transmission FORD E350 2009 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: E350, Model: FORD E350 2009Pages: 320, PDF Size: 2.24 MB

Page 220 of 320

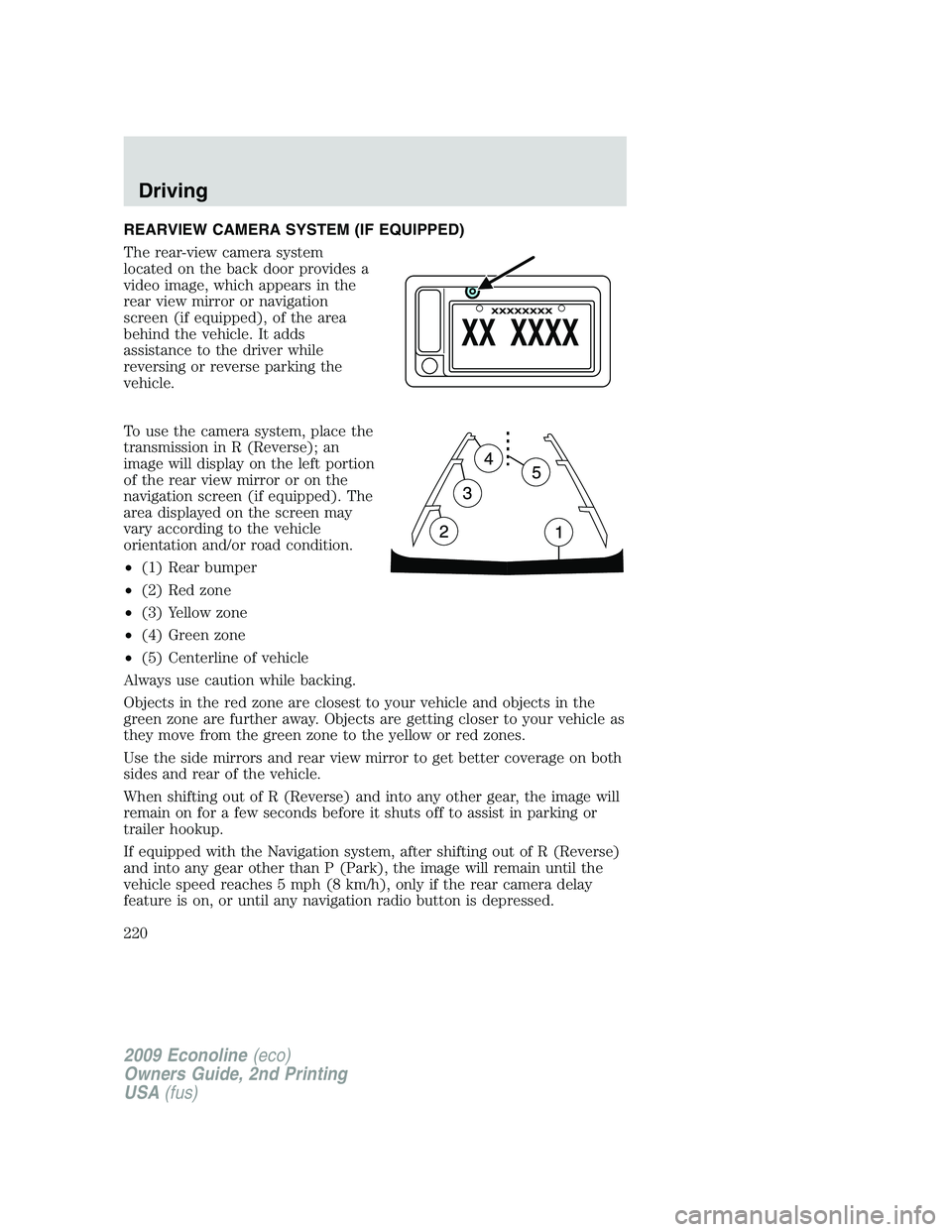

REARVIEW CAMERA SYSTEM (IF EQUIPPED)

The rear-view camera system

located on the back door provides a

video image, which appears in the

rear view mirror or navigation

screen (if equipped), of the area

behind the vehicle. It adds

assistance to the driver while

reversing or reverse parking the

vehicle.

To use the camera system, place the

transmission in R (Reverse); an

image will display on the left portion

of the rear view mirror or on the

navigation screen (if equipped). The

area displayed on the screen may

vary according to the vehicle

orientation and/or road condition.

•(1) Rear bumper

•(2) Red zone

•(3) Yellow zone

•(4) Green zone

•(5) Centerline of vehicle

Always use caution while backing.

Objects in the red zone are closest to your vehicle and objects in the

green zone are further away. Objects are getting closer to your vehicle as

they move from the green zone to the yellow or red zones.

Use the side mirrors and rear view mirror to get better coverage on both

sides and rear of the vehicle.

When shifting out of R (Reverse) and into any other gear, the image will

remain on for a few seconds before it shuts off to assist in parking or

trailer hookup.

If equipped with the Navigation system, after shifting out of R (Reverse)

and into any gear other than P (Park), the image will remain until the

vehicle speed reaches 5 mph (8 km/h), only if the rear camera delay

feature is on, or until any navigation radio button is depressed.

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Driving

220

Page 222 of 320

Servicing

•If the image comes on while the vehicle is not in R (Reverse), have

the system inspected by your authorized dealer.

•If the image is not clear, then check if there is anything covering the

lens such as dirt, mud, ice, snow, etc. If the image is still not clear

after cleaning, have your system inspected by your authorized dealer.

VEHICLE USED AS A STATIONARY POWER SOURCE

Auxiliary equipment called power take-off or PTO, is often added to the

engine or transmission to operate utility equipment. Examples include a

wheel-lift for tow trucks, cranes, tools for construction or tire service and

pumping fluids. PTO applications draw auxiliary horsepower from the

powertrain, often while the vehicle is stationary. In this condition, there

is limited cooling air flow through the radiator and around the vehicle

that normally occurs when a vehicle is moving. The aftermarket PTO

system installer, having the most knowledge of the final application, is

responsible for determining whether additional chassis heat protection or

powertrain cooling is required, and alerting the user to the safe and

proper operation.

Your vehicle is qualified for use as a stationary power source, within

limits detailed in theFord Truck Body Builders Layout Book,found at

www.fleet.ford.com/truckbbas, and through the Ford Truck Body Builders

Advisory Service.

Gas engine vehicles are qualified for up to 10 minutes of continuous

operation as a stationary power source, due to the potential for the

normal venting of fuel vapors. For stationary PTO operation of extended

duration (beyond 10 minutes), diesel engine is recommended. Further

consult your aftermarket PTO installer, since the duration of operation

limit for the aftermarket PTO may be less than the vehicle is capable of.

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Driving

222

Page 223 of 320

DRIVING THROUGH WATER

If driving through deep or standing

water is unavoidable, proceed very

slowly especially when the depth is

not known. Never drive through

water that is higher than the bottom

of the wheel rims (for cars) or the

bottom of the hubs (for trucks).

When driving through water, traction or brake capability may be limited.

Also, water may enter your engine’s air intake and severely damage your

engine or your vehicle may stall.Driving through deep water where

the transmission vent tube is submerged may allow water into the

transmission and cause internal transmission damage.

Once through the water, always dry the brakes by moving your

vehicle slowly while applying light pressure on the brake pedal.

Wet brakes do not stop the vehicle as quickly as dry brakes.

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Driving

223

Page 235 of 320

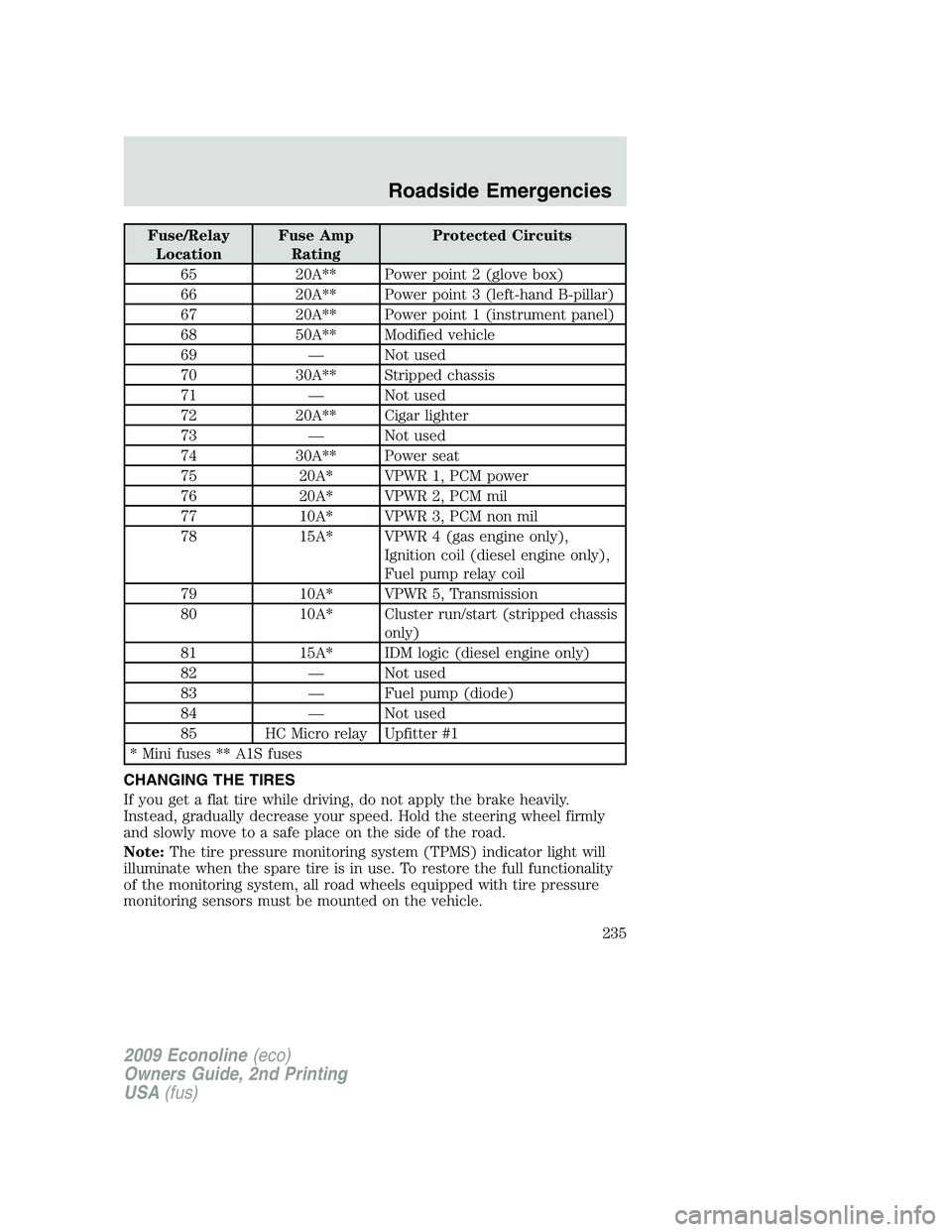

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

65 20A** Power point 2 (glove box)

66 20A** Power point 3 (left-hand B-pillar)

67 20A** Power point 1 (instrument panel)

68 50A** Modified vehicle

69 — Not used

70 30A** Stripped chassis

71 — Not used

72 20A** Cigar lighter

73 — Not used

74 30A** Power seat

75 20A* VPWR 1, PCM power

76 20A* VPWR 2, PCM mil

77 10A* VPWR 3, PCM non mil

78 15A* VPWR 4 (gas engine only),

Ignition coil (diesel engine only),

Fuel pump relay coil

79 10A* VPWR 5, Transmission

80 10A* Cluster run/start (stripped chassis

only)

81 15A* IDM logic (diesel engine only)

82 — Not used

83 — Fuel pump (diode)

84 — Not used

85 HC Micro relay Upfitter #1

* Mini fuses ** A1S fuses

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Note:The tire pressure monitoring system (TPMS) indicator light will

illuminate when the spare tire is in use. To restore the full functionality

of the monitoring system, all road wheels equipped with tire pressure

monitoring sensors must be mounted on the vehicle.

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Roadside Emergencies

235

Page 239 of 320

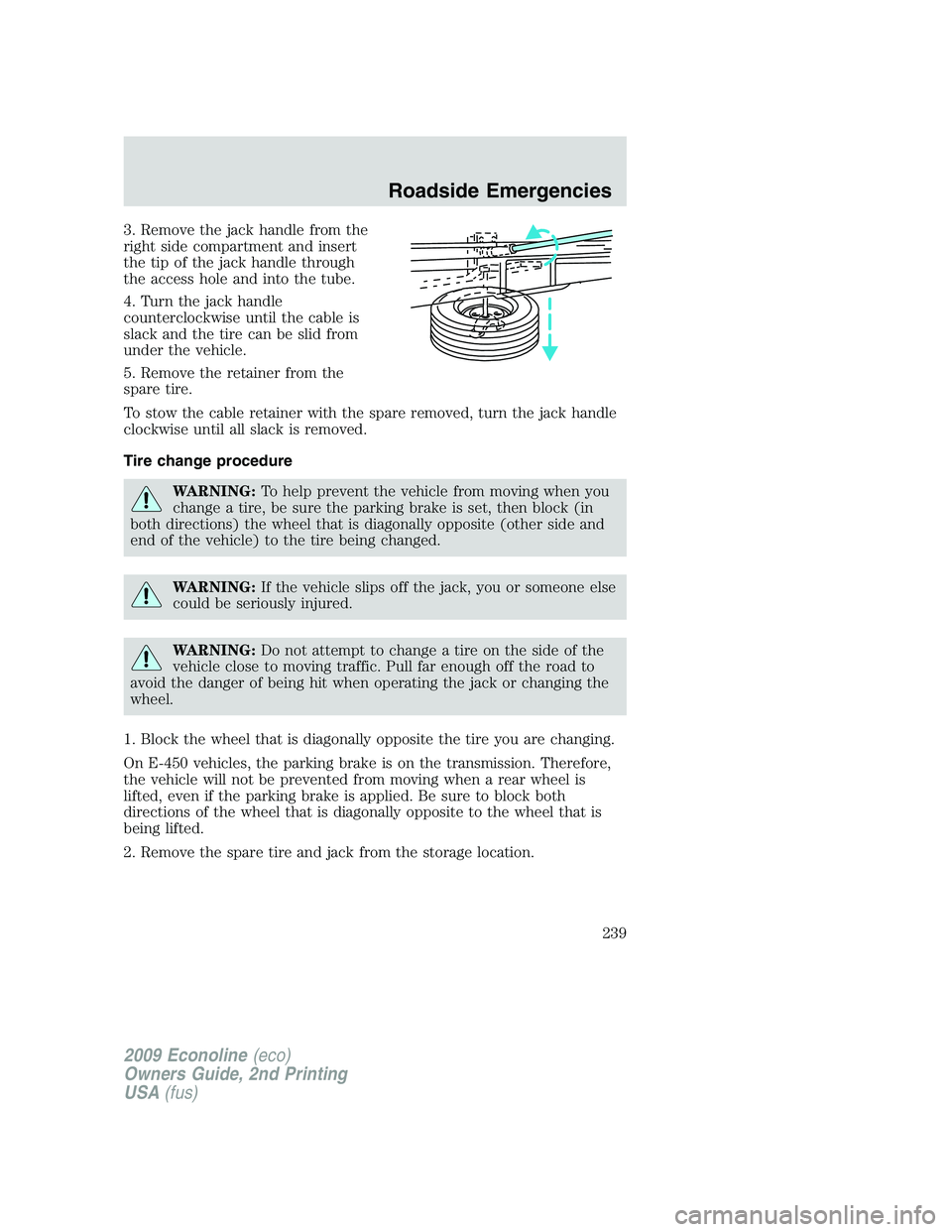

3. Remove the jack handle from the

right side compartment and insert

the tip of the jack handle through

the access hole and into the tube.

4. Turn the jack handle

counterclockwise until the cable is

slack and the tire can be slid from

under the vehicle.

5. Remove the retainer from the

spare tire.

To stow the cable retainer with the spare removed, turn the jack handle

clockwise until all slack is removed.

Tire change procedure

WARNING:To help prevent the vehicle from moving when you

change a tire, be sure the parking brake is set, then block (in

both directions) the wheel that is diagonally opposite (other side and

end of the vehicle) to the tire being changed.

WARNING:If the vehicle slips off the jack, you or someone else

could be seriously injured.

WARNING:Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off the road to

avoid the danger of being hit when operating the jack or changing the

wheel.

1. Block the wheel that is diagonally opposite the tire you are changing.

On E-450 vehicles, the parking brake is on the transmission. Therefore,

the vehicle will not be prevented from moving when a rear wheel is

lifted, even if the parking brake is applied. Be sure to block both

directions of the wheel that is diagonally opposite to the wheel that is

being lifted.

2. Remove the spare tire and jack from the storage location.

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Roadside Emergencies

239

Page 240 of 320

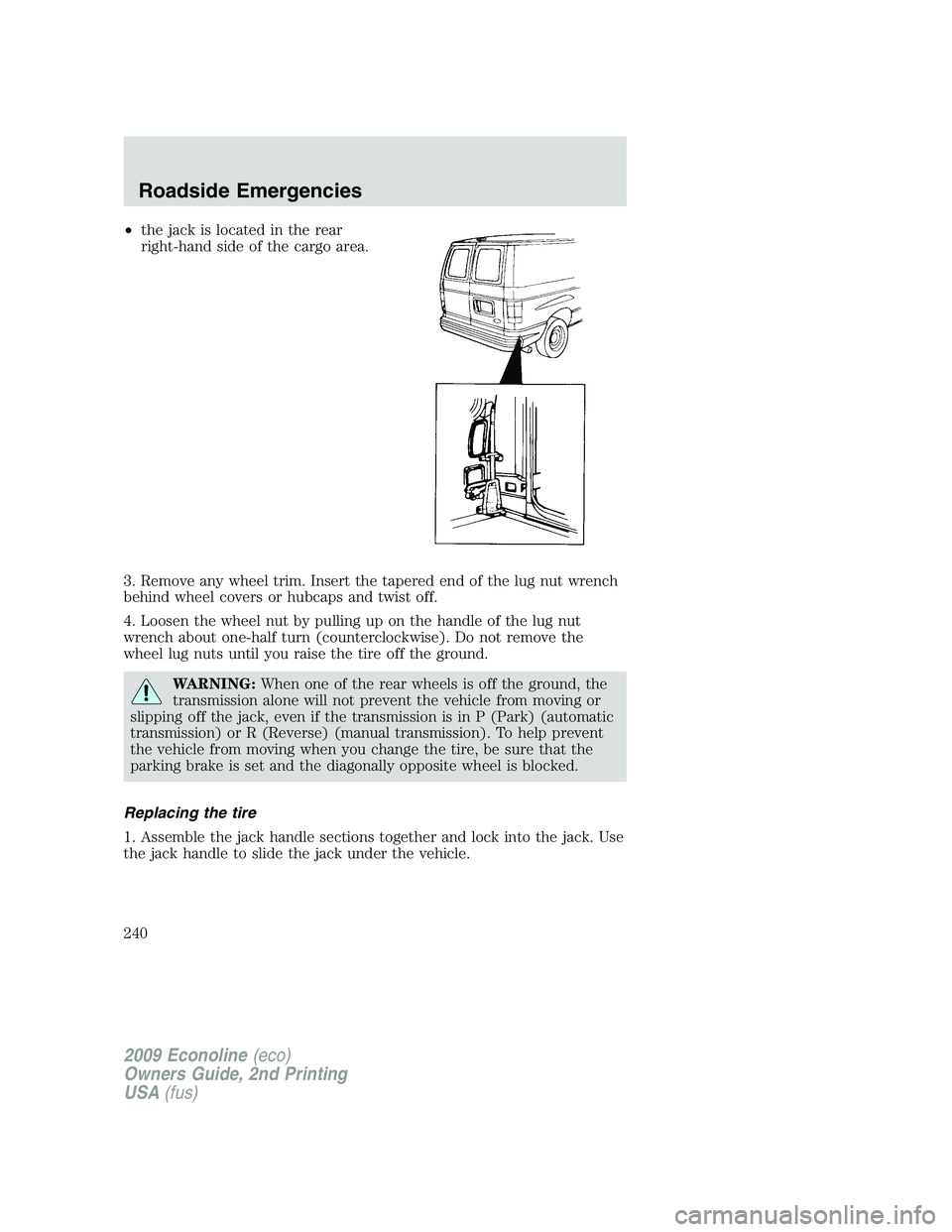

•the jack is located in the rear

right-hand side of the cargo area.

3. Remove any wheel trim. Insert the tapered end of the lug nut wrench

behind wheel covers or hubcaps and twist off.

4. Loosen the wheel nut by pulling up on the handle of the lug nut

wrench about one-half turn (counterclockwise). Do not remove the

wheel lug nuts until you raise the tire off the ground.

WARNING:When one of the rear wheels is off the ground, the

transmission alone will not prevent the vehicle from moving or

slipping off the jack, even if the transmission is in P (Park) (automatic

transmission) or R (Reverse) (manual transmission). To help prevent

the vehicle from moving when you change the tire, be sure that the

parking brake is set and the diagonally opposite wheel is blocked.

Replacing the tire

1. Assemble the jack handle sections together and lock into the jack. Use

the jack handle to slide the jack under the vehicle.

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Roadside Emergencies

240

Page 245 of 320

WARNING:When a wheel is installed, always remove any

corrosion, dirt or foreign materials present on the mounting

surfaces of the wheel or the surface of the wheel hub, brake drum or

brake disc that contacts the wheel. Ensure that any fasteners that

attach the rotor to the hub are secured so they do not interfere with

the mounting surfaces of the wheel. Installing wheels without correct

metal-to-metal contact at the wheel mounting surfaces can cause the

wheel nuts to loosen and the wheel to come off while the vehicle is in

motion, resulting in loss of control.

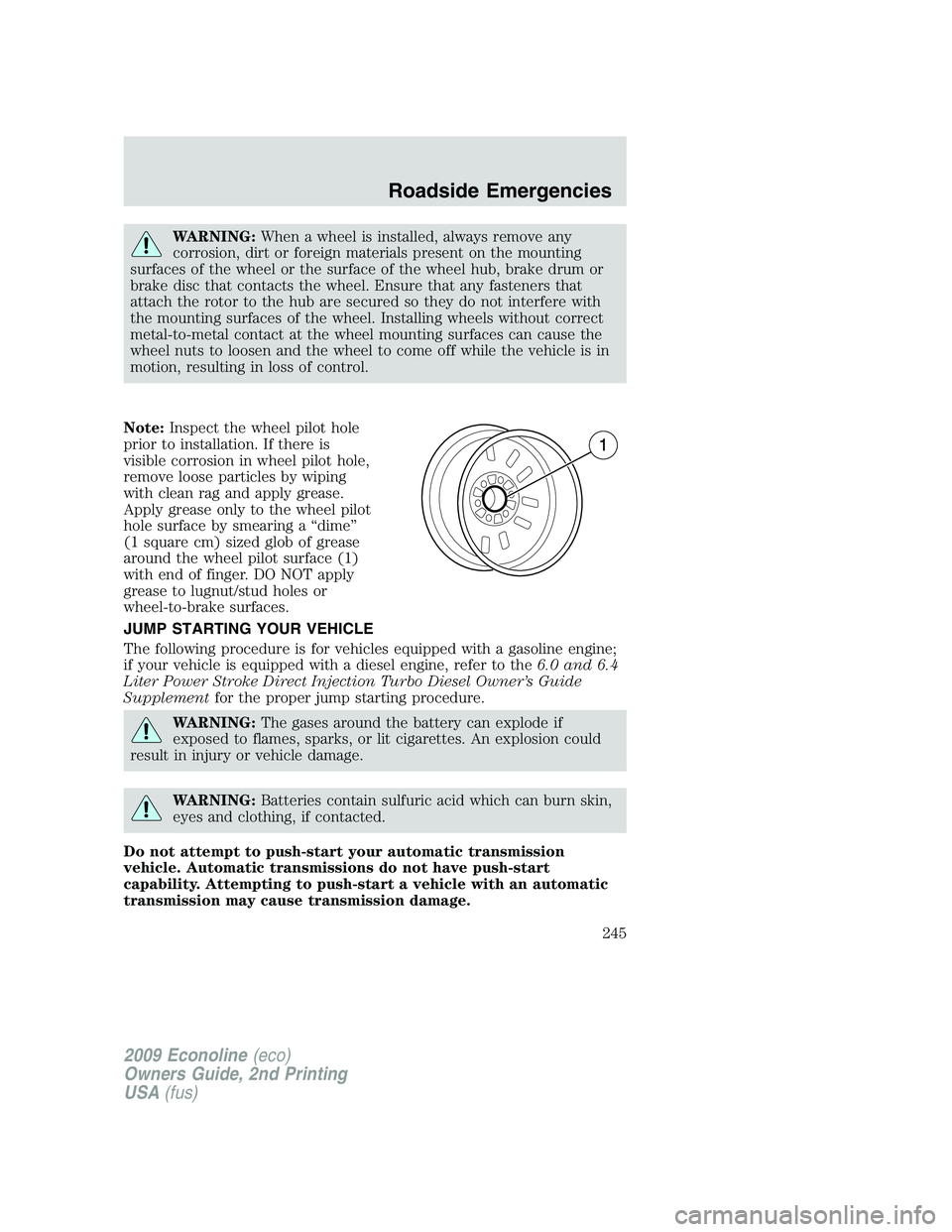

Note:Inspect the wheel pilot hole

prior to installation. If there is

visible corrosion in wheel pilot hole,

remove loose particles by wiping

with clean rag and apply grease.

Apply grease only to the wheel pilot

hole surface by smearing a “dime”

(1 square cm) sized glob of grease

around the wheel pilot surface (1)

with end of finger. DO NOT apply

grease to lugnut/stud holes or

wheel-to-brake surfaces.

JUMP STARTING YOUR VEHICLE

The following procedure is for vehicles equipped with a gasoline engine;

if your vehicle is equipped with a diesel engine, refer to the6.0 and 6.4

Liter Power Stroke Direct Injection Turbo Diesel Owner’s Guide

Supplementfor the proper jump starting procedure.

WARNING:The gases around the battery can explode if

exposed to flames, sparks, or lit cigarettes. An explosion could

result in injury or vehicle damage.

WARNING:Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not attempt to push-start your automatic transmission

vehicle. Automatic transmissions do not have push-start

capability. Attempting to push-start a vehicle with an automatic

transmission may cause transmission damage.

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Roadside Emergencies

245

Page 246 of 320

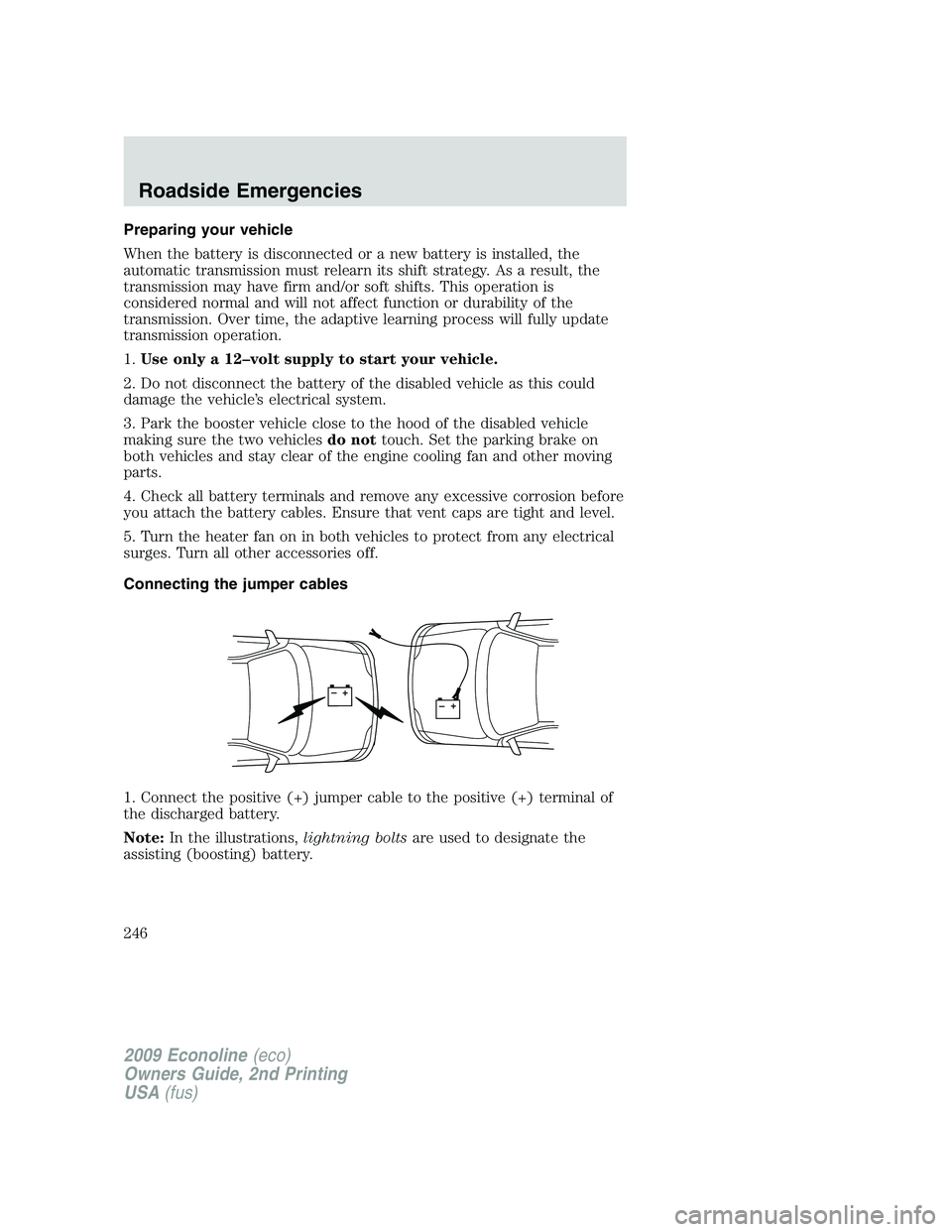

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

automatic transmission must relearn its shift strategy. As a result, the

transmission may have firm and/or soft shifts. This operation is

considered normal and will not affect function or durability of the

transmission. Over time, the adaptive learning process will fully update

transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Roadside Emergencies

246

Page 252 of 320

Emergency towing

In case of a roadside emergency with a disabled vehicle (without access

to wheel dollies, car hauling trailer, or flatbed transport vehicle) your

vehicle (regardless of transmission powertrain configuration) can be flat

towed (all wheels on the ground) under the following conditions:

•Vehicle is facing forward so that it is being towed in a forward

direction.

•Place the transmission in N (Neutral). Refer toBrake shift interlock

in theDrivingchapter for specific instructions if you cannot move the

gear shift lever into N (Neutral).

•Maximum speed is not to exceed 35 mph (56 km/h).

•Maximum distance is 50 miles (80 km).

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Roadside Emergencies

252

Page 270 of 320

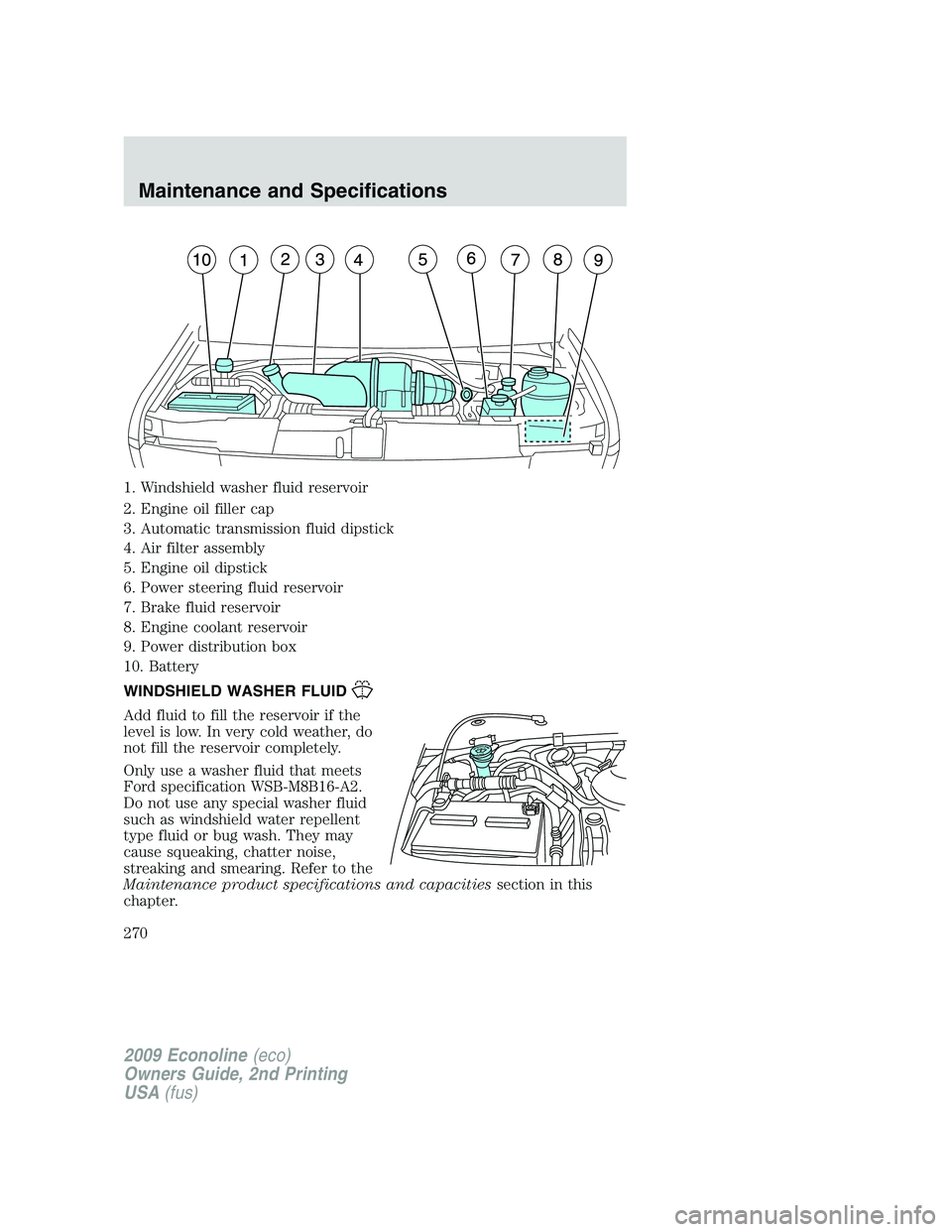

1. Windshield washer fluid reservoir

2. Engine oil filler cap

3. Automatic transmission fluid dipstick

4. Air filter assembly

5. Engine oil dipstick

6. Power steering fluid reservoir

7. Brake fluid reservoir

8. Engine coolant reservoir

9. Power distribution box

10. Battery

WINDSHIELD WASHER FLUID

Add fluid to fill the reservoir if the

level is low. In very cold weather, do

not fill the reservoir completely.

Only use a washer fluid that meets

Ford specification WSB-M8B16-A2.

Do not use any special washer fluid

such as windshield water repellent

type fluid or bug wash. They may

cause squeaking, chatter noise,

streaking and smearing. Refer to the

Maintenance product specifications and capacitiessection in this

chapter.

2009 Econoline(eco)

Owners Guide, 2nd Printing

USA(fus)

Maintenance and Specifications

270