FORD EXPEDITION 2019 Owners Manual

Manufacturer: FORD, Model Year: 2019, Model line: EXPEDITION, Model: FORD EXPEDITION 2019Pages: 583, PDF Size: 6.71 MB

Page 381 of 583

When Inflating Your Tires

WARNING: Do not use the tire

pressure displayed in the information

display as a tire pressure gauge. Failure

to follow this instruction could result in

personal injury or death.

When putting air into your tires (such as at

a gas station or in your garage), the tire

pressure monitoring system will not

respond immediately to the air added to

your tires.

It could take up to two minutes of driving

over 20 mph (32 km/h) for the light to turn

off after you have filled your tires to the

recommended inflation pressure.

How Temperature Affects Your Tire

Pressure

The tire pressure monitoring system

monitors tire pressure in each pneumatic

tire. While driving in a normal manner, a

typical passenger tire inflation pressure

could increase about

2 –4 psi (14– 28 kPa)

from a cold start situation. If the vehicle is

stationary overnight with the outside

temperature significantly lower than the

daytime temperature, the tire pressure

could decrease about

3 psi (21 kPa) for a

drop of 30°F (17°C) in ambient

temperature. This lower pressure value

could be detected by the tire pressure

monitoring system as being significantly

lower than the recommended inflation

pressure and activate the system warning

light for low tire pressure. If the low tire

pressure warning light is on, visually check

each tire to verify that no tire is flat. If one

or more tires are flat, repair as necessary.

Check the air pressure in the road tires. If

any tire is under-inflated, carefully drive

the vehicle to the nearest location where

air can be added to the tires. Inflate all the

tires to the recommended inflation

pressure. Tire Pressure Monitoring System Reset

Procedure WARNING:

To determine the

required pressure(s) for your vehicle, see

the Safety Compliance Certification

Label (on the door hinge pillar,

door-latch post or the door edge that

meets the door-latch post, next to the

driver seat) or the Tire Label on the

B-Pillar or the edge of the driver door.

Note: You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation.

To provide the vehicle's load carrying

capability, some vehicles require different

recommended tire pressures in the front

tires as compared to the rear tires. The tire

pressure monitoring system equipped on

these vehicles is designed to illuminate the

low tire pressure warning light at two

different pressures; one for the front tires

and one for the rear tires.

Since tires need to be rotated to provide

consistent performance and maximum tire

life, the tire pressure monitoring system

needs to know when the tires are rotated

to determine which set of tires are on the

front and which are on the rear. With this

information, the system can detect and

properly warn of low tire pressures.

System reset tips:

378

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and Tires

Page 382 of 583

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least 3 ft

(1 m) away from another Ford Motor

Company vehicle undergoing the

system reset procedure at the same

time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system can time-out and you have

to repeat the entire procedure on all

four wheels.

• A double horn sounds indicating the

need to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, seek service from your

authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front -

driver side front tire, Right front -

passenger side front tire, Right rear -

passenger side rear tire, Left rear -

driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn tone confirms that

the sensor identification code has been

learned by the module for this position. If a

double horn is heard, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver

side rear tire, the system indicator

stops flashing, and a message shows

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

379

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and Tires

Page 383 of 583

11.

Set all four tires to the recommended

air pressure as indicated on the

Safety Compliance Certification

Label, affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver seating position or

Tire Label located on the B-Pillar or

the edge of the driver door.

CHANGING A ROAD WHEEL WARNING: If the tire pressure

monitor sensor becomes damaged it

may not function.

Note: You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

Note: The tire pressure monitoring system

indicator light illuminates when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on this vehicle.

If you get a flat tire when driving, do not

apply the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe

place on the side of the road.

Have a flat serviced by an authorized

dealer in order to prevent damage to the

system sensors.

See Tire Pressure

Monitoring System (page 374). Replace

the spare tire with a road tire as soon as

possible. During repairing or replacing of

the flat tire, have the authorized dealer

inspect the system sensor for damage. Dissimilar Spare Wheel and Tire

Assembly Information WARNING:

Failure to follow these

guidelines could result in an increased

risk of loss of vehicle control, injury or

death.

If you have a dissimilar spare wheel and

tire, then it is intended for temporary use

only. This means that if you need to use it,

you should replace it as soon as possible

with a road wheel and tire assembly that

is the same size and type as the road tires

and wheels that were originally provided.

If the dissimilar spare tire or wheel is

damaged, it should be replaced rather than

repaired.

A dissimilar spare wheel and tire assembly

is defined as a spare wheel and tire

assembly that is different in brand, size or

appearance from the road tires and

wheels.

Full-size dissimilar spare

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

When driving with the full-size dissimilar

spare wheel and tire assembly, it is

recommended that you do not:

• Exceed

50 mph (80 km/h) in 4WD.

• Engage 4WD unless the vehicle is

stationary.

• Use 4WD on dry pavement.

380

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and Tires

Page 384 of 583

The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

•

Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• Four-wheel driving capability. When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

•

Towing a trailer.

• Driving vehicles equipped with a

camper body.

• Driving vehicles with a load on the

cargo rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly

and seek service as soon as possible.

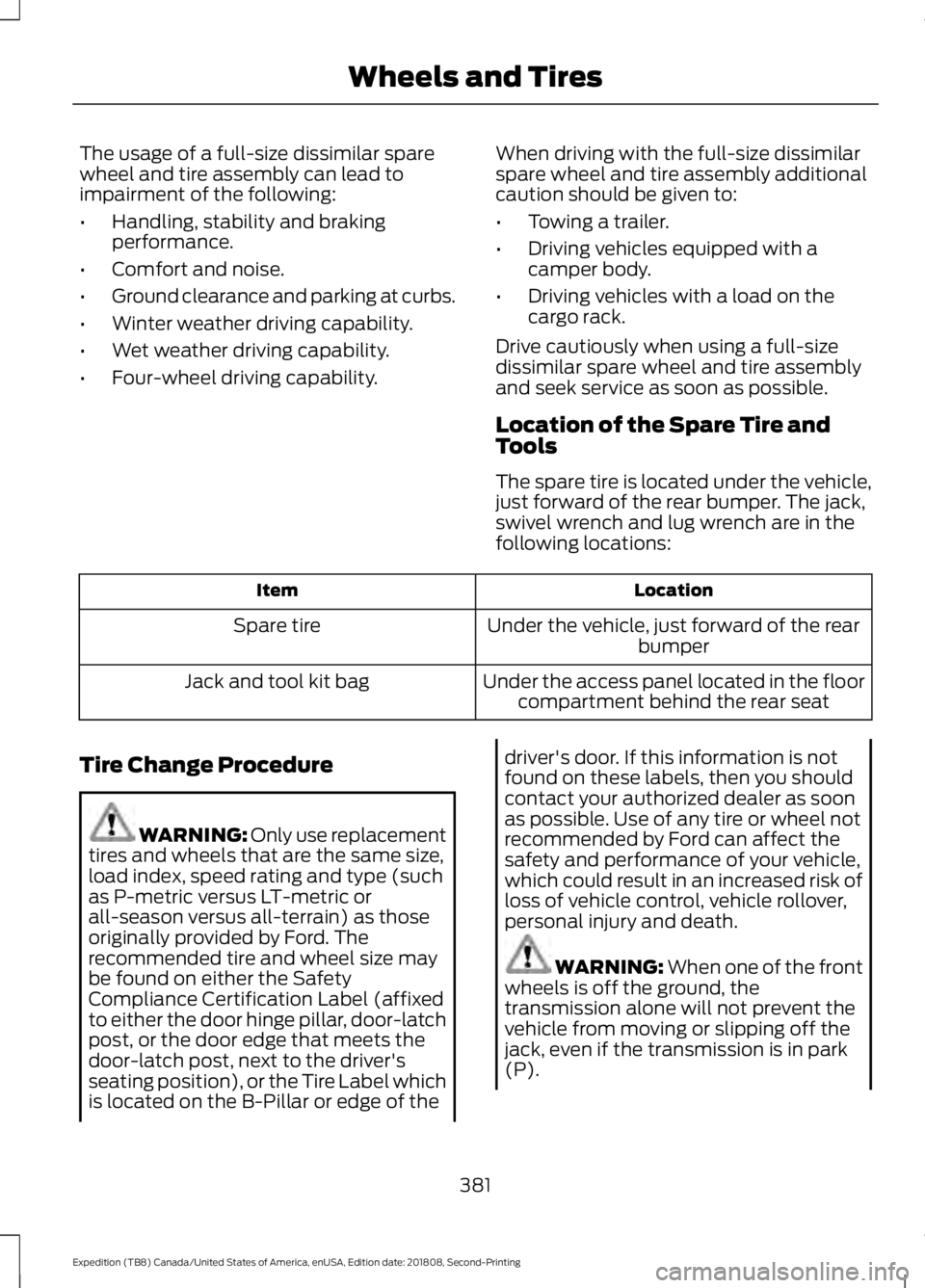

Location of the Spare Tire and

Tools

The spare tire is located under the vehicle,

just forward of the rear bumper. The jack,

swivel wrench and lug wrench are in the

following locations: Location

Item

Under the vehicle, just forward of the rearbumper

Spare tire

Under the access panel located in the floorcompartment behind the rear seat

Jack and tool kit bag

Tire Change Procedure WARNING: Only use replacement

tires and wheels that are the same size,

load index, speed rating and type (such

as P-metric versus LT-metric or

all-season versus all-terrain) as those

originally provided by Ford. The

recommended tire and wheel size may

be found on either the Safety

Compliance Certification Label (affixed

to either the door hinge pillar, door-latch

post, or the door edge that meets the

door-latch post, next to the driver's

seating position), or the Tire Label which

is located on the B-Pillar or edge of the driver's door. If this information is not

found on these labels, then you should

contact your authorized dealer as soon

as possible. Use of any tire or wheel not

recommended by Ford can affect the

safety and performance of your vehicle,

which could result in an increased risk of

loss of vehicle control, vehicle rollover,

personal injury and death.

WARNING:

When one of the front

wheels is off the ground, the

transmission alone will not prevent the

vehicle from moving or slipping off the

jack, even if the transmission is in park

(P).

381

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and Tires

Page 385 of 583

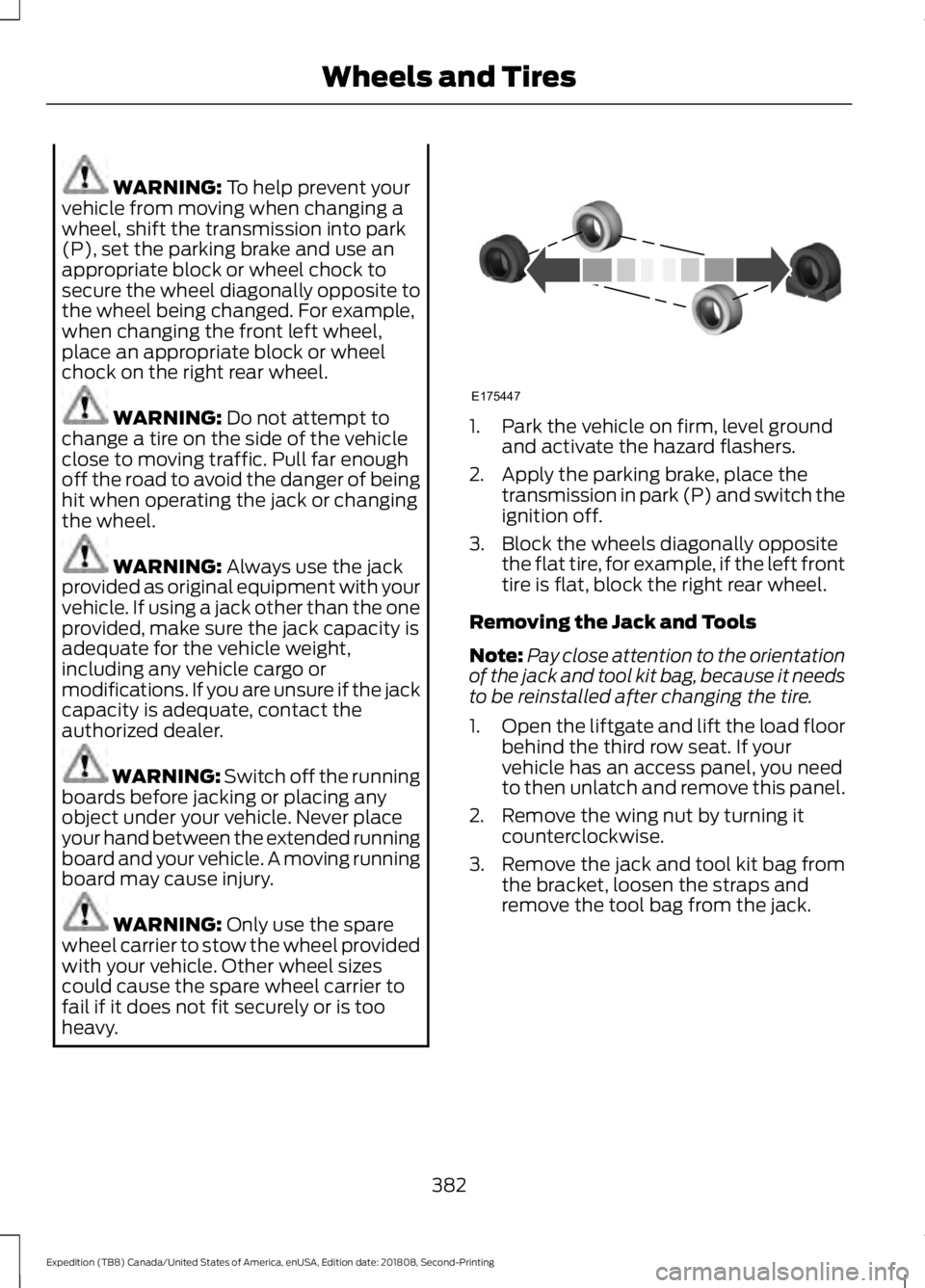

WARNING: To help prevent your

vehicle from moving when changing a

wheel, shift the transmission into park

(P), set the parking brake and use an

appropriate block or wheel chock to

secure the wheel diagonally opposite to

the wheel being changed. For example,

when changing the front left wheel,

place an appropriate block or wheel

chock on the right rear wheel. WARNING:

Do not attempt to

change a tire on the side of the vehicle

close to moving traffic. Pull far enough

off the road to avoid the danger of being

hit when operating the jack or changing

the wheel. WARNING:

Always use the jack

provided as original equipment with your

vehicle. If using a jack other than the one

provided, make sure the jack capacity is

adequate for the vehicle weight,

including any vehicle cargo or

modifications. If you are unsure if the jack

capacity is adequate, contact the

authorized dealer. WARNING:

Switch off the running

boards before jacking or placing any

object under your vehicle. Never place

your hand between the extended running

board and your vehicle. A moving running

board may cause injury. WARNING:

Only use the spare

wheel carrier to stow the wheel provided

with your vehicle. Other wheel sizes

could cause the spare wheel carrier to

fail if it does not fit securely or is too

heavy. 1. Park the vehicle on firm, level ground

and activate the hazard flashers.

2. Apply the parking brake, place the transmission in park (P) and switch the

ignition off.

3. Block the wheels diagonally opposite the flat tire, for example, if the left front

tire is flat, block the right rear wheel.

Removing the Jack and Tools

Note: Pay close attention to the orientation

of the jack and tool kit bag, because it needs

to be reinstalled after changing the tire.

1. Open the liftgate and lift the load floor

behind the third row seat. If your

vehicle has an access panel, you need

to then unlatch and remove this panel.

2. Remove the wing nut by turning it counterclockwise.

3. Remove the jack and tool kit bag from the bracket, loosen the straps and

remove the tool bag from the jack.

382

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and TiresE175447

Page 386 of 583

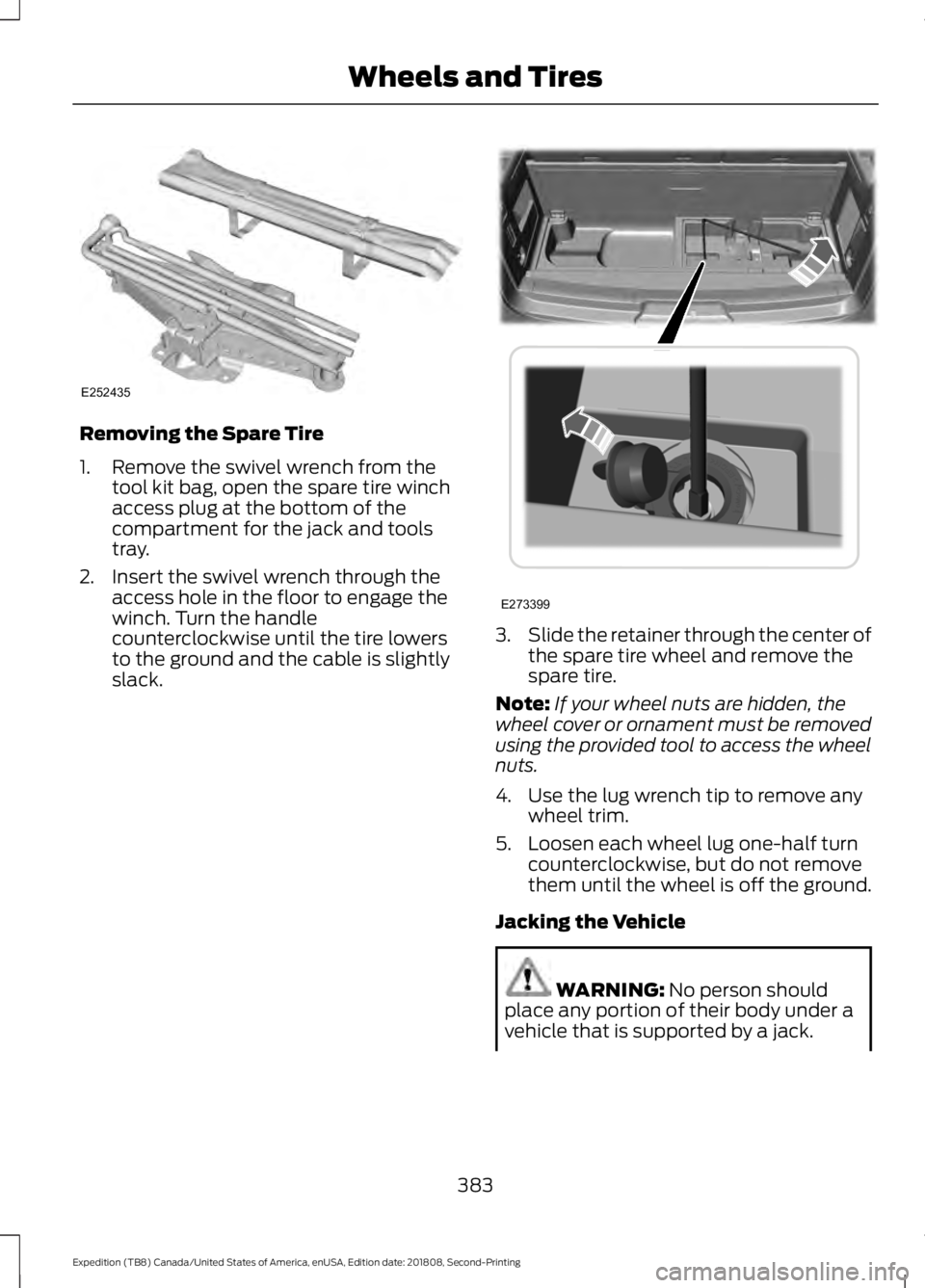

Removing the Spare Tire

1. Remove the swivel wrench from the

tool kit bag, open the spare tire winch

access plug at the bottom of the

compartment for the jack and tools

tray.

2. Insert the swivel wrench through the access hole in the floor to engage the

winch. Turn the handle

counterclockwise until the tire lowers

to the ground and the cable is slightly

slack. 3.

Slide the retainer through the center of

the spare tire wheel and remove the

spare tire.

Note: If your wheel nuts are hidden, the

wheel cover or ornament must be removed

using the provided tool to access the wheel

nuts.

4. Use the lug wrench tip to remove any wheel trim.

5. Loosen each wheel lug one-half turn counterclockwise, but do not remove

them until the wheel is off the ground.

Jacking the Vehicle WARNING: No person should

place any portion of their body under a

vehicle that is supported by a jack.

383

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and TiresE252435 E273399

Page 387 of 583

WARNING: Do not get under a

vehicle that is only supported by a

vehicle jack. WARNING:

Check that the vehicle

jack is not damaged or deformed and

the thread is lubricated and clean. WARNING: The jack supplied with

this vehicle is only intended for changing

wheels. Do not use the vehicle jack other

than when you are changing a wheel in

an emergency. WARNING:

The jack should be

used on level firm ground wherever

possible. WARNING:

Never place anything

between the vehicle jack and the ground. WARNING:

Never place anything

between the vehicle jack and your

vehicle. WARNING:

It is recommended

that the wheels of the vehicle be

chocked, and that no person should

remain in a vehicle that is being jacked. WARNING:

Failure to follow these

guidelines could result in an increased

risk of loss of vehicle control, injury or

death.

Note: The jack does not require

maintenance or additional lubrication over

the service life of your vehicle.

Note: Jack at the specified locations to

avoid damaging your vehicle.

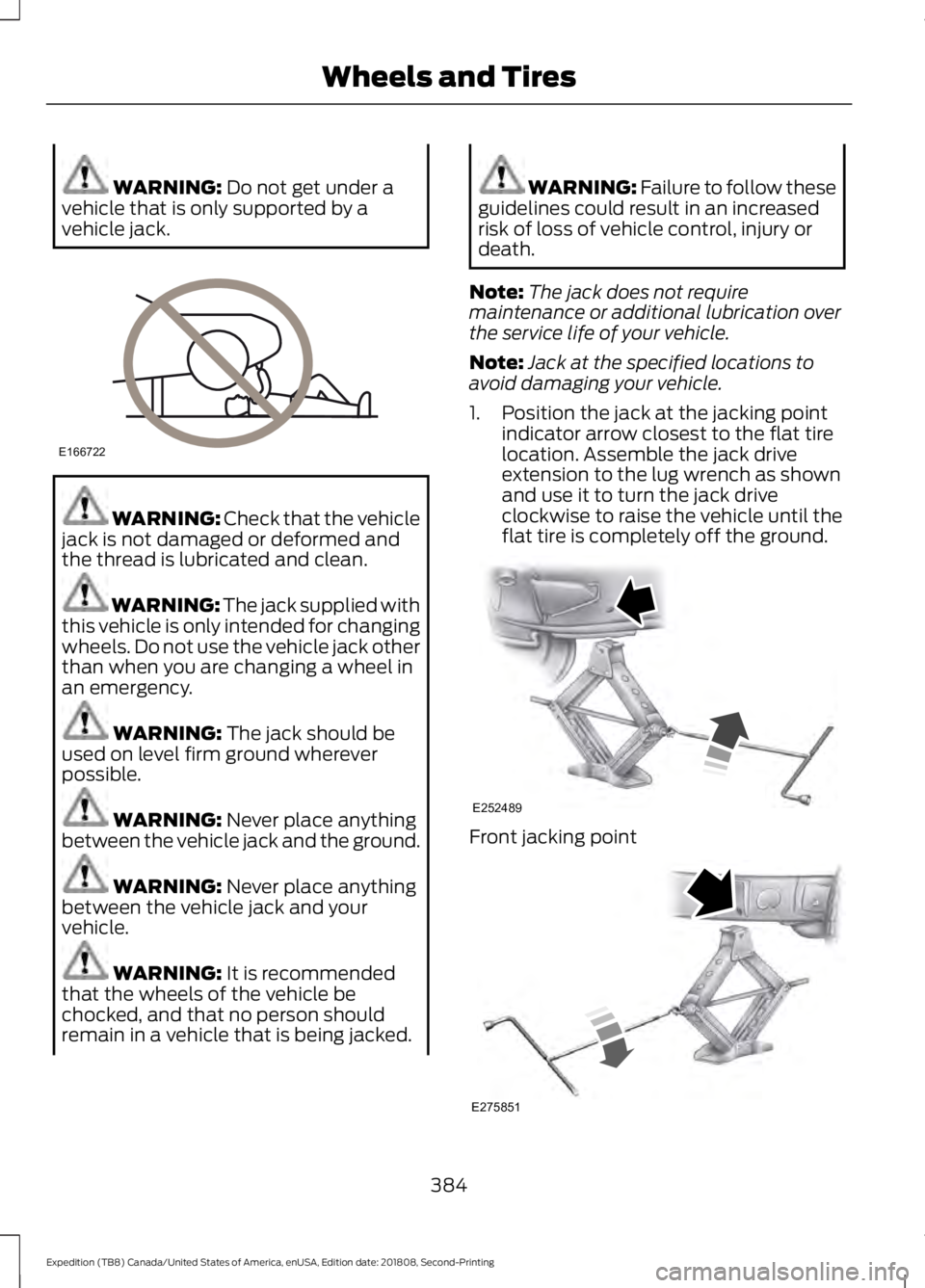

1. Position the jack at the jacking point indicator arrow closest to the flat tire

location. Assemble the jack drive

extension to the lug wrench as shown

and use it to turn the jack drive

clockwise to raise the vehicle until the

flat tire is completely off the ground. Front jacking point

384

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and TiresE166722 E252489 E275851

Page 388 of 583

Rear jacking point

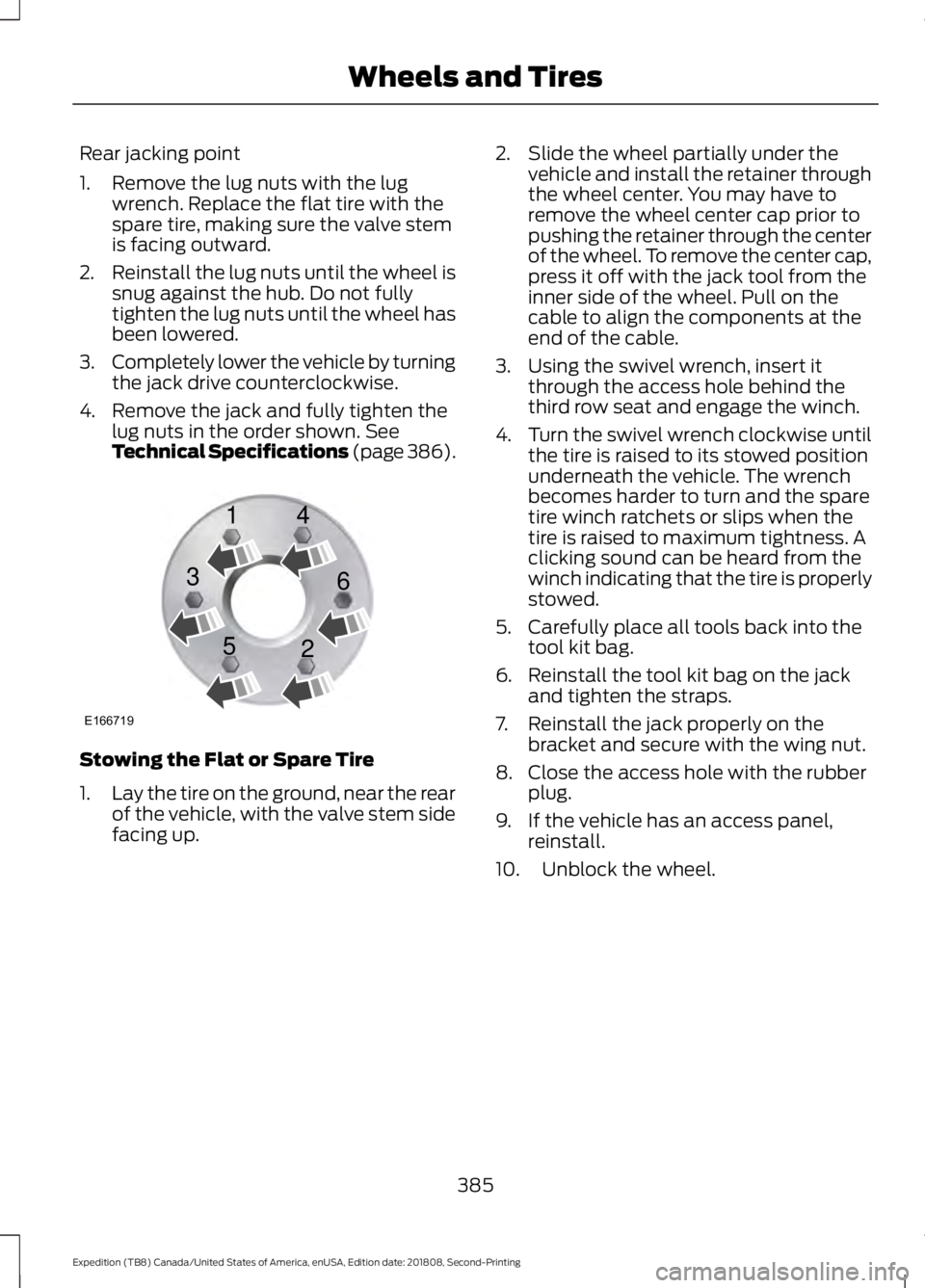

1. Remove the lug nuts with the lug

wrench. Replace the flat tire with the

spare tire, making sure the valve stem

is facing outward.

2. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully

tighten the lug nuts until the wheel has

been lowered.

3. Completely lower the vehicle by turning

the jack drive counterclockwise.

4. Remove the jack and fully tighten the lug nuts in the order shown. See

Technical Specifications (page 386). Stowing the Flat or Spare Tire

1.

Lay the tire on the ground, near the rear

of the vehicle, with the valve stem side

facing up. 2. Slide the wheel partially under the

vehicle and install the retainer through

the wheel center. You may have to

remove the wheel center cap prior to

pushing the retainer through the center

of the wheel. To remove the center cap,

press it off with the jack tool from the

inner side of the wheel. Pull on the

cable to align the components at the

end of the cable.

3. Using the swivel wrench, insert it through the access hole behind the

third row seat and engage the winch.

4. Turn the swivel wrench clockwise until

the tire is raised to its stowed position

underneath the vehicle. The wrench

becomes harder to turn and the spare

tire winch ratchets or slips when the

tire is raised to maximum tightness. A

clicking sound can be heard from the

winch indicating that the tire is properly

stowed.

5. Carefully place all tools back into the tool kit bag.

6. Reinstall the tool kit bag on the jack and tighten the straps.

7. Reinstall the jack properly on the bracket and secure with the wing nut.

8. Close the access hole with the rubber plug.

9. If the vehicle has an access panel, reinstall.

10. Unblock the wheel.

385

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and TiresE166719

1

3

5 4

6

2

Page 389 of 583

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING: When you install a wheel, always remove any corrosion, dirt or foreign

materials present on the mounting surfaces of the wheel or the surface of the wheel

hub, brake drum or brake disc that contacts the wheel. Make sure to secure any fasteners

that attach the rotor to the hub so they do not interfere with the mounting surfaces of

the wheel. Installing wheels without correct metal-to-metal contact at the wheel

mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while

your vehicle is in motion, resulting in loss of vehicle control, personal injury or death. lb.ft (Nm)

1

Bolt Size

150 lb.ft (204 Nm)

M14 x 1.5

1 Torque specifications are for nut and bolt threads free of dirt and rust. Use only our

recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kilometers) after any

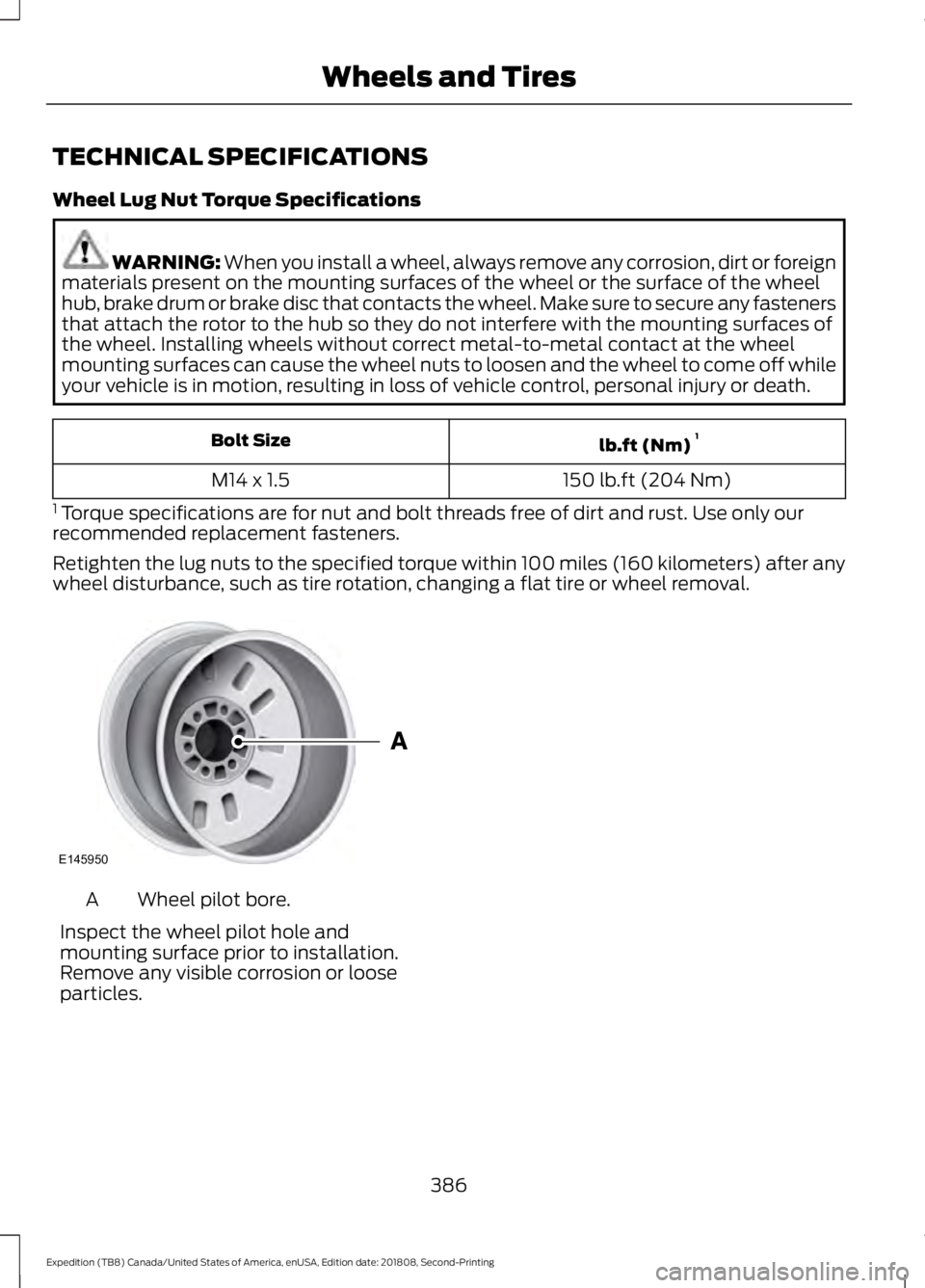

wheel disturbance, such as tire rotation, changing a flat tire or wheel removal. Wheel pilot bore.

A

Inspect the wheel pilot hole and

mounting surface prior to installation.

Remove any visible corrosion or loose

particles.

386

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Wheels and TiresE145950

Page 390 of 583

ENGINE SPECIFICATIONS

3.5L EcoBoost

Engine

214

Cubic inches

1-4-2-5-3-6

Firing order

Coil on plug

Ignition system

10.5:1

Compression ratio

0.028 in (0.7 mm) - 0.031 in (0.8 mm)

Spark plug gap

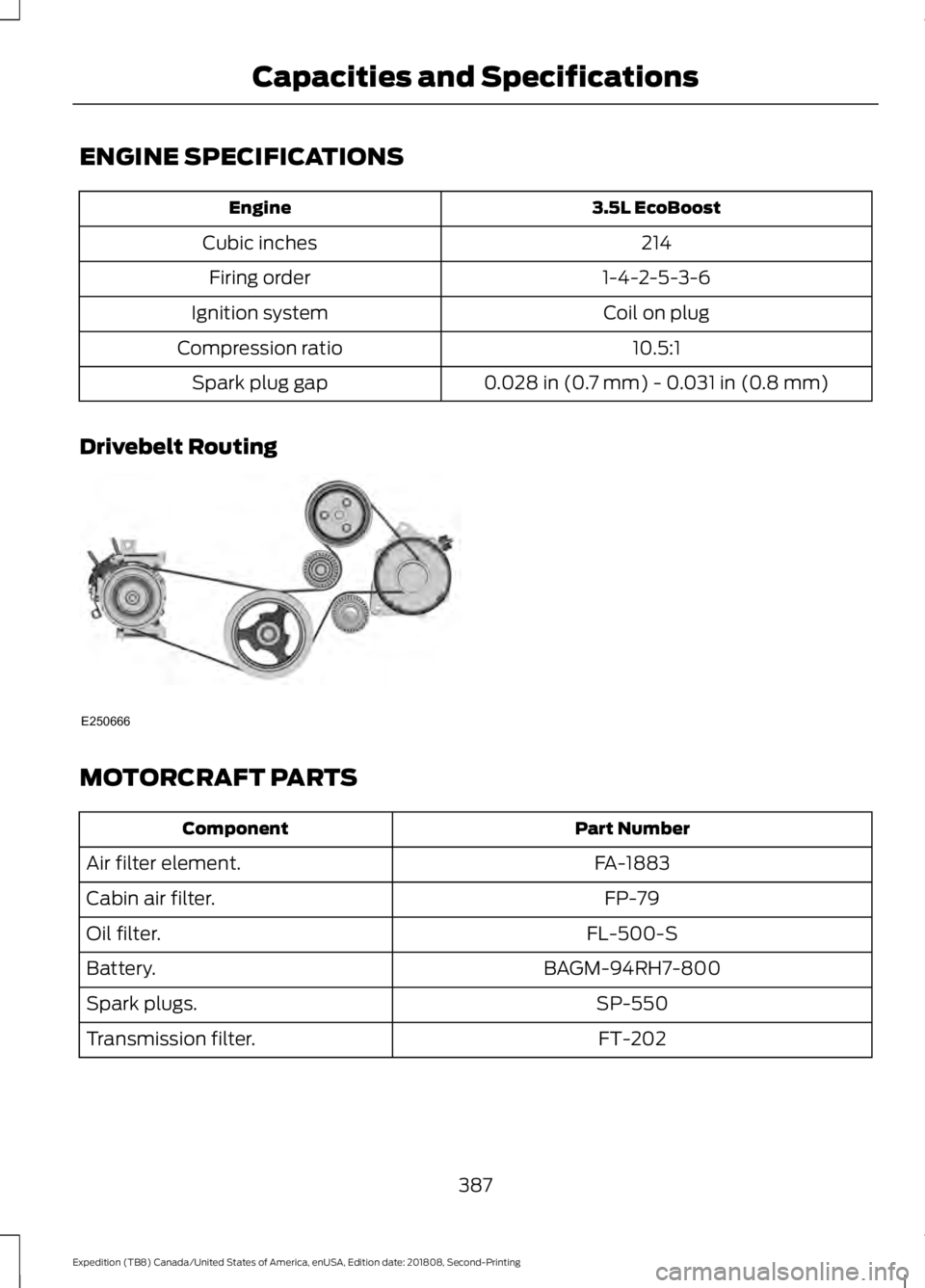

Drivebelt Routing MOTORCRAFT PARTS

Part Number

Component

FA-1883

Air filter element.

FP-79

Cabin air filter.

FL-500-S

Oil filter.

BAGM-94RH7-800

Battery.

SP-550

Spark plugs.

FT-202

Transmission filter.

387

Expedition (TB8) Canada/United States of America, enUSA, Edition date: 201808, Second-Printing Capacities and SpecificationsE250666