clock FORD ESCAPE 2002 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2002, Model line: ESCAPE, Model: FORD ESCAPE 2002 1.GPages: 280, PDF Size: 2.75 MB

Page 85 of 280

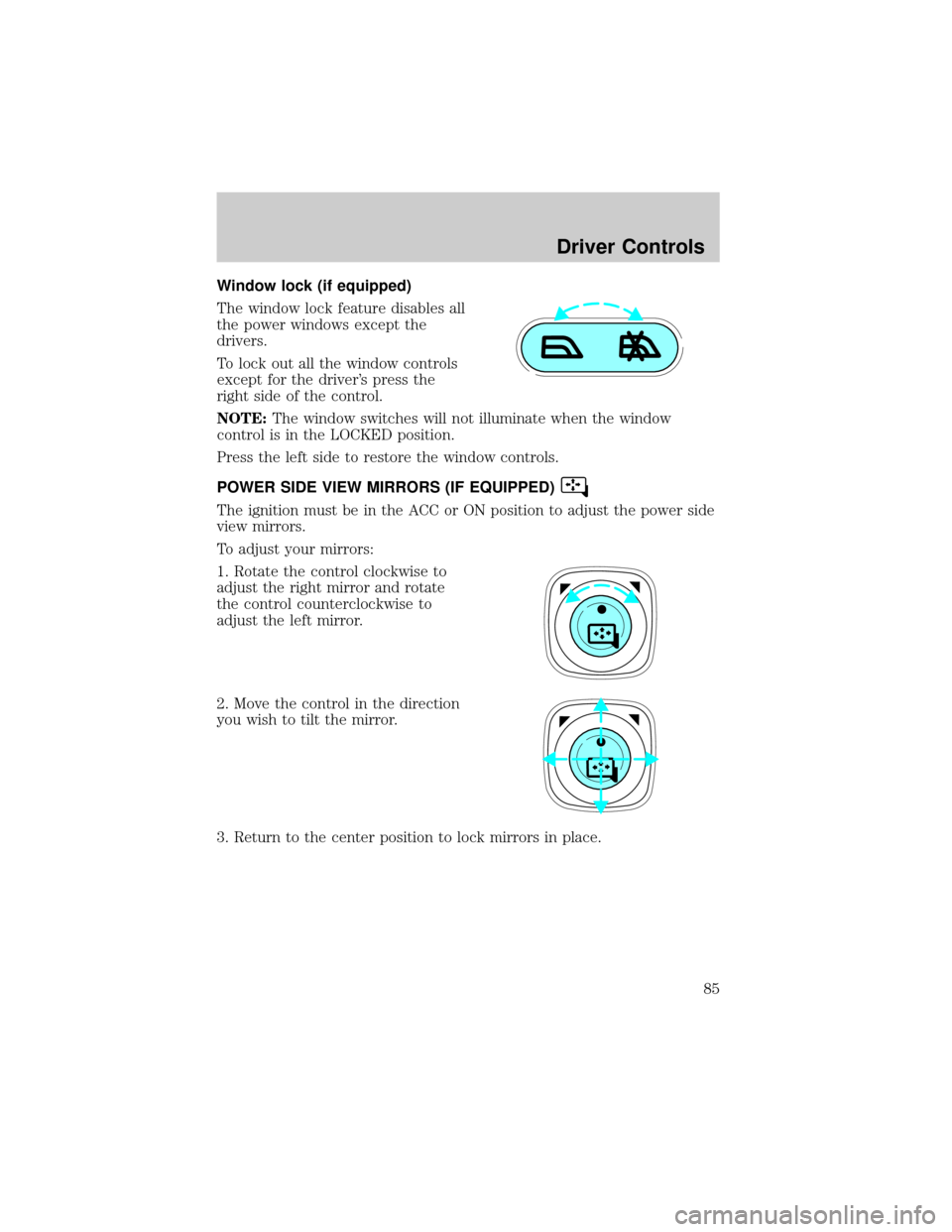

Window lock (if equipped)

The window lock feature disables all

the power windows except the

drivers.

To lock out all the window controls

except for the driver's press the

right side of the control.

NOTE:The window switches will not illuminate when the window

control is in the LOCKED position.

Press the left side to restore the window controls.

POWER SIDE VIEW MIRRORS (IF EQUIPPED)

The ignition must be in the ACC or ON position to adjust the power side

view mirrors.

To adjust your mirrors:

1. Rotate the control clockwise to

adjust the right mirror and rotate

the control counterclockwise to

adjust the left mirror.

2. Move the control in the direction

you wish to tilt the mirror.

3. Return to the center position to lock mirrors in place.

Driver Controls

85

Page 115 of 280

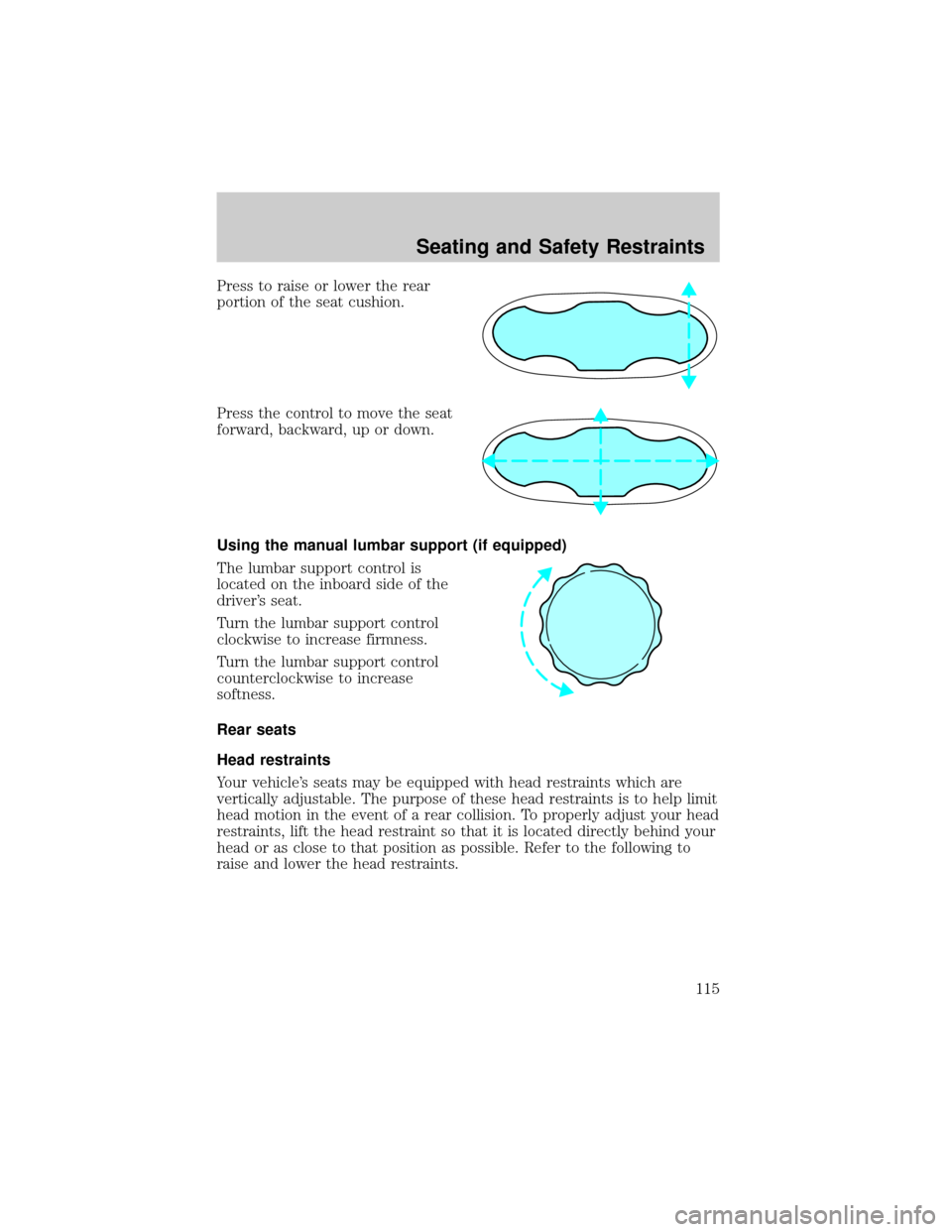

Press to raise or lower the rear

portion of the seat cushion.

Press the control to move the seat

forward, backward, up or down.

Using the manual lumbar support (if equipped)

The lumbar support control is

located on the inboard side of the

driver's seat.

Turn the lumbar support control

clockwise to increase firmness.

Turn the lumbar support control

counterclockwise to increase

softness.

Rear seats

Head restraints

Your vehicle's seats may be equipped with head restraints which are

vertically adjustable. The purpose of these head restraints is to help limit

head motion in the event of a rear collision. To properly adjust your head

restraints, lift the head restraint so that it is located directly behind your

head or as close to that position as possible. Refer to the following to

raise and lower the head restraints.

Seating and Safety Restraints

115

Page 191 of 280

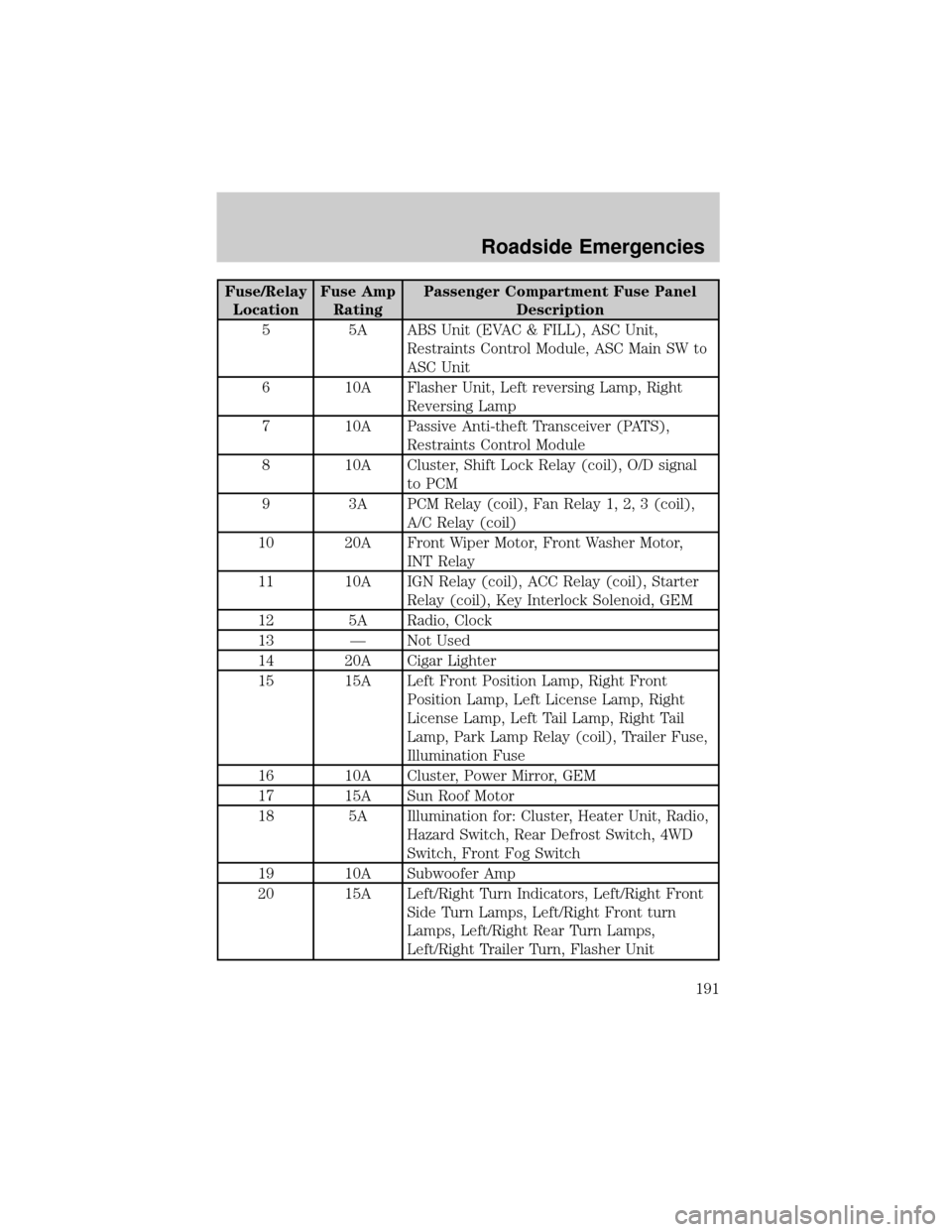

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse Panel

Description

5 5A ABS Unit (EVAC & FILL), ASC Unit,

Restraints Control Module, ASC Main SW to

ASC Unit

6 10A Flasher Unit, Left reversing Lamp, Right

Reversing Lamp

7 10A Passive Anti-theft Transceiver (PATS),

Restraints Control Module

8 10A Cluster, Shift Lock Relay (coil), O/D signal

to PCM

9 3A PCM Relay (coil), Fan Relay 1, 2, 3 (coil),

A/C Relay (coil)

10 20A Front Wiper Motor, Front Washer Motor,

INT Relay

11 10A IGN Relay (coil), ACC Relay (coil), Starter

Relay (coil), Key Interlock Solenoid, GEM

12 5A Radio, Clock

13 Ð Not Used

14 20A Cigar Lighter

15 15A Left Front Position Lamp, Right Front

Position Lamp, Left License Lamp, Right

License Lamp, Left Tail Lamp, Right Tail

Lamp, Park Lamp Relay (coil), Trailer Fuse,

Illumination Fuse

16 10A Cluster, Power Mirror, GEM

17 15A Sun Roof Motor

18 5A Illumination for: Cluster, Heater Unit, Radio,

Hazard Switch, Rear Defrost Switch, 4WD

Switch, Front Fog Switch

19 10A Subwoofer Amp

20 15A Left/Right Turn Indicators, Left/Right Front

Side Turn Lamps, Left/Right Front turn

Lamps, Left/Right Rear Turn Lamps,

Left/Right Trailer Turn, Flasher Unit

Roadside Emergencies

191

Page 194 of 280

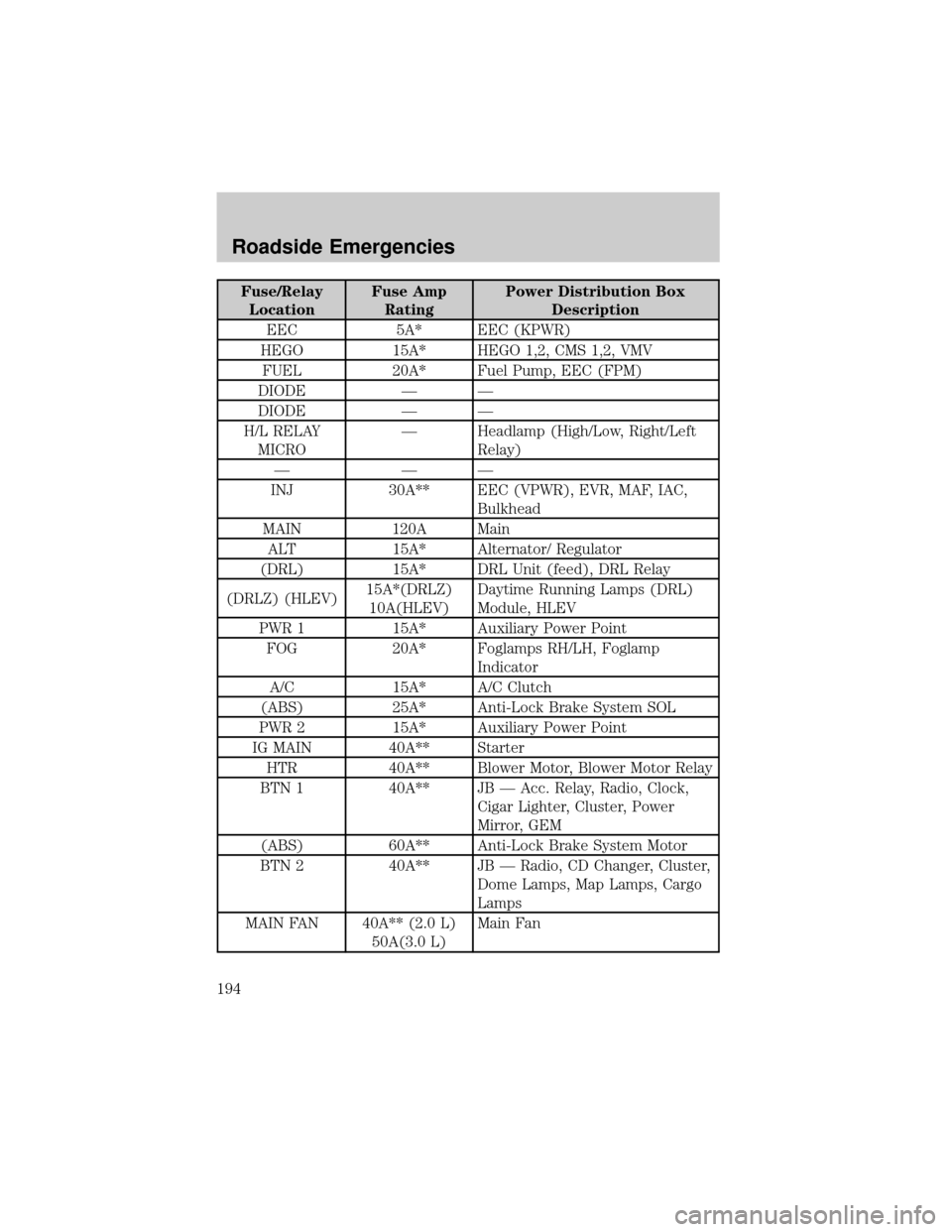

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

EEC 5A* EEC (KPWR)

HEGO 15A* HEGO 1,2, CMS 1,2, VMV

FUEL 20A* Fuel Pump, EEC (FPM)

DIODE Ð Ð

DIODE Ð Ð

H/L RELAY

MICROÐ Headlamp (High/Low, Right/Left

Relay)

ÐÐÐ

INJ 30A** EEC (VPWR), EVR, MAF, IAC,

Bulkhead

MAIN 120A Main

ALT 15A* Alternator/ Regulator

(DRL) 15A* DRL Unit (feed), DRL Relay

(DRLZ) (HLEV)15A*(DRLZ)

10A(HLEV)Daytime Running Lamps (DRL)

Module, HLEV

PWR 1 15A* Auxiliary Power Point

FOG 20A* Foglamps RH/LH, Foglamp

Indicator

A/C 15A* A/C Clutch

(ABS) 25A* Anti-Lock Brake System SOL

PWR 2 15A* Auxiliary Power Point

IG MAIN 40A** Starter

HTR 40A** Blower Motor, Blower Motor Relay

BTN 1 40A** JB Ð Acc. Relay, Radio, Clock,

Cigar Lighter, Cluster, Power

Mirror, GEM

(ABS) 60A** Anti-Lock Brake System Motor

BTN 2 40A** JB Ð Radio, CD Changer, Cluster,

Dome Lamps, Map Lamps, Cargo

Lamps

MAIN FAN 40A** (2.0 L)

50A(3.0 L)Main Fan

Roadside Emergencies

194

Page 198 of 280

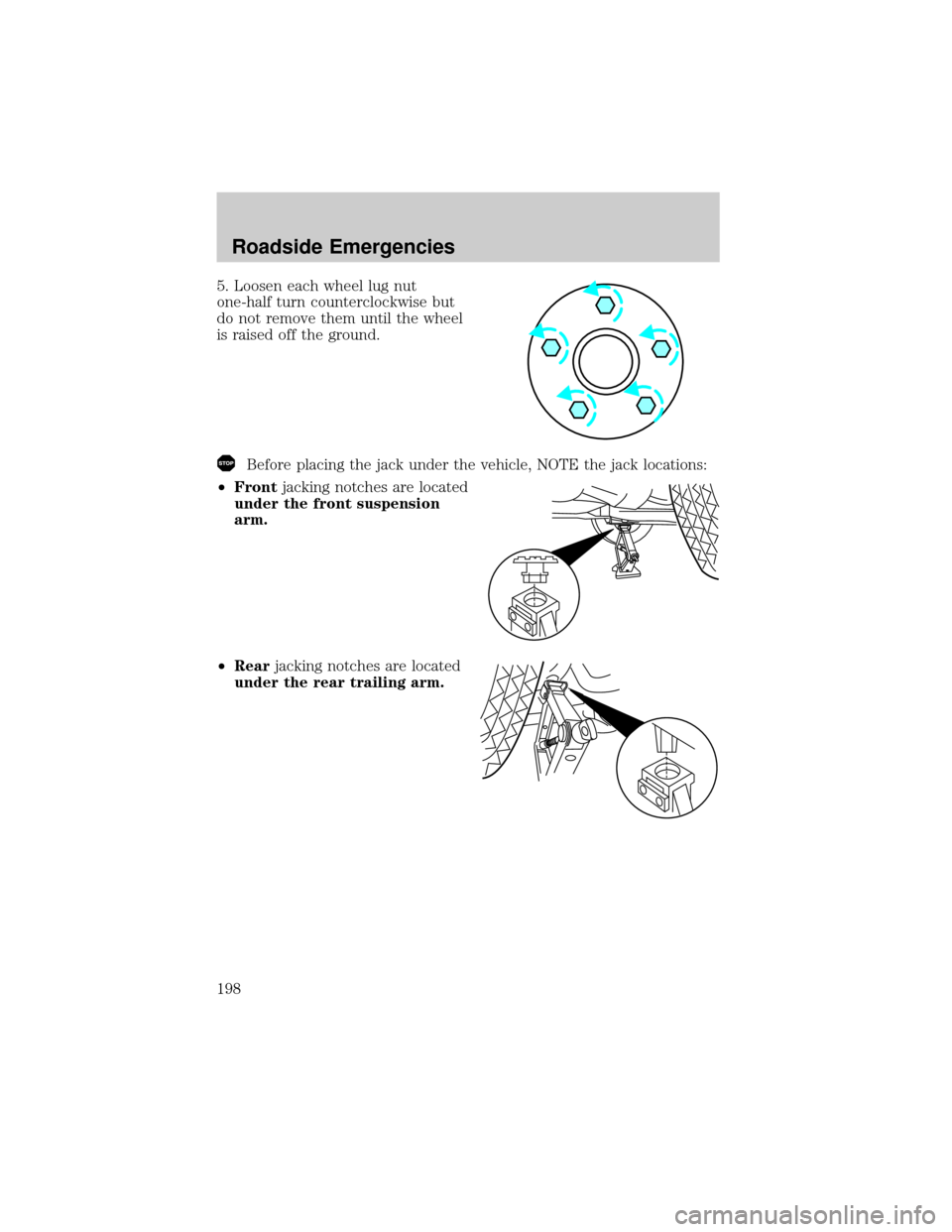

5. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

Before placing the jack under the vehicle, NOTE the jack locations:

²Frontjacking notches are located

under the front suspension

arm.

²Rearjacking notches are located

under the rear trailing arm.

Roadside Emergencies

198

Page 199 of 280

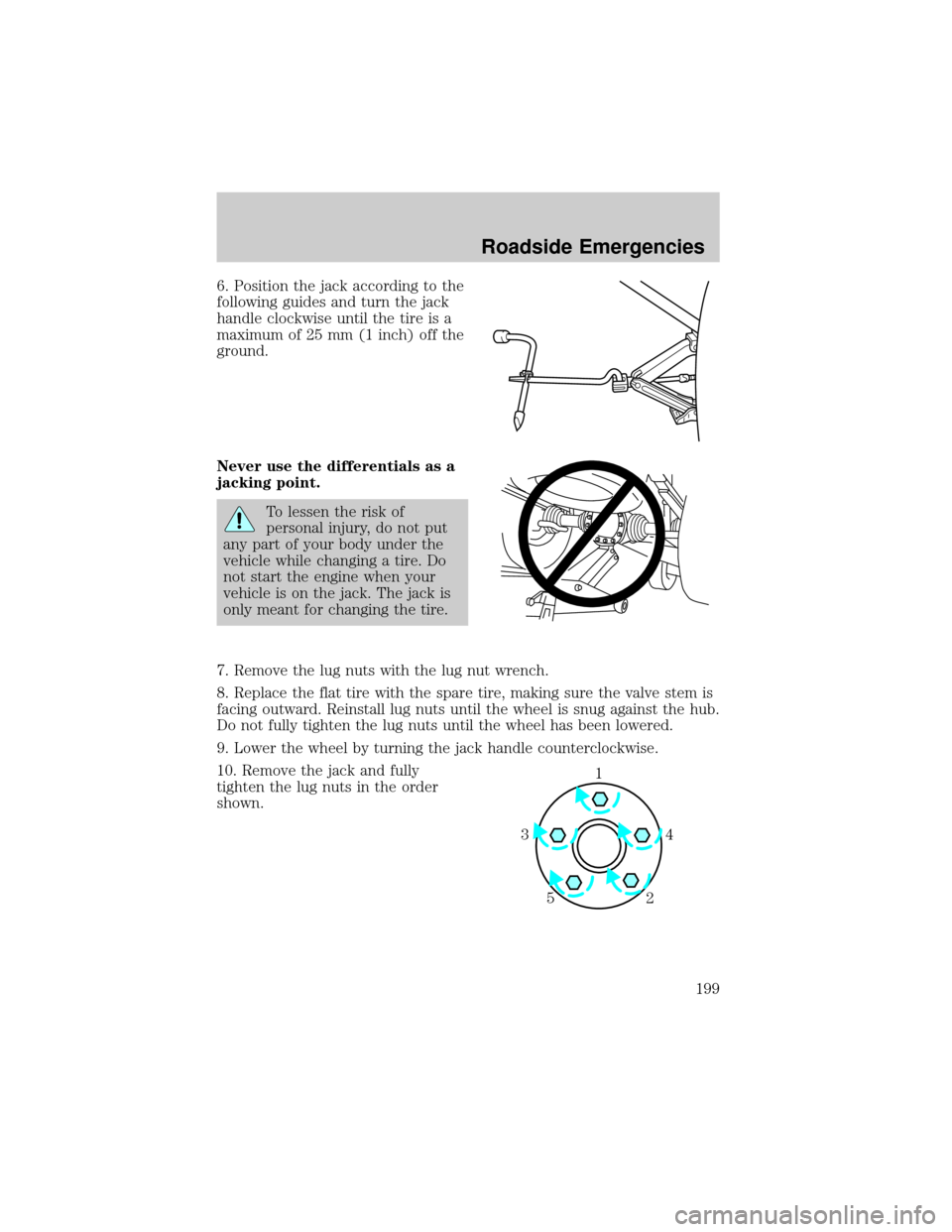

6. Position the jack according to the

following guides and turn the jack

handle clockwise until the tire is a

maximum of 25 mm (1 inch) off the

ground.

Never use the differentials as a

jacking point.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

7. Remove the lug nuts with the lug nut wrench.

8. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall lug nuts until the wheel is snug against the hub.

Do not fully tighten the lug nuts until the wheel has been lowered.

9. Lower the wheel by turning the jack handle counterclockwise.

10. Remove the jack and fully

tighten the lug nuts in the order

shown.

1

4 3

2 5

Roadside Emergencies

199

Page 233 of 280

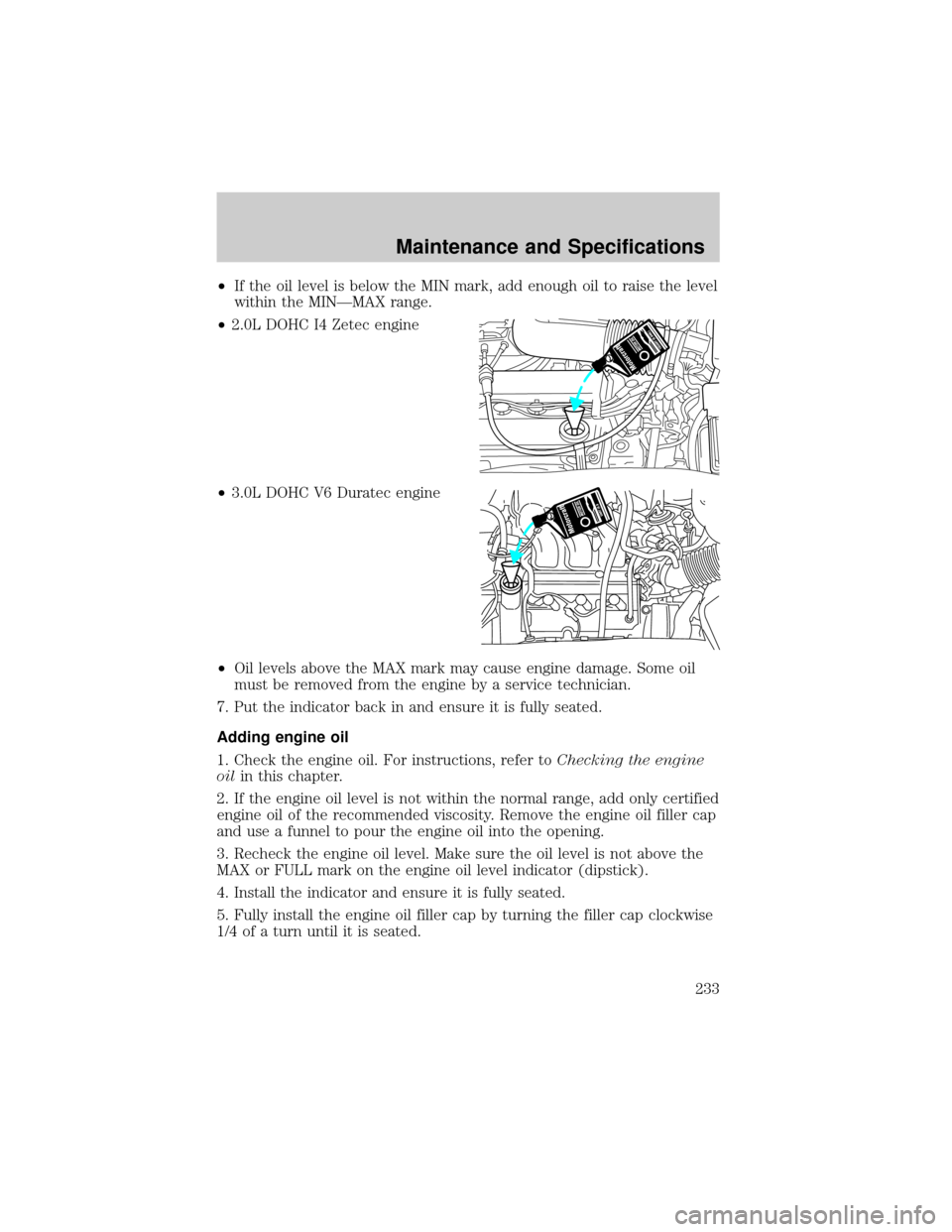

²If the oil level is below the MIN mark, add enough oil to raise the level

within the MINÐMAX range.

²2.0L DOHC I4 Zetec engine

²3.0L DOHC V6 Duratec engine

²Oil levels above the MAX mark may cause engine damage. Some oil

must be removed from the engine by a service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX or FULL mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until it is seated.

Maintenance and Specifications

233

Page 237 of 280

will not affect function or durability of the transmission. Over time the

adaptive learning process will fully update transmission operation to its

optimum shift feel.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

mileage intervals listed in the scheduled maintenance guide. The coolant

concentration should be maintained at 50/50 coolant and water, which

equates to a freeze point of -36É C (-34É F). Coolant concentration

testing is possible with a hydrometer or antifreeze tester (such as the

Rotunda Battery and Antifreeze Tester, 014±R1060). The level of coolant

should be maintained at the ªcold fullº of ªcold fill rangeº level in the

coolant reservoir. If the level falls below, add coolant per the instructions

in theAdding engine coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

60%, the engine parts could become damaged or not work properly.A

50±50 mixture of coolant and water provides the following:

²Freeze protection down to -36É C (-34É F).

²Boiling protection up to 129É C (265É F).

²Protection against rust and other forms of corrosion.

²Enables calibrated gauges to work properly.

LEAD

RETURN

RECYCLE

Maintenance and Specifications

237

Page 240 of 280

degas system with a pressurized cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator of a vehicle with an overflow

system, follow these steps to add engine coolant.

To reduce the risk of personal injury, make sure the engine is

cool before unscrewing the coolant pressure relief cap. The

cooling system is under pressure; steam and hot liquid can come out

forcefully when the cap is loosened slightly.

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (an opaque plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

5. Fill the coolant reservoir slowly with the proper coolant mixture (see

above), to within the ªcold fill rangeº or the ªcold fullº level on the

reservoir. If you removed the radiator cap in an overflow system, fill the

radiator until the coolant is visible and radiator is almost full.

6. Replace the cap. Turn until tightly installed. (Cap must be tightly

installed to prevent coolant loss.)

After any coolant has been added, check the coolant concentration see

Checking Engine Coolant section). If the concentration is not 50/50

(protection to ±34É F/±36É C), drain some coolant and adjust the

concentration. It may take several drains and additions to obtain a 50/50

coolant concentration.

Whenever coolant has been added, the coolant level in the coolant

reservoir should be checked the next few times you drive the vehicle. If

necessary, add enough 50/50 concentration of engine coolant and

distilled water to bring the liquid level to the proper level.

If you have to add more than 1.0 liter (1.0 quart) of engine coolant per

month, have your dealer check the engine cooling system. Your cooling

system may have a leak. Operating an engine with a low level of coolant

can result in engine overheating and possible engine damage.

Maintenance and Specifications

240

Page 244 of 280

The flow of fuel through a fuel pump nozzle can produce static

electricity, which can cause a fire if fuel is pumped into an

ungrounded fuel container.

Use the following guidelines to avoid static build-up when filling an

ungrounded fuel container:

²Place approved fuel container on the ground.

²DO NOT fill a fuel container while it is in the vehicle (including the

cargo area).

²Keep the fuel pump nozzle in contact with the fuel container while

filling.

²DO NOT use a device that would hold the fuel pump handle in the fill

position.

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a 1/8 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8 of a turn until it

stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it stops.

After refueling, if the ªCHECK FUEL CAPº

indicator comes on and

stays on when you start the engine, the fuel filler cap may not be

properly installed. Turn off the engine, remove the fuel filler cap, align

the cap properly and reinstall it securely. The

indicator should turn

off after three driving cycles with the fuel filler cap properly installed. A

driving cycle consists of a cold engine start-up followed by mixed

city/highway driving.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

Maintenance and Specifications

244