clock FORD EXPLORER 2021 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2021, Model line: EXPLORER, Model: FORD EXPLORER 2021Pages: 577, PDF Size: 9.79 MB

Page 40 of 577

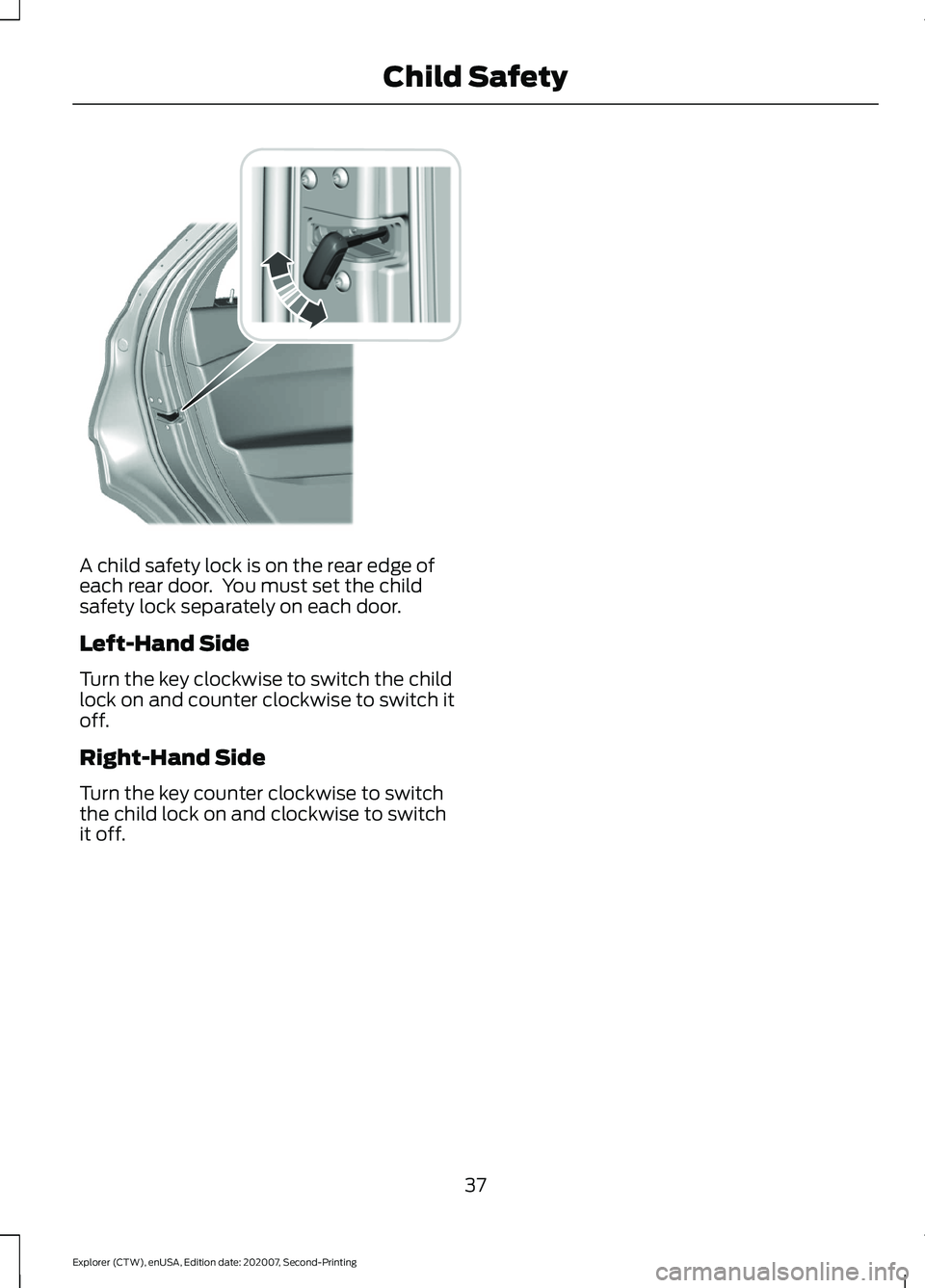

A child safety lock is on the rear edge of

each rear door. You must set the child

safety lock separately on each door.

Left-Hand Side

Turn the key clockwise to switch the child

lock on and counter clockwise to switch it

off.

Right-Hand Side

Turn the key counter clockwise to switch

the child lock on and clockwise to switch

it off.

37

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing Child Safety E287259

Page 330 of 577

8.

Make sure that the oil level is between

the maximum and minimum marks. If

the oil level is at the minimum mark,

add oil immediately. See Capacities

and Specifications (page 391).

9. If the oil level is correct, replace the dipstick and make sure it is fully seated.

Note: Do not remove the dipstick when the

engine is running.

Note: If the oil level is between the

maximum and minimum marks, the oil level

is acceptable. Do not add oil.

Note: The oil consumption of new engines

reaches its normal level after approximately

3,000 mi (5,000 km)

.

Adding Engine Oil WARNING: Do not remove the filler

cap when the engine is running.

Do not use supplemental engine oil

additives because they are unnecessary

and could lead to engine damage that may

not be covered by the vehicle Warranty. Only use oils certified for gasoline engines

by the American Petroleum Institute (API).

An oil with this trademark symbol

conforms to the current engine and

emission system protection standards and

fuel economy requirements of the

International Lubricants Specification

Advisory Committee (ILSAC).

To top up the engine oil level do the

following:

1. Clean the area surrounding the engine

oil filler cap before you remove it.

2. Remove the engine oil filler cap. See Under Hood Overview

(page 323).

Turn it counterclockwise and remove

it.

3. Add engine oil that meets our specifications. See

Capacities and

Specifications (page 391). You may

have to use a funnel to pour the engine

oil into the opening.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap

correctly.

Note: Soak up any spillage with an

absorbent cloth immediately.

OIL CHANGE INDICATOR

RESET

Use the information display controls on

the steering wheel to reset the oil change

indicator.

327

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing MaintenanceE142732

Page 335 of 577

It is very important to use prediluted

coolant approved to the correct

specification in order to avoid plugging the

small passageways in the engine cooling

system. See Capacities and

Specifications (page 391). Do not mix

different colors or types of coolant in your

vehicle. Mixing of engine coolants or using

an incorrect coolant may harm the engine

or cooling system components and may

not be covered by the vehicle Warranty.

Note: If prediluted coolant is not available,

use the approved concentrated coolant

diluting it to 50/50 with distilled water. See

Capacities and Specifications (page 391).

Using water that has not been deionised

may contribute to deposit formation,

corrosion and plugging of the small cooling

system passageways.

Note: Coolants marketed for all makes and

models may not be approved to our

specifications and may cause damage to

the cooling system. Resulting component

damage may not be covered by the vehicle

Warranty.

If the coolant level is at or below the

minimum mark, add prediluted coolant

immediately.

To top up the coolant level do the

following:

1. Unscrew the cap slowly. Any pressure escapes as you unscrew the cap.

2. Add prediluted coolant approved to the correct specification. See

Capacities and Specifications (page

391

).

3. Add enough prediluted coolant to reach the correct level.

4. Replace the coolant reservoir cap. Turn

the cap clockwise until it contacts the

hard stop. 5. Check the coolant level in the coolant

reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the correct level.

If you have to add more than

1.1 qt (1 L) of

engine coolant per month, have your

vehicle checked as soon as possible.

Operating an engine with a low level of

coolant can result in engine overheating

and possible engine damage.

In case of emergency, you can add a large

amount of water without engine coolant

in order to reach a vehicle service location.

In this instance, qualified personnel:

1. Must drain the cooling system.

2. Chemically clean the coolant system.

3. Refill with engine coolant as soon as possible.

Water alone, without engine coolant, can

cause engine damage from corrosion,

overheating or freezing.

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze.

Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or additives to

the coolant. These can be harmful and

compromise the corrosion protection of

the coolant.

Recycled Coolant

We do not recommend the use of recycled

coolant as an approved recycling process

is not yet available.

Note: Dispose of used coolant in the

appropriate manner.

332

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing Maintenance

Page 341 of 577

After battery replacement, or in some

cases after charging the battery with an

external charger, the battery management

system requires eight hours of vehicle sleep

time to relearn the battery state of charge.

During this time your vehicle must remain

fully locked with the ignition switched off.

Note:

Prior to relearning the battery state

of charge, the battery management system

may temporarily disable some electrical

systems.

Electrical Accessory Installation

To make sure the battery management

system works correctly, do not connect an

electrical device ground connection

directly to the battery negative post. This

can cause inaccurate measurements of

the battery condition and potential

incorrect system operation.

Note: If you add electrical accessories or

components to the vehicle, it may adversely

affect battery performance and durability.

This may also affect the performance of

other electrical systems in the vehicle.

Remove and Reinstall the Battery

To disconnect or remove the battery, do

the following:

1. Apply the parking brake and switch the

ignition off.

2. Switch all electrical equipment off, for

example lights and radio.

3. Wait a minimum of two minutes before

disconnecting the battery.

Note: The engine management system has

a power hold function and remains powered

for a period of time after you switch the

ignition off. This is to allow diagnostic and

adaptive tables to be stored. Disconnecting

the battery without waiting can cause

damage not covered by the vehicle

Warranty. 4. Disconnect the negative battery cable

terminal.

5. Disconnect the positive battery cable terminal.

6. Remove the battery securing clamp.

7. Remove the battery.

8. To install, reverse the removal procedure.

Note: Before reconnecting the battery,

make sure the ignition remains switched off.

Note: Make sure the battery cable terminals

are fully tightened.

If you disconnect or replace the vehicle

battery, you must reset the following

features:

• Window bounce-back. See Power

Windows (page 96).

• Clock Settings.

• Pre-set radio stations.

Battery Disposal Make sure that you dispose of

old batteries in an

environmentally friendly way.

Seek advice from your local authority

about recycling old batteries.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

If your vehicle has been involved in a crash,

have the aim of the headlamp beam

checked by an authorized dealer.

338

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing MaintenanceE107998

Page 343 of 577

5. Use a suitable tool, for example a

screwdriver or socket wrench, to turn

the adjuster clockwise or

counterclockwise to adjust the vertical

aim of the headlamp. The horizontal

edge of the brighter light should touch

the horizontal reference line.

6. Close the hood and switch off the lamps.

WASHER FLUID CHECK WARNING: If you operate your

vehicle in temperatures below 41.0°F

(5°C), use washer fluid with antifreeze

protection. Failure to use washer fluid

with antifreeze protection in cold

weather could result in impaired

windshield vision and increase the risk

of injury or accident.

Note: The front and rear washer systems

are supplied from the same reservoir.

Add fluid to fill the reservoir if the level is

low. Only use a washer fluid that meets

our specifications. See

Capacities and

Specifications (page 391).

State or local regulations on volatile

organic compounds may restrict the use

of methanol, a common windshield washer

antifreeze additive. Washer fluids

containing non-methanol antifreeze

agents should be used only if they provide

cold weather protection without damaging

the vehicle ’s paint finish, wiper blades or

washer system.

FUEL FILTER

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

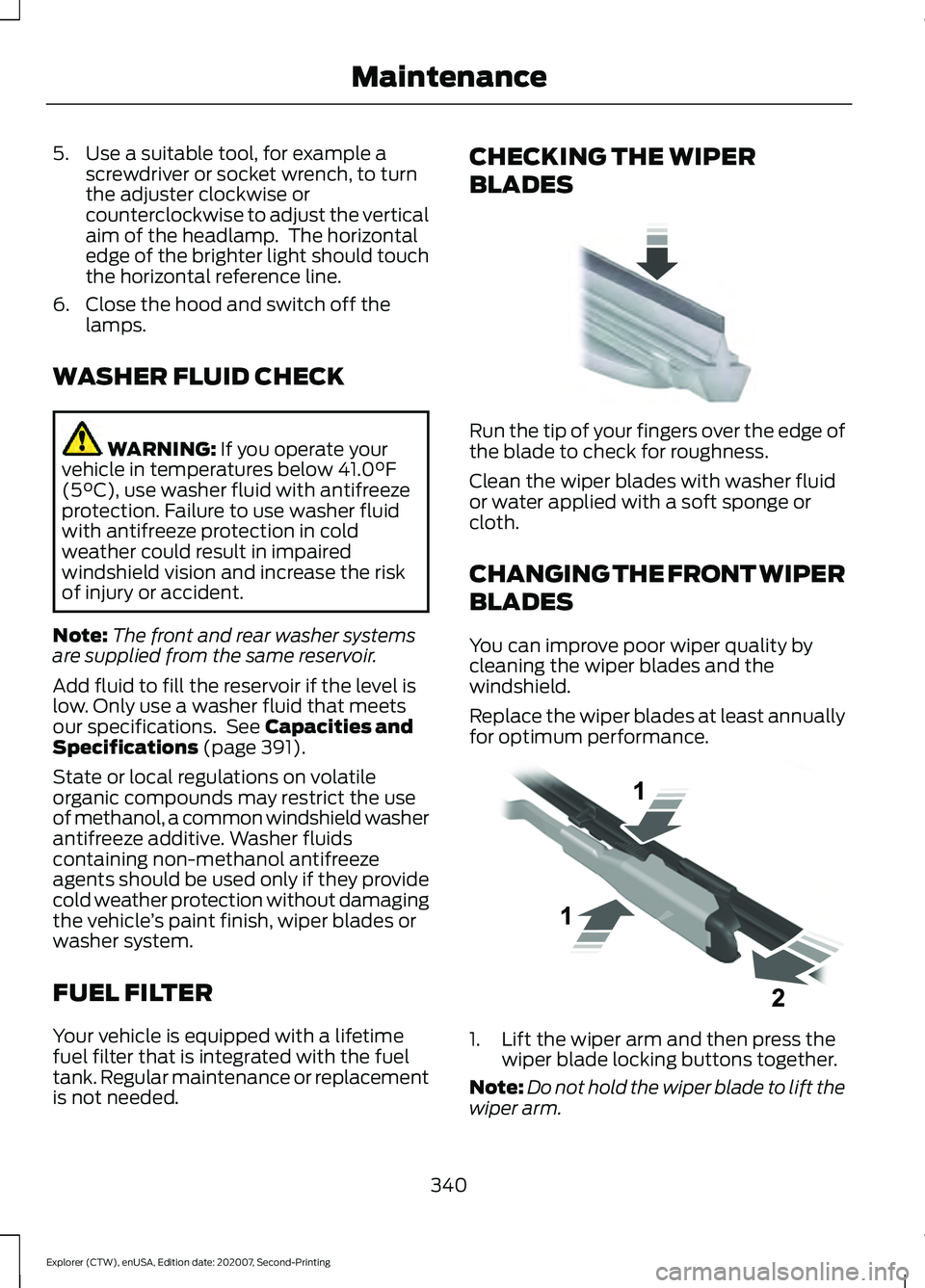

is not needed. CHECKING THE WIPER

BLADES

Run the tip of your fingers over the edge of

the blade to check for roughness.

Clean the wiper blades with washer fluid

or water applied with a soft sponge or

cloth.

CHANGING THE FRONT WIPER

BLADES

You can improve poor wiper quality by

cleaning the wiper blades and the

windshield.

Replace the wiper blades at least annually

for optimum performance.

1. Lift the wiper arm and then press the

wiper blade locking buttons together.

Note: Do not hold the wiper blade to lift the

wiper arm.

340

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing MaintenanceE142463 E129990

Page 345 of 577

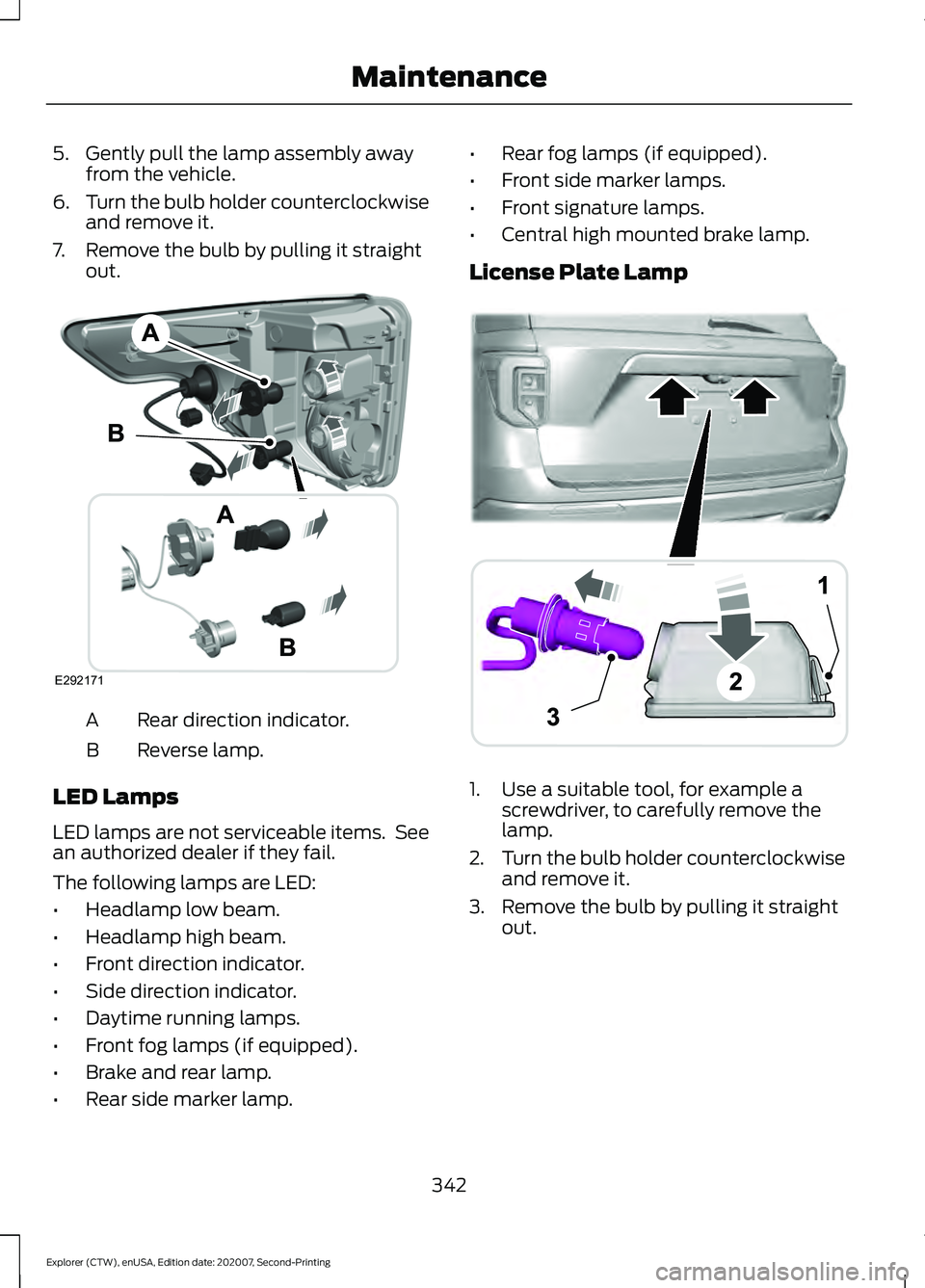

5. Gently pull the lamp assembly away

from the vehicle.

6. Turn the bulb holder counterclockwise

and remove it.

7. Remove the bulb by pulling it straight out. Rear direction indicator.

A

Reverse lamp.

B

LED Lamps

LED lamps are not serviceable items. See

an authorized dealer if they fail.

The following lamps are LED:

• Headlamp low beam.

• Headlamp high beam.

• Front direction indicator.

• Side direction indicator.

• Daytime running lamps.

• Front fog lamps (if equipped).

• Brake and rear lamp.

• Rear side marker lamp. •

Rear fog lamps (if equipped).

• Front side marker lamps.

• Front signature lamps.

• Central high mounted brake lamp.

License Plate Lamp 1. Use a suitable tool, for example a

screwdriver, to carefully remove the

lamp.

2. Turn the bulb holder counterclockwise

and remove it.

3. Remove the bulb by pulling it straight out.

342

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing MaintenanceE292171 A

B

A

12

203A

AE292276

Page 376 of 577

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least 3 ft

(1 m) away from another Ford Motor

Company vehicle undergoing the

system reset procedure at the same

time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system can time-out and you have

to repeat the entire procedure on all

four wheels.

• A double horn sounds indicating the

need to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, seek service from your

authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front -

driver side front tire, Right front -

passenger side front tire, Right rear -

passenger side rear tire, Left rear -

driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn tone confirms that

the sensor identification code has been

learned by the module for this position. If a

double horn is heard, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver

side rear tire, the system indicator

stops flashing, and a message shows

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

373

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing Wheels and Tires

Page 380 of 577

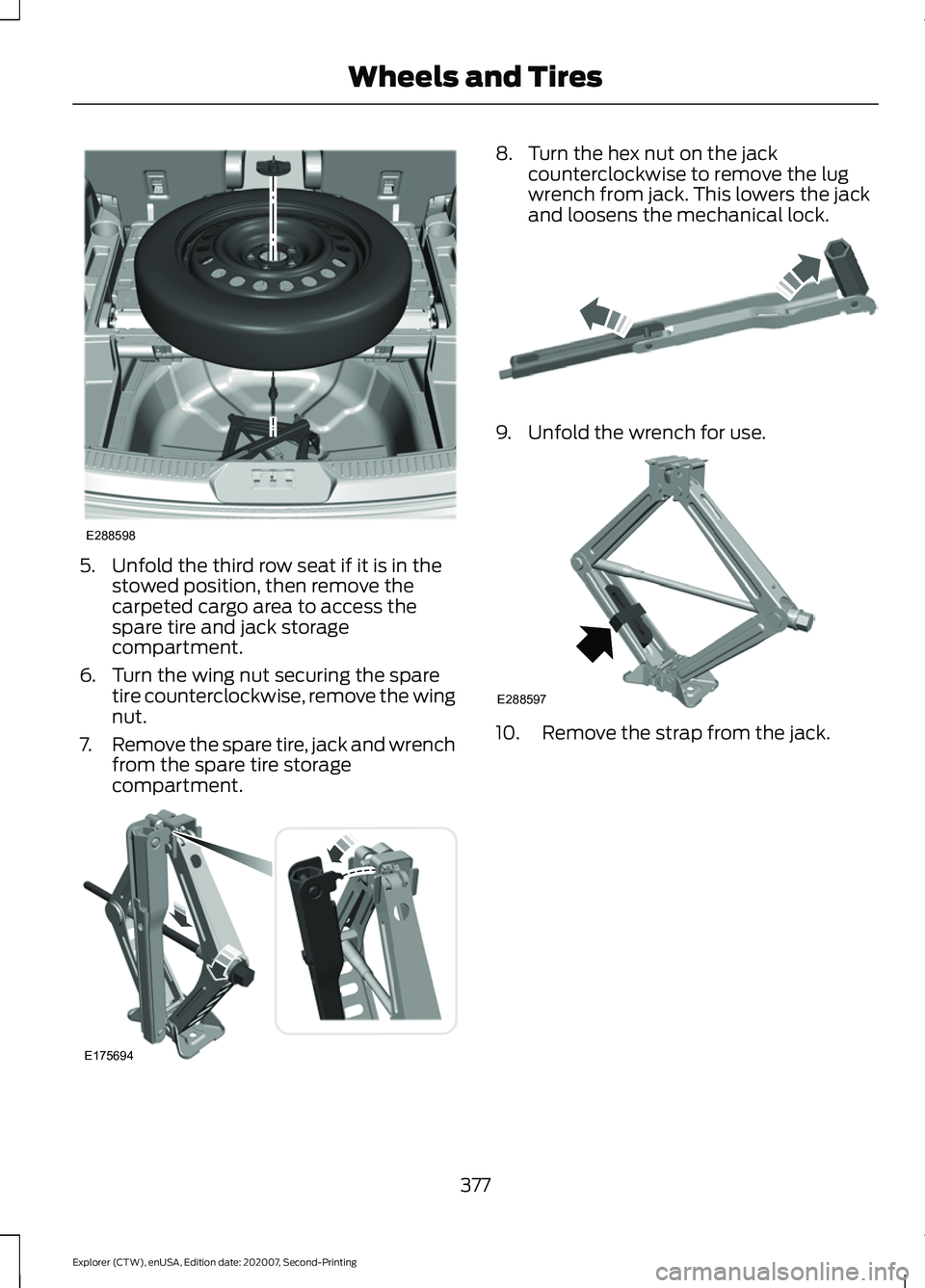

5. Unfold the third row seat if it is in the

stowed position, then remove the

carpeted cargo area to access the

spare tire and jack storage

compartment.

6. Turn the wing nut securing the spare tire counterclockwise, remove the wing

nut.

7. Remove the spare tire, jack and wrench

from the spare tire storage

compartment. 8. Turn the hex nut on the jack

counterclockwise to remove the lug

wrench from jack. This lowers the jack

and loosens the mechanical lock. 9. Unfold the wrench for use.

10. Remove the strap from the jack.

377

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing Wheels and TiresE288598 E175694 E181744 E288597

Page 381 of 577

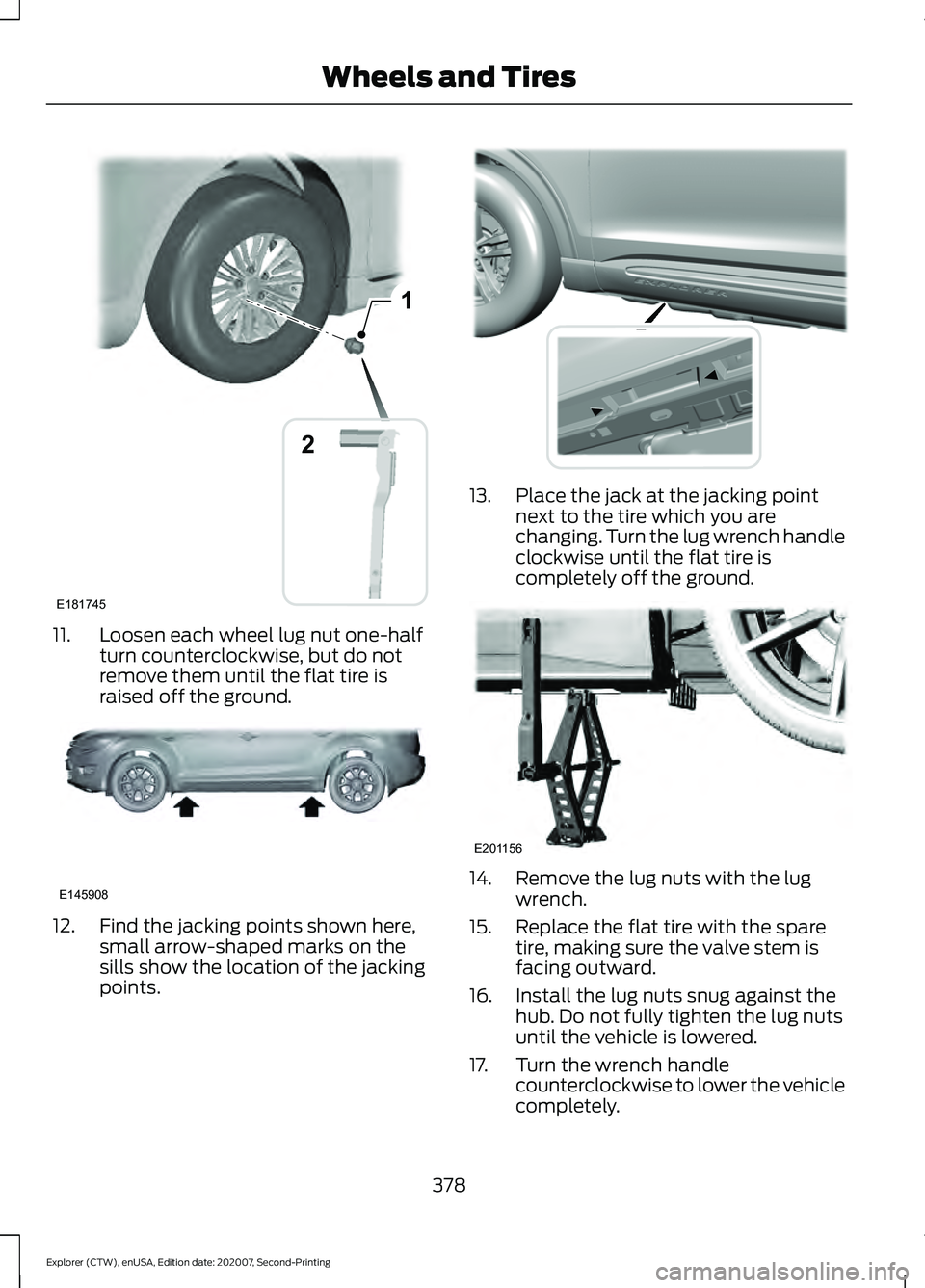

11. Loosen each wheel lug nut one-half

turn counterclockwise, but do not

remove them until the flat tire is

raised off the ground.12. Find the jacking points shown here,

small arrow-shaped marks on the

sills show the location of the jacking

points. 13. Place the jack at the jacking point

next to the tire which you are

changing. Turn the lug wrench handle

clockwise until the flat tire is

completely off the ground. 14. Remove the lug nuts with the lug

wrench.

15. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward.

16. Install the lug nuts snug against the hub. Do not fully tighten the lug nuts

until the vehicle is lowered.

17. Turn the wrench handle counterclockwise to lower the vehicle

completely.

378

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing Wheels and Tires1

E181745

2 E145908 E307859 E201156

Page 382 of 577

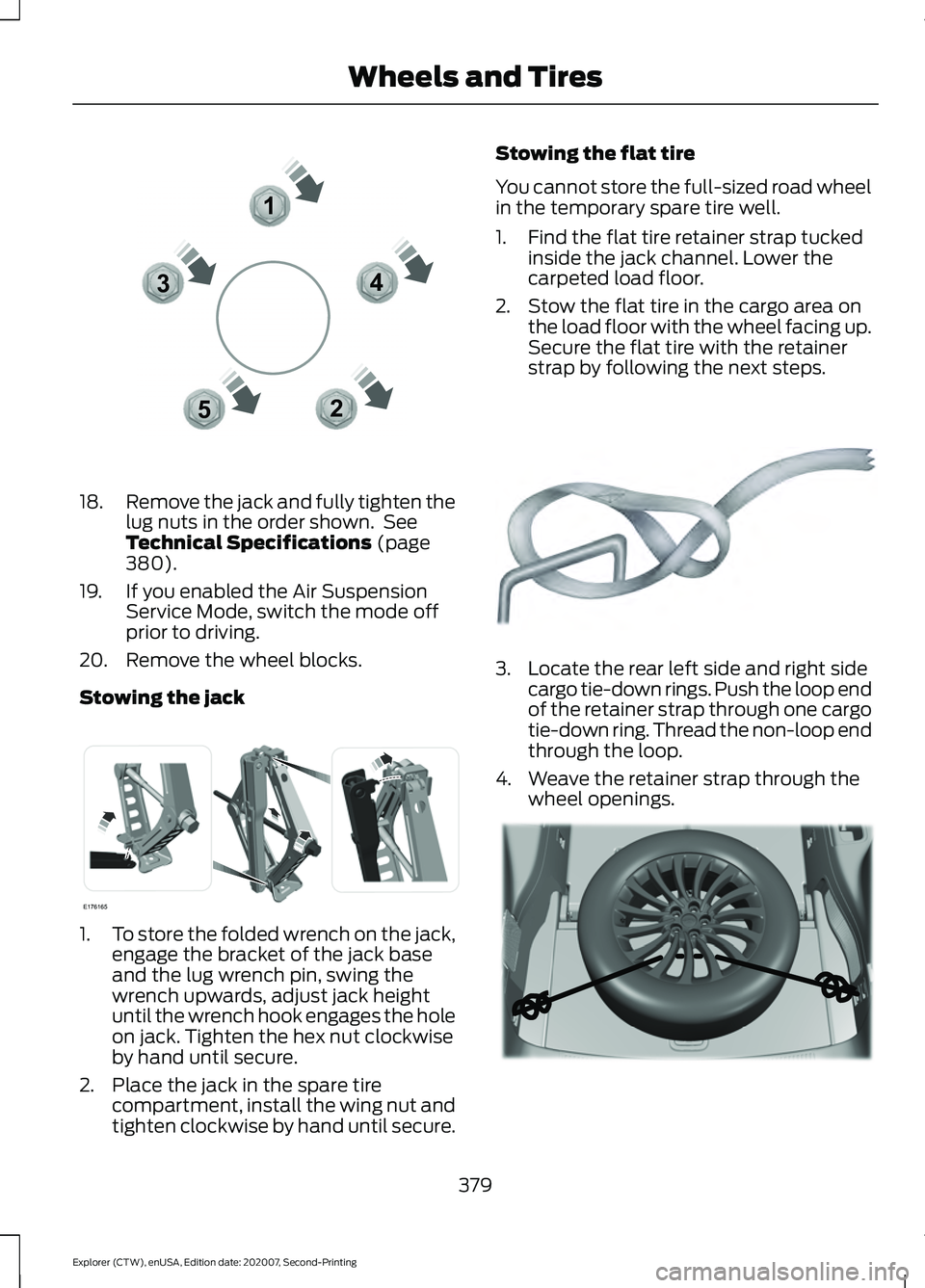

18.

Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page

380).

19. If you enabled the Air Suspension Service Mode, switch the mode off

prior to driving.

20. Remove the wheel blocks.

Stowing the jack 1.

To store the folded wrench on the jack,

engage the bracket of the jack base

and the lug wrench pin, swing the

wrench upwards, adjust jack height

until the wrench hook engages the hole

on jack. Tighten the hex nut clockwise

by hand until secure.

2. Place the jack in the spare tire compartment, install the wing nut and

tighten clockwise by hand until secure. Stowing the flat tire

You cannot store the full-sized road wheel

in the temporary spare tire well.

1. Find the flat tire retainer strap tucked

inside the jack channel. Lower the

carpeted load floor.

2. Stow the flat tire in the cargo area on the load floor with the wheel facing up.

Secure the flat tire with the retainer

strap by following the next steps. 3. Locate the rear left side and right side

cargo tie-down rings. Push the loop end

of the retainer strap through one cargo

tie-down ring. Thread the non-loop end

through the loop.

4. Weave the retainer strap through the wheel openings. 379

Explorer (CTW), enUSA, Edition date: 202007, Second-Printing Wheels and Tires12

3

4

5E306781 E176165 E142906 E294325