service FORD EXPLORER 2006 4.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: EXPLORER, Model: FORD EXPLORER 2006 4.GPages: 328, PDF Size: 3.59 MB

Page 174 of 328

TIRES

Tires are designed to give many thousands of miles of service, but they

must be maintained in order to get the maximum benefit from them.

Glossary of tire terminology

²Tire label:A label showing the OE (Original Equipment) tire sizes,

recommended inflation pressure and the maximum weight the vehicle

can carry.

²Tire Identification Number (TIN):A number on the sidewall of

each tire providing information about the tire brand and

manufacturing plant, tire size and date of manufacture.

²Inflation pressure:A measure of the amount of air in a tire.

²Standard load:A class of P-metric or Metric tires designed to carry a

maximum load at 35 psi [37 psi (2.5 bar) for Metric tires]. Increasing

the inflation pressure beyond this pressure will not increase the tire's

load carrying capability.

²Extra load:A class of P-metric or Metric tires designed to carry a

heavier maximum load at 41 psi [43 psi (2.9 bar) for Metric tires].

Increasing the inflation pressure beyond this pressure will not increase

the tire's load carrying capability.

²kPa:Kilopascal, a metric unit of air pressure.

²PSI:Pounds per square inch, a standard unit of air pressure.

²Cold inflation pressure:The tire pressure when the vehicle has

been stationary and out of direct sunlight for an hour or more and

prior to the vehicle being driven for 1 mile (1.6 km).

²Recommended inflation pressure:The cold inflation pressure found

on the Safety Compliance Certification Label or Tire Label located on

the B-Pillar or the edge of the driver's door.

²B-pillar:The structural member at the side of the vehicle behind the

front door.

²Bead area of the tire:Area of the tire next to the rim.

²Sidewall of the tire:Area between the bead area and the tread.

²Tread area of the tire:Area of the perimeter of the tire that

contacts the road when mounted on the vehicle.

²Rim:The metal support (wheel) for a tire or a tire and tube assembly

upon which the tire beads are seated.

Tires, Wheels and Loading

174

Page 175 of 328

INFLATING YOUR TIRES

Safe operation of your vehicle requires that your tires are properly

inflated. Remember that a tire can lose up to half of its air pressure

without appearing flat.

Every day before you drive, check your tires. If one looks lower than the

others, use a tire gauge to check pressure of all tires and adjust if required.

At least once a month and before long trips, inspect each tire and check

the tire pressure with a tire gauge (including spare, if equipped). Inflate

all tires to the inflation pressure recommended by Ford Motor Company.

Use a tire gauge to check the tire inflation pressure, including the spare

(if equipped), at least monthly and before long trips. You are strongly

urged to buy a reliable tire pressure gauge, as automatic service station

gauges may be inaccurate. Ford recommends the use of a digital or dial

type tire pressure gauge rather than a stick type tire pressure gauge.

Use the recommended cold inflation pressure for optimum tire

performance and wear. Under-inflation or over-inflation may cause

uneven treadwear patterns.

Under-inflation is the most common cause of tire failures and

may result in severe tire cracking, tread separation or9blowout9,

with unexpected loss of vehicle control and increased risk of injury.

Under-inflation increases sidewall flexing and rolling resistance,

resulting in heat buildup and internal damage to the tire. It also may

result in unnecessary tire stress, irregular wear, loss of vehicle control

and accidents. A tire can lose up to half of its air pressure and not

appear to be flat!

Always inflate your tires to the Ford recommended inflation pressure

even if it is less than the maximum inflation pressure information found

on the tire. The Ford recommended tire inflation pressure is found on

the Safety Compliance Certification Label or Tire Label which is located

on the B-Pillar or the edge of the driver's door. Failure to follow the tire

pressure recommendations can cause uneven treadwear patterns and

adversely affect the way your vehicle handles.

Maximum Permissible Inflation Pressureis the tire manufacturer's

maximum permissible pressure and/or the pressure at which the

maximum load can be carried by the tire. This pressure is normally

higher than the manufacturer's recommended cold inflation pressure

which can be found on the Safety Compliance Certification Label or Tire

Label which is located on the B-Pillar or the edge of the driver's door.

Tires, Wheels and Loading

175

Page 177 of 328

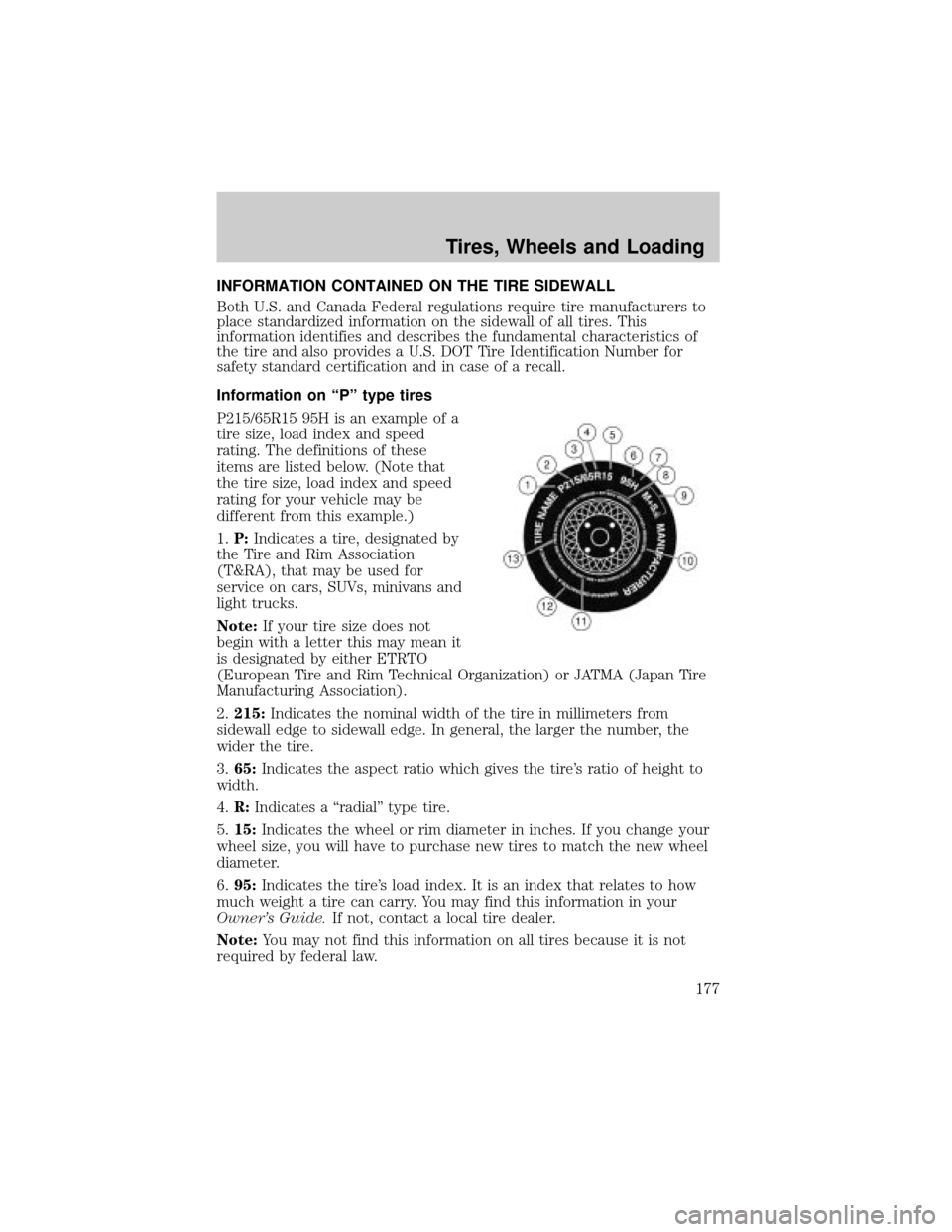

INFORMATION CONTAINED ON THE TIRE SIDEWALL

Both U.S. and Canada Federal regulations require tire manufacturers to

place standardized information on the sidewall of all tires. This

information identifies and describes the fundamental characteristics of

the tire and also provides a U.S. DOT Tire Identification Number for

safety standard certification and in case of a recall.

Information on ªPº type tires

P215/65R15 95H is an example of a

tire size, load index and speed

rating. The definitions of these

items are listed below. (Note that

the tire size, load index and speed

rating for your vehicle may be

different from this example.)

1.P:Indicates a tire, designated by

the Tire and Rim Association

(T&RA), that may be used for

service on cars, SUVs, minivans and

light trucks.

Note:If your tire size does not

begin with a letter this may mean it

is designated by either ETRTO

(European Tire and Rim Technical Organization) or JATMA (Japan Tire

Manufacturing Association).

2.215:Indicates the nominal width of the tire in millimeters from

sidewall edge to sidewall edge. In general, the larger the number, the

wider the tire.

3.65:Indicates the aspect ratio which gives the tire's ratio of height to

width.

4.R:Indicates a ªradialº type tire.

5.15:Indicates the wheel or rim diameter in inches. If you change your

wheel size, you will have to purchase new tires to match the new wheel

diameter.

6.95:Indicates the tire's load index. It is an index that relates to how

much weight a tire can carry. You may find this information in your

Owner's Guide.If not, contact a local tire dealer.

Note:You may not find this information on all tires because it is not

required by federal law.

Tires, Wheels and Loading

177

Page 180 of 328

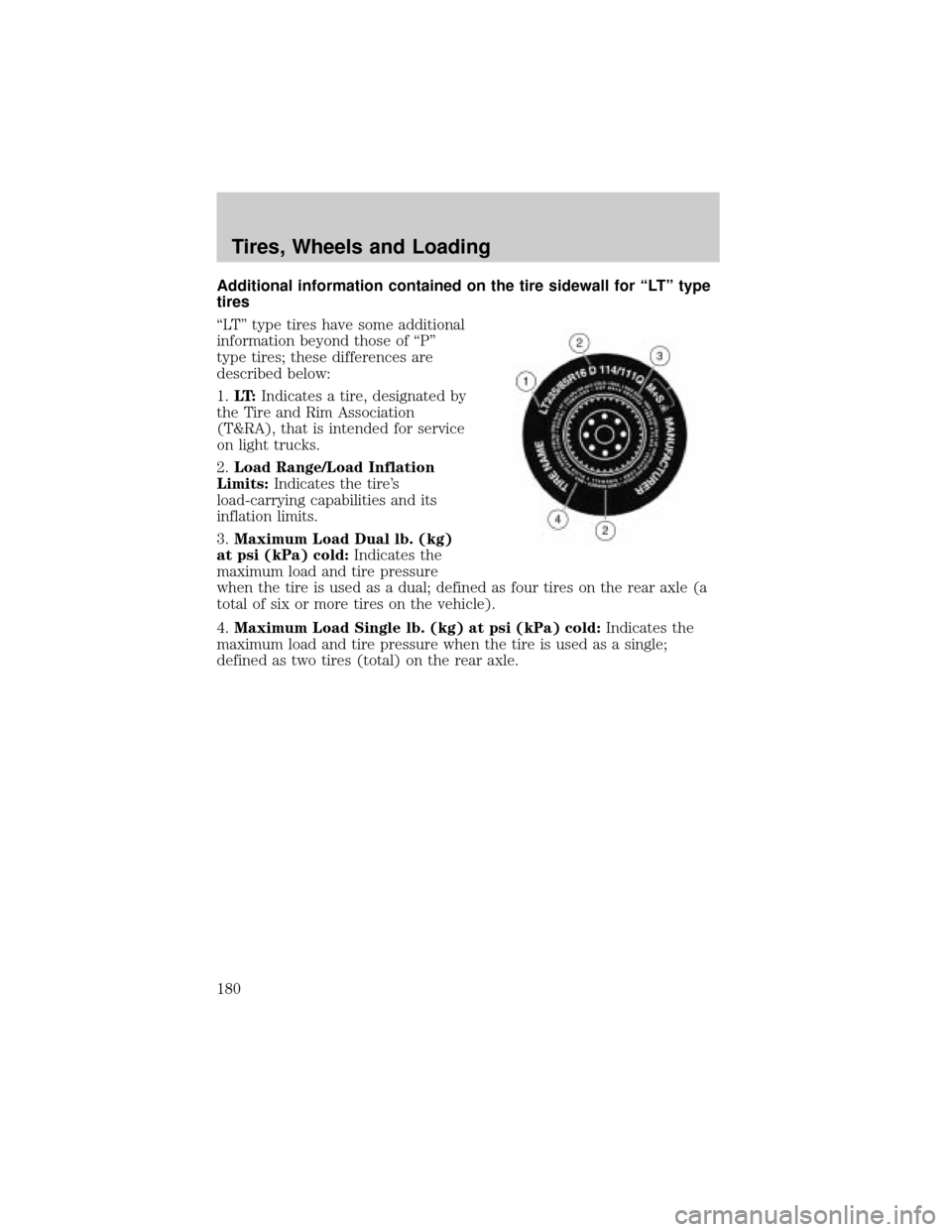

Additional information contained on the tire sidewall for ªLTº type

tires

ªLTº type tires have some additional

information beyond those of ªPº

type tires; these differences are

described below:

1.LT:Indicates a tire, designated by

the Tire and Rim Association

(T&RA), that is intended for service

on light trucks.

2.Load Range/Load Inflation

Limits:Indicates the tire's

load-carrying capabilities and its

inflation limits.

3.Maximum Load Dual lb. (kg)

at psi (kPa) cold:Indicates the

maximum load and tire pressure

when the tire is used as a dual; defined as four tires on the rear axle (a

total of six or more tires on the vehicle).

4.Maximum Load Single lb. (kg) at psi (kPa) cold:Indicates the

maximum load and tire pressure when the tire is used as a single;

defined as two tires (total) on the rear axle.

Tires, Wheels and Loading

180

Page 181 of 328

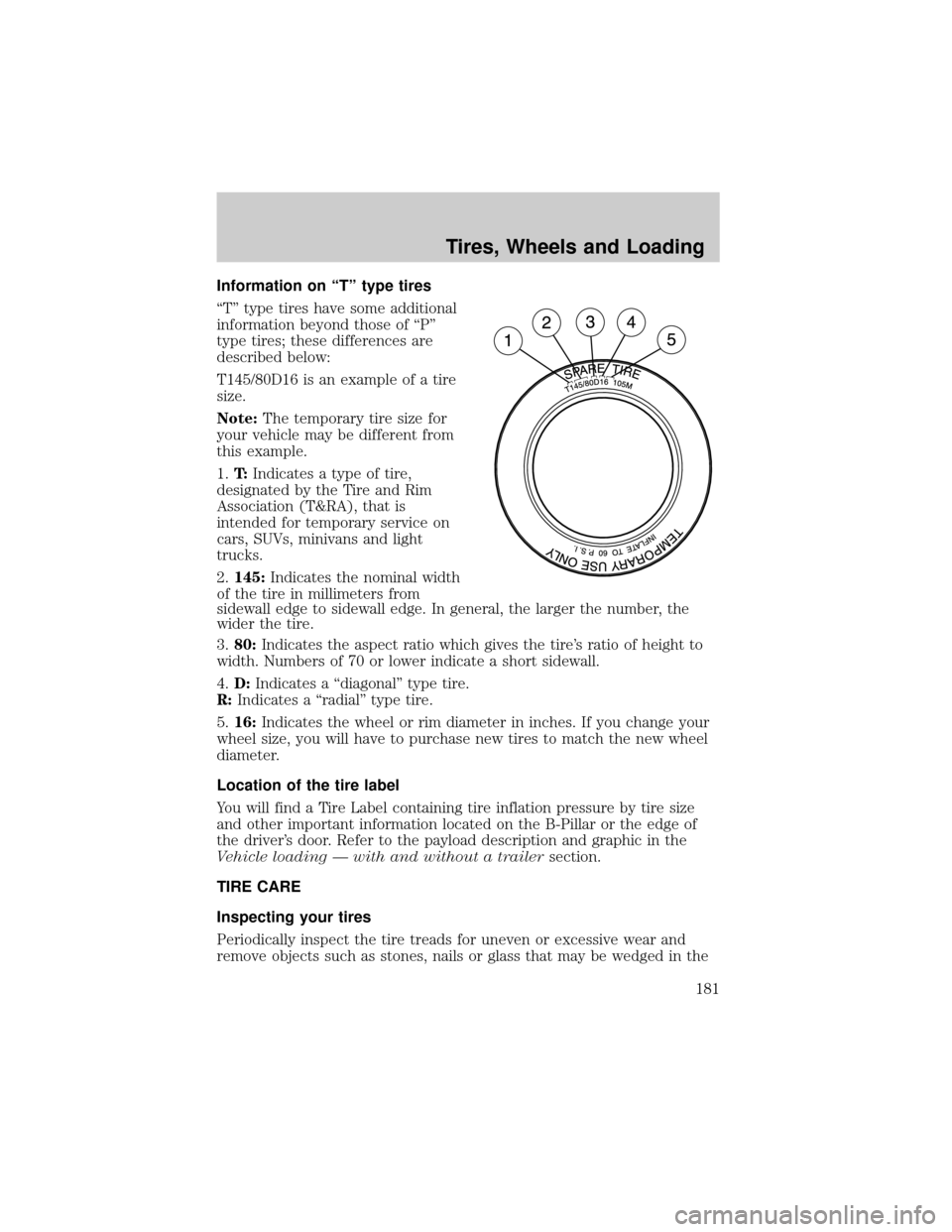

Information on ªTº type tires

ªTº type tires have some additional

information beyond those of ªPº

type tires; these differences are

described below:

T145/80D16 is an example of a tire

size.

Note:The temporary tire size for

your vehicle may be different from

this example.

1.T:Indicates a type of tire,

designated by the Tire and Rim

Association (T&RA), that is

intended for temporary service on

cars, SUVs, minivans and light

trucks.

2.145:Indicates the nominal width

of the tire in millimeters from

sidewall edge to sidewall edge. In general, the larger the number, the

wider the tire.

3.80:Indicates the aspect ratio which gives the tire's ratio of height to

width. Numbers of 70 or lower indicate a short sidewall.

4.D:Indicates a ªdiagonalº type tire.

R:Indicates a ªradialº type tire.

5.16:Indicates the wheel or rim diameter in inches. If you change your

wheel size, you will have to purchase new tires to match the new wheel

diameter.

Location of the tire label

You will find a Tire Label containing tire inflation pressure by tire size

and other important information located on the B-Pillar or the edge of

the driver's door. Refer to the payload description and graphic in the

Vehicle loading Ð with and without a trailersection.

TIRE CARE

Inspecting your tires

Periodically inspect the tire treads for uneven or excessive wear and

remove objects such as stones, nails or glass that may be wedged in the

Tires, Wheels and Loading

181

Page 182 of 328

tread grooves. Check for holes or cuts that may permit air leakage from

the tire and make necessary repairs. Also inspect the tire sidewalls for

cracking, cuts, bruises and other signs of damage or excessive wear. If

internal damage to the tire is suspected, have the tire demounted and

inspected in case it needs to be repaired or replaced. For your safety,

tires that are damaged or show signs of excessive wear should not be

used because they are more likely to blow out or fail.

Improper or inadequate vehicle maintenance can cause tires to wear

abnormally. Inspect all your tires, including the spare, frequently, and

replace them if one or more of the following conditions exist:

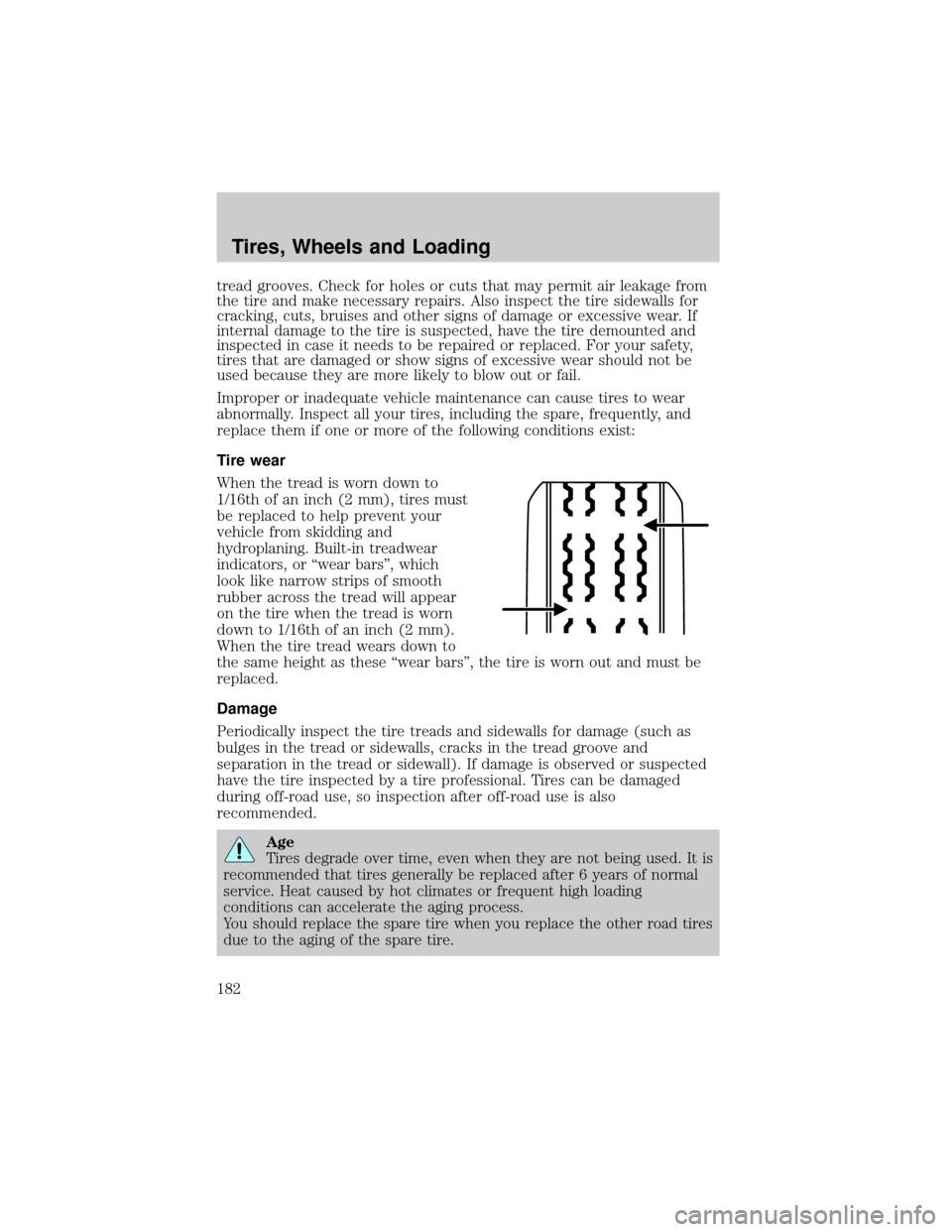

Tire wear

When the tread is worn down to

1/16th of an inch (2 mm), tires must

be replaced to help prevent your

vehicle from skidding and

hydroplaning. Built-in treadwear

indicators, or ªwear barsº, which

look like narrow strips of smooth

rubber across the tread will appear

on the tire when the tread is worn

down to 1/16th of an inch (2 mm).

When the tire tread wears down to

the same height as these ªwear barsº, the tire is worn out and must be

replaced.

Damage

Periodically inspect the tire treads and sidewalls for damage (such as

bulges in the tread or sidewalls, cracks in the tread groove and

separation in the tread or sidewall). If damage is observed or suspected

have the tire inspected by a tire professional. Tires can be damaged

during off-road use, so inspection after off-road use is also

recommended.

Age

Tires degrade over time, even when they are not being used. It is

recommended that tires generally be replaced after 6 years of normal

service. Heat caused by hot climates or frequent high loading

conditions can accelerate the aging process.

You should replace the spare tire when you replace the other road tires

due to the aging of the spare tire.

Tires, Wheels and Loading

182

Page 187 of 328

The Tire Pressure Monitoring System is NOT a substitute for

manually checking tire pressure. The tire pressure should be

checked periodically (at least monthly) using a tire gauge, see

Inflating your tiresin this chapter. Failure to properly maintain your

tire pressure could increase the risk of tire failure, loss of control,

vehicle rollover and personal injury.

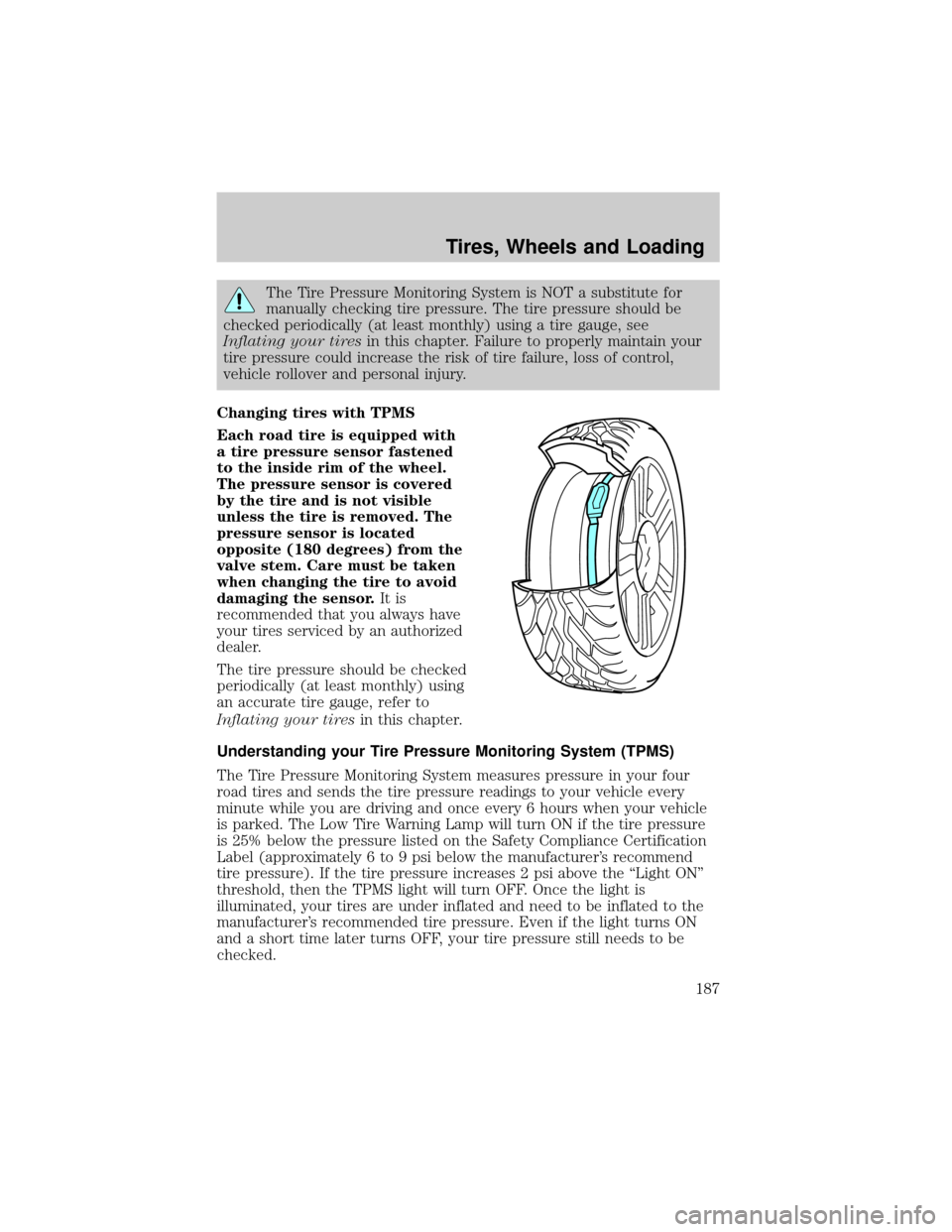

Changing tires with TPMS

Each road tire is equipped with

a tire pressure sensor fastened

to the inside rim of the wheel.

The pressure sensor is covered

by the tire and is not visible

unless the tire is removed. The

pressure sensor is located

opposite (180 degrees) from the

valve stem. Care must be taken

when changing the tire to avoid

damaging the sensor.It is

recommended that you always have

your tires serviced by an authorized

dealer.

The tire pressure should be checked

periodically (at least monthly) using

an accurate tire gauge, refer to

Inflating your tiresin this chapter.

Understanding your Tire Pressure Monitoring System (TPMS)

The Tire Pressure Monitoring System measures pressure in your four

road tires and sends the tire pressure readings to your vehicle every

minute while you are driving and once every 6 hours when your vehicle

is parked. The Low Tire Warning Lamp will turn ON if the tire pressure

is 25% below the pressure listed on the Safety Compliance Certification

Label (approximately 6 to 9 psi below the manufacturer's recommend

tire pressure). If the tire pressure increases 2 psi above the ªLight ONº

threshold, then the TPMS light will turn OFF. Once the light is

illuminated, your tires are under inflated and need to be inflated to the

manufacturer's recommended tire pressure. Even if the light turns ON

and a short time later turns OFF, your tire pressure still needs to be

checked.

Tires, Wheels and Loading

187

Page 200 of 328

²Use extra caution when driving while trailer towing. Refer toDriving

while you towin this chapter.

²Service your vehicle more frequently if you tow a trailer. Refer to the

severe duty schedule in thescheduled maintenance information.

²Do not tow a trailer until your vehicle has been driven at least 500

miles (800 km).

²Refer to the instructions included with towing accessories for the

proper installation and adjustment specifications.

Do not exceed the maximum loads listed on the Safety Compliance

Certification label. For load specification terms found on the label, refer

toVehicle loadingin this chapter when figuring the total weight of your

vehicle.

Your vehicle is equipped with a standard Class II integrated hitch and

requires only a draw bar and ball with a 19 mm (3/4 inch) shank

diameter. An optional Class III/Class IV hitch is also available.

Note:Do not exceed the GVWR or the GAWR specified on the

certification label.

Towing trailers beyond the maximum recommended gross trailer

weight exceeds the limit of the vehicle and could result in

engine damage, transmission damage, structural damage, loss of vehicle

control, vehicle rollover and personal injury.

Tires, Wheels and Loading

200

Page 204 of 328

Never connect any trailer lighting to the vehicle's taillamp

circuits, because it may damage the electrical system resulting in

fire. Contact your authorized dealer for assistance in proper trailer tow

wiring installation. Additional electrical equipment may be required.

Driving while you tow

When towing a trailer:

²Keep your speed no faster than 70 mph (112 km/h) during the first

500 miles (800 km) of towing a trailer, and don't make full throttle

starts.

²Turn off the speed control. The speed control may shut off

automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²To eliminate excessive shifting, use a lower gear. This will also assist

in transmission cooling. (For additional information, refer to the

Driving with an automatic transmissionsection in theDriving

chapter.)

²Under extreme conditions with large frontal trailers, high outside

temperatures and highway speeds, the coolant gauge may indicate

higher than normal coolant temperatures. If this occurs, reduce speed

until the coolant temperature returns to the normal range. Refer to

Engine coolant temperature gaugein theInstrument Cluster

chapter.

²Anticipate stops and brake gradually.

²Do not exceed the GCWR rating or transmission damage may occur.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to yourScheduled Maintenance

Informationfor more information.

Trailer towing tips

²Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

²Allow more distance for stopping with a trailer attached.

²If you are driving down a long or steep hill, shift to a lower gear. Do

not apply the brakes continuously, as they may overheat and become

less effective.

Tires, Wheels and Loading

204

Page 210 of 328

To reduce the risk of electrical shock, do not use your heater

with ungrounded electrical systems or two-pronged (cheater)

adapters.

BRAKES

Occasional brake noise is normal. If a metal-to-metal, continuous grinding

or continuous squeal sound is present, the brake linings may be worn-out

and should be inspected by an authorized dealer. If the vehicle has

continuous vibration or shudder in the steering wheel while braking, the

vehicle should be inspected by an authorized dealer.

Refer toBrake system warning

lightin theInstrument Cluster

chapter for information on the brake

system warning light.

Four-wheel anti-lock brake system (ABS)

Your vehicle is equipped with an Anti-lock Braking System (ABS). This

system helps you maintain steering control during emergency stops by

keeping the brakes from locking. Noise from the ABS pump motor and

brake pedal pulsation may be observed during ABS braking and the

brake pedal may suddenly travel a little farther as soon as ABS braking is

done and normal brake operation resumes. These are normal

characteristics of the ABS and should be no reason for concern.

ABS warning lamp

The ABS lamp in the instrument

cluster momentarily illuminates

when the ignition is turned on. If

the light does not illuminate during

start up, remains on or flashes, the

ABS may be disabled and may need to be serviced.

Even when the ABS is disabled,

normal braking is still effective. (If

your BRAKE warning lamp

illuminates with the parking brake

released, have your brake system

serviced immediately.)

P!

BRAKE

ABS

P!

BRAKE

Driving

210