All wheel drive FORD EDGE 2019 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2019, Model line: EDGE, Model: FORD EDGE 2019Pages: 547, PDF Size: 40.86 MB

Page 334 of 547

USING SUMMER TIRES

Summer tires provide superior

performance on wet and dry roads.

Summer tires do not have the Mud and

Snow (M+S or M/S) tire traction rating on

the tire side wall. Since summer tires do

not have the same traction performance

as All-season or Snow tires, we do not

recommend using summer tires when

temperatures drop to about 45°F (7°C) or

below (depending on tire wear and

environmental conditions) or in snow and

ice conditions. Like any tire, summer tire

performance is affected by tire wear and

environmental conditions. If you must drive

in those conditions, we recommend using

Mud and Snow (M+S, M/S), All-season or

Snow tires.

Always store your summer tires indoors at

temperatures above 19°F (-7°C). The

rubber compounds used in these tires lose

flexibility and may develop surface cracks

in the tread area at temperatures below

19°F (-7°C)

. If the tires have been

subjected to 19°F (-7°C) or less, warm

them in a heated space to at least 41°F

(5°C) for at least 24 hours before installing

them on a vehicle, or moving the vehicle

with the tires installed, or checking tire

inflation. Do not place tires near heaters

or heating devices used to warm the room

where the tires are stored. Do not apply

heat or blow heated air directly on the tires.

Always inspect the tires after storage

periods and before use. USING SNOW CHAINS WARNING:

Snow tires must be

the same size, load index, speed rating

as those originally provided by Ford. Use

of any tire or wheel not recommended

by Ford can affect the safety and

performance of your vehicle, which could

result in an increased risk of loss of

vehicle control, vehicle rollover, personal

injury and death. Additionally, the use of

non-recommended tires and wheels

could cause steering, suspension, axle,

transfer case or power transfer unit

failure.

The tires on your vehicle may have

all-weather treads to provide traction in

rain and snow. However, in some climates,

you may need to use snow tires and cables.

Your vehicle may not be compatible with

snow chain or cable usage with the

factory-fitted wheels and tires.

Follow these guidelines when using snow

tires and traction device:

• If possible, avoid fully loading your

vehicle.

• Purchase chains or cables from a

manufacturer that clearly labels body

to tire dimension restrictions.

• Use no larger than 10 mm cables or

chains ONLY on the front axle with

235/60R18 tires. Do not use chains or

cables on any other size tires.

• The snow chains or cables must be

mounted in pairs on the front axle.

• When driving with tire cables, do not

exceed

30 mph (48 km/h) or the

maximum speed recommended by the

chain manufacturer, whichever is less.

331

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Wheels and Tires

Page 335 of 547

•

Drive cautiously. If you hear the cables

rub or bang against the vehicle, stop

and re-tighten them. If this does not

work, remove the cables to prevent

vehicle damage.

• Remove the cables when you no longer

need them. Do not use cables on dry

roads.

• If a temporary spare tire is mounted on

your vehicle, do not use snow chains

on the axle with the temporary spare

tire.

If you have any questions regarding snow

chains or cables, please contact an

authorized dealer.

TIRE PRESSURE MONITORING

SYSTEM WARNING: The tire pressure

monitoring system is not a substitute for

manually checking tire pressures. You

should periodically check tire pressures

using a pressure gauge. Failure to

correctly maintain tire pressures could

increase the risk of tire failure, loss of

control, vehicle rollover and personal

injury.

Note: You should only use tire sealants in

roadside emergencies as they could cause

damage to the tire pressure monitoring

system sensor.

Note: If the tire pressure monitoring system

sensor becomes damaged, it will not

function. Each tire, including the spare (if

provided), should be checked

monthly when cold and inflated

to the inflation pressure recommended by

the vehicle manufacturer on the vehicle

placard or tire inflation pressure label. (If

your vehicle has tires of a different size

than the size indicated on the vehicle

placard or tire inflation pressure label, you

should determine the proper tire inflation

pressure for those tires).

As an added safety feature, your vehicle

has been equipped with a Tire Pressure

Monitoring System (TPMS) that

illuminates a low tire pressure telltale

when one or more of your tires is

significantly under-inflated. Accordingly,

when the low tire pressure telltale

illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly under-inflated tire causes the

tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency

and tire tread life, and could affect the

vehicle ’s handling and stopping ability.

Please note that the TPMS is not a

substitute for proper tire maintenance, and

it is the driver ’s responsibility to maintain

correct tire pressure, even if under-inflation

has not reached the level to trigger

illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with

a TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is

combined with the low tire pressure

telltale. When the system detects a

malfunction, the telltale will flash for

approximately one minute and then remain

continuously illuminated. This sequence

will continue upon subsequent vehicle

start-ups as long as the malfunction exists.

332

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Wheels and Tires

Page 338 of 547

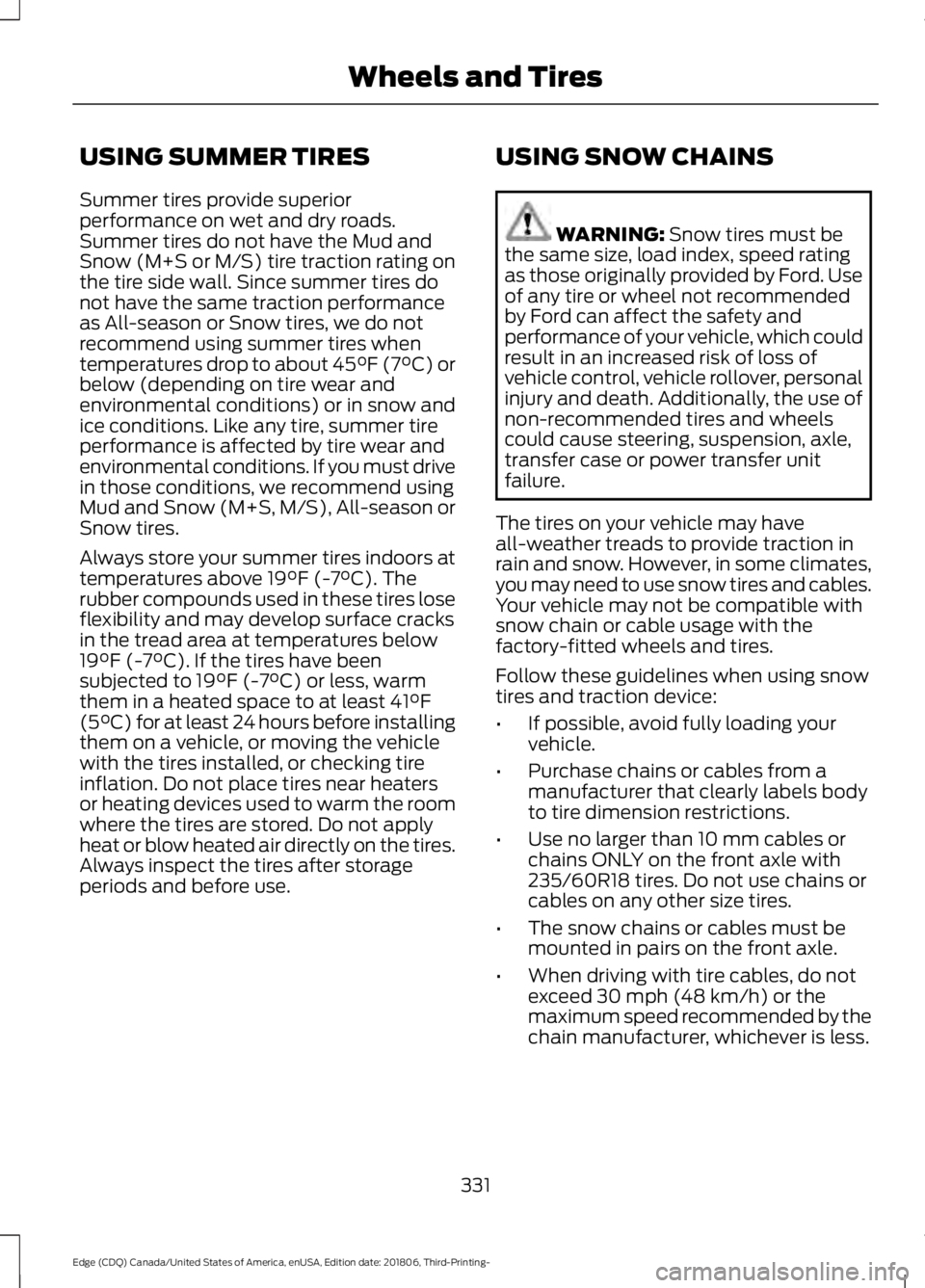

Customer action required

Possible cause

Low tire pressure

warning light

Make sure tires are at the proper pres-

sure. See Inflating your tires in this

chapter. After inflating your tires to the

manufacturer’s recommended pressure

as shown on the Tire Label (located on

the edge of driver ’s door or the B-Pillar),

the vehicle must be driven for at least

two minutes over 20 mph (32 km/h)

before the light turns off.

Tire(s) under-inflated

Solid warning light Repair the damaged road wheel and tire

assembly and reinstall it on the vehicle

to restore system function. For a

description on how the system functions,

see When Your Temporary Spare Tire

is Installed

in this section.

Spare tire in use

If the tires are properly inflated and the

spare tire is not in use but the light

remains on, contact your authorized

dealer as soon as possible.

TPMS malfunction

On vehicles with different front and rear

tire pressures, the system must be

retrained following every tire rotation.

See Tire Pressure Monitoring System

Reset

procedure later in this section.

Tire rotation without

sensor training

Repair the damaged road wheel and tire

assembly and reinstall it on the vehicle

to restore system function. For a

description on how the system functions,

see When Your Temporary Spare Tire

is Installed

in this section.

Spare tire in use

Flashing warning light

If the tires are properly inflated and the

spare tire is not in use but the light

remains on, contact your authorized

dealer as soon as possible.

TPMS malfunction

335

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Wheels and Tires

Page 339 of 547

When Inflating Your Tires

WARNING: Do not use the tire

pressure displayed in the information

display as a tire pressure gauge. Failure

to follow this instruction could result in

personal injury or death.

When putting air into your tires (such as at

a gas station or in your garage), the tire

pressure monitoring system will not

respond immediately to the air added to

your tires.

It could take up to two minutes of driving

over 20 mph (32 km/h) for the light to turn

off after you have filled your tires to the

recommended inflation pressure.

How Temperature Affects Your Tire

Pressure

The tire pressure monitoring system

monitors tire pressure in each pneumatic

tire. While driving in a normal manner, a

typical passenger tire inflation pressure

could increase about

2 –4 psi (14– 28 kPa)

from a cold start situation. If the vehicle is

stationary overnight with the outside

temperature significantly lower than the

daytime temperature, the tire pressure

could decrease about

3 psi (21 kPa) for a

drop of 30°F (17°C) in ambient

temperature. This lower pressure value

could be detected by the tire pressure

monitoring system as being significantly

lower than the recommended inflation

pressure and activate the system warning

light for low tire pressure. If the low tire

pressure warning light is on, visually check

each tire to verify that no tire is flat. If one

or more tires are flat, repair as necessary.

Check the air pressure in the road tires. If

any tire is under-inflated, carefully drive

the vehicle to the nearest location where

air can be added to the tires. Inflate all the

tires to the recommended inflation

pressure. Tire Pressure Monitoring System Reset

Procedure WARNING:

To determine the

required pressure(s) for your vehicle, see

the Safety Compliance Certification

Label (on the door hinge pillar,

door-latch post or the door edge that

meets the door-latch post, next to the

driver seat) or the Tire Label on the

B-Pillar or the edge of the driver door.

Note: You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation.

To provide the vehicle's load carrying

capability, some vehicles require different

recommended tire pressures in the front

tires as compared to the rear tires. The tire

pressure monitoring system equipped on

these vehicles is designed to illuminate the

low tire pressure warning light at two

different pressures; one for the front tires

and one for the rear tires.

Since tires need to be rotated to provide

consistent performance and maximum tire

life, the tire pressure monitoring system

needs to know when the tires are rotated

to determine which set of tires are on the

front and which are on the rear. With this

information, the system can detect and

properly warn of low tire pressures.

System reset tips:

336

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Wheels and Tires

Page 340 of 547

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least 3 ft

(1 m) away from another Ford Motor

Company vehicle undergoing the

system reset procedure at the same

time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system can time-out and you have

to repeat the entire procedure on all

four wheels.

• A double horn sounds indicating the

need to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, seek service from your

authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front -

driver side front tire, Right front -

passenger side front tire, Right rear -

passenger side rear tire, Left rear -

driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn tone confirms that

the sensor identification code has been

learned by the module for this position. If a

double horn is heard, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver

side rear tire, the system indicator

stops flashing, and a message shows

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

337

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Wheels and Tires

Page 341 of 547

11.

Set all four tires to the recommended

air pressure as indicated on the

Safety Compliance Certification

Label, affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver seating position or

Tire Label located on the B-Pillar or

the edge of the driver door.

CHANGING A ROAD WHEEL (IF

EQUIPPED) WARNING:

Do not use tire

sealants as they may damage the tire

pressure monitoring system. WARNING:

If the tire pressure

monitor sensor becomes damaged it

may not function.

Note: The use of tire sealant may damage

your tire pressure monitoring system and

should only be used in roadside

emergencies. If you must use a sealant, use

the Tire Mobility Kit sealant. Replace the tire

pressure monitoring system sensor and

valve stem on the wheel by an authorized

dealer after use of the sealant.

Note: The tire pressure monitoring system

indicator light will illuminate when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

If you get a flat tire while driving, do not

apply the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe

place on the side of the road. Have a flat serviced by an authorized

dealer in order to prevent damage to the

tire pressure monitoring system sensors.

See

Tire Pressure Monitoring System

(page 332). Replace the spare tire with a

road tire as soon as possible. During

repairing or replacing of the flat tire, have

an authorized dealer inspect the tire

pressure monitoring system sensor for

damage.

Dissimilar Spare Wheel and Tire

Assembly Information WARNING:

Failure to follow these

guidelines could result in an increased

risk of loss of vehicle control, injury or

death.

If you have a dissimilar spare wheel and

tire, then it is intended for temporary use

only. This means that if you need to use it,

you should replace it as soon as possible

with a road wheel and tire assembly that

is the same size and type as the road tires

and wheels that were originally provided

by us. If the dissimilar spare tire or wheel

is damaged, replace it instead of repairing

it.

A dissimilar spare wheel and tire assembly

is defined as a spare wheel and tire

assembly that is different in brand, size or

appearance from the road tires and wheels

and can be one of three types:

1. T-type mini-spare:

This spare tire

begins with the letter T for tire size and

may have Temporary Use Only molded in

the sidewall.

2. Full-size dissimilar spare with label

on wheel:

This spare tire has a label on

the wheel that states: THIS WHEEL AND

TIRE ASSEMBLY FOR TEMPORARY USE

ONLY.

When driving with one of the dissimilar

spare tires listed above, do not:

338

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Wheels and Tires

Page 342 of 547

•

Exceed 50 mph (80 km/h).

• Load the vehicle beyond maximum

vehicle load rating listed on the Safety

Compliance Label.

• Tow a trailer.

• Use snow chains on the end of the

vehicle with the dissimilar spare tire.

• Use more than one dissimilar spare tire

at a time.

• Use commercial car washing

equipment.

• Try to repair the dissimilar spare tire.

Use of one of the dissimilar spare tires

listed above at any one wheel location can

lead to impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability, if

applicable.

3. Full-size dissimilar spare without

label on wheel

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use commercial car washing

equipment.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly. The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

•

Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability.

When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

• Towing a trailer.

• Driving vehicles equipped with a

camper body.

• Driving vehicles with a load on the

cargo rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly

and seek service as soon as possible.

Tire Change Procedure WARNING:

When one of the front

wheels is off the ground, the

transmission alone will not prevent the

vehicle from moving or slipping off the

jack, even if the transmission is in park

(P). WARNING:

To help prevent your

vehicle from moving when changing a

wheel, shift the transmission into park

(P), set the parking brake and use an

appropriate block or wheel chock to

secure the wheel diagonally opposite to

the wheel being changed. For example,

when changing the front left wheel,

place an appropriate block or wheel

chock on the right rear wheel.

339

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Wheels and Tires

Page 345 of 547

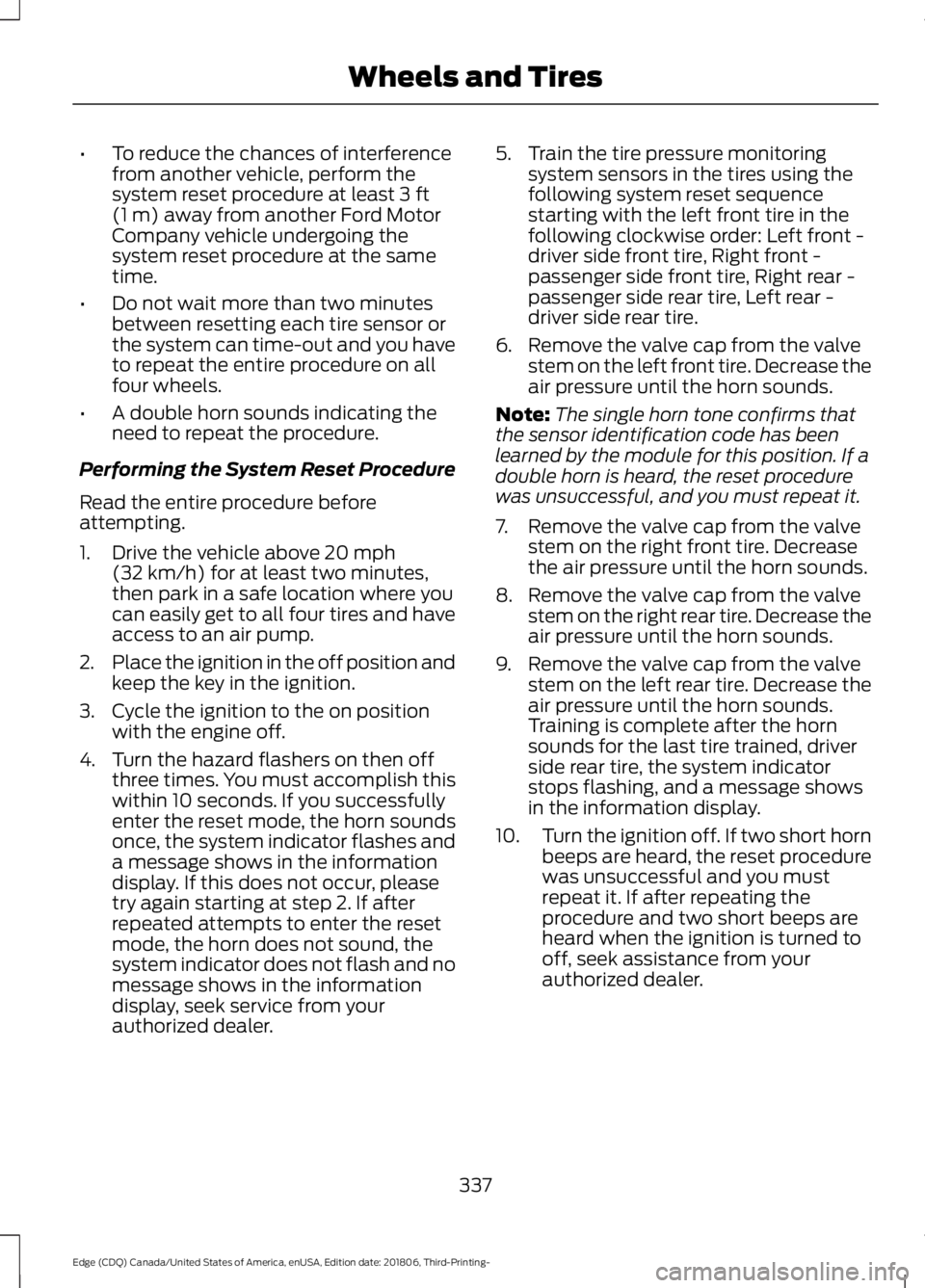

13. Arrows depict vehicle jacking points

on the underside of the vehicle at the

locations shown above. The warning

label on the jack depicts the details.

14. Find the arrows embossed on the vehicle downward flange next to the

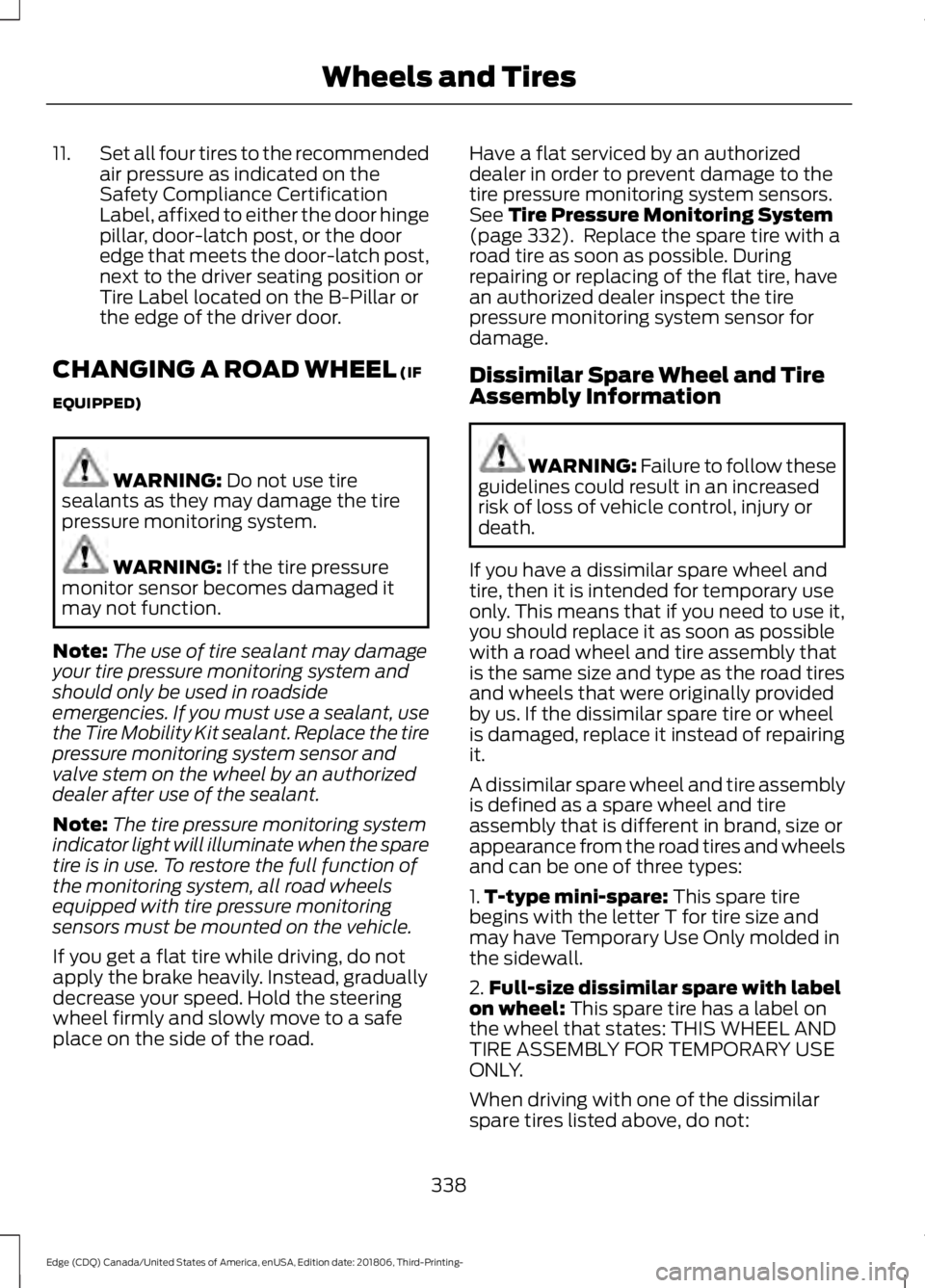

tire you are changing.15. Position the jack so that the vehicle

downward flange rests in the jack

saddle flange between the arrows,

as shown above. Raise the vehicle by

using the lug wrench to turn the jack

nut clockwise. Once the flat tire is off

the ground, remove the lug nuts with

the lug wrench. 16. Replace the flat tire with the spare

tire, making sure the valve stem is

facing outward. Reinstall the lug nuts

until the wheel is snug against the

hub. Do not fully tighten the lug nuts

until the wheel has been lowered.

17. Lower the wheel by turning the jack handle counterclockwise.

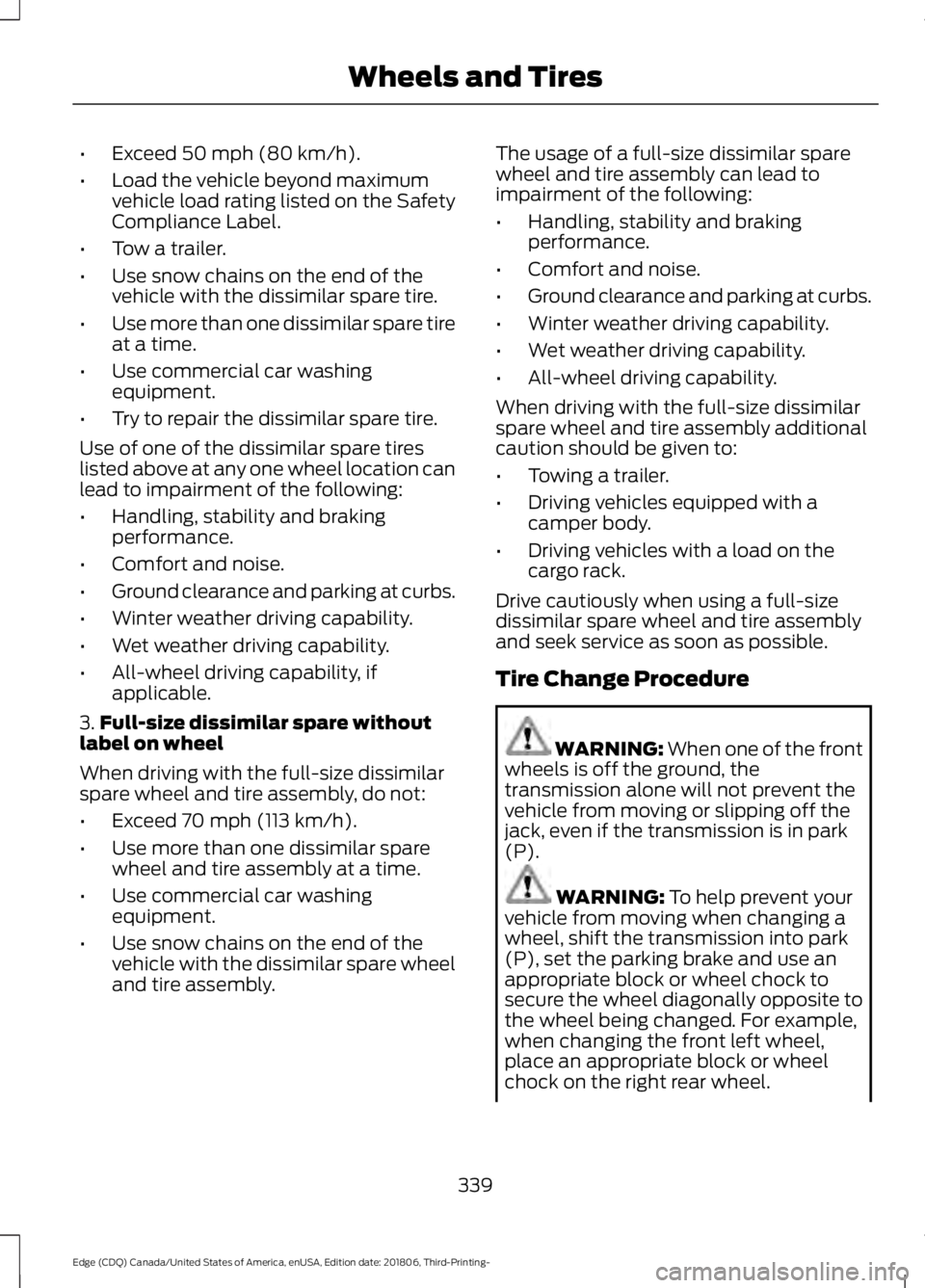

18. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page

344). 19. To store the jack kit, fold the jack

wrench handle and engage it to the

bracket of the jack base using the lug

wrench pin. Swing the wrench

upwards, adjust the jack height until

the wrench hook engages to the hole

on the jack. Turn the hex nut

clockwise by hand until secure.

Re-position the jack kit assembly into

the original vehicle position and

secure with the plastic wing nut. Make

sure the jack is fastened securely

before you drive.

342

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Wheels and TiresE242877 E201100 12

3

4

5E306781

Page 353 of 547

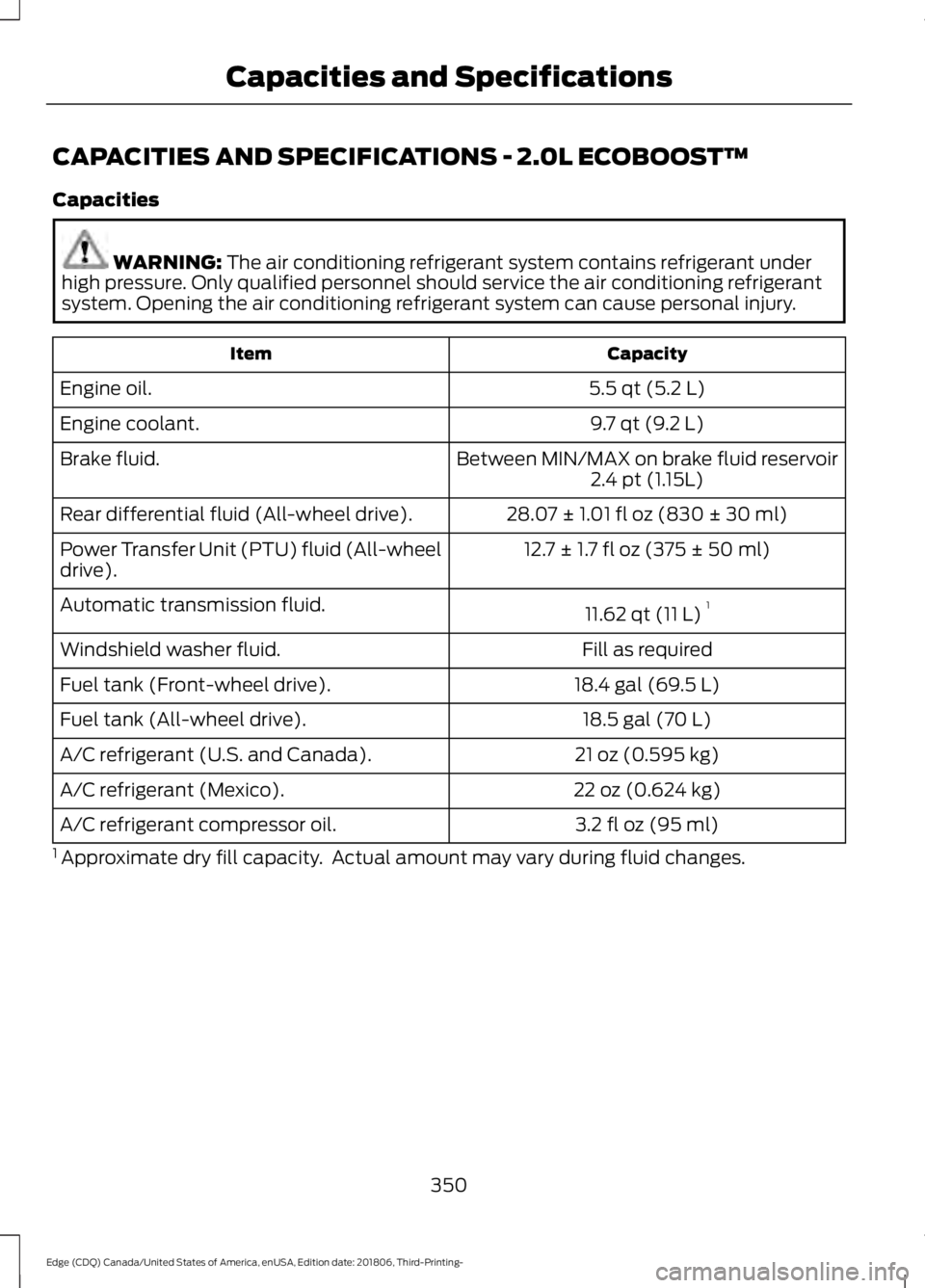

CAPACITIES AND SPECIFICATIONS - 2.0L ECOBOOST™

Capacities

WARNING: The air conditioning refrigerant system contains refrigerant under

high pressure. Only qualified personnel should service the air conditioning refrigerant

system. Opening the air conditioning refrigerant system can cause personal injury. Capacity

Item

5.5 qt (5.2 L)

Engine oil.

9.7 qt (9.2 L)

Engine coolant.

Between MIN/MAX on brake fluid reservoir

Brake fluid.

2.4 pt (1.15L)

28.07 ± 1.01 fl oz (830 ± 30 ml)

Rear differential fluid (All-wheel drive).

12.7 ± 1.7 fl oz (375 ± 50 ml)

Power Transfer Unit (PTU) fluid (All-wheel

drive).

11.62 qt (11 L)1

Automatic transmission fluid.

Fill as required

Windshield washer fluid.

18.4 gal (69.5 L)

Fuel tank (Front-wheel drive).

18.5 gal (70 L)

Fuel tank (All-wheel drive).

21 oz (0.595 kg)

A/C refrigerant (U.S. and Canada).

22 oz (0.624 kg)

A/C refrigerant (Mexico).

3.2 fl oz (95 ml)

A/C refrigerant compressor oil.

1 Approximate dry fill capacity. Actual amount may vary during fluid changes.

350

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Capacities and Specifications

Page 354 of 547

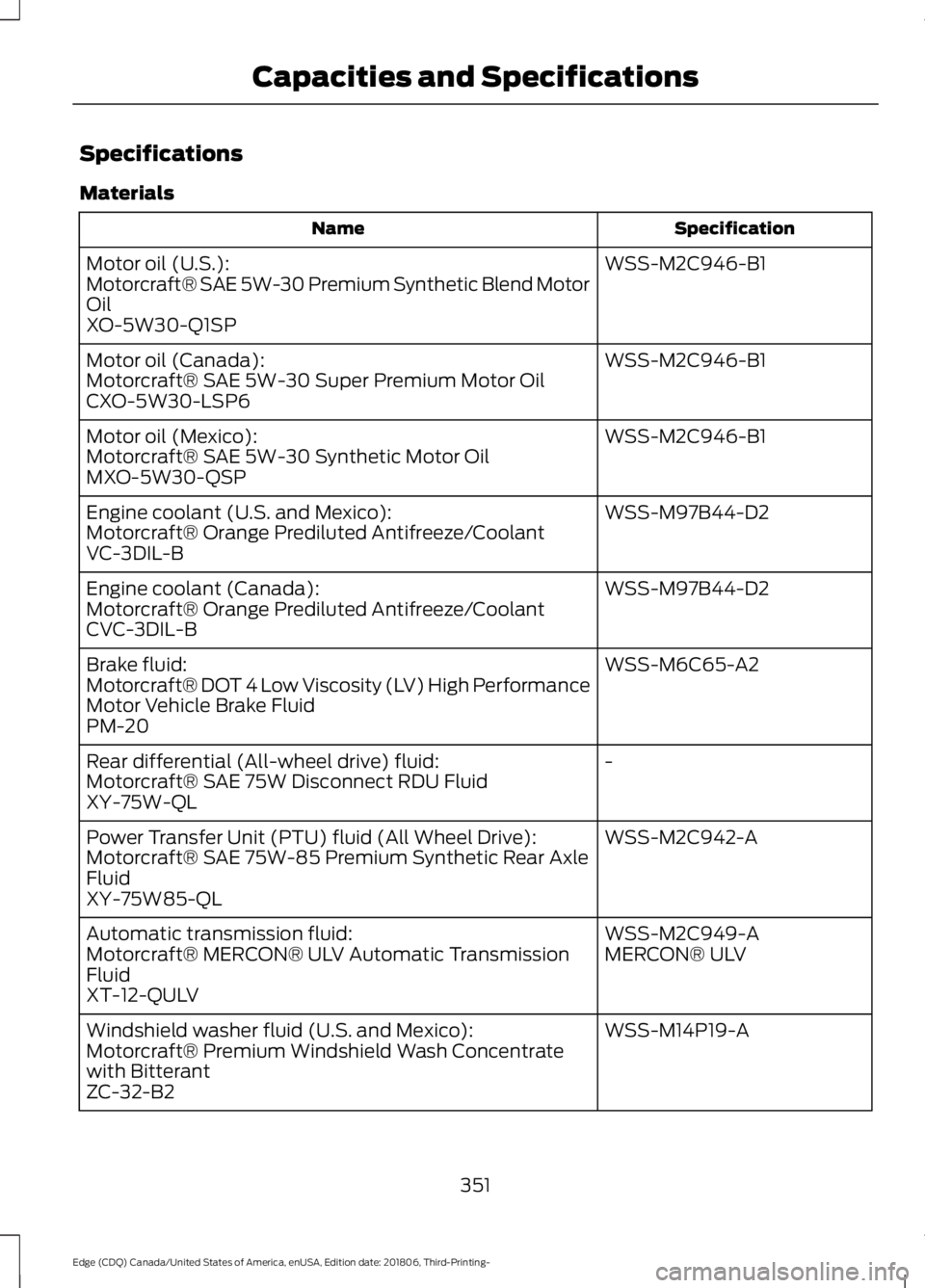

Specifications

Materials

Specification

Name

WSS-M2C946-B1

Motor oil (U.S.):

Motorcraft® SAE 5W-30 Premium Synthetic Blend Motor

Oil

XO-5W30-Q1SP

WSS-M2C946-B1

Motor oil (Canada):

Motorcraft® SAE 5W-30 Super Premium Motor Oil

CXO-5W30-LSP6

WSS-M2C946-B1

Motor oil (Mexico):

Motorcraft® SAE 5W-30 Synthetic Motor Oil

MXO-5W30-QSP

WSS-M97B44-D2

Engine coolant (U.S. and Mexico):

Motorcraft® Orange Prediluted Antifreeze/Coolant

VC-3DIL-B

WSS-M97B44-D2

Engine coolant (Canada):

Motorcraft® Orange Prediluted Antifreeze/Coolant

CVC-3DIL-B

WSS-M6C65-A2

Brake fluid:

Motorcraft® DOT 4 Low Viscosity (LV) High Performance

Motor Vehicle Brake Fluid

PM-20

-

Rear differential (All-wheel drive) fluid:

Motorcraft® SAE 75W Disconnect RDU Fluid

XY-75W-QL

WSS-M2C942-A

Power Transfer Unit (PTU) fluid (All Wheel Drive):

Motorcraft® SAE 75W-85 Premium Synthetic Rear Axle

Fluid

XY-75W85-QL

WSS-M2C949-A

Automatic transmission fluid:

MERCON® ULV

Motorcraft® MERCON® ULV Automatic Transmission

Fluid

XT-12-QULV

WSS-M14P19-A

Windshield washer fluid (U.S. and Mexico):

Motorcraft® Premium Windshield Wash Concentrate

with Bitterant

ZC-32-B2

351

Edge (CDQ) Canada/United States of America, enUSA, Edition date: 201806, Third-Printing- Capacities and Specifications