spare wheel FORD EXPEDITION EL 2016 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: EXPEDITION EL, Model: FORD EXPEDITION EL 2016Pages: 421, PDF Size: 7.39 MB

Page 292 of 421

Wheel misalignment in the frontor the rear can cause uneven andrapid treadwear of your tires andshould be corrected by anauthorized dealer. Front-wheeldrive vehicles and those with anindependent rear suspension mayrequire alignment of all fourwheels.

The tires should also be balancedperiodically. An unbalanced tireand wheel assembly may result inirregular tire wear.

Tire Rotation

WARNING

If the tire label showsdifferent tire pressures for thefront and rear tires and the vehicle

is equipped with a tire pressuremonitoring system, then thesettings for the system sensorsneed to be updated. Alwaysperform the system resetprocedure after tire rotation. If thesystem is not reset, it may notprovide a low tire pressurewarning when necessary. See thetire pressure monitoring systemreset procedure in this chapter.

Note:If your tires show unevenwear ask an authorized dealer tocheck for and correct any wheelmisalignment, tire imbalance ormechanical problem involvedbefore tire rotation.

Note:Your vehicle may beequipped with a dissimilar sparewheel and tire assembly. Adissimilar spare wheel and tireassembly is defined as a sparewheel and tire assembly that isdifferent in brand, size orappearance from the road tires andwheels. If you have a dissimilarspare wheel and tire assembly it isintended for temporary use onlyand should not be used in a tirerotation.

Note:After having your tiresrotated, inflation pressure must bechecked and adjusted to thevehicle requirements.

Rotating your tires at therecommended interval (asindicated in the ScheduledMaintenance chapter) will helpyour tires wear more evenly,providing better tire performanceand longer tire life.

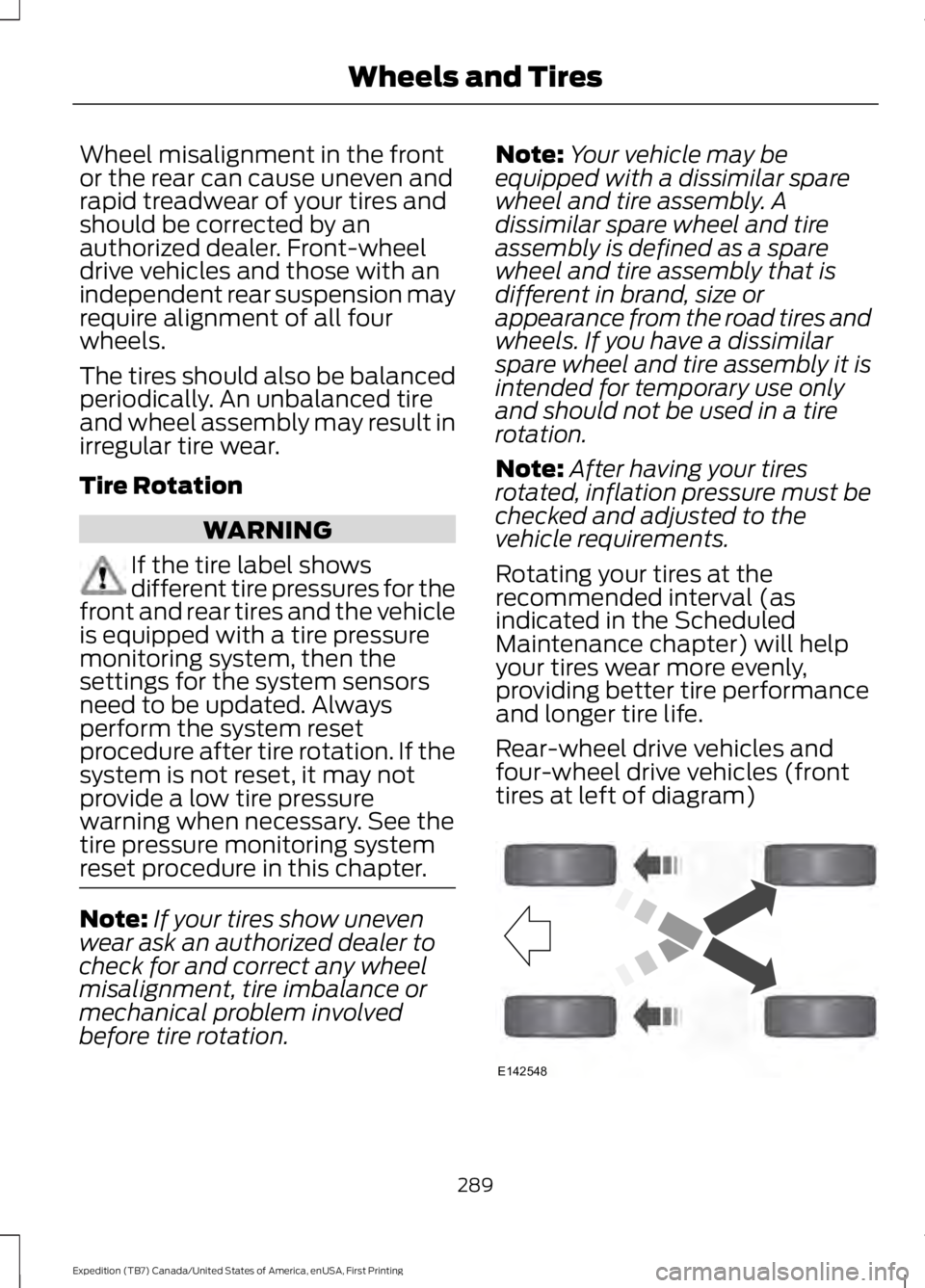

Rear-wheel drive vehicles andfour-wheel drive vehicles (fronttires at left of diagram)

289

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and TiresE142548

Page 294 of 421

Each tire, including the spare (ifprovided), should be checkedmonthly when cold and inflatedto the inflation pressure recommended bythe vehicle manufacturer on the vehicleplacard or tire inflation pressure label. (Ifyour vehicle has tires of a different sizethan the size indicated on the vehicleplacard or tire inflation pressure label, youshould determine the proper tire inflationpressure for those tires.)

As an added safety feature, your vehiclehas been equipped with a Tire PressureMonitoring System (TPMS) thatilluminates a low tire pressure telltalewhen one or more of your tires issignificantly under-inflated. Accordingly,when the low tire pressure telltaleilluminates, you should stop and checkyour tires as soon as possible, and inflatethem to the proper pressure. Driving on asignificantly under-inflated tire causes thetire to overheat and can lead to tire failure.Under-inflation also reduces fuel efficiencyand tire tread life, and may affect thevehicle’s handling and stopping ability.

Please note that the TPMS is not asubstitute for proper tire maintenance, andit is the driver’s responsibility to maintaincorrect tire pressure, even if under-inflationhas not reached the level to triggerillumination of the TPMS low tire pressuretelltale.

Your vehicle has also been equipped witha TPMS malfunction indicator to indicatewhen the system is not operating properly.The TPMS malfunction indicator iscombined with the low tire pressuretelltale. When the system detects amalfunction, the telltale will flash forapproximately one minute and then remaincontinuously illuminated. This sequencewill continue upon subsequent vehiclestart-ups as long as the malfunction exists.

When the malfunction indicator isilluminated, the system may not be ableto detect or signal low tire pressure asintended. TPMS malfunctions may occurfor a variety of reasons, including theinstallation of replacement or alternatetires or wheels on the vehicle that preventthe TPMS from functioning properly.Always check the TPMS malfunctiontelltale after replacing one or more tires orwheels on your vehicle to ensure that thereplacement or alternate tires and wheelsallow the TPMS to continue to functionproperly.

The tire pressure monitoring systemcomplies with part 15 of the FCC rules andwith RSS-210 of Industry Canada.Operation is subject to the following twoconditions: (1) This device may not causeharmful interference, and (2) This devicemust accept any interference received,including interference that may causeundesired operation.

This device complies with part 15 of theFCC Rules and with Licence exempt RSSStandards of Industry Canada. Operationis subject to the following two conditions:

•This device may not cause harmfulinterference.

•This device must accept anyinterference received, includinginterference that may cause undesiredoperation.

291

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 295 of 421

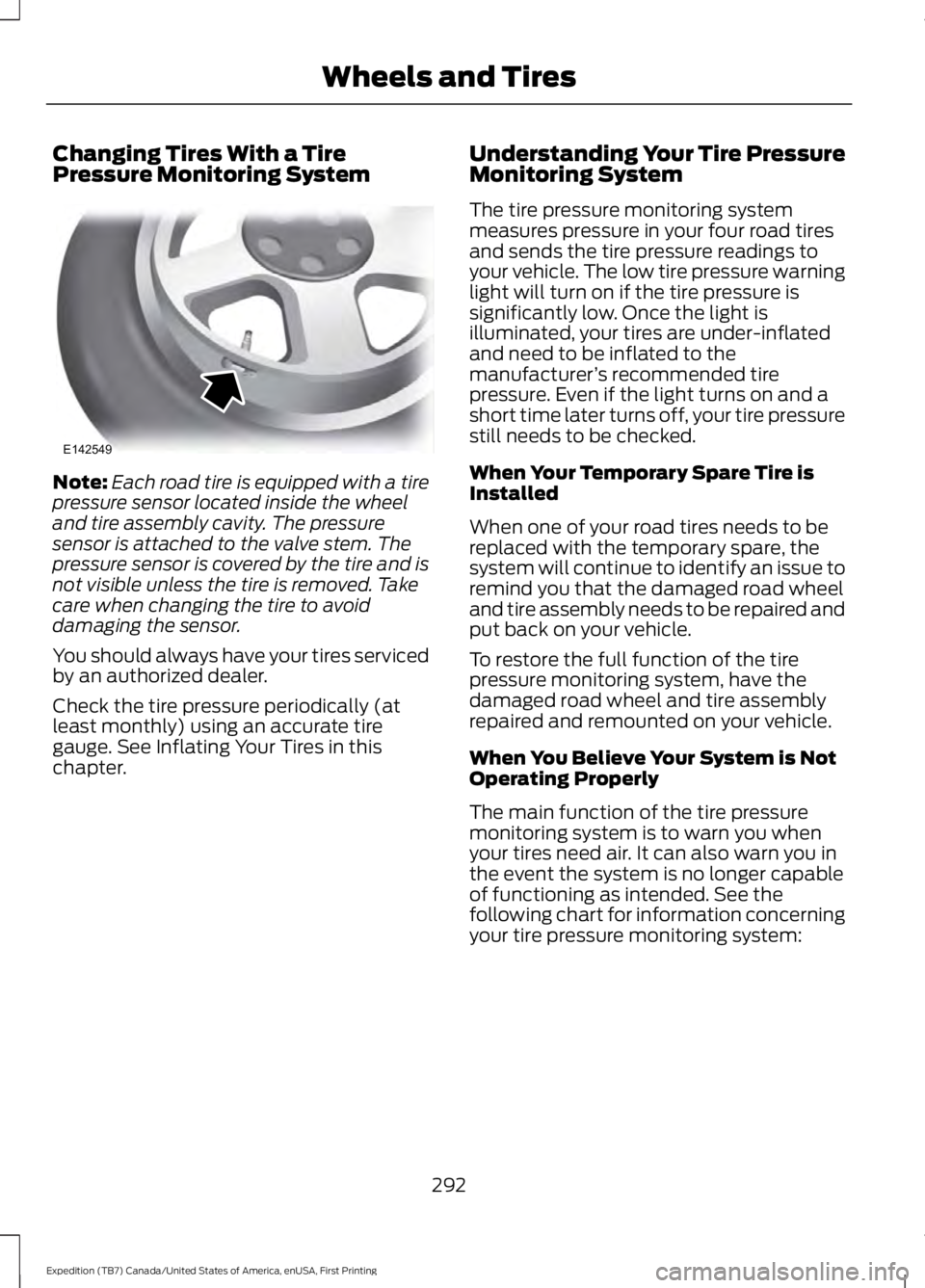

Changing Tires With a TirePressure Monitoring System

Note:Each road tire is equipped with a tirepressure sensor located inside the wheeland tire assembly cavity. The pressuresensor is attached to the valve stem. Thepressure sensor is covered by the tire and isnot visible unless the tire is removed. Takecare when changing the tire to avoiddamaging the sensor.

You should always have your tires servicedby an authorized dealer.

Check the tire pressure periodically (atleast monthly) using an accurate tiregauge. See Inflating Your Tires in thischapter.

Understanding Your Tire PressureMonitoring System

The tire pressure monitoring systemmeasures pressure in your four road tiresand sends the tire pressure readings toyour vehicle. The low tire pressure warninglight will turn on if the tire pressure issignificantly low. Once the light isilluminated, your tires are under-inflatedand need to be inflated to themanufacturer’s recommended tirepressure. Even if the light turns on and ashort time later turns off, your tire pressurestill needs to be checked.

When Your Temporary Spare Tire isInstalled

When one of your road tires needs to bereplaced with the temporary spare, thesystem will continue to identify an issue toremind you that the damaged road wheeland tire assembly needs to be repaired andput back on your vehicle.

To restore the full function of the tirepressure monitoring system, have thedamaged road wheel and tire assemblyrepaired and remounted on your vehicle.

When You Believe Your System is NotOperating Properly

The main function of the tire pressuremonitoring system is to warn you whenyour tires need air. It can also warn you inthe event the system is no longer capableof functioning as intended. See thefollowing chart for information concerningyour tire pressure monitoring system:

292

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and TiresE142549

Page 296 of 421

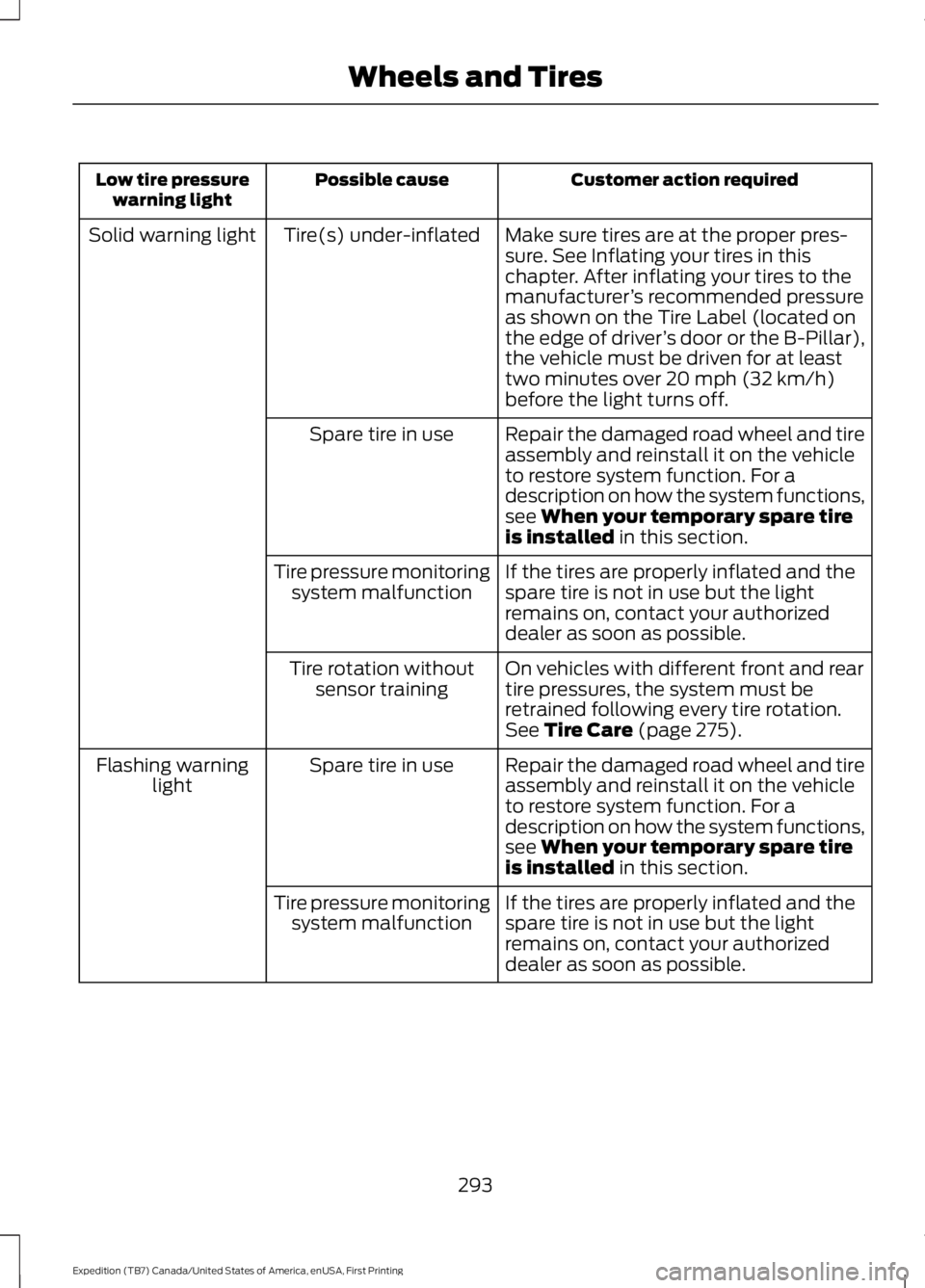

Customer action requiredPossible causeLow tire pressurewarning light

Make sure tires are at the proper pres-sure. See Inflating your tires in thischapter. After inflating your tires to themanufacturer’s recommended pressureas shown on the Tire Label (located onthe edge of driver’s door or the B-Pillar),the vehicle must be driven for at leasttwo minutes over 20 mph (32 km/h)before the light turns off.

Tire(s) under-inflatedSolid warning light

Repair the damaged road wheel and tireassembly and reinstall it on the vehicleto restore system function. For adescription on how the system functions,see When your temporary spare tireis installed in this section.

Spare tire in use

If the tires are properly inflated and thespare tire is not in use but the lightremains on, contact your authorizeddealer as soon as possible.

Tire pressure monitoringsystem malfunction

On vehicles with different front and reartire pressures, the system must beretrained following every tire rotation.See Tire Care (page 275).

Tire rotation withoutsensor training

Repair the damaged road wheel and tireassembly and reinstall it on the vehicleto restore system function. For adescription on how the system functions,see When your temporary spare tireis installed in this section.

Spare tire in useFlashing warninglight

If the tires are properly inflated and thespare tire is not in use but the lightremains on, contact your authorizeddealer as soon as possible.

Tire pressure monitoringsystem malfunction

293

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 299 of 421

11.Set all four tires to the recommendedair pressure as indicated on theSafety Compliance CertificationLabel (affixed to either the door hingepillar, door-latch post, or the dooredge that meets the door-latch post,next to the driver's seating position)or Tire Label located on the B-Pillaror the edge of the driver's door.

CHANGING A ROAD WHEEL

WARNINGS

The use of tire sealant may damageyour tire pressure monitoring systemand should only be used in roadsideemergencies. If you must use a sealant, theFord Tire Mobility Kit sealant should beused. The tire pressure monitoring systemsensor and valve stem on the wheel mustbe replaced by an authorized dealer afteruse of the sealant.

If the tire pressure monitor sensorbecomes damaged, it will no longerfunction. See Tire PressureMonitoring System (page 290).

Note:The tire pressure monitoring systemindicator light will illuminate when the sparetire is in use. To restore the full function ofthe monitoring system, all road wheelsequipped with tire pressure monitoringsensors must be mounted on this vehicle.

If you get a flat tire while driving, do notapply the brake heavily. Instead, graduallydecrease your speed. Hold the steeringwheel firmly and slowly move to a safeplace on the side of the road.

Have a flat serviced by an authorizeddealer in order to prevent damage to thesystem sensors See Tire PressureMonitoring System (page 290). Replacethe spare tire with a road tire as soon aspossible. During repairing or replacing ofthe flat tire, have the authorized dealerinspect the system sensor for damage.

Dissimilar Spare Wheel and TireAssembly Information

WARNING

Failure to follow these guidelinescould result in an increased risk ofloss of vehicle control, injury or death.

If you have a dissimilar spare wheel andtire, then it is intended for temporary useonly. This means that if you need to use it,you should replace it as soon as possiblewith a road wheel and tire assembly thatis the same size and type as the road tiresand wheels that were originally providedby Ford. If the dissimilar spare tire or wheelis damaged, it should be replaced ratherthan repaired.

A dissimilar spare wheel and tire assemblyis defined as a spare wheel and tireassembly that is different in brand, size orappearance from the road tires and wheelsand can be one of three types:

1.T-type mini-spare: This spare tirebegins with the letter T for tire size andmay have Temporary Use Only molded inthe sidewall.

2.Full-size dissimilar spare with labelon wheel: This spare tire has a label onthe wheel that states: THIS WHEEL ANDTIRE ASSEMBLY FOR TEMPORARY USEONLY

296

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 300 of 421

When driving with one of the dissimilarspare tires listed above, do not:

•Exceed 50 mph (80 km/h).

•Load the vehicle beyond maximumvehicle load rating listed on the SafetyCompliance Label.

•Tow a trailer.

•Use snow chains on the end of thevehicle with the dissimilar spare tire.

•Use more than one dissimilar spare tireat a time.

•Use commercial car washingequipment.

•Try to repair the dissimilar spare tire.

Use of one of the dissimilar spare tireslisted above at any one wheel location canlead to impairment of the following:

•Handling, stability and brakingperformance.

•Comfort and noise.

•Ground clearance and parking at curbs.

•Winter weather driving capability.

•Wet weather driving capability.

•All-wheel driving capability.

3.Full-size dissimilar spare withoutlabel on wheel

When driving with the full-size dissimilarspare wheel and tire assembly, do not:

•Exceed 70 mph (113 km/h).

•Use more than one dissimilar sparewheel and tire assembly at a time.

•Use commercial car washingequipment.

•Use snow chains on the end of thevehicle with the dissimilar spare wheeland tire assembly.

The usage of a full-size dissimilar sparewheel and tire assembly can lead toimpairment of the following:

•Handling, stability and brakingperformance.

•Comfort and noise.

•Ground clearance and parking at curbs.

•Winter weather driving capability.

•Wet weather driving capability.

•All-wheel driving capability.

When driving with the full-size dissimilarspare wheel and tire assembly additionalcaution should be given to:

•Towing a trailer.

•Driving vehicles equipped with acamper body.

•Driving vehicles with a load on thecargo rack.

Drive cautiously when using a full-sizedissimilar spare wheel and tire assemblyand seek service as soon as possible.

Location of the Spare Tire andTools

The spare tire is located under the vehicle,just forward of the rear bumper. The jack,jack handle and lug wrench are located inthe following locations:

LocationItem

Under the vehicle, just forward of the rearbumperSpare tire

Under the access panel located in the floorcompartment behind the rear seatJack tools

297

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 301 of 421

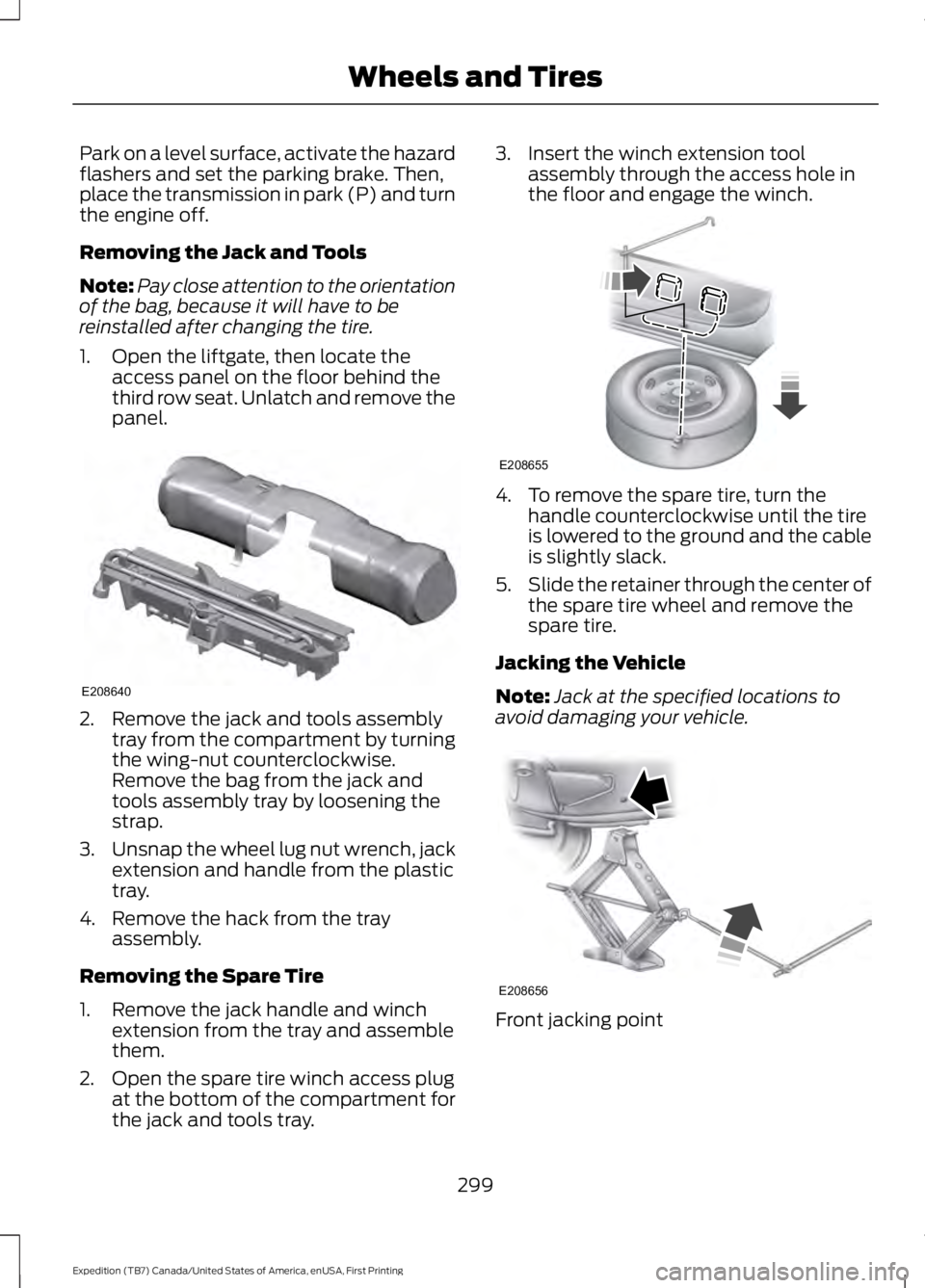

Tire Change Procedure

WARNINGS

Only use replacement tires andwheels that are the same size, loadindex, speed rating and type (suchas P-metric versus LT-metric or all-seasonversus all-terrain) as those originallyprovided by Ford. The recommended tireand wheel size may be found on either theSafety Compliance Certification Label(affixed to either the door hinge pillar,door-latch post, or the door edge thatmeets the door-latch post, next to thedriver’s seating position) or the Tire Labelwhich is located on the B-Pillar or edge ofthe driver’s door. If this information is notfound on these labels then you shouldcontact your authorized dealer as soon aspossible. Use of any tire or wheel notrecommended by Ford can affect thesafety and performance of your vehicle,which could result in an increased risk ofloss of vehicle control, vehicle rollover,personal injury and death. Additionally theuse of non-recommended tires and wheelscould cause steering, suspension, axle,transfer case or power transfer unit failure.If you have questions regarding tirereplacement, contact your authorizeddealer as soon as possible.

When one of the front wheels is offthe ground, the transmission alonewill not prevent the vehicle frommoving or slipping off the jack.

To help prevent the vehicle frommoving when you change a tire, besure to place the transmission in park(P), set the parking brake and block (inboth directions) the wheel that isdiagonally opposite (other side and end ofthe vehicle) to the tire being changed.

Never get underneath a vehicle thatis supported only by a jack. If thevehicle slips off the jack, you orsomeone else could be seriously injured.

WARNINGS

Do not attempt to change a tire onthe side of the vehicle close tomoving traffic. Pull far enough off theroad to avoid the danger of being hit whenoperating the jack or changing the wheel.

Always use the jack provided asoriginal equipment with your vehicle.If using a jack other than the oneprovided as original equipment with yourvehicle, make sure the jack capacity isadequate for the vehicle weight, includingany vehicle cargo or modifications.

Disable the power running boardsbefore jacking, lifting, or placing anyobject under the vehicle. Never placeyour hand between the power runningboard and the vehicle as extended powerrunning boards will retract when the doorsare closed. Failure to follow theseinstructions may result in personal injury.

Failure to follow these instructionswhen using the spare tire carriercould cause loss of the wheel andtire and lead to personal injury: Only usethe spare tire carrier to stow the tire andwheel combination specified on the TireLabel or Safety Compliance CertificationLabel on the B-Pillar or the edge of thedriver door. Other tire and wheelcombinations could cause the carrier tofail if it does not fit securely or is too heavy.Do not use impact tools or power toolsoperating over 200 RPM, which may causewinch malfunction and prevent a securefit. Override the winch at least three times(there will be an audible click each time)to ensure a tight secure fit of the wheel andtire.

Note:Passengers should not remain in thevehicle when the vehicle is being jacked.

298

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 302 of 421

Park on a level surface, activate the hazardflashers and set the parking brake. Then,place the transmission in park (P) and turnthe engine off.

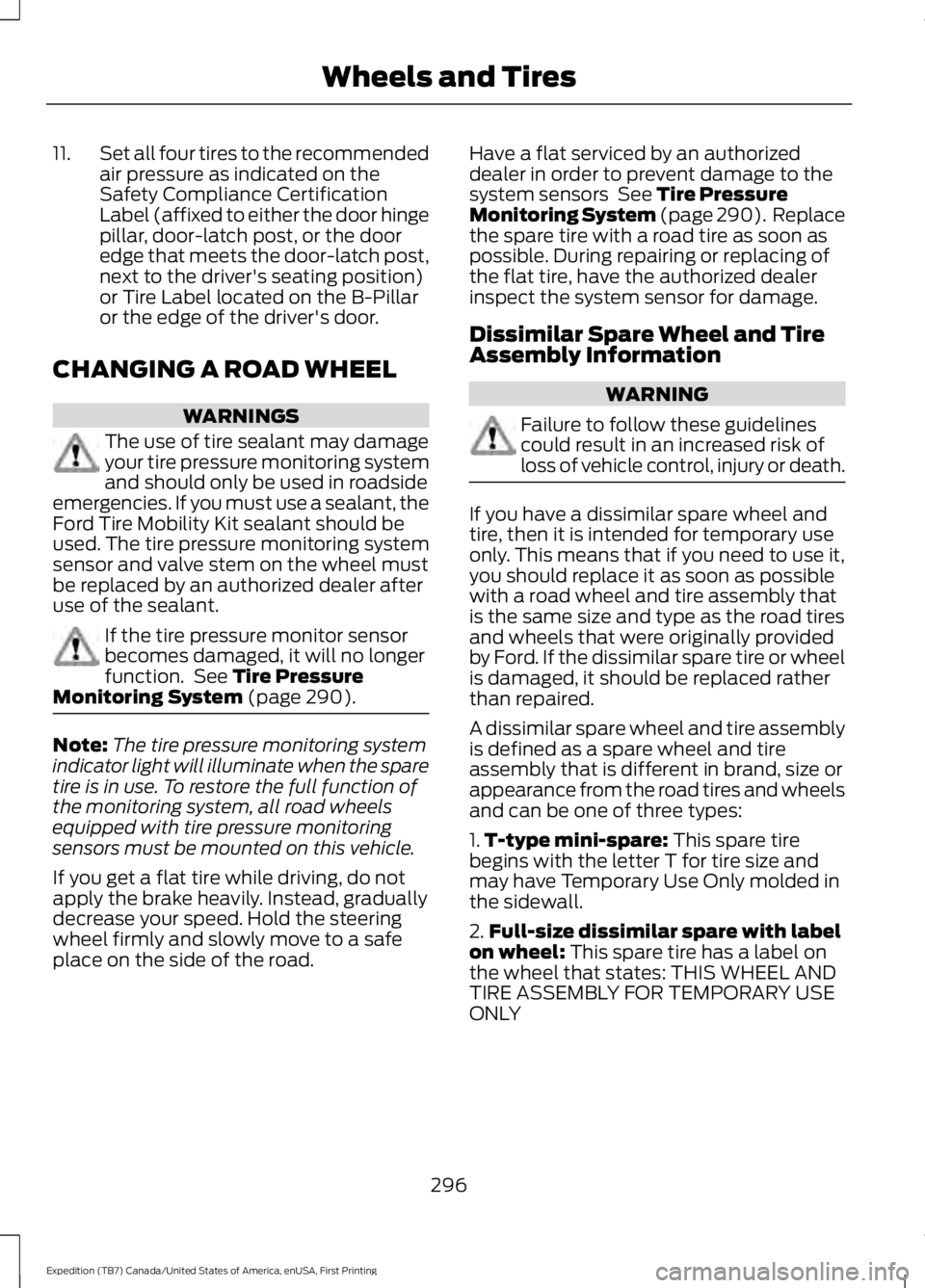

Removing the Jack and Tools

Note:Pay close attention to the orientationof the bag, because it will have to bereinstalled after changing the tire.

1. Open the liftgate, then locate theaccess panel on the floor behind thethird row seat. Unlatch and remove thepanel.

2. Remove the jack and tools assemblytray from the compartment by turningthe wing-nut counterclockwise.Remove the bag from the jack andtools assembly tray by loosening thestrap.

3.Unsnap the wheel lug nut wrench, jackextension and handle from the plastictray.

4. Remove the hack from the trayassembly.

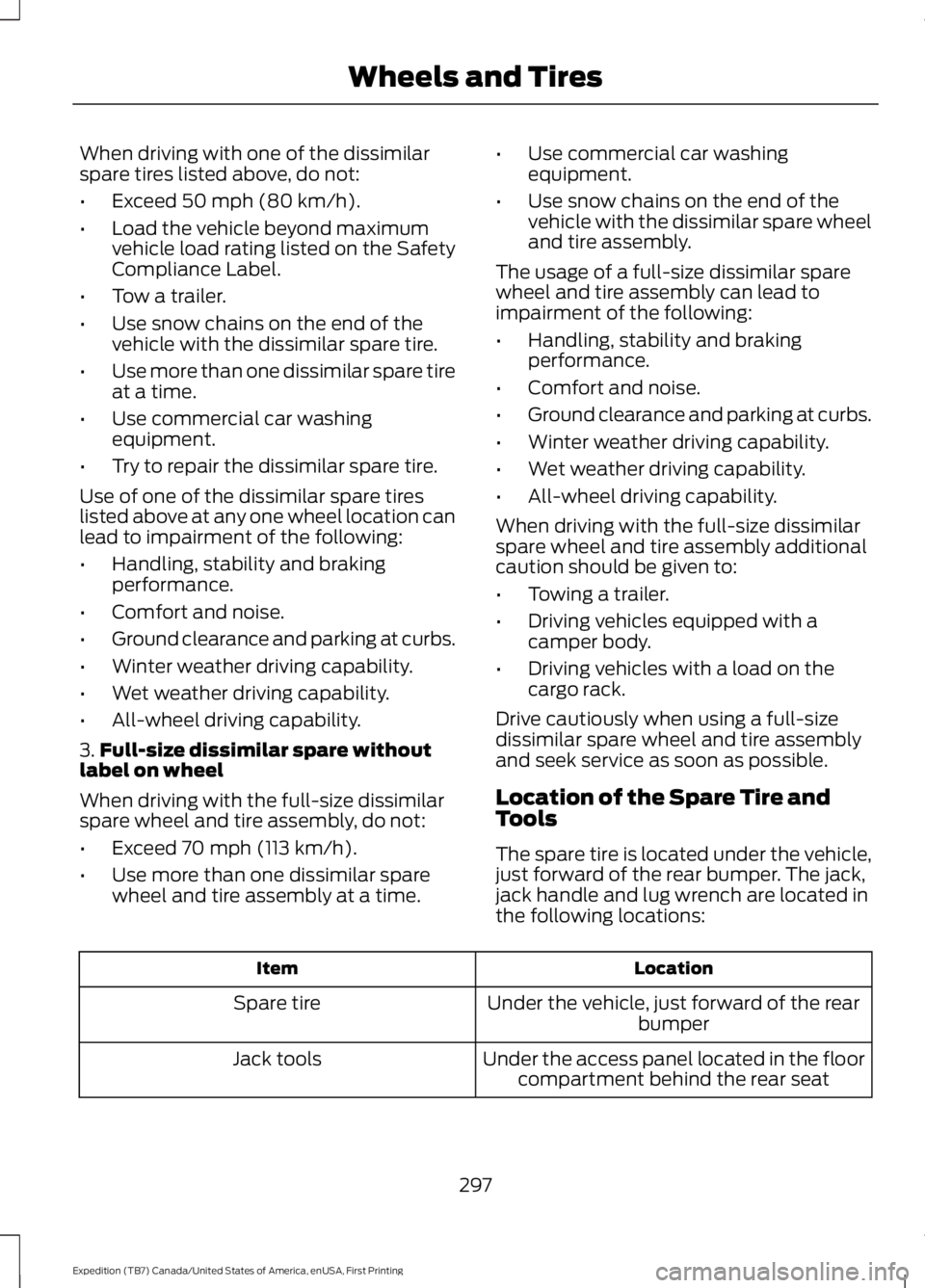

Removing the Spare Tire

1. Remove the jack handle and winchextension from the tray and assemblethem.

2. Open the spare tire winch access plugat the bottom of the compartment forthe jack and tools tray.

3. Insert the winch extension toolassembly through the access hole inthe floor and engage the winch.

4. To remove the spare tire, turn thehandle counterclockwise until the tireis lowered to the ground and the cableis slightly slack.

5.Slide the retainer through the center ofthe spare tire wheel and remove thespare tire.

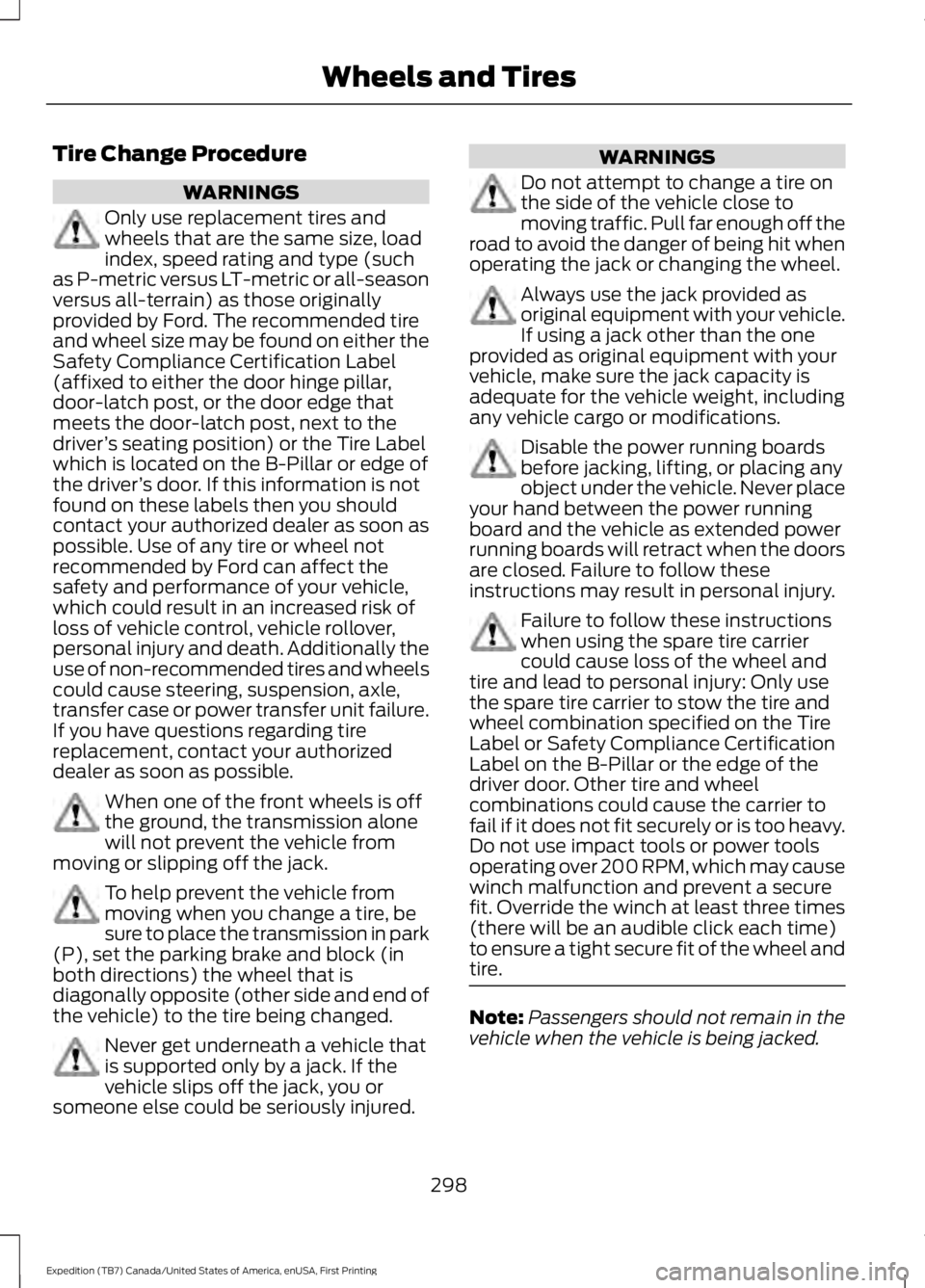

Jacking the Vehicle

Note:Jack at the specified locations toavoid damaging your vehicle.

Front jacking point

299

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and TiresE208640 E208655 E208656

Page 303 of 421

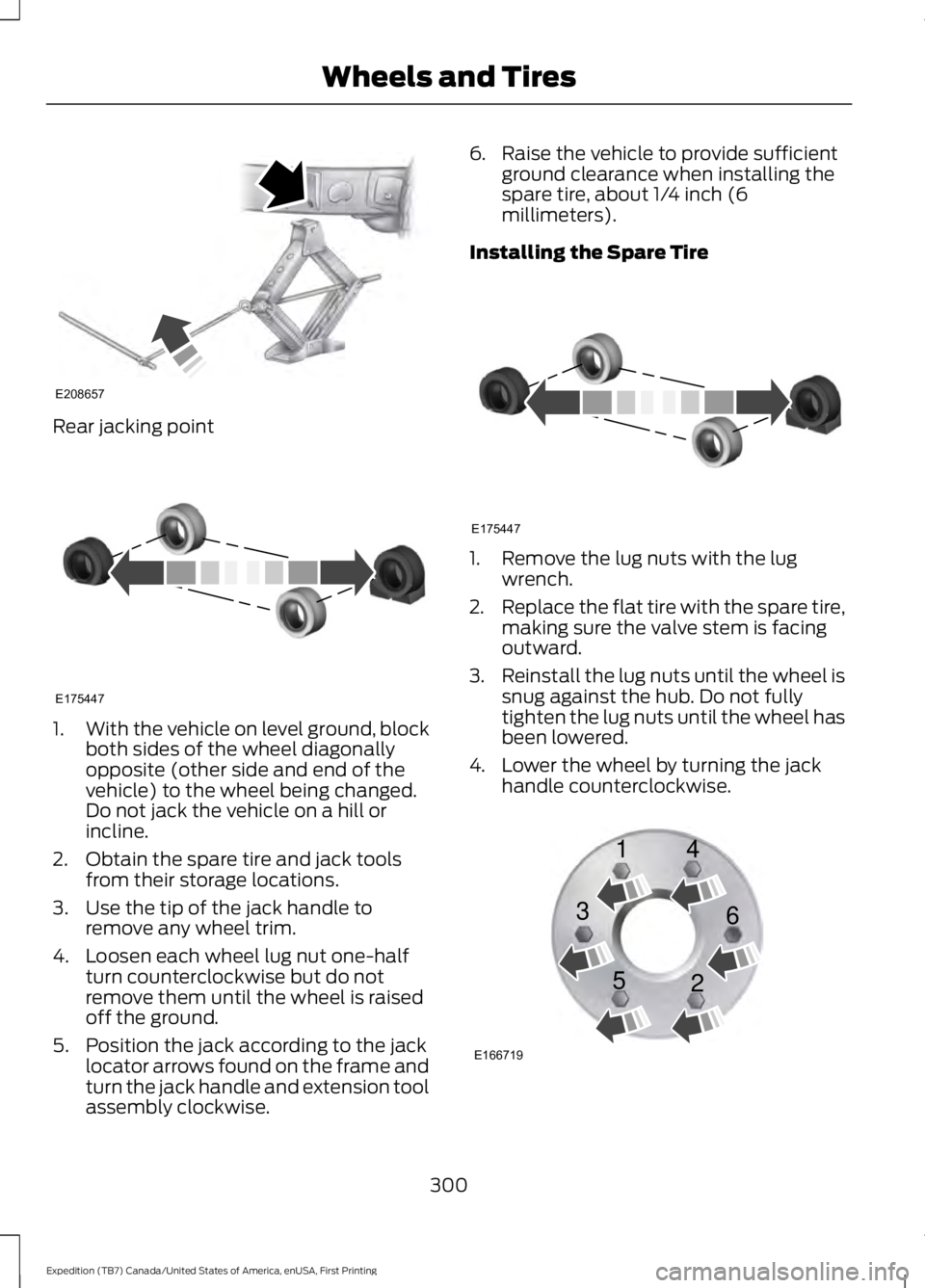

Rear jacking point

1.With the vehicle on level ground, blockboth sides of the wheel diagonallyopposite (other side and end of thevehicle) to the wheel being changed.Do not jack the vehicle on a hill orincline.

2. Obtain the spare tire and jack toolsfrom their storage locations.

3. Use the tip of the jack handle toremove any wheel trim.

4. Loosen each wheel lug nut one-halfturn counterclockwise but do notremove them until the wheel is raisedoff the ground.

5. Position the jack according to the jacklocator arrows found on the frame andturn the jack handle and extension toolassembly clockwise.

6. Raise the vehicle to provide sufficientground clearance when installing thespare tire, about 1/4 inch (6millimeters).

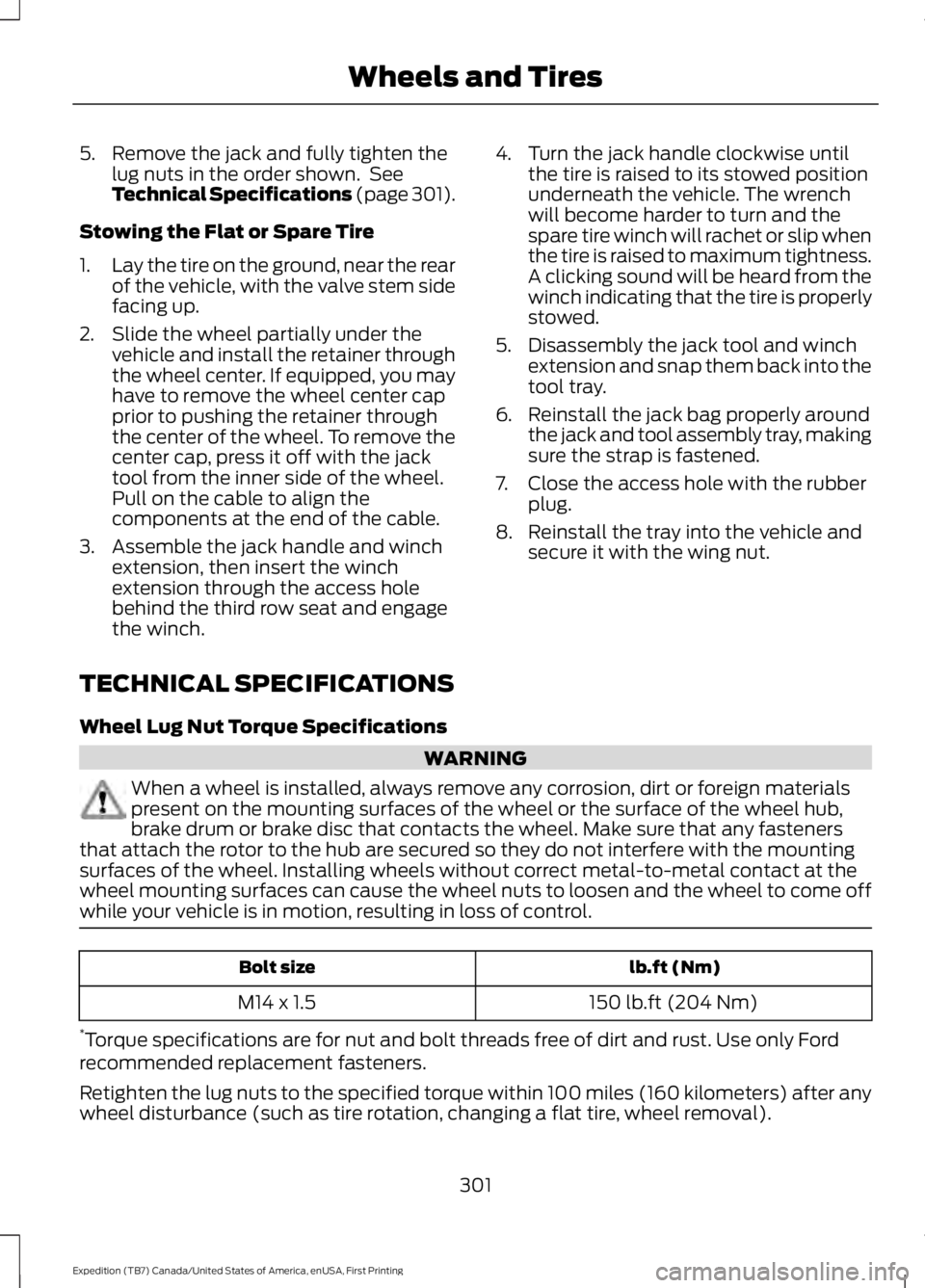

Installing the Spare Tire

1. Remove the lug nuts with the lugwrench.

2.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward.

3.Reinstall the lug nuts until the wheel issnug against the hub. Do not fullytighten the lug nuts until the wheel hasbeen lowered.

4. Lower the wheel by turning the jackhandle counterclockwise.

300

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and TiresE208657 E175447 E175447 E166719

1

3

5 4

6

2

Page 304 of 421

5. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 301).

Stowing the Flat or Spare Tire

1.Lay the tire on the ground, near the rearof the vehicle, with the valve stem sidefacing up.

2. Slide the wheel partially under thevehicle and install the retainer throughthe wheel center. If equipped, you mayhave to remove the wheel center capprior to pushing the retainer throughthe center of the wheel. To remove thecenter cap, press it off with the jacktool from the inner side of the wheel.Pull on the cable to align thecomponents at the end of the cable.

3. Assemble the jack handle and winchextension, then insert the winchextension through the access holebehind the third row seat and engagethe winch.

4. Turn the jack handle clockwise untilthe tire is raised to its stowed positionunderneath the vehicle. The wrenchwill become harder to turn and thespare tire winch will rachet or slip whenthe tire is raised to maximum tightness.A clicking sound will be heard from thewinch indicating that the tire is properlystowed.

5. Disassembly the jack tool and winchextension and snap them back into thetool tray.

6. Reinstall the jack bag properly aroundthe jack and tool assembly tray, makingsure the strap is fastened.

7. Close the access hole with the rubberplug.

8. Reinstall the tray into the vehicle andsecure it with the wing nut.

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign materialspresent on the mounting surfaces of the wheel or the surface of the wheel hub,brake drum or brake disc that contacts the wheel. Make sure that any fastenersthat attach the rotor to the hub are secured so they do not interfere with the mountingsurfaces of the wheel. Installing wheels without correct metal-to-metal contact at thewheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come offwhile your vehicle is in motion, resulting in loss of control.

lb.ft (Nm)Bolt size

150 lb.ft (204 Nm)M14 x 1.5

*Torque specifications are for nut and bolt threads free of dirt and rust. Use only Fordrecommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kilometers) after anywheel disturbance (such as tire rotation, changing a flat tire, wheel removal).

301

Expedition (TB7) Canada/United States of America, enUSA, First Printing

Wheels and Tires