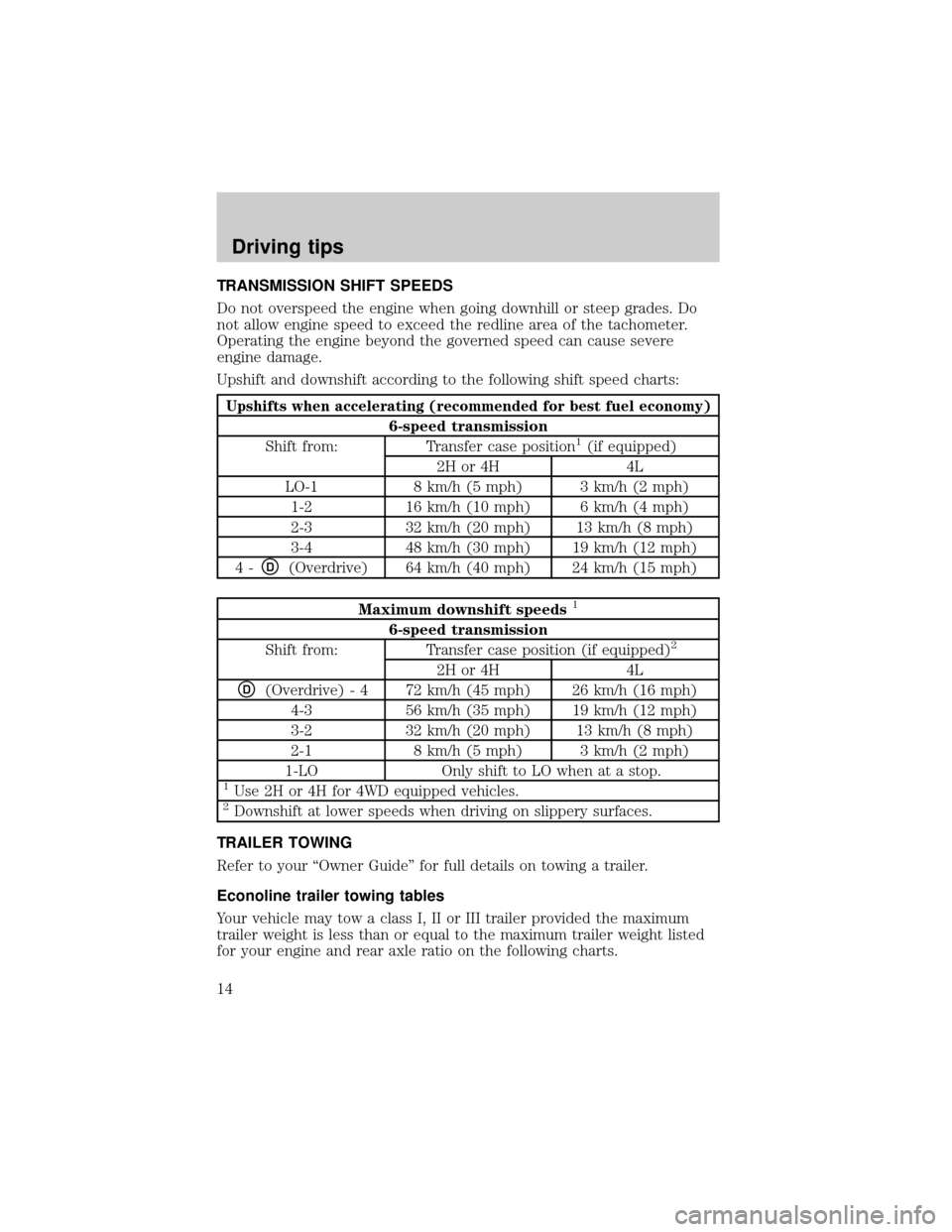

TRANSMISSION SHIFT SPEEDS

Do not overspeed the engine when going downhill or steep grades. Do

not allow engine speed to exceed the redline area of the tachometer.

Operating the engine beyond the governed speed can cause severe

engine damage.

Upshift and downshift according to the following shift speed charts:

Upshifts when accelerating (recommended for best fuel economy)

6-speed transmission

Shift from: Transfer case position1(if equipped)

2H or 4H 4L

LO-1 8 km/h (5 mph) 3 km/h (2 mph)

1-2 16 km/h (10 mph) 6 km/h (4 mph)

2-3 32 km/h (20 mph) 13 km/h (8 mph)

3-4 48 km/h (30 mph) 19 km/h (12 mph)

4-

D(Overdrive) 64 km/h (40 mph) 24 km/h (15 mph)

Maximum downshift speeds1

6-speed transmission

Shift from: Transfer case position (if equipped)2

2H or 4H 4L

D(Overdrive) - 4 72 km/h (45 mph) 26 km/h (16 mph)

4-3 56 km/h (35 mph) 19 km/h (12 mph)

3-2 32 km/h (20 mph) 13 km/h (8 mph)

2-1 8 km/h (5 mph) 3 km/h (2 mph)

1-LO Only shift to LO when at a stop.

1Use 2H or 4H for 4WD equipped vehicles.2Downshift at lower speeds when driving on slippery surfaces.

TRAILER TOWING

Refer to your ªOwner Guideº for full details on towing a trailer.

Econoline trailer towing tables

Your vehicle may tow a class I, II or III trailer provided the maximum

trailer weight is less than or equal to the maximum trailer weight listed

for your engine and rear axle ratio on the following charts.

Driving tips

14

Page 16 of 39

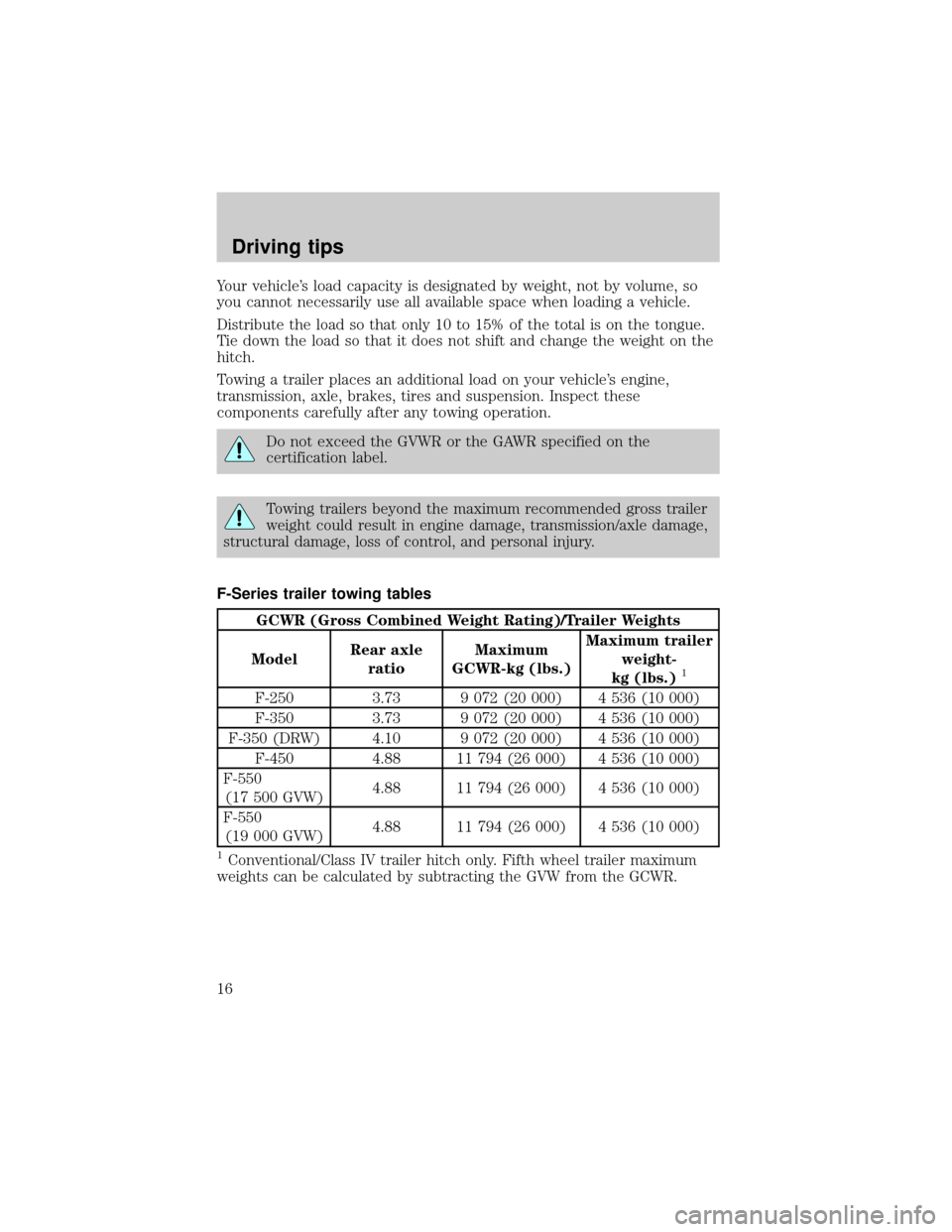

Your vehicle's load capacity is designated by weight, not by volume, so

you cannot necessarily use all available space when loading a vehicle.

Distribute the load so that only 10 to 15% of the total is on the tongue.

Tie down the load so that it does not shift and change the weight on the

hitch.

Towing a trailer places an additional load on your vehicle's engine,

transmission, axle, brakes, tires and suspension. Inspect these

components carefully after any towing operation.

Do not exceed the GVWR or the GAWR specified on the

certification label.

Towing trailers beyond the maximum recommended gross trailer

weight could result in engine damage, transmission/axle damage,

structural damage, loss of control, and personal injury.

F-Series trailer towing tables

GCWR (Gross Combined Weight Rating)/Trailer Weights

ModelRear axle

ratioMaximum

GCWR-kg (lbs.)Maximum trailer

weight-

kg (lbs.)

1

F-250 3.73 9 072 (20 000) 4 536 (10 000)

F-350 3.73 9 072 (20 000) 4 536 (10 000)

F-350 (DRW) 4.10 9 072 (20 000) 4 536 (10 000)

F-450 4.88 11 794 (26 000) 4 536 (10 000)

F-550

(17 500 GVW)4.88 11 794 (26 000) 4 536 (10 000)

F-550

(19 000 GVW)4.88 11 794 (26 000) 4 536 (10 000)

1Conventional/Class IV trailer hitch only. Fifth wheel trailer maximum

weights can be calculated by subtracting the GVW from the GCWR.

Driving tips

16

Page 17 of 39

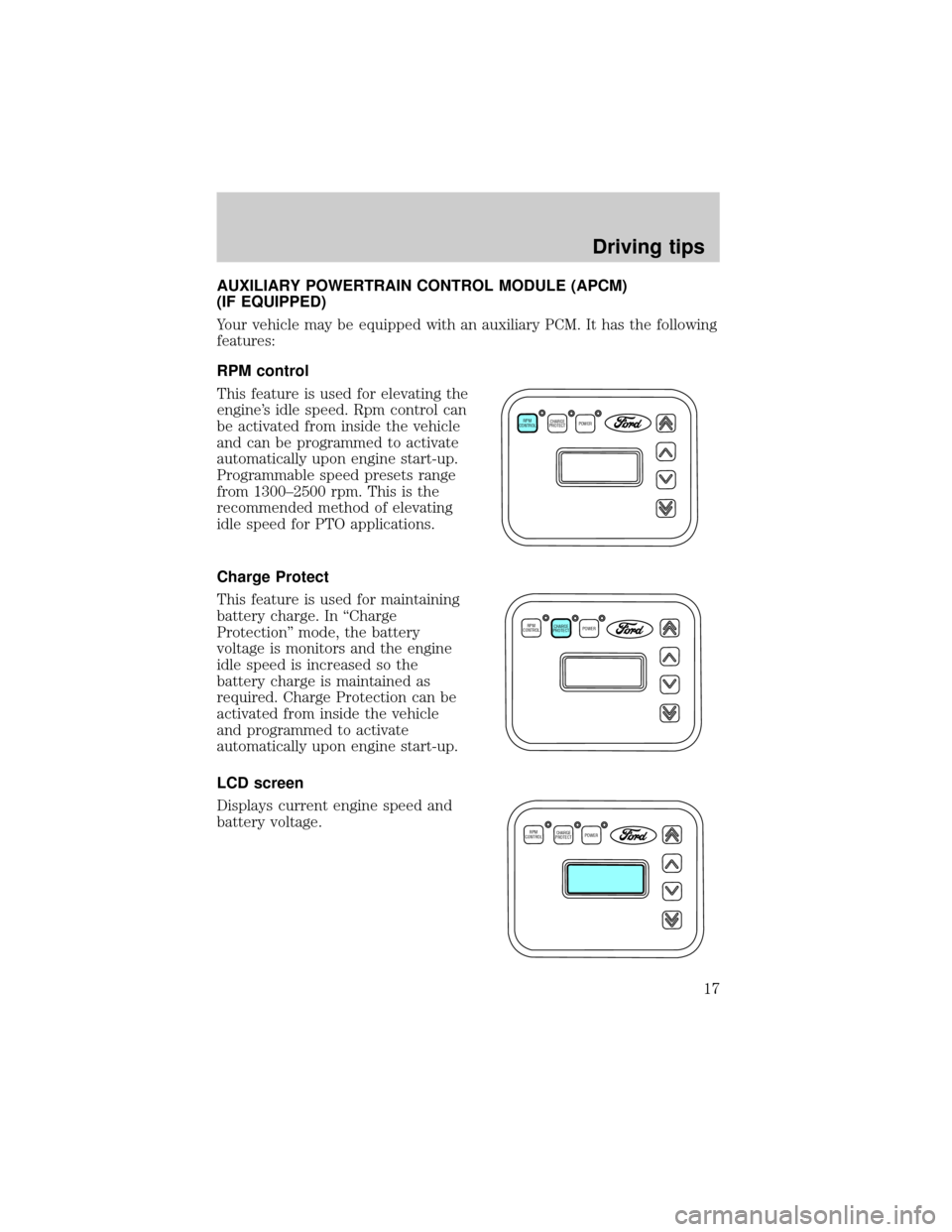

AUXILIARY POWERTRAIN CONTROL MODULE (APCM)

(IF EQUIPPED)

Your vehicle may be equipped with an auxiliary PCM. It has the following

features:

RPM control

This feature is used for elevating the

engine's idle speed. Rpm control can

be activated from inside the vehicle

and can be programmed to activate

automatically upon engine start-up.

Programmable speed presets range

from 1300±2500 rpm. This is the

recommended method of elevating

idle speed for PTO applications.

Charge Protect

This feature is used for maintaining

battery charge. In ªCharge

Protectionº mode, the battery

voltage is monitors and the engine

idle speed is increased so the

battery charge is maintained as

required. Charge Protection can be

activated from inside the vehicle

and programmed to activate

automatically upon engine start-up.

LCD screen

Displays current engine speed and

battery voltage.

RPM

CONTROLCHARGE

PROTECTPOWER

RPM

CONTROLCHARGE

PROTECTPOWER

RPM

CONTROLCHARGE

PROTECTPOWER

Driving tips

17

Page 18 of 39

Arrow keys

Each arrow key contains a preset

speed allowing four programmable

rpm settings. The arrow keys can

also be used to manually increase or

decrease engine idle speed at a

faster of slower rate.

RPM

CONTROLCHARGE

PROTECTPOWER

Driving tips

18

Page 19 of 39

SCHEDULED MAINTENANCE

The Scheduled Maintenance Services in the Service Guide are required

because they are considered essential to the life and performance of

your vehicle.

Use only recommended fuel, lubricants, fluids and service parts

conforming to Ford specifications. Motorcraft parts are designed and

built for best performance in your vehicle.

WASHING THE DIESEL ENGINE

Never wash the engine when it is warm, hot or running. Spraying water

or other cleaning fluids on a warm engine can seriously damage the

engine's fuel system. When washing the engine, the air cleaner must be

in place to prevent water from splashing into the engine.

FUEL REQUIREMENTS

The engine is designed to use low sulfur number 1±D or 2±D diesel fuel

only. At temperatures below -7ÉC (20ÉF), number 1±D or winter blend

number 2±D fuel is recommended. (See ªCold Weather Operationº in the

Startingchapter.)

Do not use fuel intended for agricultural use (agricultural fuel is

dyed red), home heating oil or any diesel fuel not intended for

highway use. Damage to the fuel injection system or engine can

occur if an improper fuel is used.

Do not add gasoline, gasohol or alcohol to diesel fuel. This practice

creates a serious fire hazard and engine performance problems.

It should not be necessary to add any aftermarket additives to your fuel

tank if you use a properly formulated diesel fuel that meets the ASTM D

975 industry specification. Aftermarket additives can damage the injector

system or engine.

Do not blend used engine oil with diesel fuel under any circumstances.

Blending used oil with the fuel will significantly increase your vehicle's

exhaust emissions and reduce engine life due to increased internal wear.

Do not crank the engine for more than 30 seconds at a time as

damage to the starter motor may result.

If the engine fails to start in 30 seconds, turn the key to the OFF

position and wait 30 seconds before trying again.

General maintenance information

19

Page 20 of 39

Truck stops have pumps and nozzles designed for larger, heavy-duty

trucks. When refueling at truck stops: if the nozzle shuts off repeatedly

when refueling, wait 5±10 seconds; then use a slower rate of flow (don't

depress the nozzle trigger as far).

If air is allowed to enter the fuel system (during fuel filter change or if

you run out of fuel) the engine will purge the trapped air as it runs. The

engine may run rough and produce white smoke while air is in the

system. This is normal and should correct itself in a short time.

An engine that suddenly becomes noisy or operates poorly after a fuel fill

could be using substandard fuel (i.e., high water content, low octane

rating or gasoline in the fuel). Diesel fuel should be purchased from a

reputable station which sells a large amount of diesel fuel.

Care should be taken whenever diesel fuel is stored. Use only clean,

approved containers which will prevent the entry of dirt or water.

Diesel fuel must not be stored in a galvanized container. The fuel will

dissolve the zinc in a galvanized container. The zinc will then remain in

solution until it is run through the engine where it will be deposited in

the fuel injectors causing expensive-to-repair damage.

General maintenance information

20

Page 21 of 39

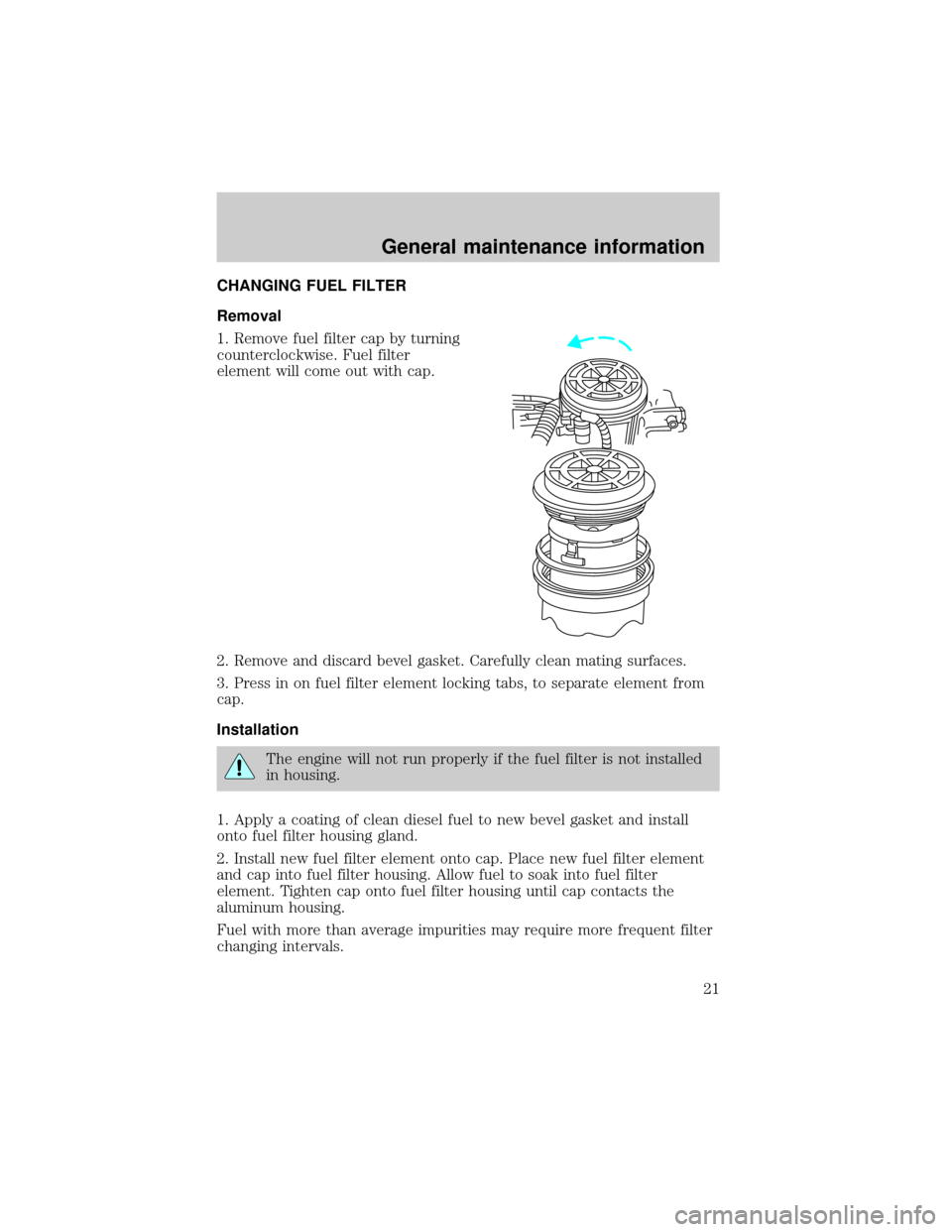

CHANGING FUEL FILTER

Removal

1. Remove fuel filter cap by turning

counterclockwise. Fuel filter

element will come out with cap.

2. Remove and discard bevel gasket. Carefully clean mating surfaces.

3. Press in on fuel filter element locking tabs, to separate element from

cap.

Installation

The engine will not run properly if the fuel filter is not installed

in housing.

1. Apply a coating of clean diesel fuel to new bevel gasket and install

onto fuel filter housing gland.

2. Install new fuel filter element onto cap. Place new fuel filter element

and cap into fuel filter housing. Allow fuel to soak into fuel filter

element. Tighten cap onto fuel filter housing until cap contacts the

aluminum housing.

Fuel with more than average impurities may require more frequent filter

changing intervals.

General maintenance information

21

Page 22 of 39

After changing the fuel filter, the engine will purge the trapped air as it

runs. Engine may run roughly and smoke until the air is completely

eliminated.

ENGINE OIL

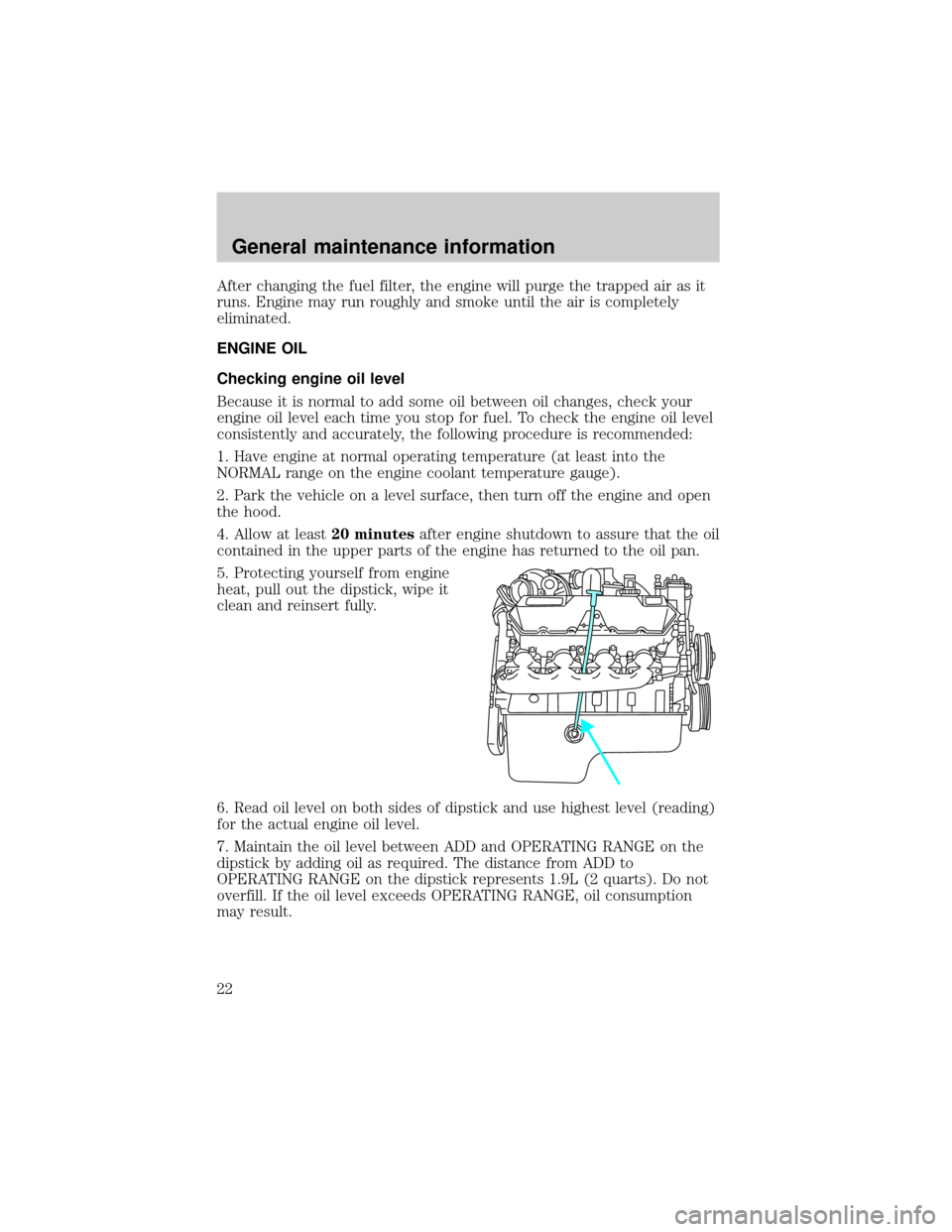

Checking engine oil level

Because it is normal to add some oil between oil changes, check your

engine oil level each time you stop for fuel. To check the engine oil level

consistently and accurately, the following procedure is recommended:

1. Have engine at normal operating temperature (at least into the

NORMAL range on the engine coolant temperature gauge).

2. Park the vehicle on a level surface, then turn off the engine and open

the hood.

4. Allow at least20 minutesafter engine shutdown to assure that the oil

contained in the upper parts of the engine has returned to the oil pan.

5. Protecting yourself from engine

heat, pull out the dipstick, wipe it

clean and reinsert fully.

6. Read oil level on both sides of dipstick and use highest level (reading)

for the actual engine oil level.

7. Maintain the oil level between ADD and OPERATING RANGE on the

dipstick by adding oil as required. The distance from ADD to

OPERATING RANGE on the dipstick represents 1.9L (2 quarts). Do not

overfill. If the oil level exceeds OPERATING RANGE, oil consumption

may result.

General maintenance information

22

Page 23 of 39

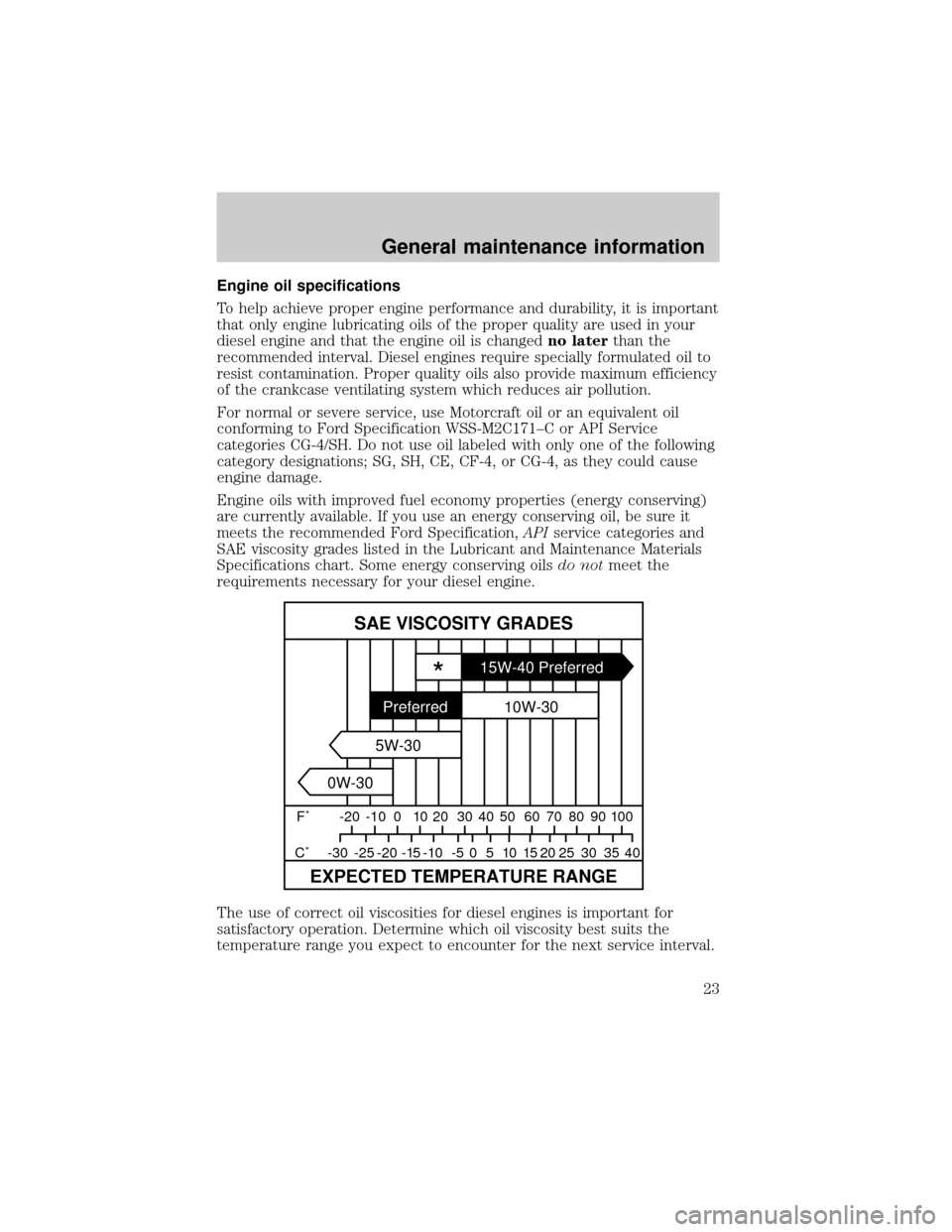

Engine oil specifications

To help achieve proper engine performance and durability, it is important

that only engine lubricating oils of the proper quality are used in your

diesel engine and that the engine oil is changedno laterthan the

recommended interval. Diesel engines require specially formulated oil to

resist contamination. Proper quality oils also provide maximum efficiency

of the crankcase ventilating system which reduces air pollution.

For normal or severe service, use Motorcraft oil or an equivalent oil

conforming to Ford Specification WSS-M2C171±C or API Service

categories CG-4/SH. Do not use oil labeled with only one of the following

category designations; SG, SH, CE, CF-4, or CG-4, as they could cause

engine damage.

Engine oils with improved fuel economy properties (energy conserving)

are currently available. If you use an energy conserving oil, be sure it

meets the recommended Ford Specification,APIservice categories and

SAE viscosity grades listed in the Lubricant and Maintenance Materials

Specifications chart. Some energy conserving oilsdo notmeet the

requirements necessary for your diesel engine.

The use of correct oil viscosities for diesel engines is important for

satisfactory operation. Determine which oil viscosity best suits the

temperature range you expect to encounter for the next service interval.

SAE VISCOSITY GRADES

EXPECTED TEMPERATURE RANGE

F˚ -20 -10 0 10 20 30 40

40 35 30 25 20 15 10 5 0 -5 -10 -15 -20 -25 -30 C˚50 60 70 80 90 100

*15W-40 Preferred

10W-30

5W-30

0W-30Preferred

General maintenance information

23