check engine light FORD ESCORT 2003 7.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2003, Model line: ESCORT, Model: FORD ESCORT 2003 7.GPages: 184, PDF Size: 1.28 MB

Page 10 of 184

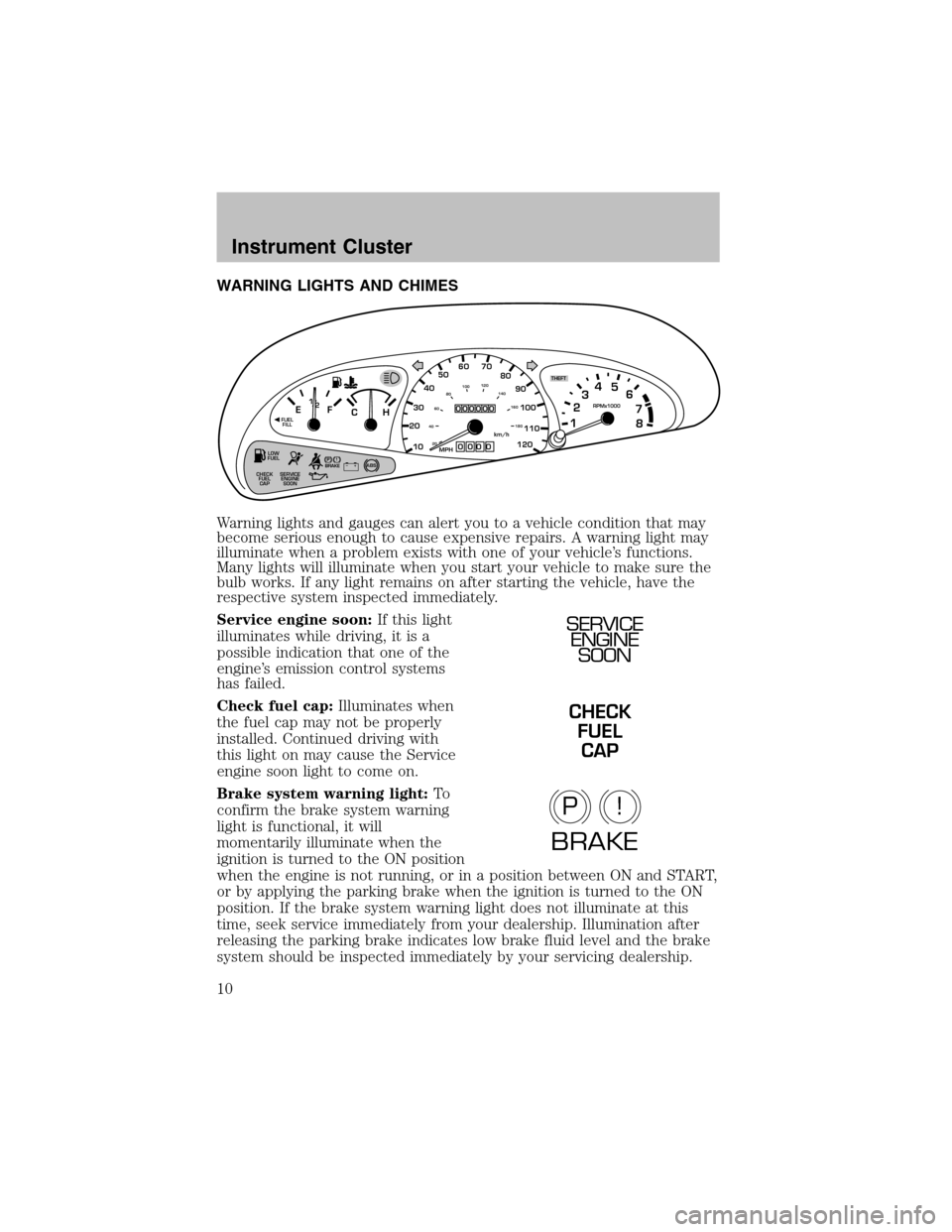

WARNING LIGHTS AND CHIMES

Warning lights and gauges can alert you to a vehicle condition that may

become serious enough to cause expensive repairs. A warning light may

illuminate when a problem exists with one of your vehicle’s functions.

Many lights will illuminate when you start your vehicle to make sure the

bulb works. If any light remains on after starting the vehicle, have the

respective system inspected immediately.

Service engine soon:If this light

illuminates while driving, it is a

possible indication that one of the

engine’s emission control systems

has failed.

Check fuel cap:Illuminates when

the fuel cap may not be properly

installed. Continued driving with

this light on may cause the Service

engine soon light to come on.

Brake system warning light:To

confirmthe brake systemwarning

light is functional, it will

momentarily illuminate when the

ignition is turned to the ON position

when the engine is not running, or in a position between ON and START,

or by applying the parking brake when the ignition is turned to the ON

position. If the brake systemwarning light does not illuminate at this

time, seek service immediately from your dealership. Illumination after

releasing the parking brake indicates low brake fluid level and the brake

system should be inspected immediately by your servicing dealership.

!

THEFT

LOW

FUEL

SERVICE

ENGINE

SOON CHECK

FUEL

CAP

PBRAKEABS+ –MPH

205060 70FUEL

FILLEF

CH1

2 /RPMx1000

1234

5

6

7

8

304080

90

100

110

120

10

20 406080100120

140

160

180km/h

0

000000

00 0

SERVICE

ENGINE

SOON

CHECK

FUEL

CAP

P!

BRAKE

Instrument Cluster

10

Page 11 of 184

Driving a vehicle with the brake systemwarning light on is

dangerous. A significant decrease in braking performance may

occur. It will take you longer to stop the vehicle. Have the vehicle

checked by your dealer immediately.

Anti-lock brake system:If the ABS

light stays illuminated or continues to

flash, a malfunction has been

detected, have the systemserviced

immediately. Normal braking is still

functional unless the brake warning light also is illuminated.

Air bag readiness:If this light fails

to illuminate when ignition is turned

to ON, continues to flash or remains

on, have the systemserviced

immediately. A chime will also

sound when a malfunction in the supplemental restraint system has been

detected.

Safety belt:Reminds you to fasten

your safety belt. A chime will also

sound to remind you to fasten your

safety belt.

Charging system:Illuminates when

the battery is not charging properly.

Engine oil pressure:Illuminates

when the oil pressure falls below the

normal range. Refer toEngine oil

in theMaintenance and

Specificationschapter.

Low fuel:Illuminates when the fuel

level in the fuel tank is at, or near

empty (refer toFuel gaugein this

chapter).

Turn signal:Illuminates when the

left or right turn signal or the

hazard lights are turned on. If the

indicators stay on or flash faster, check for a burned out bulb.

ABS

LOW

FUEL

Instrument Cluster

11

Page 85 of 184

If you smell exhaust fumes inside your vehicle, have your dealer

inspect your vehicle immediately. Do not drive if you smell

exhaust fumes.

Make sure the corresponding lights illuminate or illuminate briefly. If a

light fails to illuminate, have the vehicle serviced.

•If the driver’s safety belt is fastened, the

light may not illuminate.

Important safety precautions

When the engine starts, the idle RPM runs faster to warmthe engine. If

the engine idle speed does not slow down automatically, have the vehicle

checked.

Before starting the vehicle:

1. Make sure all occupants buckle their safety belts. For more

information on safety belts and their proper usage, refer to theSeating

and safety restraintschapter.

2. Make sure the headlamps and electrical accessories are off.

If starting a vehicle with an automatic transaxle:

•Make sure the parking brake is

set.

Driving

85

Page 87 of 184

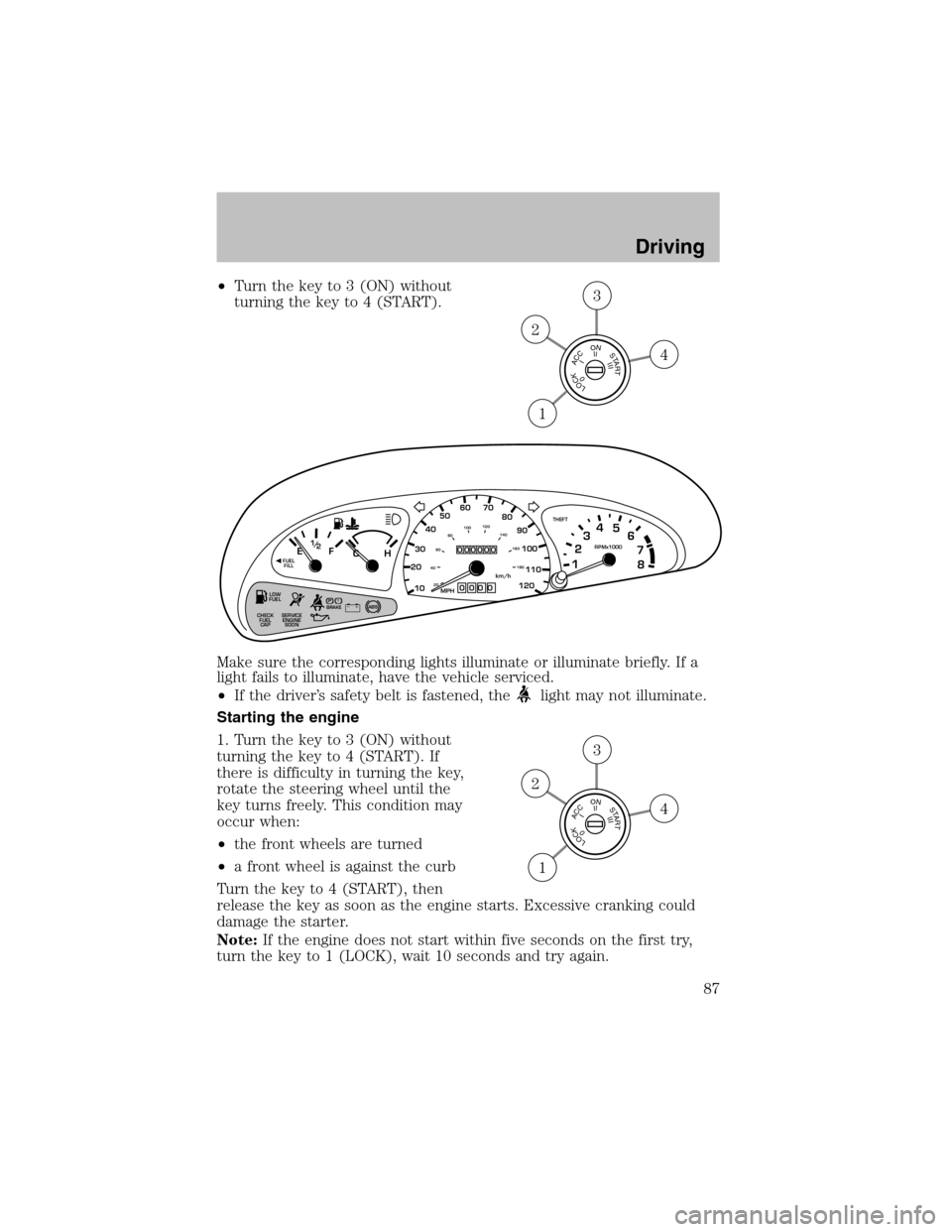

•Turn the key to 3 (ON) without

turning the key to 4 (START).

Make sure the corresponding lights illuminate or illuminate briefly. If a

light fails to illuminate, have the vehicle serviced.

•If the driver’s safety belt is fastened, the

light may not illuminate.

Starting the engine

1. Turn the key to 3 (ON) without

turning the key to 4 (START). If

there is difficulty in turning the key,

rotate the steering wheel until the

key turns freely. This condition may

occur when:

•the front wheels are turned

•a front wheel is against the curb

Turn the key to 4 (START), then

release the key as soon as the engine starts. Excessive cranking could

damage the starter.

Note:If the engine does not start within five seconds on the first try,

turn the key to 1 (LOCK), wait 10 seconds and try again.

LOCKACCONSTART0IIIIII4

3

2

1

!

THEFT

LOW

FUEL

SERVICE

ENGINE

SOON CHECK

FUEL

CAP

PBRAKEABS+ –MPH

205060 70FUEL

FILLEF

CH1

2 /RPMx1000

1234

5

6

7

8

304080

90

100

110

120

10

20 406080100120

140

160

180km/h

0

000000

00 0

LOCKACCONSTART0IIIIII4

3

2

1

Driving

87

Page 89 of 184

If you are driving down a long or steep hill, shift to a lower gear.

Do not apply your brakes continuously, as they may overheat

and become less effective.

Under normal operating conditions, brake dust may accumulate on the

wheels. Some brake dust is inevitable as brakes wear and does not

contribute to brake noise. The use of modern friction materials with

emphasis on improved performance and environmental considerations

can lead to more dust than in the past. Brake dust can be cleaned by

weekly washing with soapy water and a soft sponge. Heavier deposits can

be removed with Motorcraft Wheel and Tire Cleaner (ZC-37–A).

Anti-lock brake system (ABS) (if equipped)

On vehicles equipped with an anti-lock braking system(ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle’s

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

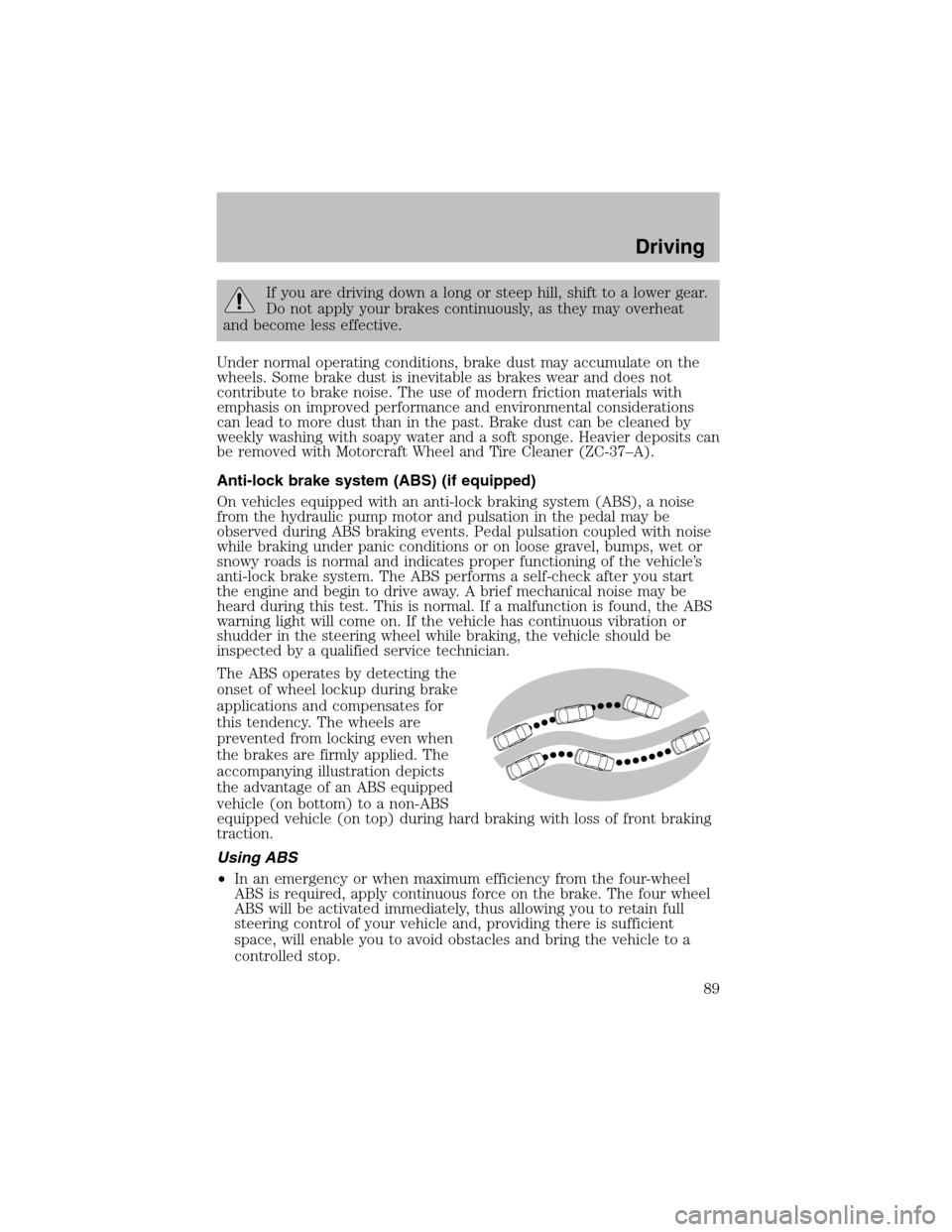

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented fromlocking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Using ABS

•In an emergency or when maximum efficiency from the four-wheel

ABS is required, apply continuous force on the brake. The four wheel

ABS will be activated immediately, thus allowing you to retain full

steering control of your vehicle and, providing there is sufficient

space, will enable you to avoid obstacles and bring the vehicle to a

controlled stop.

Driving

89

Page 98 of 184

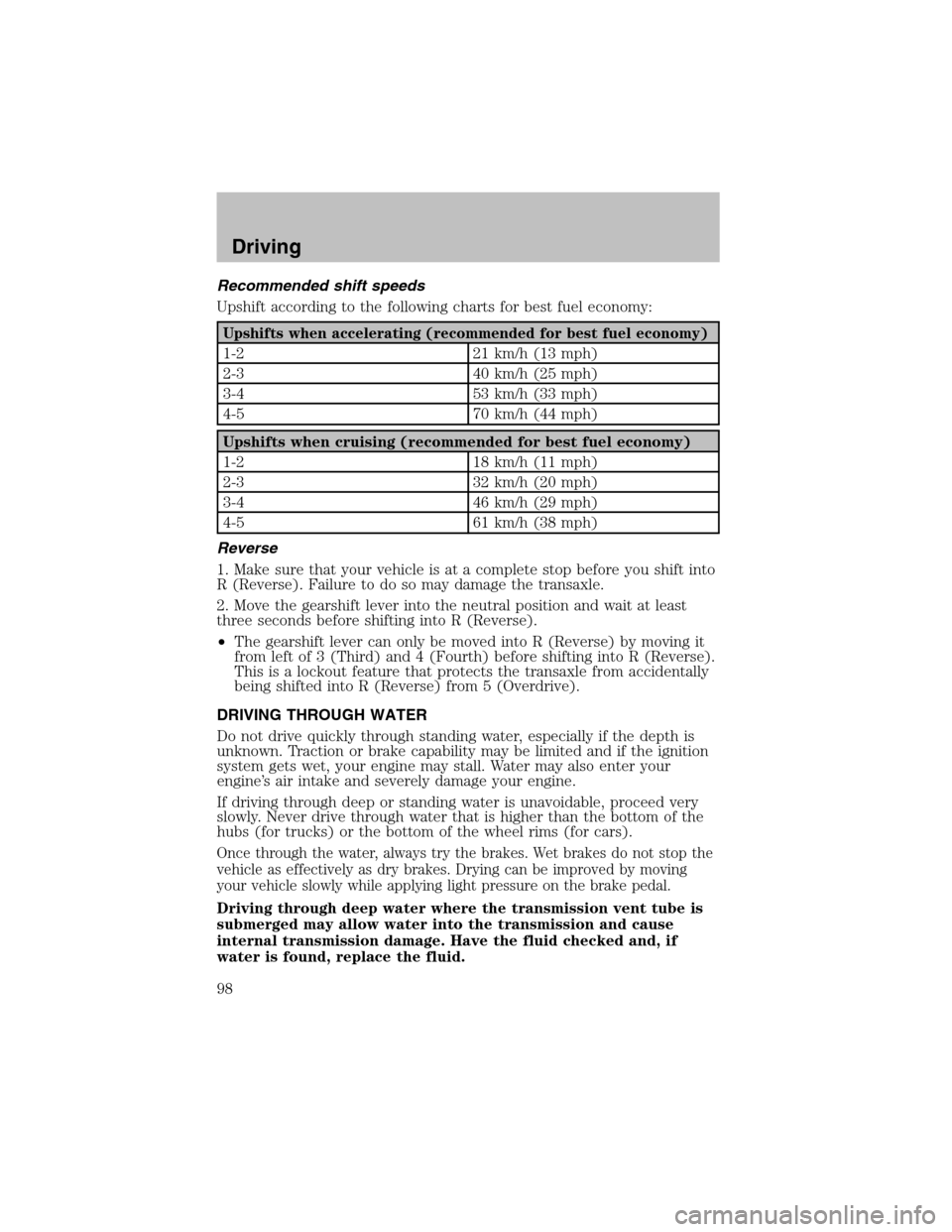

Recommended shift speeds

Upshift according to the following charts for best fuel economy:

Upshifts when accelerating (recommended for best fuel economy)

1-2 21 km/h (13 mph)

2-3 40 km/h (25 mph)

3-4 53 km/h (33 mph)

4-5 70 km/h (44 mph)

Upshifts when cruising (recommended for best fuel economy)

1-2 18 km/h (11 mph)

2-3 32 km/h (20 mph)

3-4 46 km/h (29 mph)

4-5 61 km/h (38 mph)

Reverse

1. Make sure that your vehicle is at a complete stop before you shift into

R (Reverse). Failure to do so may damage the transaxle.

2. Move the gearshift lever into the neutral position and wait at least

three seconds before shifting into R (Reverse).

•The gearshift lever can only be moved into R (Reverse) by moving it

fromleft of 3 (Third) and 4 (Fourth) before shifting into R (Reverse).

This is a lockout feature that protects the transaxle fromaccidentally

being shifted into R (Reverse) from5 (Overdrive).

DRIVING THROUGH WATER

Do not drive quickly through standing water, especially if the depth is

unknown. Traction or brake capability may be limited and if the ignition

system gets wet, your engine may stall. Water may also enter your

engine’s air intake and severely damage your engine.

If driving through deep or standing water is unavoidable, proceed very

slowly. Never drive through water that is higher than the bottomof the

hubs (for trucks) or the bottomof the wheel rims (for cars).

Once through the water, always try the brakes. Wet brakes do not stop the

vehicle as effectively as dry brakes. Drying can be improved by moving

your vehicle slowly while applying light pressure on the brake pedal.

Driving through deep water where the transmission vent tube is

submerged may allow water into the transmission and cause

internal transmission damage. Have the fluid checked and, if

water is found, replace the fluid.

Driving

98

Page 136 of 184

SERVICE RECOMMENDATIONS

To help you service your vehicle:

•We highlight do-it-yourself items in the engine compartment for easy

location.

•We provide a scheduled maintenance guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

the necessary parts and service. Check yourWarranty Guide/Owner

Information Guideto find out which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

•Do not work on a hot engine.

•Make sure that nothing gets caught in moving parts.

•Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

•Keep all open flames and other burning (cigarettes) material away

fromthe battery and all fuel related parts.

2. Turn off the engine and remove

the key.

3. Block the wheels to prevent the

vehicle frommoving unexpectedly.

•Manual transaxle:

P

RNDDL

Maintenance and Specifications

136

Page 141 of 184

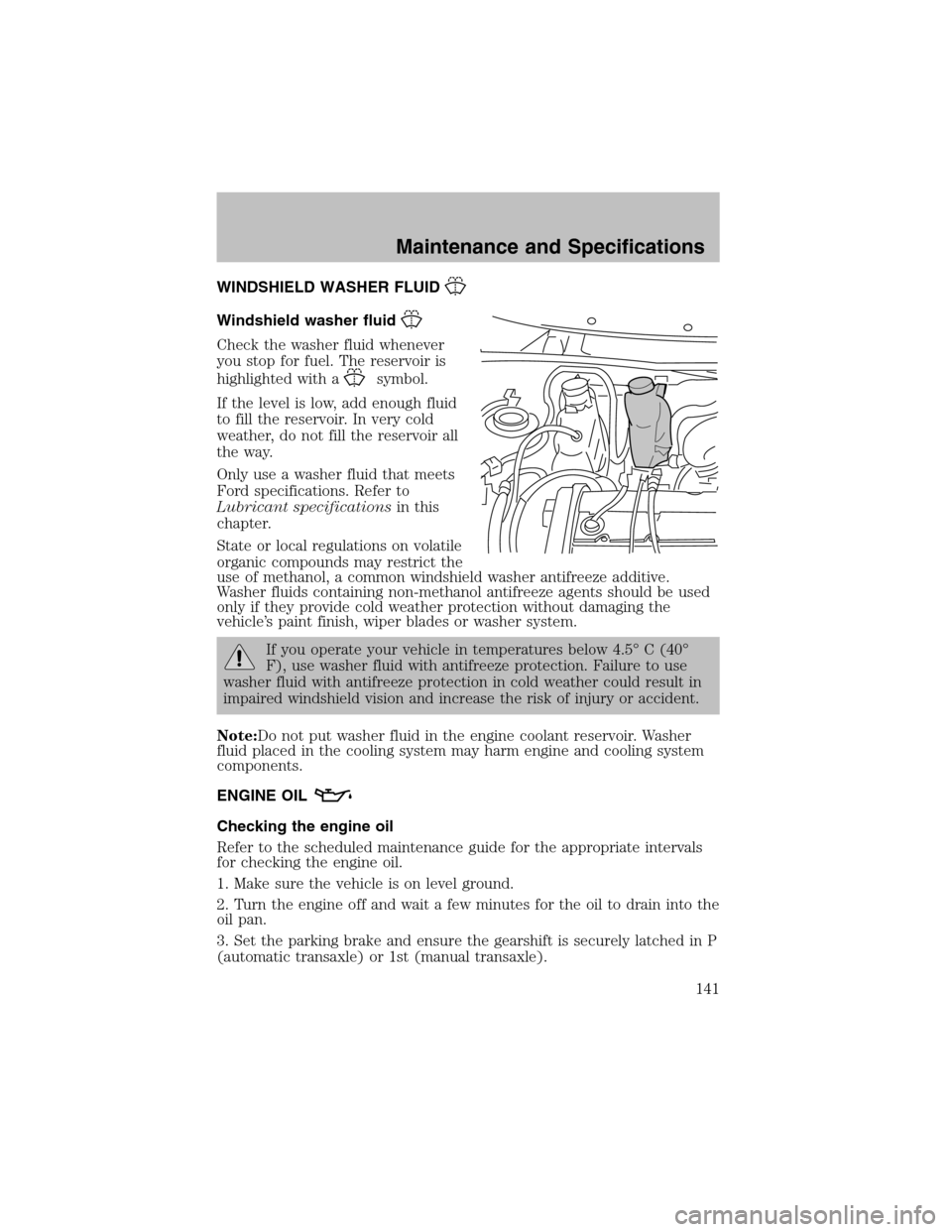

WINDSHIELD WASHER FLUID

Windshield washer fluid

Check the washer fluid whenever

you stop for fuel. The reservoir is

highlighted with a

symbol.

If the level is low, add enough fluid

to fill the reservoir. In very cold

weather, do not fill the reservoir all

the way.

Only use a washer fluid that meets

Ford specifications. Refer to

Lubricant specificationsin this

chapter.

State or local regulations on volatile

organic compounds may restrict the

use of methanol, a common windshield washer antifreeze additive.

Washer fluids containing non-methanol antifreeze agents should be used

only if they provide cold weather protection without damaging the

vehicle’s paint finish, wiper blades or washer system.

If you operate your vehicle in temperatures below 4.5° C (40°

F), use washer fluid with antifreeze protection. Failure to use

washer fluid with antifreeze protection in cold weather could result in

impaired windshield vision and increase the risk of injury or accident.

Note:Do not put washer fluid in the engine coolant reservoir. Washer

fluid placed in the cooling systemmay harmengine and cooling system

components.

ENGINE OIL

Checking the engine oil

Refer to the scheduled maintenance guide for the appropriate intervals

for checking the engine oil.

1. Make sure the vehicle is on level ground.

2. Turn the engine off and wait a few minutes for the oil to drain into the

oil pan.

3. Set the parking brake and ensure the gearshift is securely latched in P

(automatic transaxle) or 1st (manual transaxle).

Maintenance and Specifications

141

Page 144 of 184

that does not meet Ford material and design specifications, start-up

engine noises or knock may be experienced.

It is recommended you use the appropriate Motorcraft oil filter (or

another brand meeting Ford specifications) for your engine application.

BATTERY

Your vehicle is equipped with a

Motorcraft maintenance-free battery

which normally does not require

additional water during its life of

service.

However, for severe usage or in high temperature climates, check the

battery electrolyte level. Refer to the scheduled maintenance guide for

the service interval schedules.

Keep the electrolyte level in each cell up to the “level indicator”.

Do not overfill the battery cells.

If the electrolyte level in the battery is low, you can add plain tap water

to the battery, as long as you do not use hard water (water with a high

mineral or alkali content). If possible, however, try to only fill the battery

cells with distilled water. If the battery needs water often, have the

charging systemchecked.

If your battery has a cover/shield, make sure it is reinstalled

after the battery has been cleaned or replaced.

For longer, trouble-free operation, keep the top of the battery clean and

dry. Also, make certain the battery cables are always tightly fastened to

the battery terminals.

If you see any corrosion on the battery or terminals, remove the cables

fromthe terminals and clean with a wire brush. You can neutralize the

acid with a solution of baking soda and water.

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

Maintenance and Specifications

144

Page 149 of 184

To reduce the risk of personal injury, make sure the engine is

cool before unscrewing the coolant pressure relief cap. The

cooling systemis under pressure; steamand hot liquid can come out

forcefully when the cap is loosened slightly.

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (an opaque plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

5. Fill the coolant reservoir slowly with the proper coolant mixture (see

above), to within the “cold fill range” or the “cold full” level on the

reservoir. If you removed the radiator cap in an overflow system, fill the

radiator until the coolant is visible and radiator is almost full.

6. Replace the cap. Turn until tightly installed. (Cap must be tightly

installed to prevent coolant loss.)

After any coolant has been added, check the coolant concentration, refer

toChecking Engine Coolantsection. If the concentration is not 50/50

(protection to –34° F/–36° C), drain some coolant and adjust the

concentration. It may take several drains and additions to obtain a 50/50

coolant concentration.

Whenever coolant has been added, the coolant level in the coolant

reservoir should be checked the next few times you drive the vehicle. If

necessary, add enough 50/50 concentration of engine coolant and

distilled water to bring the liquid level to the proper level.

If you have to add more than 1.0 liter (1.0 quart) of engine coolant per

month, have your dealer check the engine cooling system. Your cooling

systemmay have a leak. Operating an engine with a low level of coolant

can result in engine overheating and possible engine damage.

Recycled engine coolant

Ford Motor Company recommends the use of a recycled engine coolant

produced by Ford-approved processes in vehicles originally equipped

with Motorcraft Premium Engine Coolant (green-colored). However, not

all coolant recycling processes produce coolant that meets Ford

specification ESE-M97B44–A. Use of such coolant may harm the engine

and cooling systemcomponents.

Maintenance and Specifications

149