clock FORD EXPEDITION 2003 2.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2003, Model line: EXPEDITION, Model: FORD EXPEDITION 2003 2.GPages: 320, PDF Size: 3.67 MB

Page 237 of 320

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Item Location

Spare tire Under the vehicle, just forward of

the rear bumper

Jack tools and jacking instructions Under the access panel located in

the floor compartment behind the

rear seat

Removing the jack and tools

1. Open the liftgate, then locate the access panel behind the rear seat.

Unlatch and remove the panel.

2. Remove the jack and tools assembly tray from the compartment by

turning the T-nut counterclockwise to relieve tension against the jack

assembly tray.

3. Unsnap the wheel lug nut wrench, jack extension and handle from the

plastic tray. Remove the jack and instruction sheet from the tray

assembly.

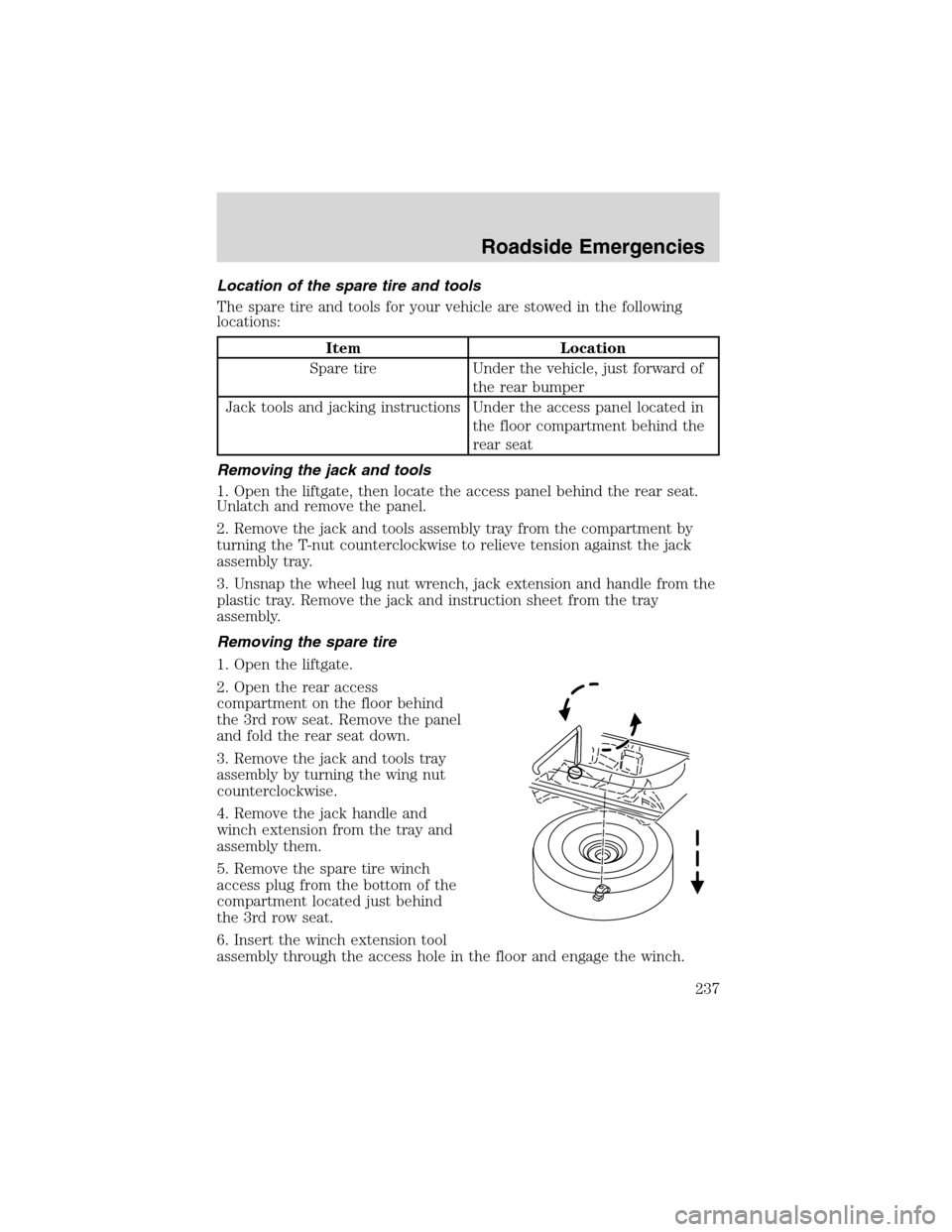

Removing the spare tire

1. Open the liftgate.

2. Open the rear access

compartment on the floor behind

the 3rd row seat. Remove the panel

and fold the rear seat down.

3. Remove the jack and tools tray

assembly by turning the wing nut

counterclockwise.

4. Remove the jack handle and

winch extension from the tray and

assembly them.

5. Remove the spare tire winch

access plug from the bottom of the

compartment located just behind

the 3rd row seat.

6. Insert the winch extension tool

assembly through the access hole in the floor and engage the winch.

Roadside Emergencies

237

Page 238 of 320

7. To remove the spare tire, turn the handle counterclockwise until the

tire is lowered to the ground and the cable is slightly slack.

8. Slide the retainer through the center of the spare tire wheel.

Tire change procedure

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block (in both directions) the

wheel that is diagonally opposite (other side and end of the vehicle) to

the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

On vehicles equipped with Air Suspension, turn OFF the Air

Suspension switch prior to jacking, hoisting or towing your

vehicle.

Refer to the instruction sheet (located in the rear floor compartment

behind the 3rd row seat with the jack tray tools assembly kit) for

detailed tire change instructions.

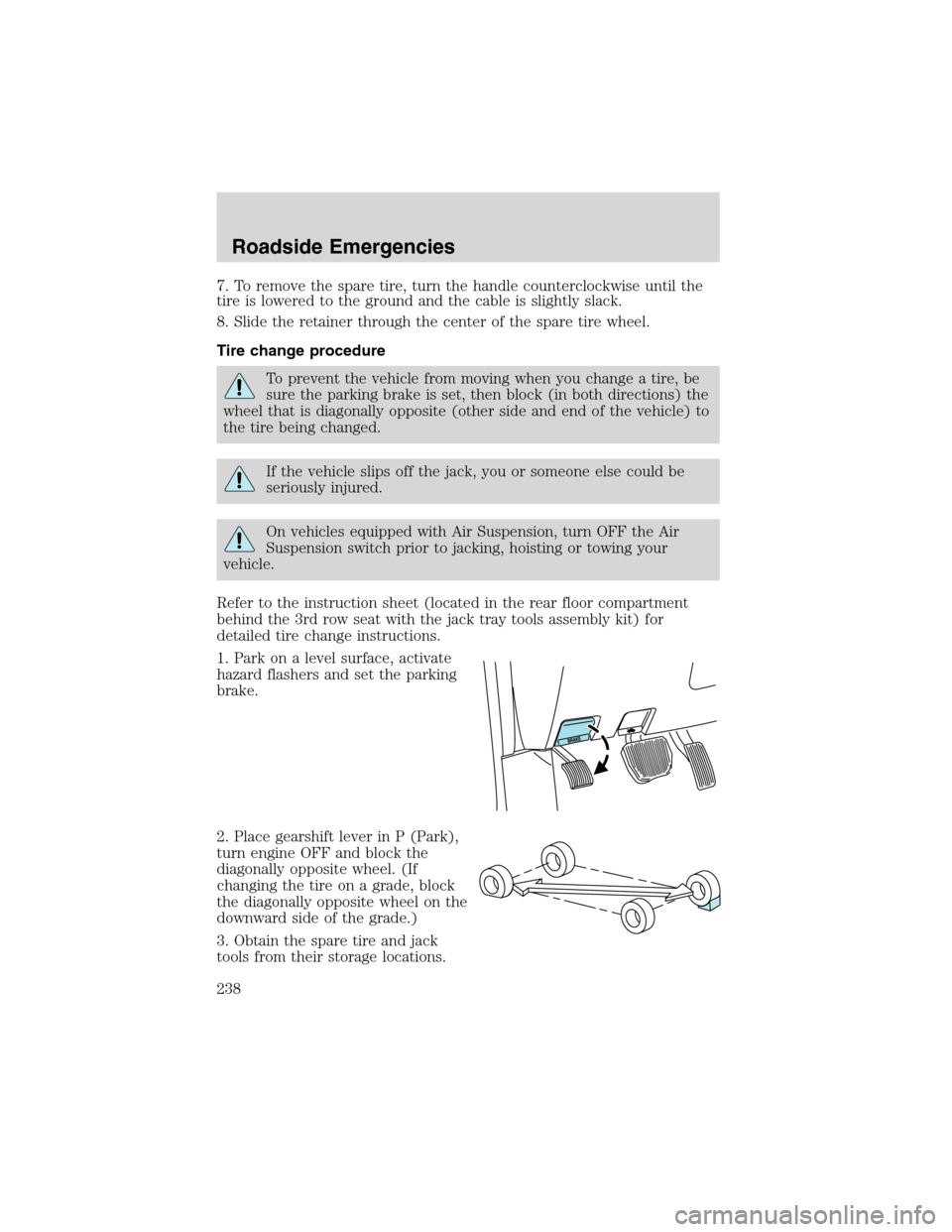

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

2. Place gearshift lever in P (Park),

turn engine OFF and block the

diagonally opposite wheel. (If

changing the tire on a grade, block

the diagonally opposite wheel on the

downward side of the grade.)

3. Obtain the spare tire and jack

tools from their storage locations.

Roadside Emergencies

238

Page 239 of 320

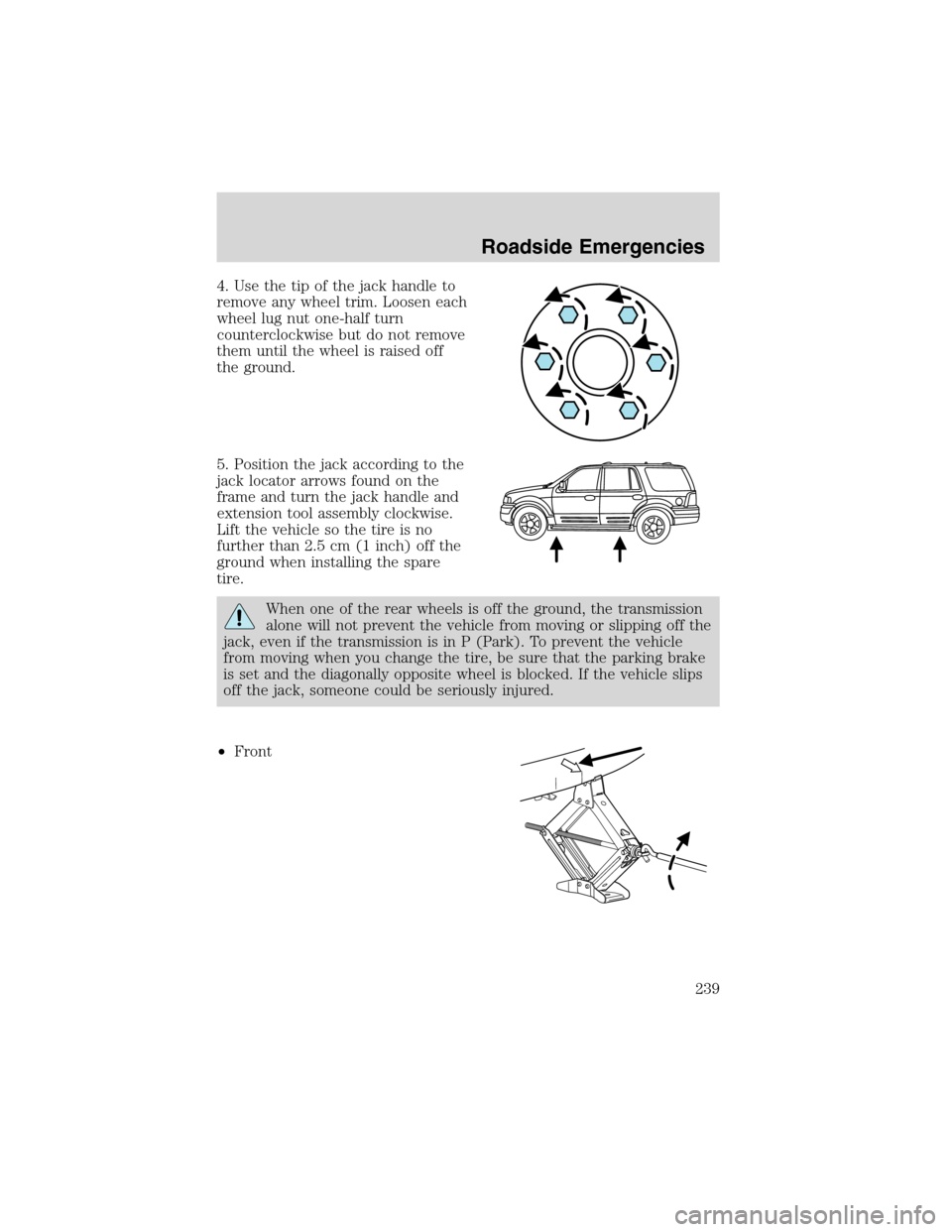

4. Use the tip of the jack handle to

remove any wheel trim. Loosen each

wheel lug nut one-half turn

counterclockwise but do not remove

them until the wheel is raised off

the ground.

5. Position the jack according to the

jack locator arrows found on the

frame and turn the jack handle and

extension tool assembly clockwise.

Lift the vehicle so the tire is no

further than 2.5 cm (1 inch) off the

ground when installing the spare

tire.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park). To prevent the vehicle

from moving when you change the tire, be sure that the parking brake

is set and the diagonally opposite wheel is blocked. If the vehicle slips

off the jack, someone could be seriously injured.

•Front

Roadside Emergencies

239

Page 240 of 320

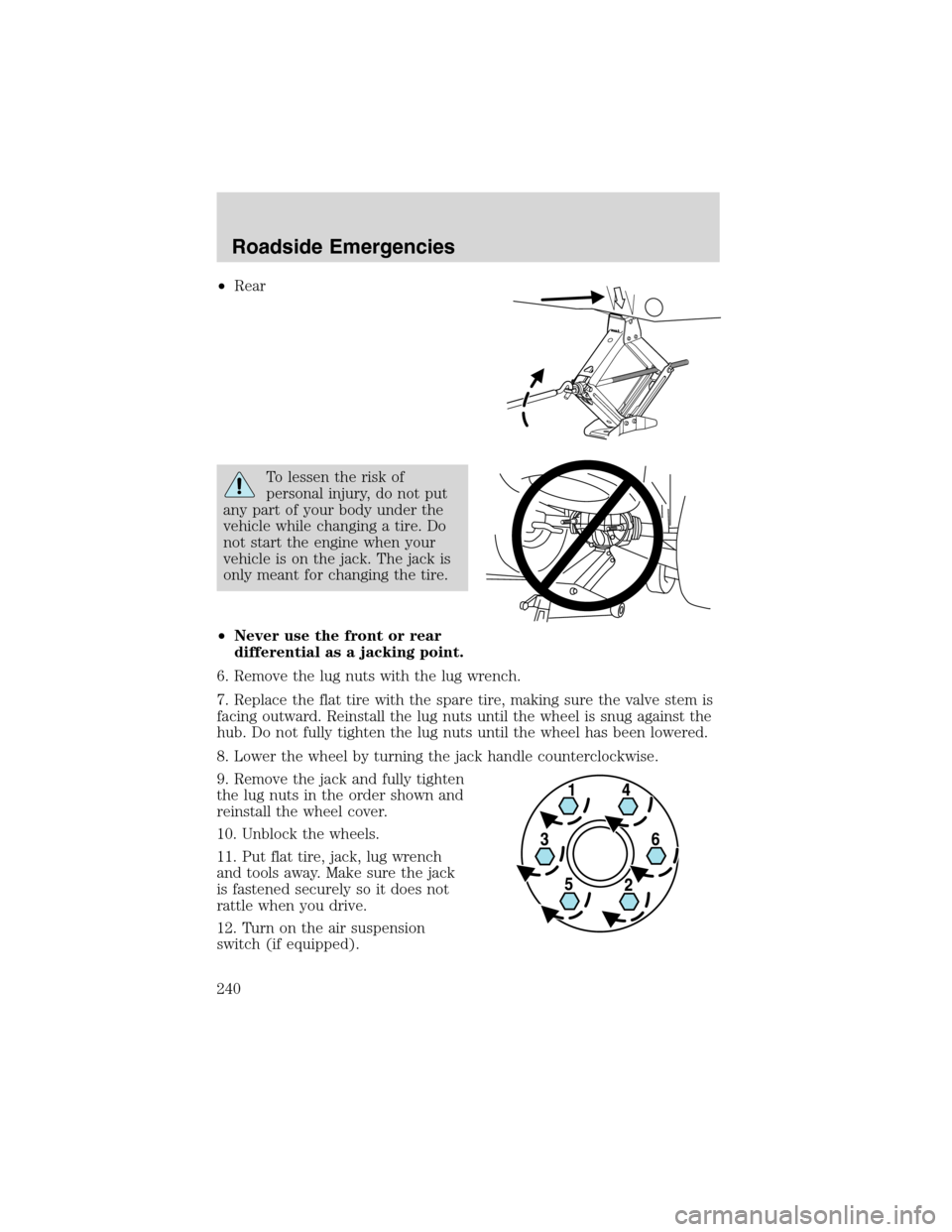

•Rear

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

•Never use the front or rear

differential as a jacking point.

6. Remove the lug nuts with the lug wrench.

7. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

8. Lower the wheel by turning the jack handle counterclockwise.

9. Remove the jack and fully tighten

the lug nuts in the order shown and

reinstall the wheel cover.

10. Unblock the wheels.

11. Put flat tire, jack, lug wrench

and tools away. Make sure the jack

is fastened securely so it does not

rattle when you drive.

12. Turn on the air suspension

switch (if equipped).

Roadside Emergencies

240

Page 241 of 320

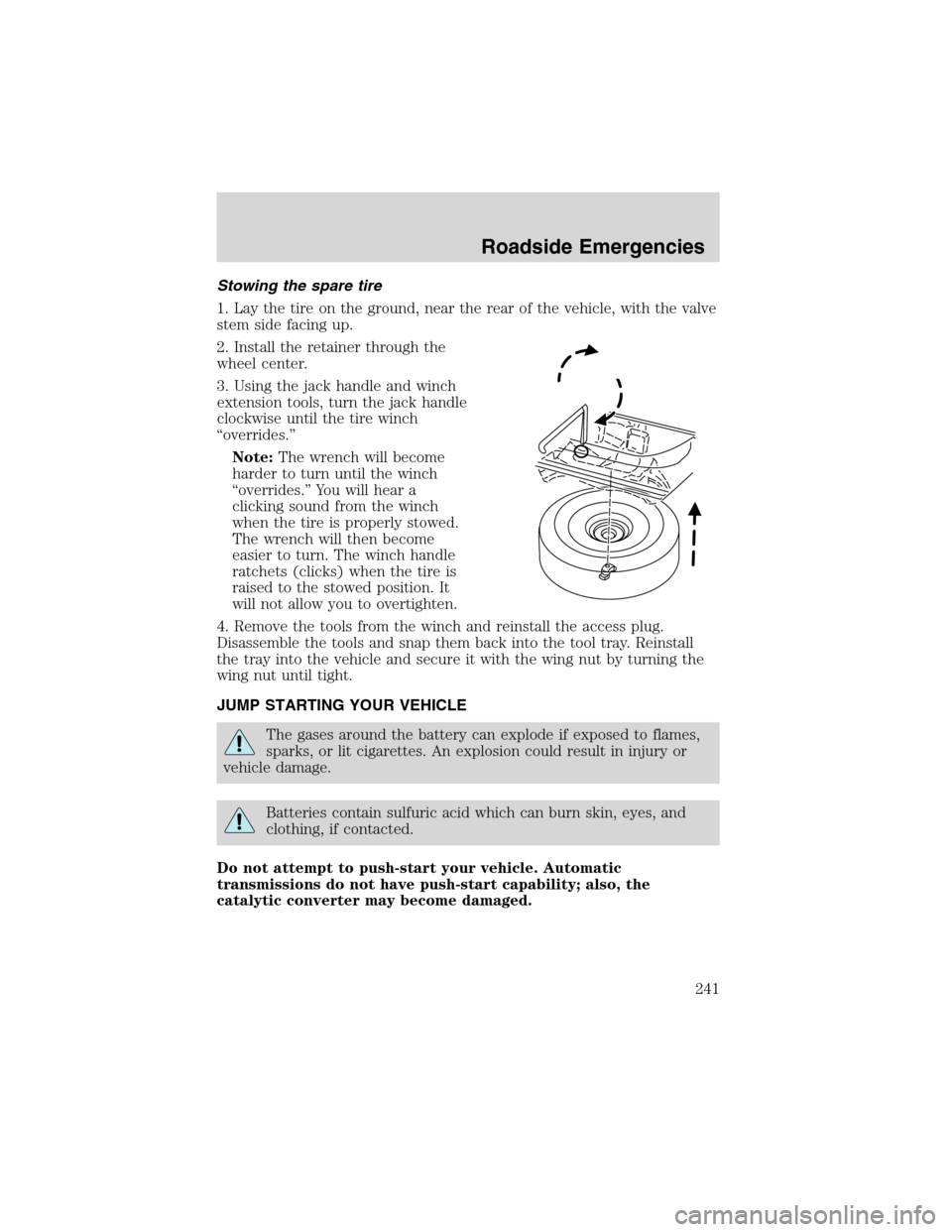

Stowing the spare tire

1. Lay the tire on the ground, near the rear of the vehicle, with the valve

stem side facing up.

2. Install the retainer through the

wheel center.

3. Using the jack handle and winch

extension tools, turn the jack handle

clockwise until the tire winch

“overrides.”

Note:The wrench will become

harder to turn until the winch

“overrides.”You will hear a

clicking sound from the winch

when the tire is properly stowed.

The wrench will then become

easier to turn. The winch handle

ratchets (clicks) when the tire is

raised to the stowed position. It

will not allow you to overtighten.

4. Remove the tools from the winch and reinstall the access plug.

Disassemble the tools and snap them back into the tool tray. Reinstall

the tray into the vehicle and secure it with the wing nut by turning the

wing nut until tight.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes, and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; also, the

catalytic converter may become damaged.

Roadside Emergencies

241

Page 271 of 320

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

1/4 of a turn until the cap is fully seated.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Engine oil and filter recommendations

Look for this certification

trademark.

SAE 5W-20 engine oil is recommended.

Only use oils“Certified For Gasoline Engines”by the American

Petroleum Institute (API). Use Motorcraft or an equivalent oil meeting

Ford specification WSS-M2C153–H.SAE 5W-20 oil provides optimum

fuel economy and durability performance meeting all

requirements for your vehicle’s engine.

Do not use supplemental engine oil additives, oil treatments or engine

treatments. They are unnecessary and could, under certain conditions,

lead to engine damage which is not covered by your warranty.

Change your engine oil and filter according to the appropriate schedule

listed in the scheduled maintenance guide.

Ford production and aftermarket (Motorcraft) oil filters are designed for

added engine protection and long life. If a replacement oil filter is used

that does not meet Ford material and design specifications, start-up

engine noises or knock may be experienced.

It is recommended you use the appropriate Motorcraft oil filter (or

another brand meeting Ford specifications) for your engine application.

Maintenance and Specifications

271

Page 274 of 320

3. Run the engine until it reaches normal operating temperature.

4. Allow the engine to idle for at least one minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

6. With your foot on the brake pedal and with the A/C on, put the

vehicle in D (Drive) and allow the engine to idle for at least one minute.

7. Drive the vehicle to complete the relearning process.

•The vehicle may need to be driven 16 km (10 miles) or more to

relearn the idle and fuel trim strategy.

•If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

•Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center

to find out more about recycling

automotive batteries.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

mileage intervals listed in the scheduled maintenance guide. The coolant

concentration should be maintained at 50/50 coolant and water, which

equates to a freeze point of -36°C (-34°F). Coolant concentration

testing is possible with a hydrometer or antifreeze tester (such as the

Rotunda Battery and Antifreeze Tester, 014–R1060). The level of coolant

should be maintained at the“cold full”of“cold fill range”level in the

coolant reservoir. If the level falls below, add coolant per the instructions

in theAdding engine coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

LEAD

RETURN

RECYCLE

Maintenance and Specifications

274

Page 277 of 320

•Do not use alcohol, methanol, brine or any engine coolants

mixed with alcohol or methanol antifreeze (coolant).Alcohol

and other liquids can cause engine damage from overheating or

freezing.

•Do not add extra inhibitors or additives to the coolant.These

can be harmful and compromise the corrosion protection of the engine

coolant.

•Do not mix with recycled coolant unless from a Ford-approved

recycling process (seeUse of Recycled engine coolantsection).

For vehicles with overflow coolant systems with a non-pressurized cap

on the coolant recovery system, add coolant to the coolant recovery

reservoir when the engine is cool. Add the proper mixture of coolant and

water to the“cold full”level. For all other vehicles, which have a coolant

degas system with a pressurized cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator of a vehicle with an overflow

system, follow these steps to add engine coolant.

To reduce the risk of personal injury, make sure the engine is

cool before unscrewing the coolant pressure relief cap. The

cooling system is under pressure; steam and hot liquid can come out

forcefully when the cap is loosened slightly.

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (an opaque plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

5. Fill the coolant reservoir slowly with the proper coolant mixture (see

above), to within the“cold fill range”or the“cold full”level on the

reservoir. If you removed the radiator cap in an overflow system, fill the

radiator until the coolant is visible and radiator is almost full.

6. Replace the cap. Turn until tightly installed. (Cap must be tightly

installed to prevent coolant loss.)

After any coolant has been added, check the coolant concentration, refer

toChecking Engine Coolantsection. If the concentration is not 50/50

(protection to–34°F/–36°C), drain some coolant and adjust the

concentration. It may take several drains and additions to obtain a 50/50

coolant concentration.

Maintenance and Specifications

277

Page 282 of 320

•Fuels can also be harmful if absorbed through the skin. If fuel is

splashed on the skin and/or clothing, promptly remove contaminated

clothing and wash skin thoroughly with soap and water. Repeated or

prolonged skin contact with fuel liquid or vapor causes skin irritation.

•

Be particularly careful if you are taking“Antabuse”or other forms of

disulfiram for the treatment of alcoholism. Breathing gasoline vapors, or

skin contact could cause an adverse reaction. In sensitive individuals,

serious personal injury or sickness may result. If fuel is splashed on the

skin, promptly wash skin thoroughly with soap and water. Consult a

physician immediately if you experience an adverse reaction.

When refueling always shut the engine off and never allow

sparks or open flames near the filler neck. Never smoke while

refueling. Fuel vapor is extremely hazardous under certain conditions.

Care should be taken to avoid inhaling excess fumes.

The flow of fuel through a fuel pump nozzle can produce static

electricity, which can cause a fire if fuel is pumped into an

ungrounded fuel container.

Use the following guidelines to avoid static build-up when filling an

ungrounded fuel container:

•Place approved fuel container on the ground.

•DO NOT fill a fuel container while it is in the vehicle (including the

cargo area).

•

Keep the fuel pump nozzle in contact with the fuel container while filling.

•DO NOT use a device that would hold the fuel pump handle in the fill

position.

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a 1/8 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2.

Carefully turn the filler cap counterclockwise 1/8 of a turn until it stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it stops.

Maintenance and Specifications

282

Page 314 of 320

Changing a tire .........................236

Child safety restraints ..............177

child safety belts ....................177

Child safety seats ......................180

in front seat ............................181

in rear seat ......................181, 184

Cleaning your vehicle

engine compartment ..............260

instrument panel ....................262

interior .............................262–263

plastic parts ............................261

washing ....................................259

waxing .....................................259

wheels ......................................260

wiper blades ............................262

Climate control (see Air

conditioning or Heating) ......69, 72

Clock ................................23, 34, 43

Compass, electronic ..........100, 112

calibration ...............................113

set zone adjustment .......113, 115

Console ......................................125

overhead ..............................95, 97

Controls

power seat ...............................143

steering column ......................106

Coolant

checking and adding ..............274

refill capacities ................278, 300

specifications ..................303, 305

Cruise control

(see Speed control) ..................103

Customer Assistance ................227

Ford accessories for your

vehicle .....................................264

Ford Extended Service Plan .251

Getting assistance outside

the U.S. and Canada ..............255Getting roadside assistance ...227

Getting the service

you need .................................249

Ordering additional

owner’s literature ...................256

The Dispute Settlement

Board .......................................252

Utilizing the Mediation/

Arbitration Program ...............255

D

Daytime running lamps

(see Lamps) ................................82

Defrost

rear window ..............................80

Dipstick

automatic transmission

fluid ..........................................291

engine oil .................................269

Doors

door ajar warning ...............13, 15

lubricant specifications ..........303

Driveline universal joint

and slip yoke .............................293

Driving under special

conditions ..........................212, 215

sand .........................................214

snow and ice ...........................216

through water .................215, 219

E

Electronic message center .......114

Emergencies, roadside

jump-starting ..........................241

Emission control system ..........288

Engine ........................................305

check engine/service engine

soon light ..................................10

Index

314