maintenance FORD EXPLORER SPORT 2001 1.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2001, Model line: EXPLORER SPORT, Model: FORD EXPLORER SPORT 2001 1.GPages: 256, PDF Size: 2.12 MB

Page 1 of 256

Before driving

Introduction 2

Instrumentation 8

Controls and features 20

Seating and safety restraints 87

Starting and driving

Starting 120

Driving 125

Roadside emergencies 151

Servicing

Maintenance and care 174

Capacities and specifications 224

Customer assistance 232

Reporting safety defects 244

Index 245

All rights reserved. Reproduction by any means, electronic or mechanical including

photocopying, recording or by any information storage and retrieval system or translation

in whole or part is not permitted without written authorization from Ford Motor Company.

Ford may change the contents without notice and without incurring obligation.

Copyright 2001 Ford Motor Company

Contents

1

Page 11 of 256

3.The fuel cap may not have been properly installed and securely

tightened.

These temporary malfunctions can be corrected by filling the fuel tank

with high quality fuel of the recommended octane and/or properly

installing and securely tightening the gas cap. After three driving cycles

without these or any other temporary malfunctions present, theCheck

Enginelight should turn off. (A driving cycle consists of a cold engine

startup followed by mixed city/highway driving.) No additional vehicle

service is required.

If theCheck Enginelight remains on, have your vehicle serviced at the

first available opportunity.

Light is blinking:

Engine misfire is occurring which could damage your catalytic converter.

You should drive in a moderate fashion (avoid heavy acceleration and

deceleration) and have your vehicle serviced at the first available

opportunity.

Under engine misfire conditions, excessive exhaust temperatures

could damage the catalytic converter, the fuel system, interior

floor coverings or other vehicle components, possibly causing a fire.

Check fuel cap

Momentarily illuminates when the

ignition is turned to the ON position

to ensure your bulb is working.

When this light turns on, check the

fuel filler cap. Continuing to operate

the vehicle with the check fuel cap light on, can activate theService

Engine Soon/Check Enginewarning light. When the fuel filler cap is

properly re-installed, the light(s) will turn off after a period of normal

driving. This period will vary depending on driving conditions.

It may take a long period of time for the system to detect an

improperly installed fuel filler cap.

For more information, refer toFuel filler capin theMaintenance and

carechapter.

CHECK

FUEL

CAP

Instrumentation

11

Page 13 of 256

Turn signal

Illuminates when the left or right

turn signal or the hazard lights are

turned on. If one or both of the

indicators stay on continuously or

flash faster, check for a burned-out

turn signal bulb. Refer toBulbsin theMaintenance and carechapter.

High beams

Illuminates when the high beam

headlamps are turned on.

Anti-theft system (if equipped)

Refer toSecuriLockypassive

anti-theft systemin theControls

and featureschapter.

Charging system

Illuminates when the ignition is

turned to the ON position and the

engine is off. The light also

illuminates when the battery is not

charging properly, requiring

electrical system service.

Check gage

Illuminates when the engine coolant

temperature is high, the engine oil

pressure is low or the fuel gauge is

at or near empty. The ignition must

be in the ON position for this lamp to illuminate. The lamp will also stay

illuminated after the ignition is turned to the ON position. Refer to

Engine coolant temperature gauge, Engine oil pressure gaugeor

Fuel gaugein this chapter for more information.

THEFT

CHECK

GAGE

Instrumentation

13

Page 17 of 256

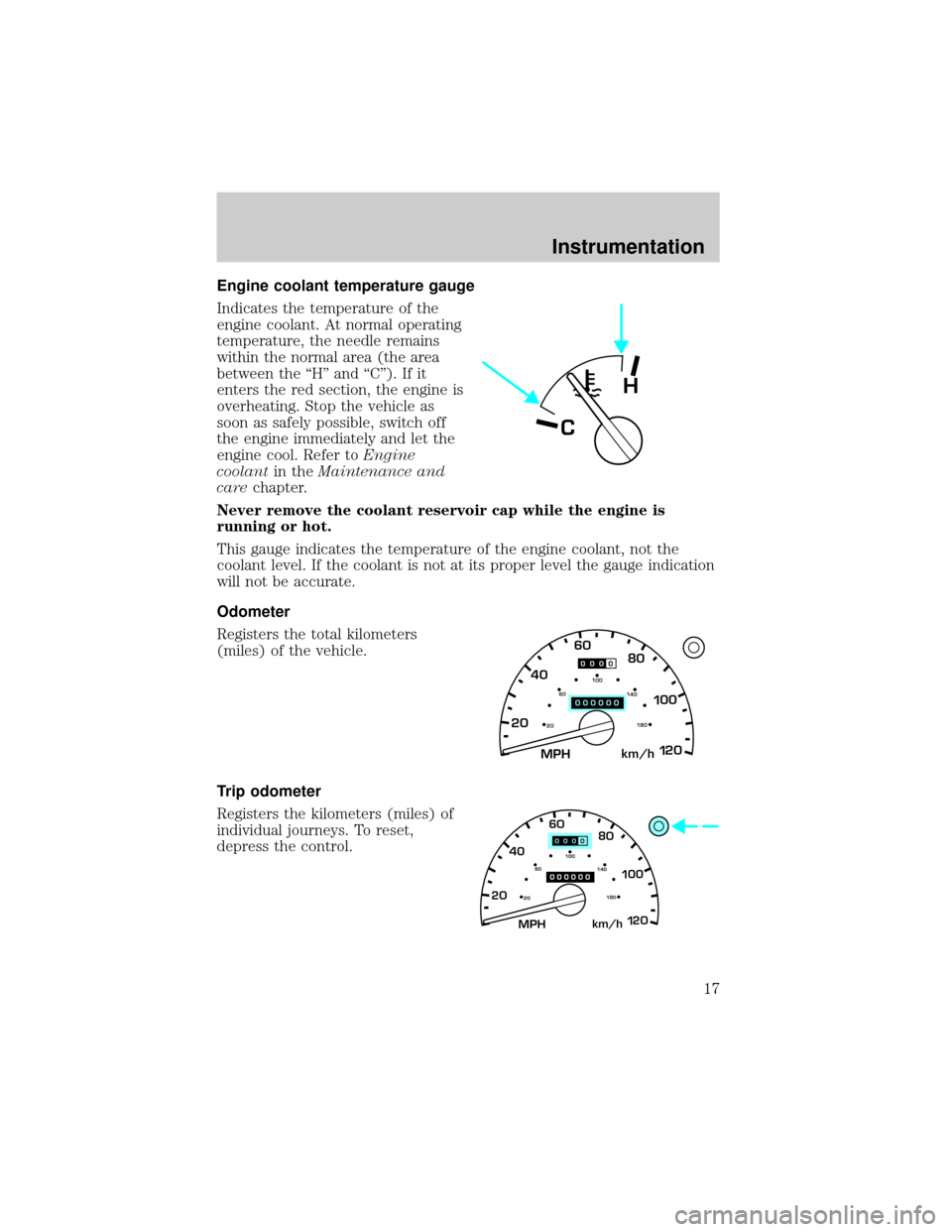

Engine coolant temperature gauge

Indicates the temperature of the

engine coolant. At normal operating

temperature, the needle remains

within the normal area (the area

between the ªHº and ªCº). If it

enters the red section, the engine is

overheating. Stop the vehicle as

soon as safely possible, switch off

the engine immediately and let the

engine cool. Refer toEngine

coolantin theMaintenance and

carechapter.

Never remove the coolant reservoir cap while the engine is

running or hot.

This gauge indicates the temperature of the engine coolant, not the

coolant level. If the coolant is not at its proper level the gauge indication

will not be accurate.

Odometer

Registers the total kilometers

(miles) of the vehicle.

Trip odometer

Registers the kilometers (miles) of

individual journeys. To reset,

depress the control.

C

H

MPH 2060

4080

km/h

00

1

20

160100

140

180

20

MPH 2060

4080

km/h

00

1

20

160100

140

180

20

Instrumentation

17

Page 18 of 256

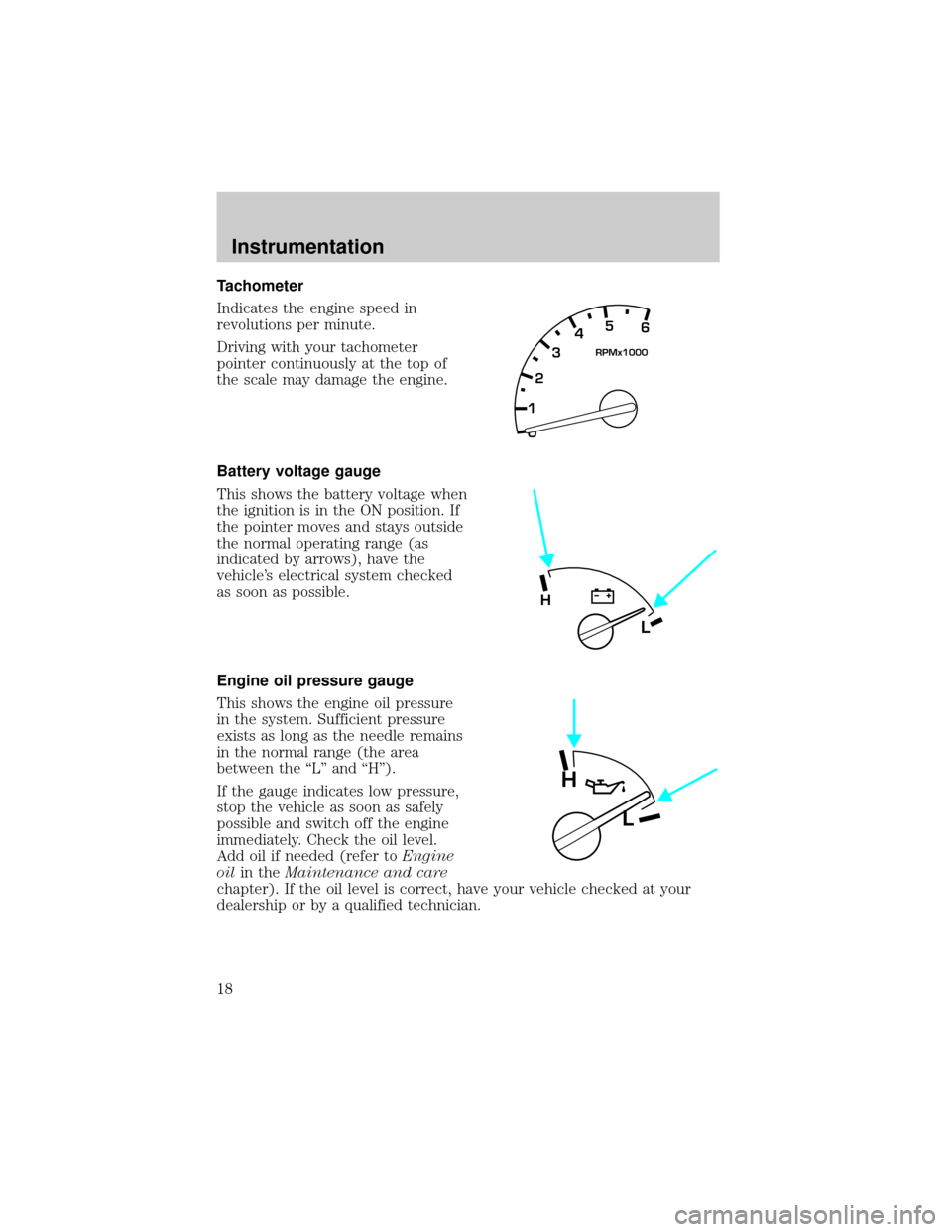

Tachometer

Indicates the engine speed in

revolutions per minute.

Driving with your tachometer

pointer continuously at the top of

the scale may damage the engine.

Battery voltage gauge

This shows the battery voltage when

the ignition is in the ON position. If

the pointer moves and stays outside

the normal operating range (as

indicated by arrows), have the

vehicle's electrical system checked

as soon as possible.

Engine oil pressure gauge

This shows the engine oil pressure

in the system. Sufficient pressure

exists as long as the needle remains

in the normal range (the area

between the ªLº and ªHº).

If the gauge indicates low pressure,

stop the vehicle as soon as safely

possible and switch off the engine

immediately. Check the oil level.

Add oil if needed (refer toEngine

oilin theMaintenance and care

chapter). If the oil level is correct, have your vehicle checked at your

dealership or by a qualified technician.

0 12345

6

RPMx1000

L

H

H

L

Instrumentation

18

Page 102 of 256

6. Within seven seconds of the safety belt warning light turning off,

buckle then unbuckle the safety belt.

²This will disable Belt Minder if it is currently enabled, or enable Belt

Minder if it is currently disabled.

7. Confirmation of disabling Belt Minder is provided by the safety belt

warning light flashing four times per second for three seconds.

8. Confirmation of enabling Belt Minder is provided by:

²The safety belt warning light flashing four times per second for three

seconds.

²Followed by three seconds with the safety belt warning light off.

²Once again, the safety belt warning light will flash four times per

second for three seconds.

9. After receiving confirmation, the deactivation/activation procedure is

complete.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, tears or cuts. Replace if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), shoulder belt guide on seatback (if

equipped), child safety seat tether bracket assemblies (if equipped),

LATCH child seat tether anchors and lower anchors (if equipped), and

attaching hardware, should be inspected after a collision. Ford

recommends that all safety belt assemblies used in vehicles involved in a

collision be replaced. However, if the collision was minor and a qualified

technician finds that the belts do not show damage and continue to

operate properly, they do not need to be replaced. Safety belt assemblies

not in use during a collision should also be inspected and replaced if

either damage or improper operation is noted.

Failure to inspect and if necessary replace the safety belt

assembly under the above conditions could result in severe

personal injuries in the event of a collision.

Refer toCleaning and maintaining the safety beltsin the

Maintenacne and Caresection.

Seating and safety restraints

102

Page 108 of 256

Several air bag system components get hot after inflation. Do not

touch them after inflation.

If the air bag has deployed,the air bag will not function

again and must be replaced immediately.If the air bag is not

replaced, the unrepaired area will increase the risk of injury in a

collision.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after

ignition is turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and/or light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a collision.

Seating and safety restraints

108

Page 111 of 256

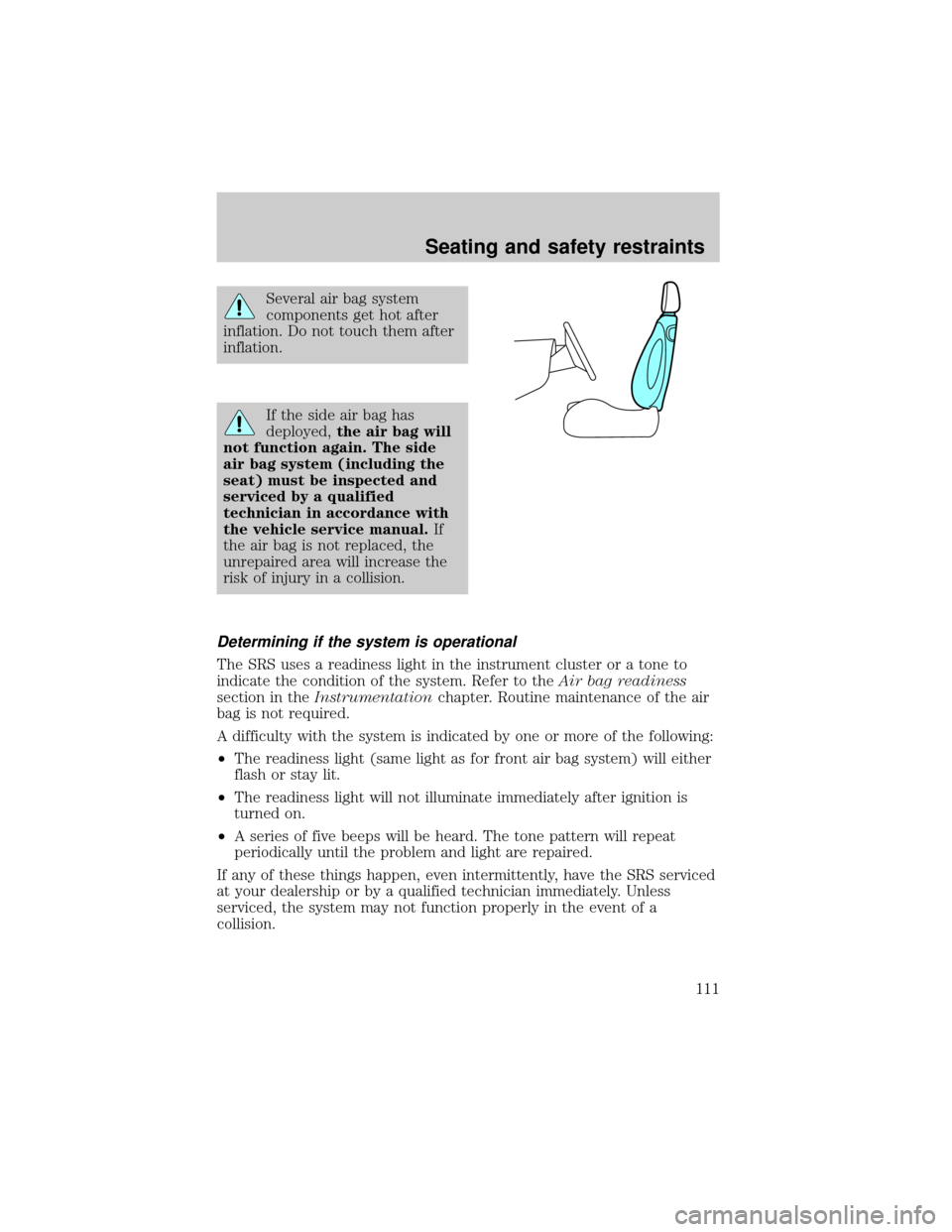

Several air bag system

components get hot after

inflation. Do not touch them after

inflation.

If the side air bag has

deployed,the air bag will

not function again. The side

air bag system (including the

seat) must be inspected and

serviced by a qualified

technician in accordance with

the vehicle service manual.If

the air bag is not replaced, the

unrepaired area will increase the

risk of injury in a collision.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light (same light as for front air bag system) will either

flash or stay lit.

²The readiness light will not illuminate immediately after ignition is

turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a

collision.

Seating and safety restraints

111

Page 125 of 256

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Four-wheel anti-lock brake system (ABS)

This vehicle is equipped with an anti-lock braking system (ABS). A noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. If the vehicle has continuous vibration or shudder

in the steering wheel while braking, the vehicle should be inspected by a

qualified service technician.

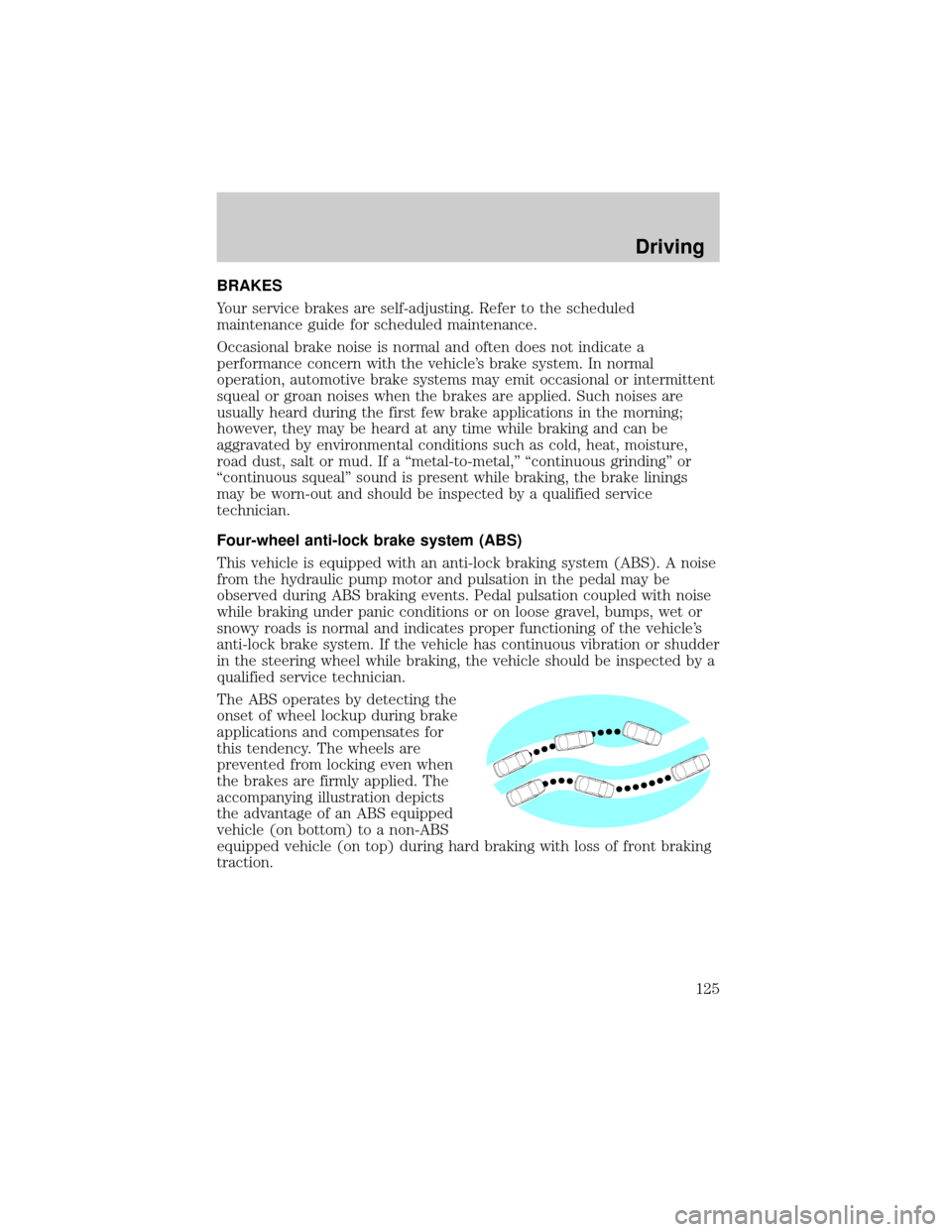

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

125

Page 144 of 256

²Thoroughly prepare your vehicle for towing. Refer toPreparing to

towin this chapter.

²Use extra caution when driving while trailer towing. Refer toDriving

while you towin this chapter.

²Service your vehicle more frequently if you tow a trailer. Refer to the

severe duty schedule in the scheduled maintenance guide.

²Do not tow a trailer until your vehicle has been driven at least 800 km

(500 miles).

²Refer to the instructions included with towing accessories for the

proper installation and adjustment specifications.

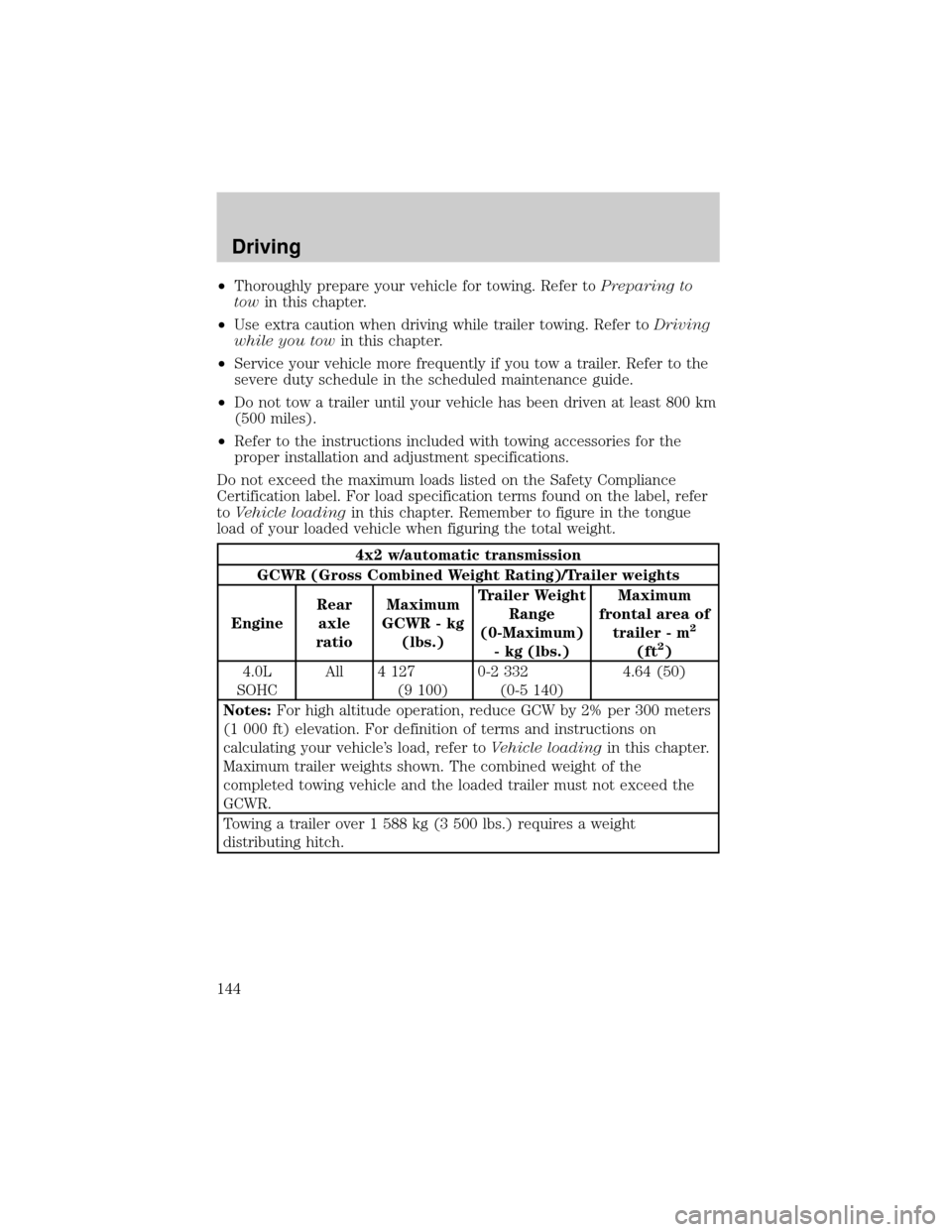

Do not exceed the maximum loads listed on the Safety Compliance

Certification label. For load specification terms found on the label, refer

toVehicle loadingin this chapter. Remember to figure in the tongue

load of your loaded vehicle when figuring the total weight.

4x2 w/automatic transmission

GCWR (Gross Combined Weight Rating)/Trailer weights

EngineRear

axle

ratioMaximum

GCWR - kg

(lbs.)Trailer Weight

Range

(0-Maximum)

- kg (lbs.)Maximum

frontal area of

trailer - m

2

(ft2)

4.0L

SOHCAll 4 127

(9 100)0-2 332

(0-5 140)4.64 (50)

Notes:For high altitude operation, reduce GCW by 2% per 300 meters

(1 000 ft) elevation. For definition of terms and instructions on

calculating your vehicle's load, refer toVehicle loadingin this chapter.

Maximum trailer weights shown. The combined weight of the

completed towing vehicle and the loaded trailer must not exceed the

GCWR.

Towing a trailer over 1 588 kg (3 500 lbs.) requires a weight

distributing hitch.

Driving

144