clock FORD E SERIES 2022 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2022, Model line: E SERIES, Model: FORD E SERIES 2022Pages: 300, PDF Size: 3.18 MB

Page 83 of 300

12 Volt DC Power Point

WARNING: Do not plug optional

electrical accessories into the cigar

lighter socket. Incorrect use of the cigar

lighter can cause damage not covered

by the vehicle warranty, and can result

in fire or serious injury.

Note: When you switch the ignition on, you

can use the socket to power 12 volt

appliances with a maximum current rating

of 15 amps.

If the power supply does not work after you

switch the ignition off, switch the ignition

on.

Note: Do not hang any accessory from the

accessory plug.

Note: Do not use the power point over the

vehicle capacity of 12 volt DC 180 watts or

a fuse may blow.

Note: Always keep the power point caps

closed when not in use.

Do not insert objects other than an

accessory plug into the power point. This

damages the power point and may blow

the fuse.

Run the vehicle for full capacity use of the

power point.

To prevent the battery from running out of

charge:

• Do not use the power point longer than

necessary when the vehicle is not

running.

• Do not leave devices plugged in

overnight or when you park your vehicle

for extended periods. Locations

Power points may be in the following

locations:

•

On the instrument panel.

• Inside the glove box.

• Behind the driver's seat, upper trim

panel.

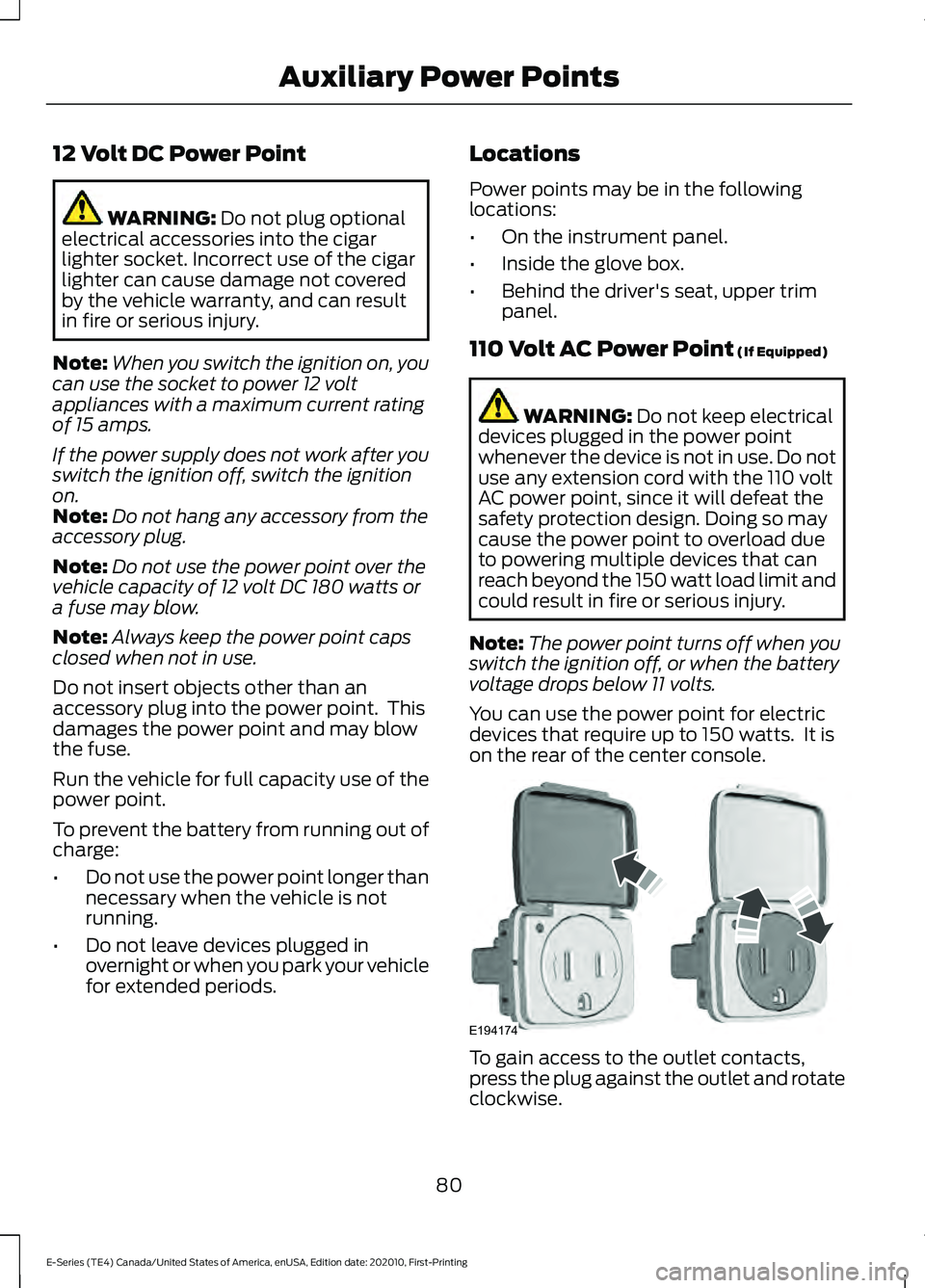

110 Volt AC Power Point

(If Equipped) WARNING:

Do not keep electrical

devices plugged in the power point

whenever the device is not in use. Do not

use any extension cord with the 110 volt

AC power point, since it will defeat the

safety protection design. Doing so may

cause the power point to overload due

to powering multiple devices that can

reach beyond the 150 watt load limit and

could result in fire or serious injury.

Note: The power point turns off when you

switch the ignition off, or when the battery

voltage drops below 11 volts.

You can use the power point for electric

devices that require up to 150 watts. It is

on the rear of the center console. To gain access to the outlet contacts,

press the plug against the outlet and rotate

clockwise.

80

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Auxiliary Power PointsE194174

Page 93 of 300

Fuel Filler Cap

WARNING: The fuel system may

be under pressure. If you hear a hissing

sound near the fuel filler inlet, do not

refuel until the sound stops. Otherwise,

fuel may spray out, which could cause

serious personal injury.

Note: If you must replace the fuel filler cap,

replace it with a fuel filler cap that is

designed for your vehicle. The customer

warranty may be void for any damage to the

fuel tank or fuel system if the correct

genuine Ford, Motorcraft or other certified

fuel filler cap is not used.

Your vehicle has a threaded fuel filler cap.

When fueling your vehicle:

1. Put your vehicle in park (P).

2. Switch the engine off.

3. Carefully turn the filler cap counterclockwise until it spins off.

4. Pull to remove the cap from the fuel filler pipe and place on the fuel door

hanging hook if equipped.

5. To install the fuel filler cap, hold the cap by the cover handle and place the

threaded end of the cap into filler pipe.

Turn the cap clockwise until it clicks at

least once.

If the Check Fuel Cap light or a Check Fuel

Cap message appears in the instrument

cluster and stays on after you start the

engine, you may not have installed the fuel

filler properly. If the fuel cap light remains on, at the next

opportunity, safely pull off of the road,

remove the fuel filler cap, align the cap

properly and reinstall it. The check fuel cap

light or Check fuel cap message may not

reset immediately. It may take several

driving cycles for the indicators to turn off.

A driving cycle consists of an engine

start-up (after four or more hours with the

engine off) followed by normal city and

highway driving.

FUEL CONSUMPTION

Advertised Capacity

The advertised capacity is the maximum

amount of fuel that you can add to the fuel

tank after running out of fuel. Included in

the advertised capacity is an empty

reserve. The empty reserve is an

unspecified amount of fuel that remains

in the fuel tank when the fuel gauge

indicates empty.

Note:

The amount of fuel in the empty

reserve varies and should not be relied upon

to increase driving range.

Fuel Economy

Your vehicle calculates fuel economy

figures through the trip computer average

fuel function. See

General Information

(page 65).

The first

1,000 mi (1,500 km) of driving is

the break-in period of the engine. A more

accurate measurement is obtained after

2,000 mi (3,000 km)

.

Impacting Fuel Economy

• Incorrect tire inflation pressures.

• Fully loading your vehicle.

• Carrying unnecessary weight.

90

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Fuel and Refueling

Page 170 of 300

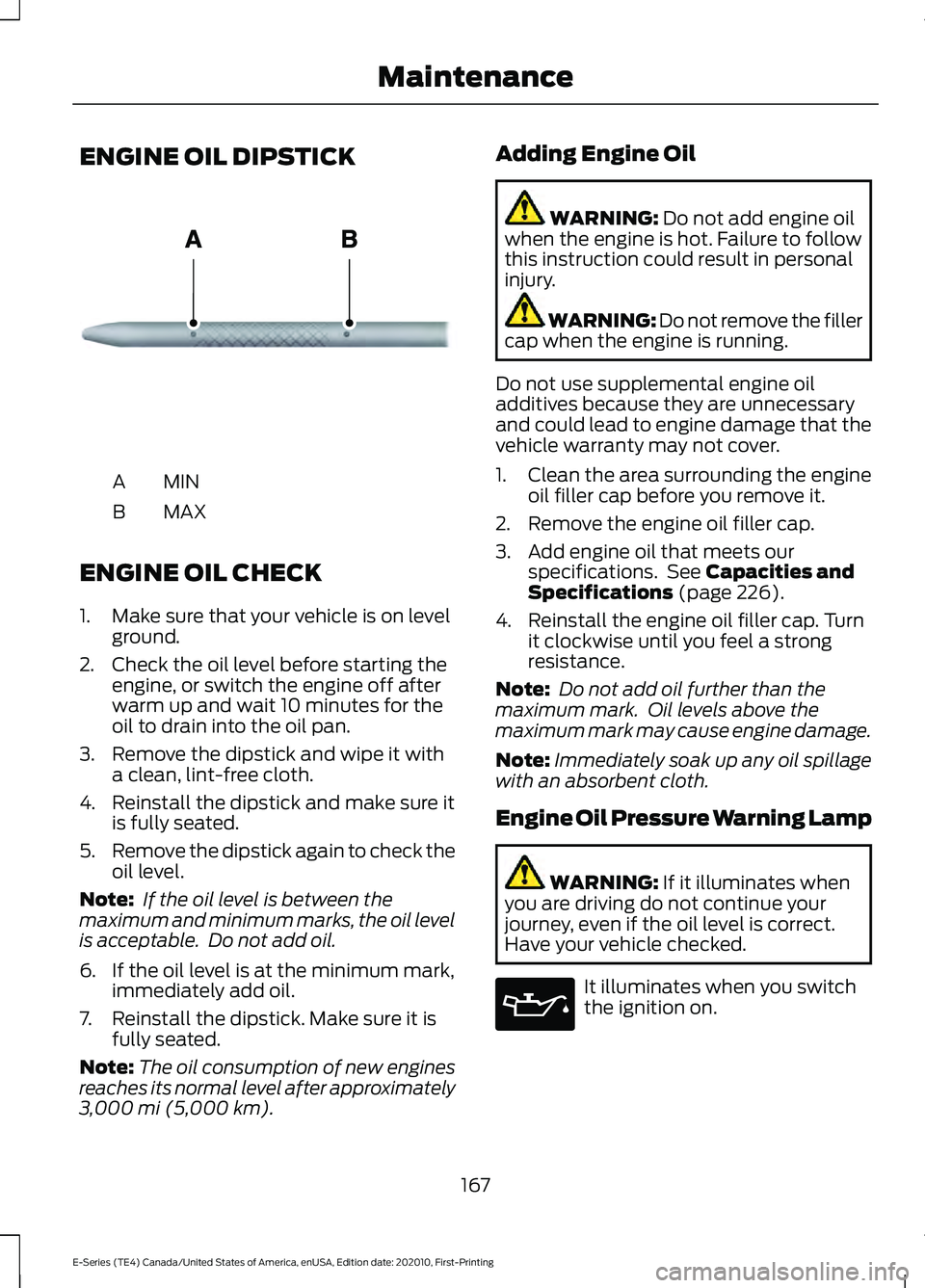

ENGINE OIL DIPSTICK

MINA

MAX

B

ENGINE OIL CHECK

1. Make sure that your vehicle is on level ground.

2. Check the oil level before starting the engine, or switch the engine off after

warm up and wait 10 minutes for the

oil to drain into the oil pan.

3. Remove the dipstick and wipe it with a clean, lint-free cloth.

4. Reinstall the dipstick and make sure it is fully seated.

5. Remove the dipstick again to check the

oil level.

Note: If the oil level is between the

maximum and minimum marks, the oil level

is acceptable. Do not add oil.

6. If the oil level is at the minimum mark, immediately add oil.

7. Reinstall the dipstick. Make sure it is fully seated.

Note: The oil consumption of new engines

reaches its normal level after approximately

3,000 mi (5,000 km). Adding Engine Oil WARNING:

Do not add engine oil

when the engine is hot. Failure to follow

this instruction could result in personal

injury. WARNING: Do not remove the filler

cap when the engine is running.

Do not use supplemental engine oil

additives because they are unnecessary

and could lead to engine damage that the

vehicle warranty may not cover.

1. Clean the area surrounding the engine oil filler cap before you remove it.

2. Remove the engine oil filler cap.

3. Add engine oil that meets our specifications. See

Capacities and

Specifications (page 226).

4. Reinstall the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Immediately soak up any oil spillage

with an absorbent cloth.

Engine Oil Pressure Warning Lamp WARNING:

If it illuminates when

you are driving do not continue your

journey, even if the oil level is correct.

Have your vehicle checked. It illuminates when you switch

the ignition on.

167

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing MaintenanceE161560

Page 174 of 300

4.

Replace the coolant reservoir cap. Turn

the cap clockwise until it contacts the

hard stop.

5. Check the coolant level in the coolant reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the correct level.

If you have to add more than 1.1 qt (1 L) of

engine coolant per month, have your

vehicle checked as soon as possible.

Operating an engine with a low level of

coolant can result in engine overheating

and possible engine damage.

Note: During normal vehicle operation, the

coolant may change color, and slightly

darken. As long as the coolant is clear and

uncontaminated, this color change does not

indicate the coolant has degraded nor does

it require the coolant to be drained, the

system to be flushed, or the coolant to be

replaced.

In case of emergency, you can add a large

amount of water without coolant in order

to reach a vehicle service location. In this

instance, qualified personnel:

1. Must drain the cooling system.

2. Chemically clean the coolant system.

3. Refill with coolant that meets the correct specification. See

Capacities

and Specifications (page 223).

Water alone, without coolant, can cause

engine damage from corrosion,

overheating or freezing.

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze. Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or additives to

the coolant. These can be harmful and

compromise the corrosion protection of

the coolant.

Recycled Coolant

We do not recommend the use of recycled

coolant as an approved recycling process

is not yet available.

Dispose of used engine coolant in an

appropriate manner. Follow your

community's regulations and standards

for recycling and disposing of automotive

fluids.

Severe Climates

If you drive in extremely cold climates:

•

It may be necessary to increase the

coolant concentration above 50%.

• A coolant concentration of 60%

provides improved freeze point

protection. Coolant concentrations

above 60% decrease the overheat

protection characteristics of the

coolant and may cause engine

damage.

If you drive in extremely hot climates:

• You can decrease the coolant

concentration to 40%.

• Coolant concentrations below 40%

decrease the freeze and corrosion

protection characteristics of the

coolant and may cause engine

damage.

Vehicles driven year-round in non-extreme

climates should use prediluted coolant for

optimum cooling system and engine

protection.

171

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Maintenance

Page 183 of 300

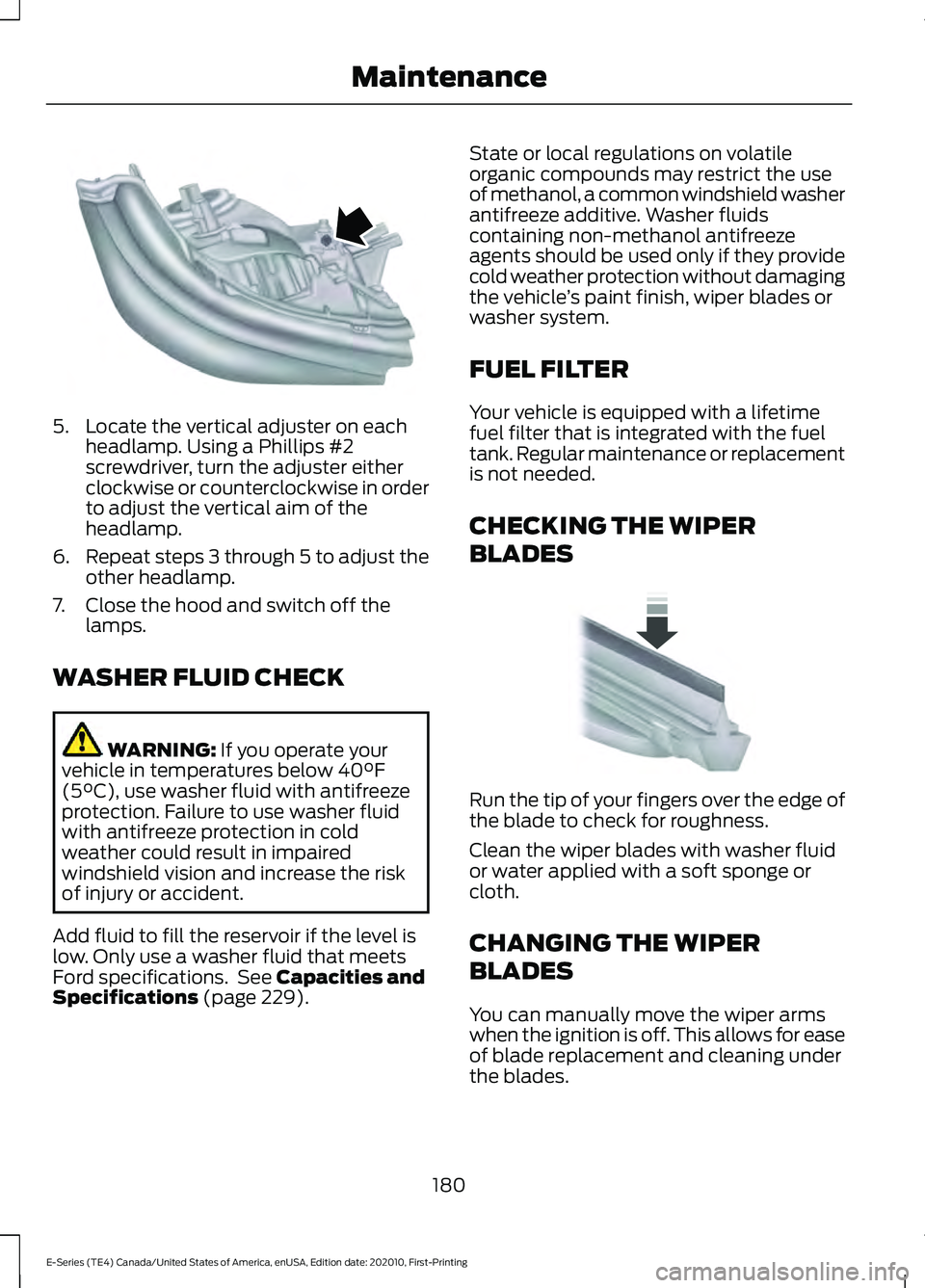

5. Locate the vertical adjuster on each

headlamp. Using a Phillips #2

screwdriver, turn the adjuster either

clockwise or counterclockwise in order

to adjust the vertical aim of the

headlamp.

6. Repeat steps 3 through 5 to adjust the

other headlamp.

7. Close the hood and switch off the lamps.

WASHER FLUID CHECK WARNING: If you operate your

vehicle in temperatures below 40°F

(5°C), use washer fluid with antifreeze

protection. Failure to use washer fluid

with antifreeze protection in cold

weather could result in impaired

windshield vision and increase the risk

of injury or accident.

Add fluid to fill the reservoir if the level is

low. Only use a washer fluid that meets

Ford specifications. See

Capacities and

Specifications (page 229). State or local regulations on volatile

organic compounds may restrict the use

of methanol, a common windshield washer

antifreeze additive. Washer fluids

containing non-methanol antifreeze

agents should be used only if they provide

cold weather protection without damaging

the vehicle

’s paint finish, wiper blades or

washer system.

FUEL FILTER

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

is not needed.

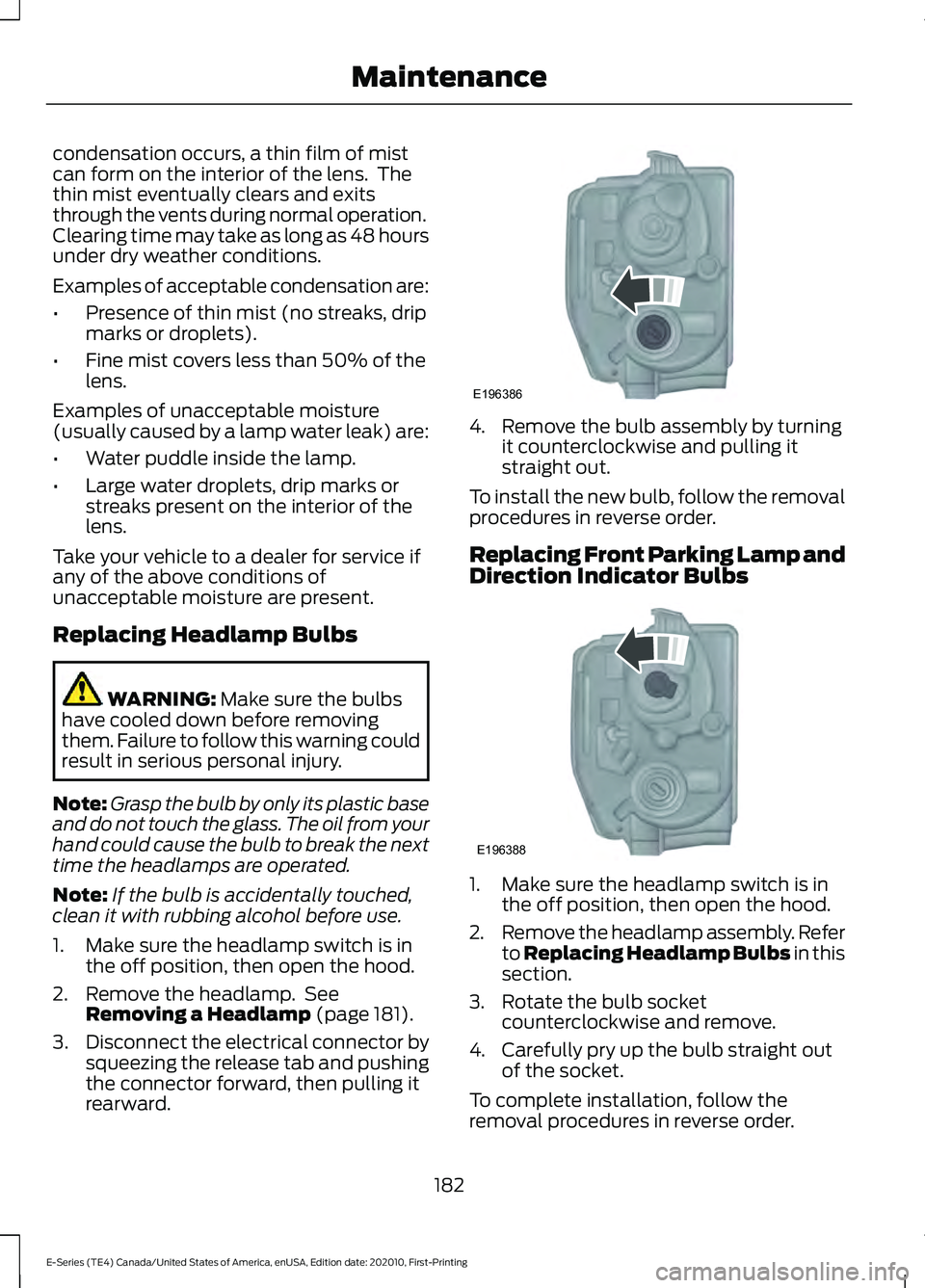

CHECKING THE WIPER

BLADES Run the tip of your fingers over the edge of

the blade to check for roughness.

Clean the wiper blades with washer fluid

or water applied with a soft sponge or

cloth.

CHANGING THE WIPER

BLADES

You can manually move the wiper arms

when the ignition is off. This allows for ease

of blade replacement and cleaning under

the blades.

180

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing MaintenanceE163806 E142463

Page 185 of 300

condensation occurs, a thin film of mist

can form on the interior of the lens. The

thin mist eventually clears and exits

through the vents during normal operation.

Clearing time may take as long as 48 hours

under dry weather conditions.

Examples of acceptable condensation are:

•

Presence of thin mist (no streaks, drip

marks or droplets).

• Fine mist covers less than 50% of the

lens.

Examples of unacceptable moisture

(usually caused by a lamp water leak) are:

• Water puddle inside the lamp.

• Large water droplets, drip marks or

streaks present on the interior of the

lens.

Take your vehicle to a dealer for service if

any of the above conditions of

unacceptable moisture are present.

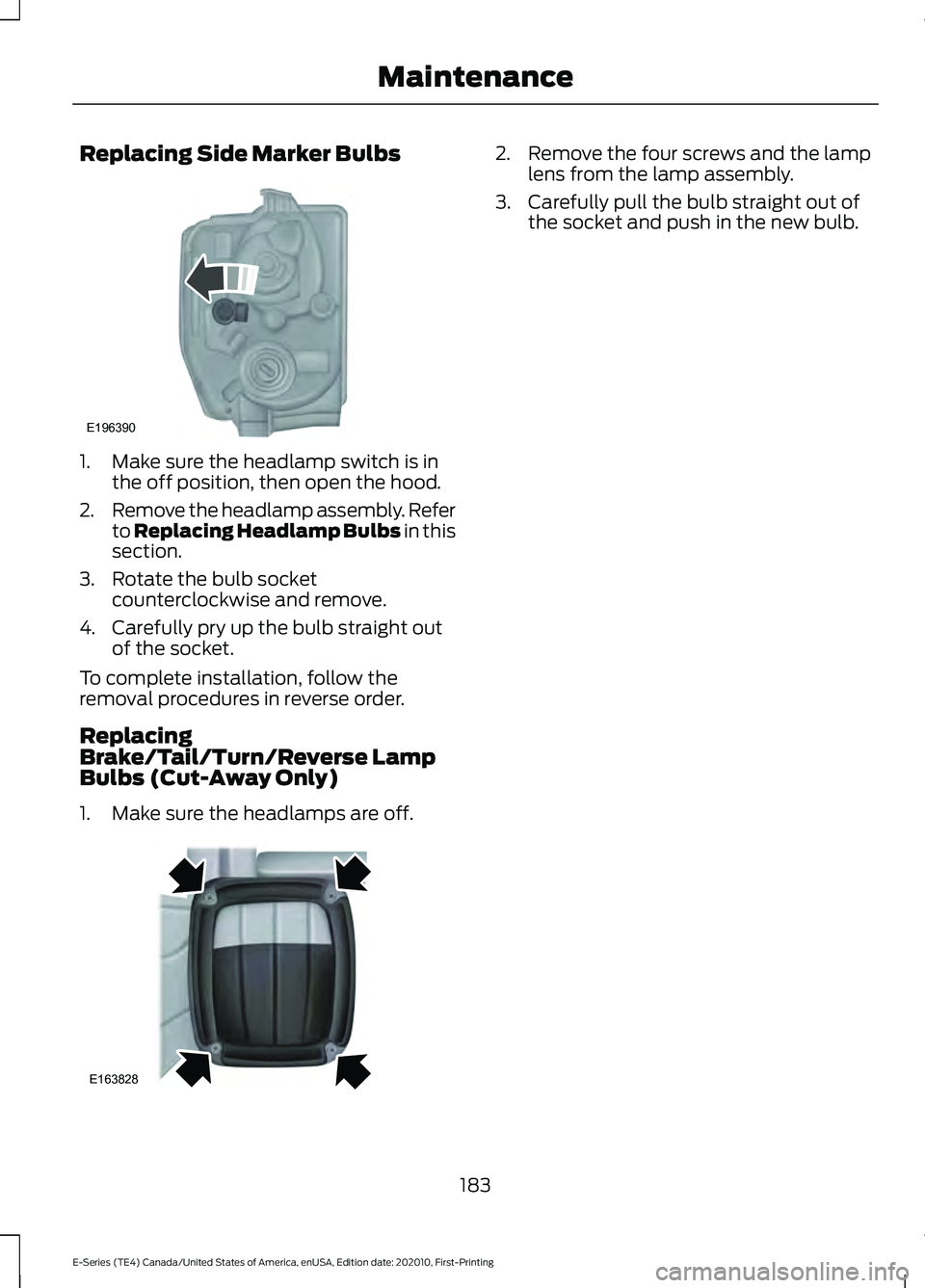

Replacing Headlamp Bulbs WARNING: Make sure the bulbs

have cooled down before removing

them. Failure to follow this warning could

result in serious personal injury.

Note: Grasp the bulb by only its plastic base

and do not touch the glass. The oil from your

hand could cause the bulb to break the next

time the headlamps are operated.

Note: If the bulb is accidentally touched,

clean it with rubbing alcohol before use.

1. Make sure the headlamp switch is in the off position, then open the hood.

2. Remove the headlamp. See Removing a Headlamp

(page 181).

3. Disconnect the electrical connector by

squeezing the release tab and pushing

the connector forward, then pulling it

rearward. 4. Remove the bulb assembly by turning

it counterclockwise and pulling it

straight out.

To install the new bulb, follow the removal

procedures in reverse order.

Replacing Front Parking Lamp and

Direction Indicator Bulbs 1. Make sure the headlamp switch is in

the off position, then open the hood.

2. Remove the headlamp assembly. Refer

to

Replacing Headlamp Bulbs in this

section.

3. Rotate the bulb socket counterclockwise and remove.

4. Carefully pry up the bulb straight out of the socket.

To complete installation, follow the

removal procedures in reverse order.

182

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing MaintenanceE196386 E196388

Page 186 of 300

Replacing Side Marker Bulbs

1. Make sure the headlamp switch is in

the off position, then open the hood.

2. Remove the headlamp assembly. Refer

to Replacing Headlamp Bulbs in this

section.

3. Rotate the bulb socket counterclockwise and remove.

4. Carefully pry up the bulb straight out of the socket.

To complete installation, follow the

removal procedures in reverse order.

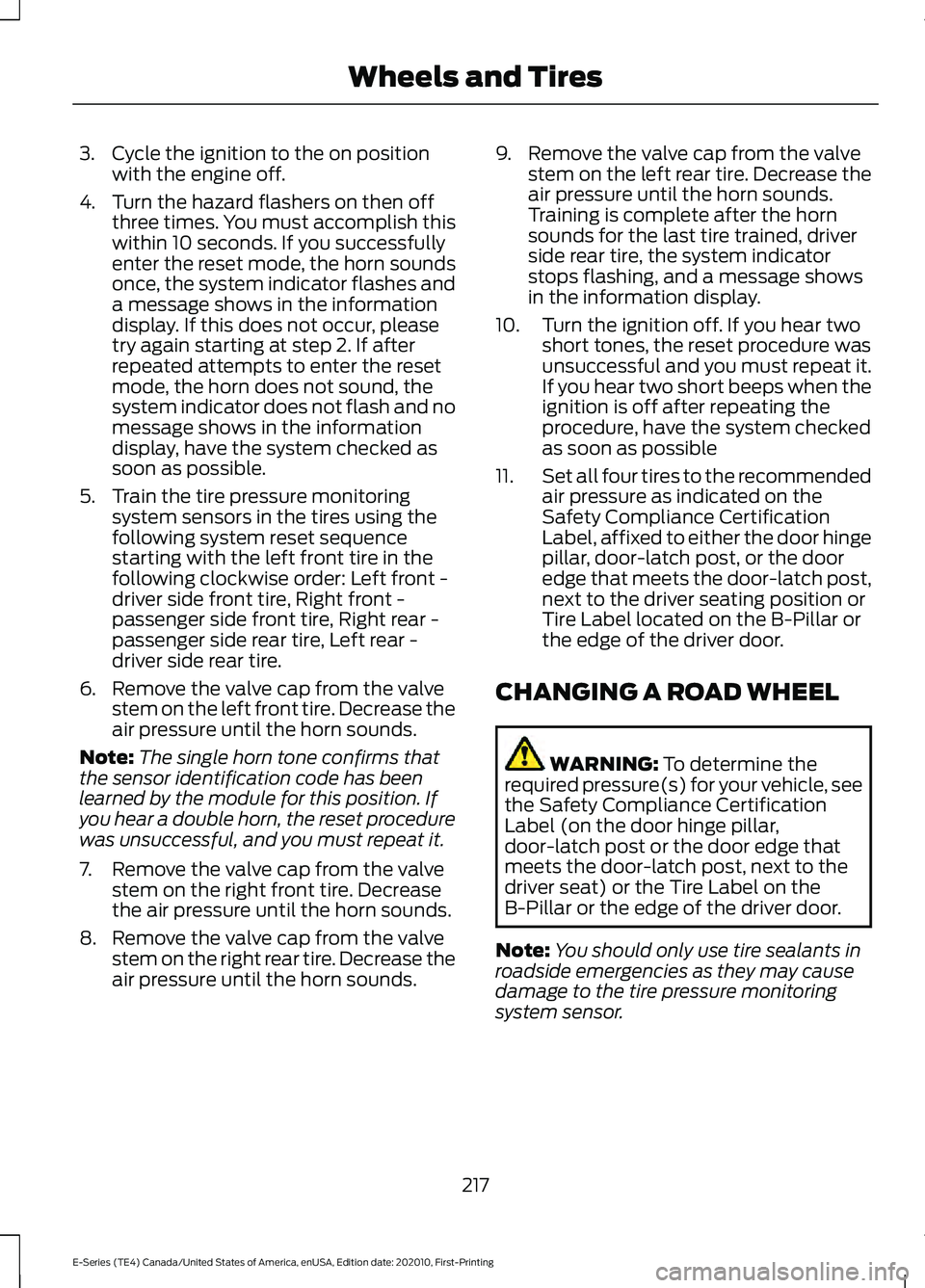

Replacing

Brake/Tail/Turn/Reverse Lamp

Bulbs (Cut-Away Only)

1. Make sure the headlamps are off. 2. Remove the four screws and the lamp

lens from the lamp assembly.

3. Carefully pull the bulb straight out of the socket and push in the new bulb.

183

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing MaintenanceE196390 E163828

Page 220 of 300

3. Cycle the ignition to the on position

with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, have the system checked as

soon as possible.

5. Train the tire pressure monitoring system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front -

driver side front tire, Right front -

passenger side front tire, Right rear -

passenger side rear tire, Left rear -

driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn tone confirms that

the sensor identification code has been

learned by the module for this position. If

you hear a double horn, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds. 9. Remove the valve cap from the valve

stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver

side rear tire, the system indicator

stops flashing, and a message shows

in the information display.

10. Turn the ignition off. If you hear two short tones, the reset procedure was

unsuccessful and you must repeat it.

If you hear two short beeps when the

ignition is off after repeating the

procedure, have the system checked

as soon as possible

11. Set all four tires to the recommended

air pressure as indicated on the

Safety Compliance Certification

Label, affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver seating position or

Tire Label located on the B-Pillar or

the edge of the driver door.

CHANGING A ROAD WHEEL WARNING: To determine the

required pressure(s) for your vehicle, see

the Safety Compliance Certification

Label (on the door hinge pillar,

door-latch post or the door edge that

meets the door-latch post, next to the

driver seat) or the Tire Label on the

B-Pillar or the edge of the driver door.

Note: You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

217

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Wheels and Tires

Page 223 of 300

3.

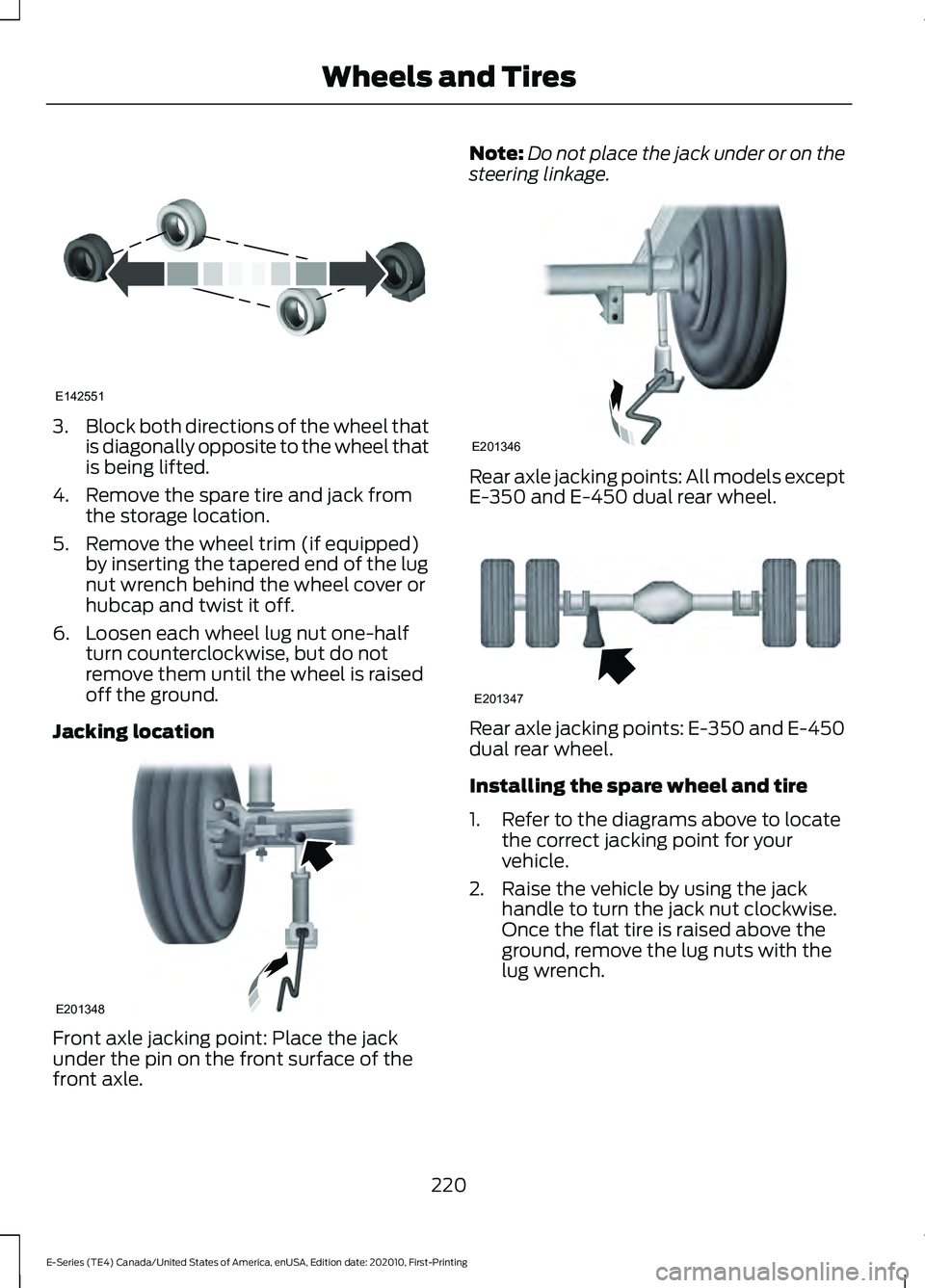

Block both directions of the wheel that

is diagonally opposite to the wheel that

is being lifted.

4. Remove the spare tire and jack from the storage location.

5. Remove the wheel trim (if equipped) by inserting the tapered end of the lug

nut wrench behind the wheel cover or

hubcap and twist it off.

6. Loosen each wheel lug nut one-half turn counterclockwise, but do not

remove them until the wheel is raised

off the ground.

Jacking location Front axle jacking point: Place the jack

under the pin on the front surface of the

front axle. Note:

Do not place the jack under or on the

steering linkage. Rear axle jacking points: All models except

E-350 and E-450 dual rear wheel.

Rear axle jacking points: E-350 and E-450

dual rear wheel.

Installing the spare wheel and tire

1. Refer to the diagrams above to locate

the correct jacking point for your

vehicle.

2. Raise the vehicle by using the jack handle to turn the jack nut clockwise.

Once the flat tire is raised above the

ground, remove the lug nuts with the

lug wrench.

220

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Wheels and TiresE142551 E201348 E201346 E201347

Page 224 of 300

3. Replace the flat tire with the spare,

making sure the valve stem of the

spare is facing outward when replacing

a front wheel or the rear wheel position

on vehicles with single rear wheel

fitments. For vehicles with dual rear

wheels, the valve stem of the spare

must face outward when replacing an

inner wheel, but must face inward

when replacing an outboard wheel.

4. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully

tighten the lug nuts until the vehicle

has been lowered.

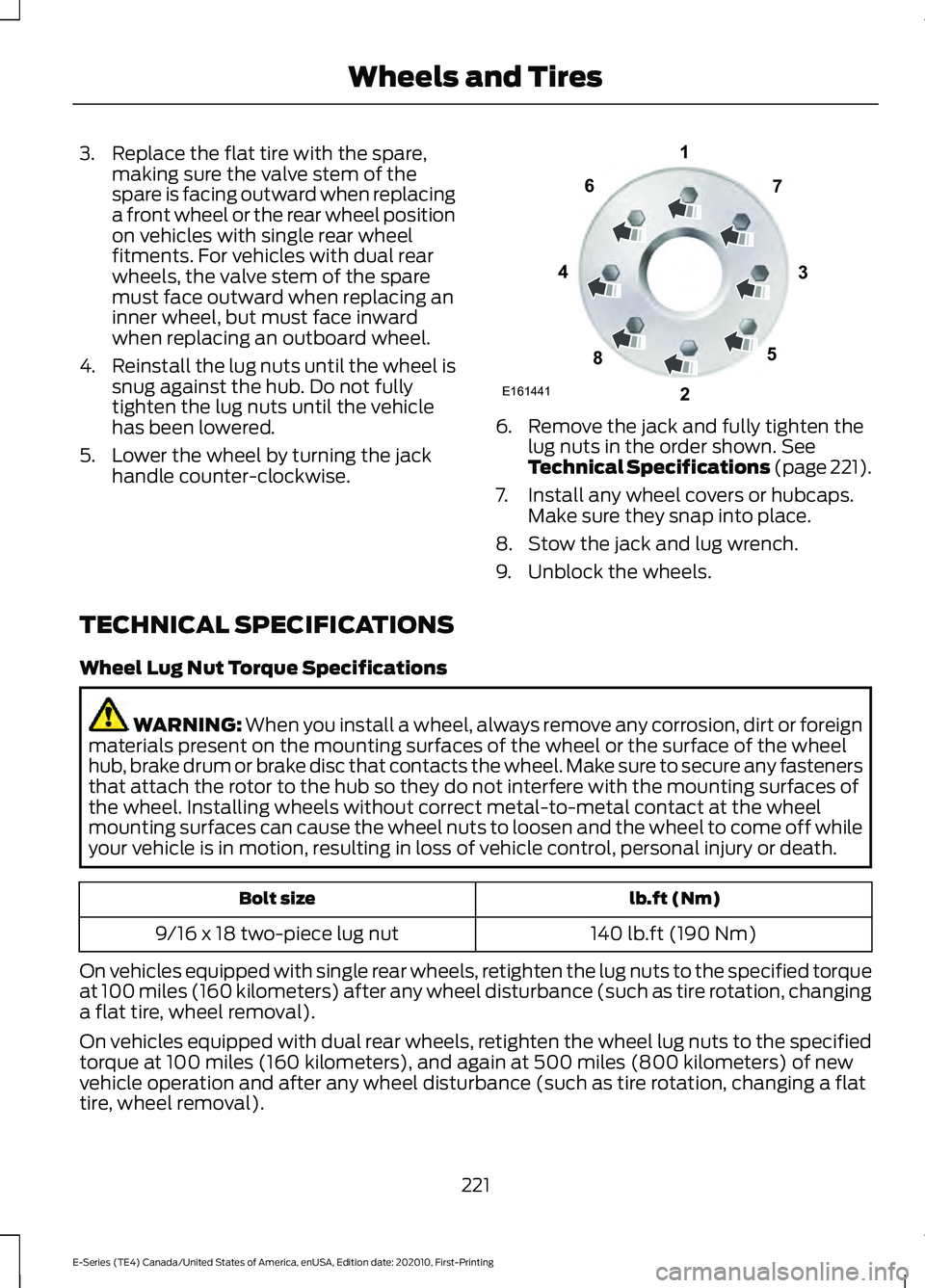

5. Lower the wheel by turning the jack handle counter-clockwise. 6. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page 221).

7. Install any wheel covers or hubcaps. Make sure they snap into place.

8. Stow the jack and lug wrench.

9. Unblock the wheels.

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications WARNING: When you install a wheel, always remove any corrosion, dirt or foreign

materials present on the mounting surfaces of the wheel or the surface of the wheel

hub, brake drum or brake disc that contacts the wheel. Make sure to secure any fasteners

that attach the rotor to the hub so they do not interfere with the mounting surfaces of

the wheel. Installing wheels without correct metal-to-metal contact at the wheel

mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while

your vehicle is in motion, resulting in loss of vehicle control, personal injury or death. lb.ft (Nm)

Bolt size

140 lb.ft (190 Nm)

9/16 x 18 two-piece lug nut

On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque

at 100 miles (160 kilometers) after any wheel disturbance (such as tire rotation, changing

a flat tire, wheel removal).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts to the specified

torque at 100 miles (160 kilometers), and again at 500 miles (800 kilometers) of new

vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat

tire, wheel removal).

221

E-Series (TE4) Canada/United States of America, enUSA, Edition date: 202010, First-Printing Wheels and TiresE161441

13

4

27

6

5

8