fuel FORD EXCURSION 2000 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: EXCURSION, Model: FORD EXCURSION 2000 1.GPages: 232, PDF Size: 2.01 MB

Page 137 of 232

Roadside coverage beyond basic warranty

In the United States, you may purchase additional roadside assistance

coverage beyond this period through the Ford Auto Club by contacting

your Ford or Lincoln Mercury dealer.

Similarly in Canada, you may purchase additional coverage beyond the

basic coverage period by consulting the Ford Roadside Assistance Club

brochure or by calling 1±877±294±CLUB (1±877±894±2582).

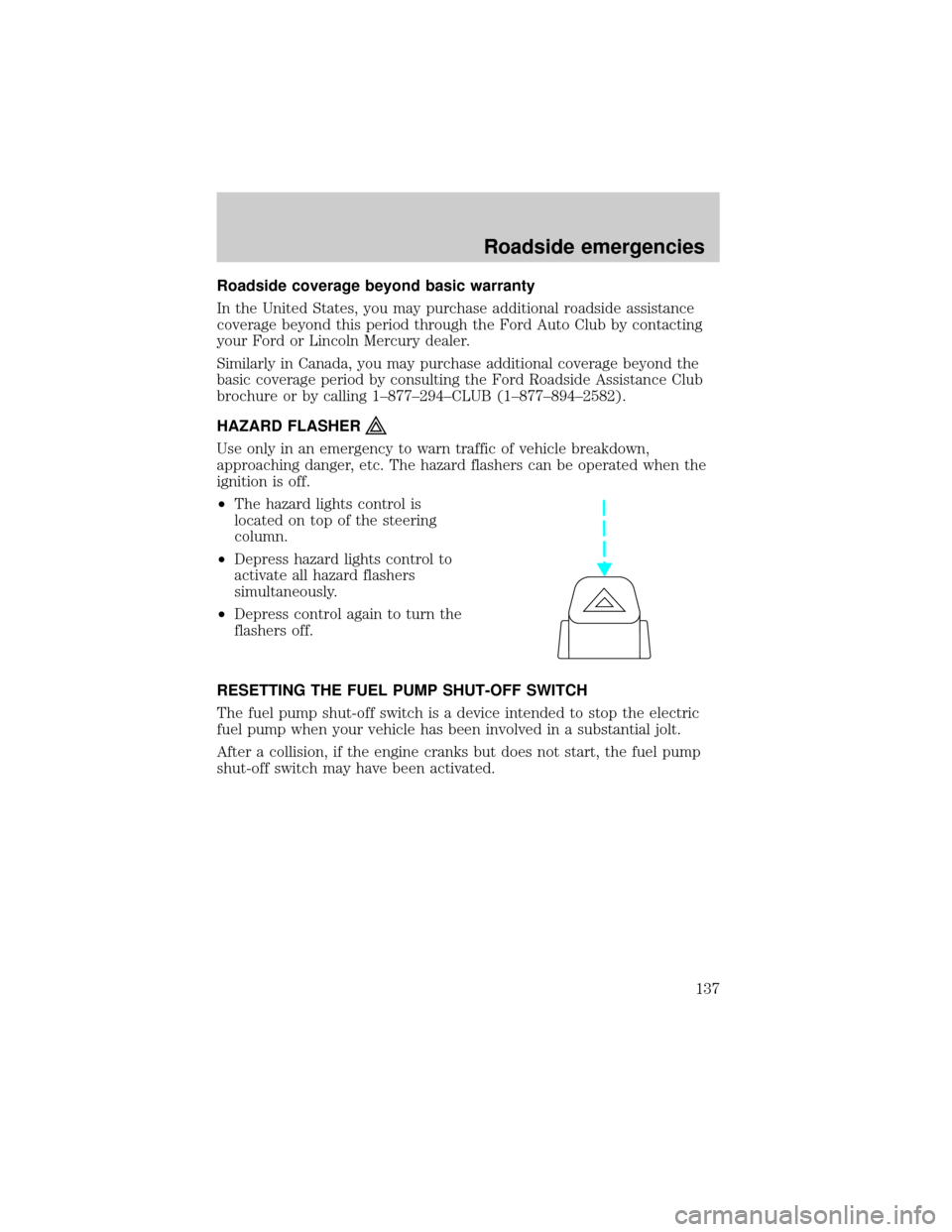

HAZARD FLASHER

Use only in an emergency to warn traffic of vehicle breakdown,

approaching danger, etc. The hazard flashers can be operated when the

ignition is off.

²The hazard lights control is

located on top of the steering

column.

²Depress hazard lights control to

activate all hazard flashers

simultaneously.

²Depress control again to turn the

flashers off.

RESETTING THE FUEL PUMP SHUT-OFF SWITCH

The fuel pump shut-off switch is a device intended to stop the electric

fuel pump when your vehicle has been involved in a substantial jolt.

After a collision, if the engine cranks but does not start, the fuel pump

shut-off switch may have been activated.

Roadside emergencies

137

Page 138 of 232

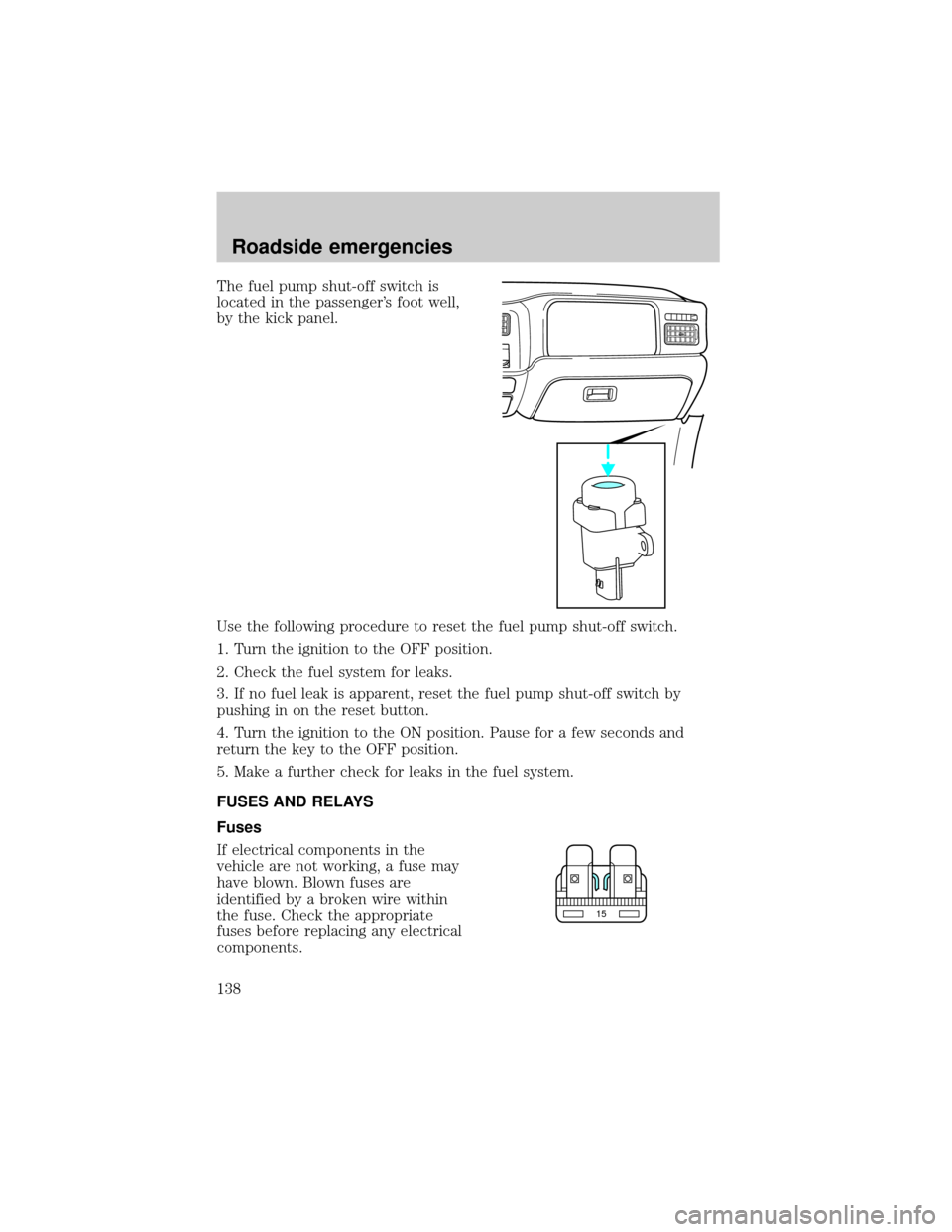

The fuel pump shut-off switch is

located in the passenger's foot well,

by the kick panel.

Use the following procedure to reset the fuel pump shut-off switch.

1. Turn the ignition to the OFF position.

2. Check the fuel system for leaks.

3. If no fuel leak is apparent, reset the fuel pump shut-off switch by

pushing in on the reset button.

4. Turn the ignition to the ON position. Pause for a few seconds and

return the key to the OFF position.

5. Make a further check for leaks in the fuel system.

FUSES AND RELAYS

Fuses

If electrical components in the

vehicle are not working, a fuse may

have blown. Blown fuses are

identified by a broken wire within

the fuse. Check the appropriate

fuses before replacing any electrical

components.

15

Roadside emergencies

138

Page 142 of 232

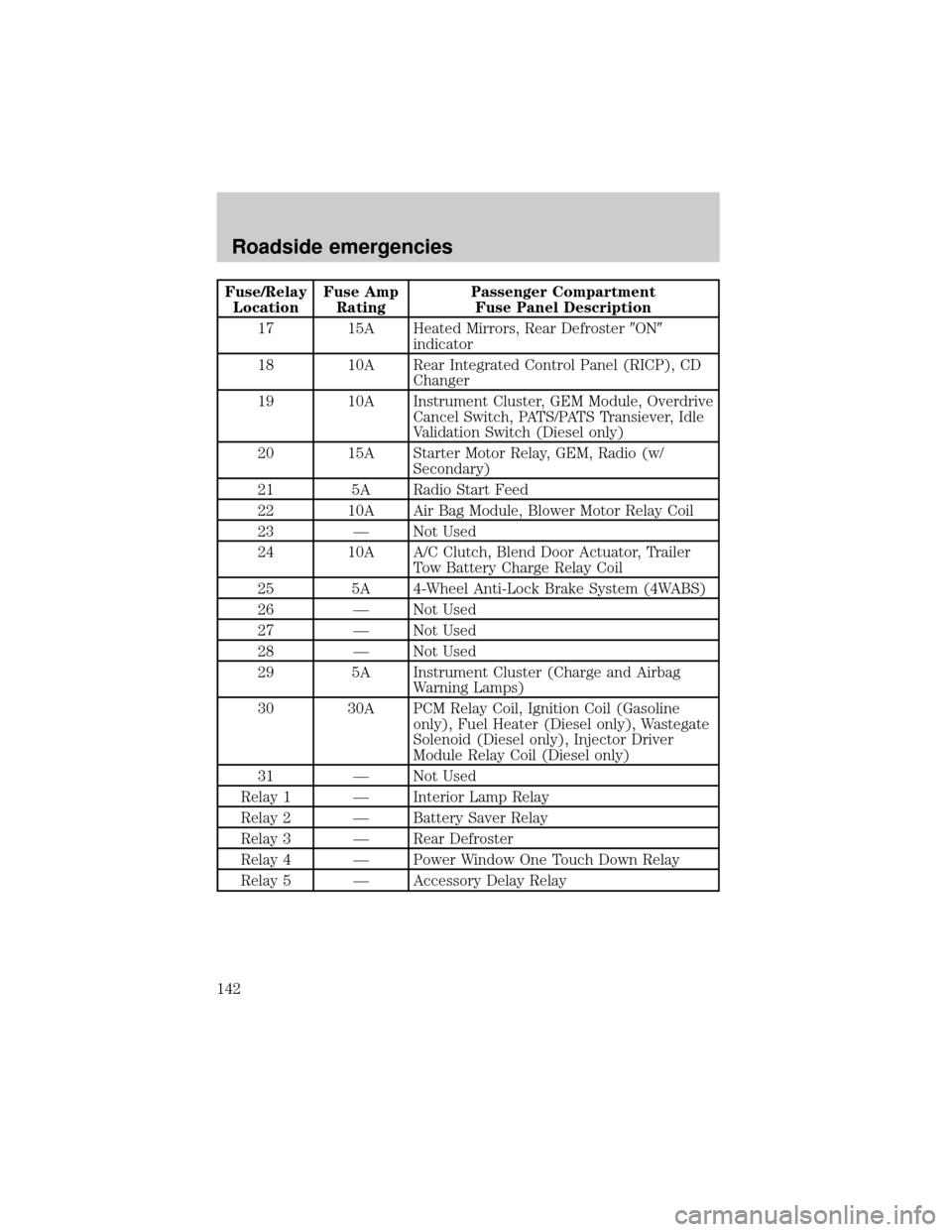

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment

Fuse Panel Description

17 15A Heated Mirrors, Rear Defroster9ON9

indicator

18 10A Rear Integrated Control Panel (RICP), CD

Changer

19 10A Instrument Cluster, GEM Module, Overdrive

Cancel Switch, PATS/PATS Transiever, Idle

Validation Switch (Diesel only)

20 15A Starter Motor Relay, GEM, Radio (w/

Secondary)

21 5A Radio Start Feed

22 10A Air Bag Module, Blower Motor Relay Coil

23 Ð Not Used

24 10A A/C Clutch, Blend Door Actuator, Trailer

Tow Battery Charge Relay Coil

25 5A 4-Wheel Anti-Lock Brake System (4WABS)

26 Ð Not Used

27 Ð Not Used

28 Ð Not Used

29 5A Instrument Cluster (Charge and Airbag

Warning Lamps)

30 30A PCM Relay Coil, Ignition Coil (Gasoline

only), Fuel Heater (Diesel only), Wastegate

Solenoid (Diesel only), Injector Driver

Module Relay Coil (Diesel only)

31 Ð Not Used

Relay 1 Ð Interior Lamp Relay

Relay 2 Ð Battery Saver Relay

Relay 3 Ð Rear Defroster

Relay 4 Ð Power Window One Touch Down Relay

Relay 5 Ð Accessory Delay Relay

Roadside emergencies

142

Page 145 of 232

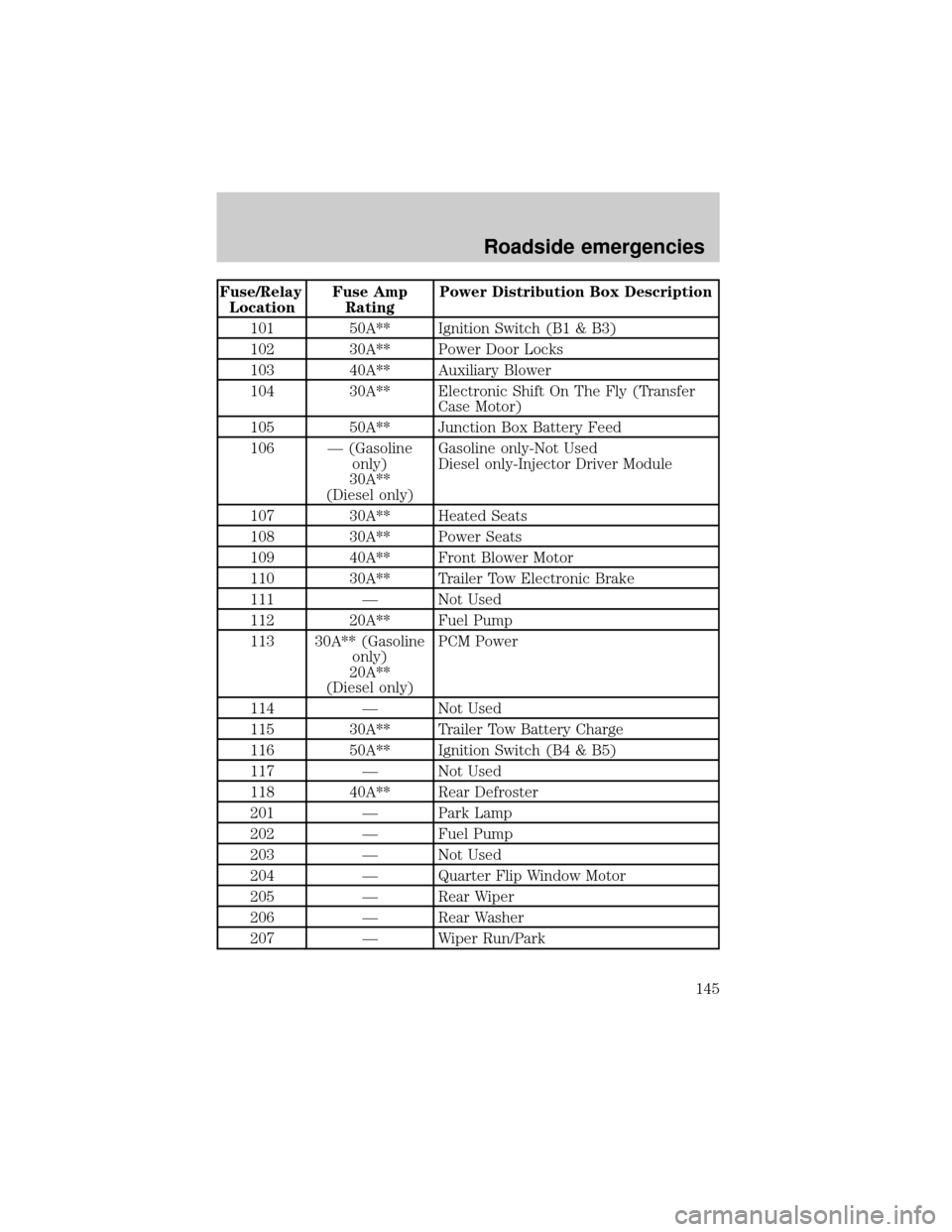

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

101 50A** Ignition Switch (B1 & B3)

102 30A** Power Door Locks

103 40A** Auxiliary Blower

104 30A** Electronic Shift On The Fly (Transfer

Case Motor)

105 50A** Junction Box Battery Feed

106 Ð (Gasoline

only)

30A**

(Diesel only)Gasoline only-Not Used

Diesel only-Injector Driver Module

107 30A** Heated Seats

108 30A** Power Seats

109 40A** Front Blower Motor

110 30A** Trailer Tow Electronic Brake

111 Ð Not Used

112 20A** Fuel Pump

113 30A** (Gasoline

only)

20A**

(Diesel only)PCM Power

114 Ð Not Used

115 30A** Trailer Tow Battery Charge

116 50A** Ignition Switch (B4 & B5)

117 Ð Not Used

118 40A** Rear Defroster

201 Ð Park Lamp

202 Ð Fuel Pump

203 Ð Not Used

204 Ð Quarter Flip Window Motor

205 Ð Rear Wiper

206 Ð Rear Washer

207 Ð Wiper Run/Park

Roadside emergencies

145

Page 153 of 232

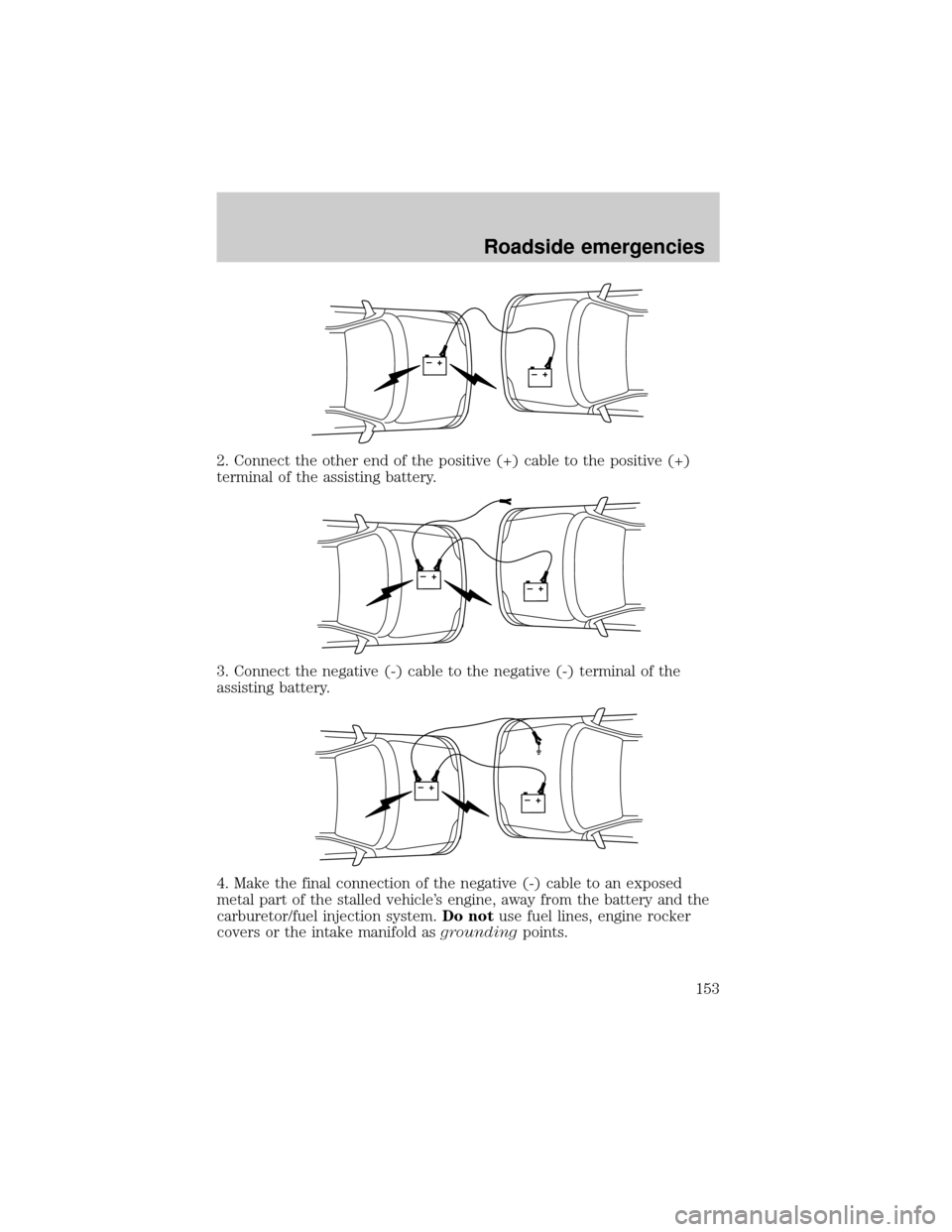

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle's engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

+–+–

+–+–

+–+–

Roadside emergencies

153

Page 154 of 232

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

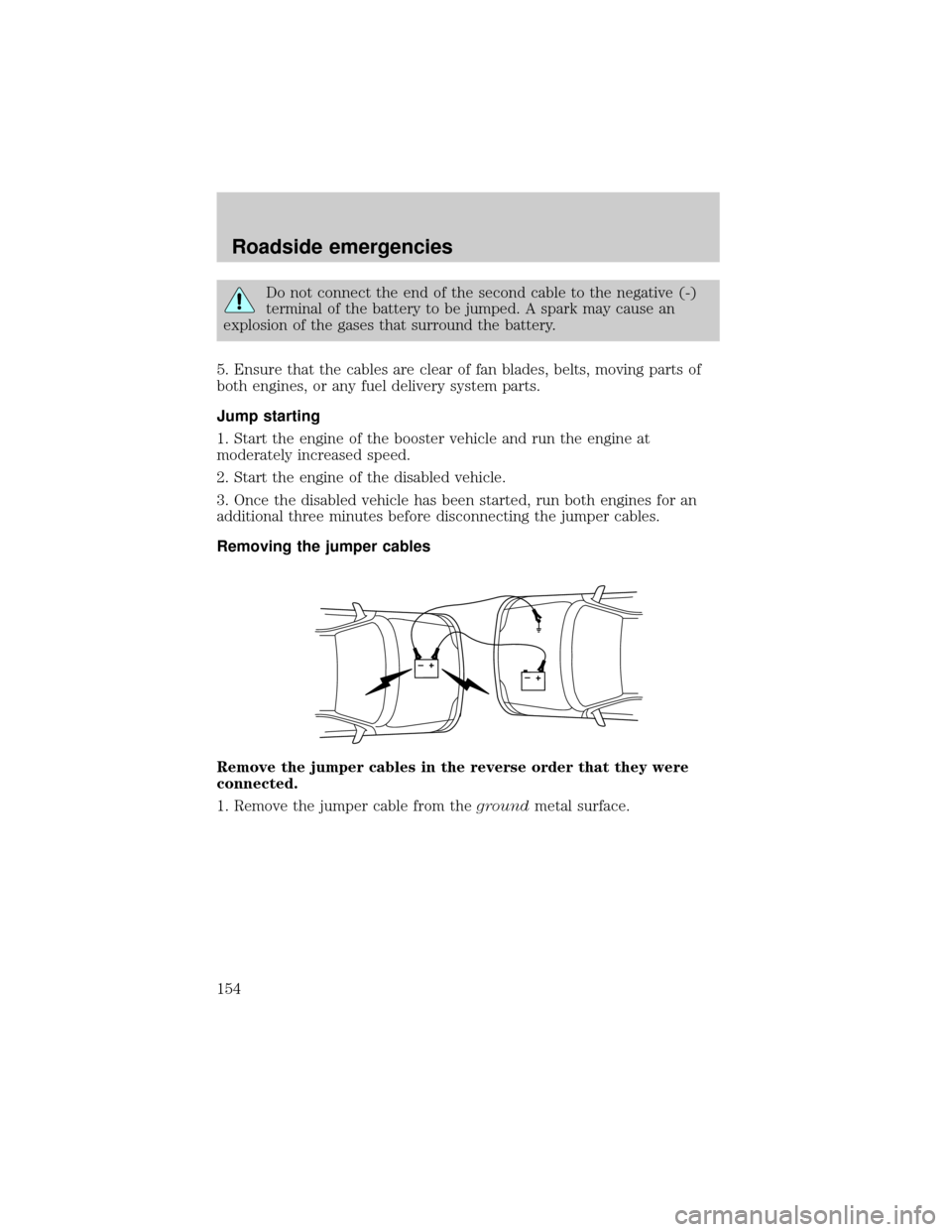

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

+–+–

Roadside emergencies

154

Page 158 of 232

SERVICE RECOMMENDATIONS

To help you service your vehicle:

²We highlight do-it-yourself items in the engine compartment for easy

location.

²We provide a scheduled maintenance guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

necessary parts and service. Check your ªWarranty Guideº to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

²Do not work on a hot engine.

²When the engine is running, keep loose clothing, jewelry or long hair

away from moving parts.

²Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

²Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must ªrelearnº its idle

conditions before your vehicle will drive properly, as explained in the

Batterysection in this chapter.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Maintenance and care

158

Page 165 of 232

Brake system fluid should be replaced on a regular basis to maintain

optimum braking performance, especially under heavy-duty driving

conditions such as frequent steep grades or heavy loads. Refer to the

scheduled maintenance guide for the service interval.

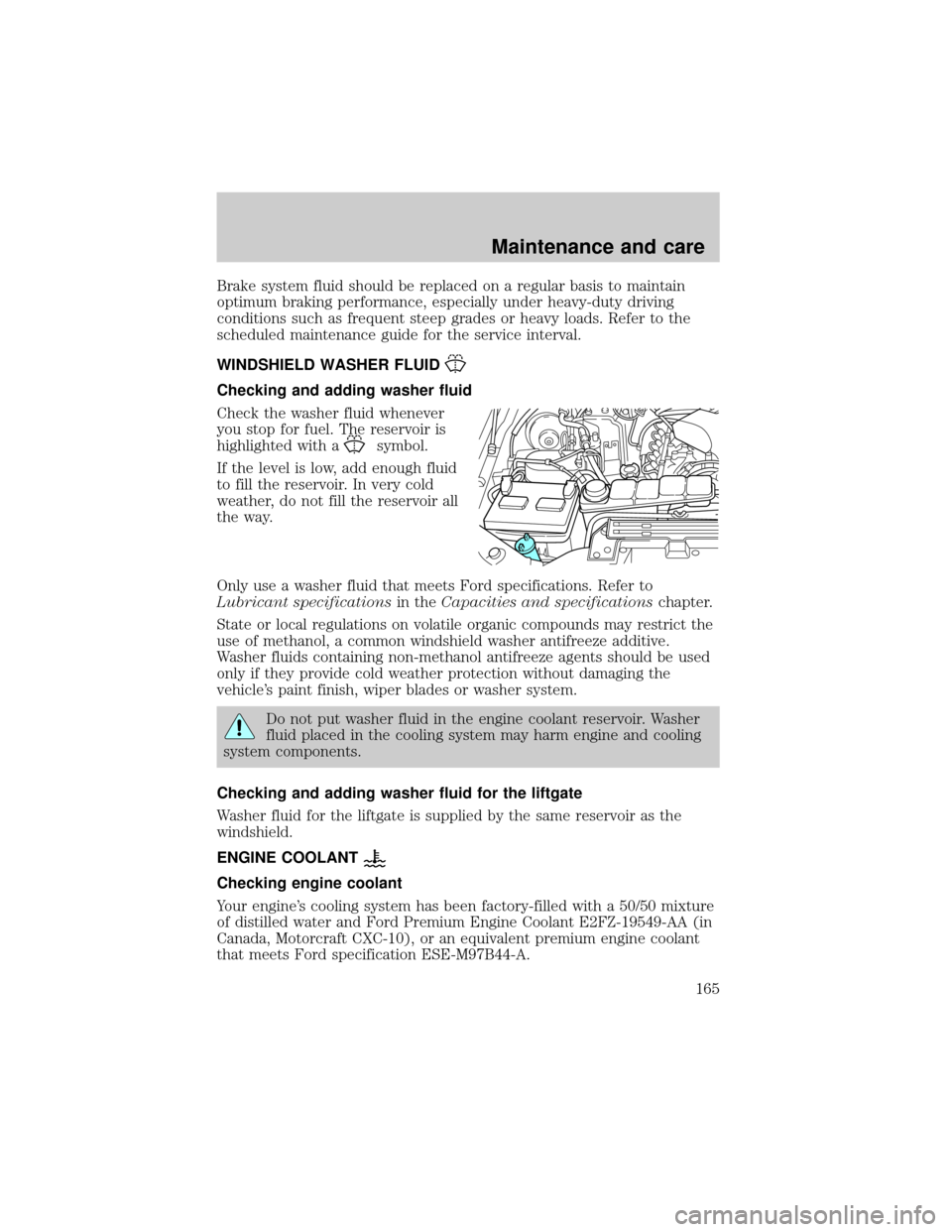

WINDSHIELD WASHER FLUID

Checking and adding washer fluid

Check the washer fluid whenever

you stop for fuel. The reservoir is

highlighted with a

symbol.

If the level is low, add enough fluid

to fill the reservoir. In very cold

weather, do not fill the reservoir all

the way.

Only use a washer fluid that meets Ford specifications. Refer to

Lubricant specificationsin theCapacities and specificationschapter.

State or local regulations on volatile organic compounds may restrict the

use of methanol, a common windshield washer antifreeze additive.

Washer fluids containing non-methanol antifreeze agents should be used

only if they provide cold weather protection without damaging the

vehicle's paint finish, wiper blades or washer system.

Do not put washer fluid in the engine coolant reservoir. Washer

fluid placed in the cooling system may harm engine and cooling

system components.

Checking and adding washer fluid for the liftgate

Washer fluid for the liftgate is supplied by the same reservoir as the

windshield.

ENGINE COOLANT

Checking engine coolant

Your engine's cooling system has been factory-filled with a 50/50 mixture

of distilled water and Ford Premium Engine Coolant E2FZ-19549-AA (in

Canada, Motorcraft CXC-10), or an equivalent premium engine coolant

that meets Ford specification ESE-M97B44-A.

Maintenance and care

165

Page 176 of 232

For longer, trouble-free operation, keep the top of the battery clean and

dry. Also, make certain the battery cables are always tightly fastened to

the battery terminals.

If you see any corrosion on the battery or terminals, remove the cables

from the terminals and clean with a wire brush. You can neutralize the

acid with a solution of baking soda and water.

When the battery is disconnected or a new battery installed, the

transmission must learn its adaptive strategy. As a result of this, the

transmission may shift firmly. This operation is considered normal and

will fully update transmission operation to its optimum shift feel.

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

When lifting a plastic-cased battery, excessive pressure on the

end walls could cause acid to flow through the vent caps,

resulting in personal injury and/or damage to the vehicle or battery.

Lift the battery with a battery carrier or with your hands on opposite

corners.

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

Battery posts, terminals and related accessories contain lead and

lead compunds.Wash hands after handling.

Because your vehicle's engine is electronically controlled by a computer,

some control conditions are maintained by power from the battery. When

the battery is disconnected or a new battery is installed, the engine must

relearn its idle and fuel trim strategy for optimum driveability and

performance. To begin this process:

Maintenance and care

176

Page 177 of 232

1. With the vehicle at a complete stop, set the parking brake.

2. Put the gearshift in P (Park), turn off all accessories and start the

engine.

3. Run the engine until it reaches normal operating temperature.

4. Allow the engine to idle for at least one minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

6. With your foot on the brake pedal and with the A/C on, put the

vehicle in D (Drive) and allow the engine to idle for at least one minute.

7. Drive the vehicle to complete the relearning process.

²The vehicle may need to be driven 16 km (10 miles) or more to

relearn the idle and fuel trim strategy.

²If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock must be reset once the battery is reconnected.

²Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

AIR FILTER MAINTENANCE

Refer to the scheduled maintenance guide for the appropriate intervals

for changing the air filter element.

When changing the air filter element, use only the Motorcraft air filter

element listed. Refer toMotorcraft Part Numbersin theCapacities and

specificationschapter.

Do not start your engine with the air cleaner removed and do

not remove it while the engine is running.

LEAD

RETURN

RECYCLE

Maintenance and care

177