lock FORD F-250 2019 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2019, Model line: F-250, Model: FORD F-250 2019Pages: 666, PDF Size: 13.6 MB

Page 375 of 666

section. Blocked or plugged holes or

removal/modification of the system

could result in elevated exhaust gas

temperatures which may result in

vehicle/property damage or personal

injury.

WARNING: The normal operating

temperature of the exhaust system is

very high. Never work around or attempt

to repair any part of the exhaust system

until it has cooled. Use special care when

working around the diesel oxidation

catalytic converter and/or the diesel

particulate filter (DPF). The diesel

oxidation catalytic converter and/or the

DPF heats up to a high temperature after

only a short period of engine operation

and can stay hot even after the engine

is turned off. Failure to follow these

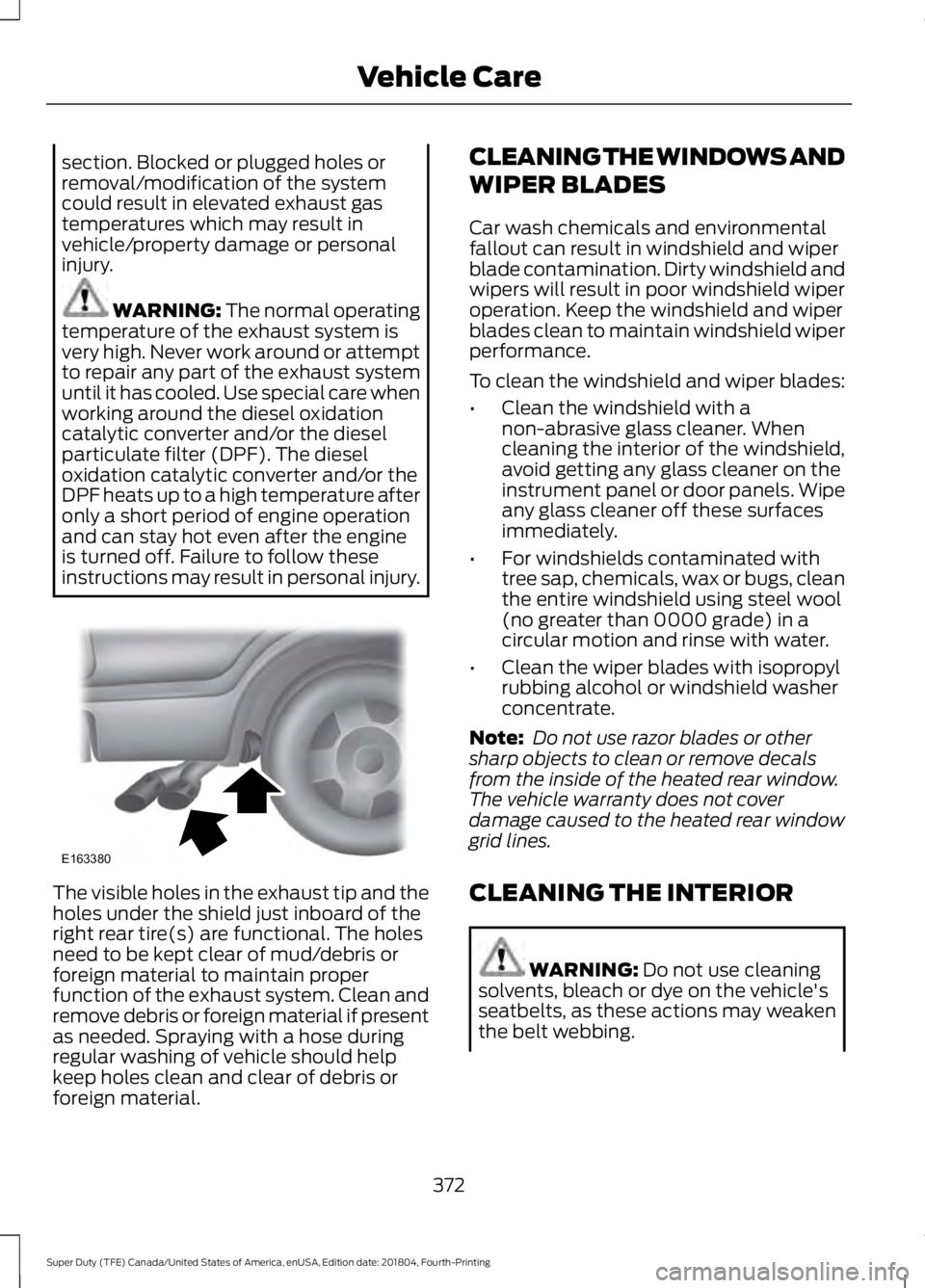

instructions may result in personal injury. The visible holes in the exhaust tip and the

holes under the shield just inboard of the

right rear tire(s) are functional. The holes

need to be kept clear of mud/debris or

foreign material to maintain proper

function of the exhaust system. Clean and

remove debris or foreign material if present

as needed. Spraying with a hose during

regular washing of vehicle should help

keep holes clean and clear of debris or

foreign material. CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmental

fallout can result in windshield and wiper

blade contamination. Dirty windshield and

wipers will result in poor windshield wiper

operation. Keep the windshield and wiper

blades clean to maintain windshield wiper

performance.

To clean the windshield and wiper blades:

•

Clean the windshield with a

non-abrasive glass cleaner. When

cleaning the interior of the windshield,

avoid getting any glass cleaner on the

instrument panel or door panels. Wipe

any glass cleaner off these surfaces

immediately.

• For windshields contaminated with

tree sap, chemicals, wax or bugs, clean

the entire windshield using steel wool

(no greater than 0000 grade) in a

circular motion and rinse with water.

• Clean the wiper blades with isopropyl

rubbing alcohol or windshield washer

concentrate.

Note: Do not use razor blades or other

sharp objects to clean or remove decals

from the inside of the heated rear window.

The vehicle warranty does not cover

damage caused to the heated rear window

grid lines.

CLEANING THE INTERIOR WARNING:

Do not use cleaning

solvents, bleach or dye on the vehicle's

seatbelts, as these actions may weaken

the belt webbing.

372

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Vehicle CareE163380

Page 406 of 666

•

To reduce the chances of interference

from another vehicle, perform the

system reset procedure at least 3 ft

(1 m) away from another Ford Motor

Company vehicle undergoing the

system reset procedure at the same

time.

• Do not wait more than two minutes

between resetting each tire sensor or

the system can time-out and you have

to repeat the entire procedure on all

four wheels.

• A double horn sounds indicating the

need to repeat the procedure.

Performing the System Reset Procedure

- Single Rear Wheel

Read the entire procedure before

attempting.

1. Drive the vehicle above

20 mph

(32 km/h) for at least two minutes,

then park in a safe location where you

can easily get to all four tires and have

access to an air pump.

2. Place the ignition in the off position and

keep the key in the ignition.

3. Cycle the ignition to the on position with the engine off.

4. Turn the hazard flashers on then off three times. You must accomplish this

within 10 seconds. If you successfully

enter the reset mode, the horn sounds

once, the system indicator flashes and

a message shows in the information

display. If this does not occur, please

try again starting at step 2. If after

repeated attempts to enter the reset

mode, the horn does not sound, the

system indicator does not flash and no

message shows in the information

display, seek service from your

authorized dealer. 5. Train the tire pressure monitoring

system sensors in the tires using the

following system reset sequence

starting with the left front tire in the

following clockwise order: Left front -

driver side front tire, Right front -

passenger side front tire, Right rear -

passenger side rear tire, Left rear -

driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds.

Note: The single horn tone confirms that

the sensor identification code has been

learned by the module for this position. If a

double horn is heard, the reset procedure

was unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease

the air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver

side rear tire, the system indicator

stops flashing, and a message shows

in the information display.

10. Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

403

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Wheels and Tires

Page 411 of 666

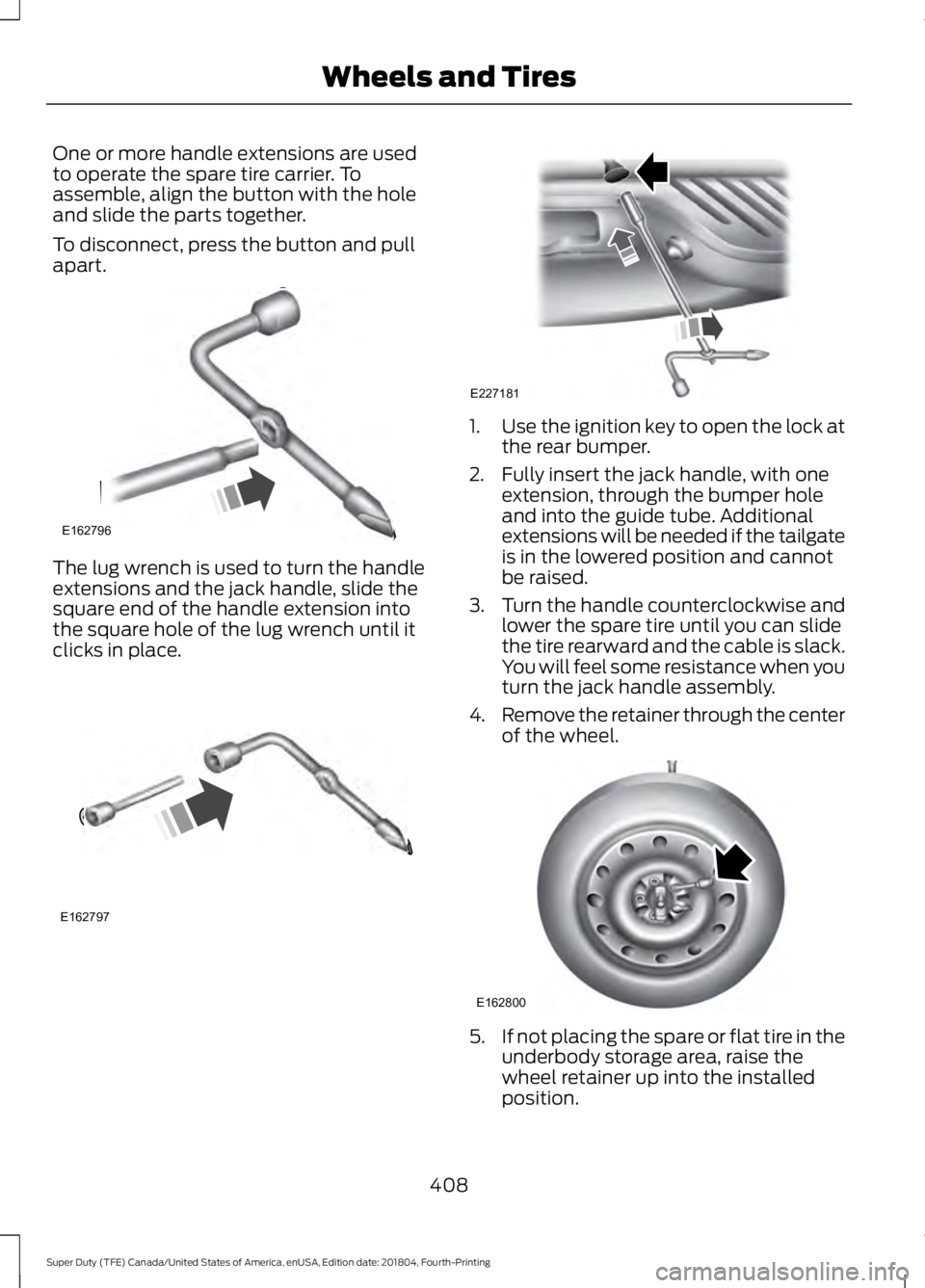

One or more handle extensions are used

to operate the spare tire carrier. To

assemble, align the button with the hole

and slide the parts together.

To disconnect, press the button and pull

apart.

The lug wrench is used to turn the handle

extensions and the jack handle, slide the

square end of the handle extension into

the square hole of the lug wrench until it

clicks in place. 1.

Use the ignition key to open the lock at

the rear bumper.

2. Fully insert the jack handle, with one extension, through the bumper hole

and into the guide tube. Additional

extensions will be needed if the tailgate

is in the lowered position and cannot

be raised.

3. Turn the handle counterclockwise and

lower the spare tire until you can slide

the tire rearward and the cable is slack.

You will feel some resistance when you

turn the jack handle assembly.

4. Remove the retainer through the center

of the wheel. 5.

If not placing the spare or flat tire in the

underbody storage area, raise the

wheel retainer up into the installed

position.

408

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Wheels and TiresE162796 E162797 E227181 E162800

Page 412 of 666

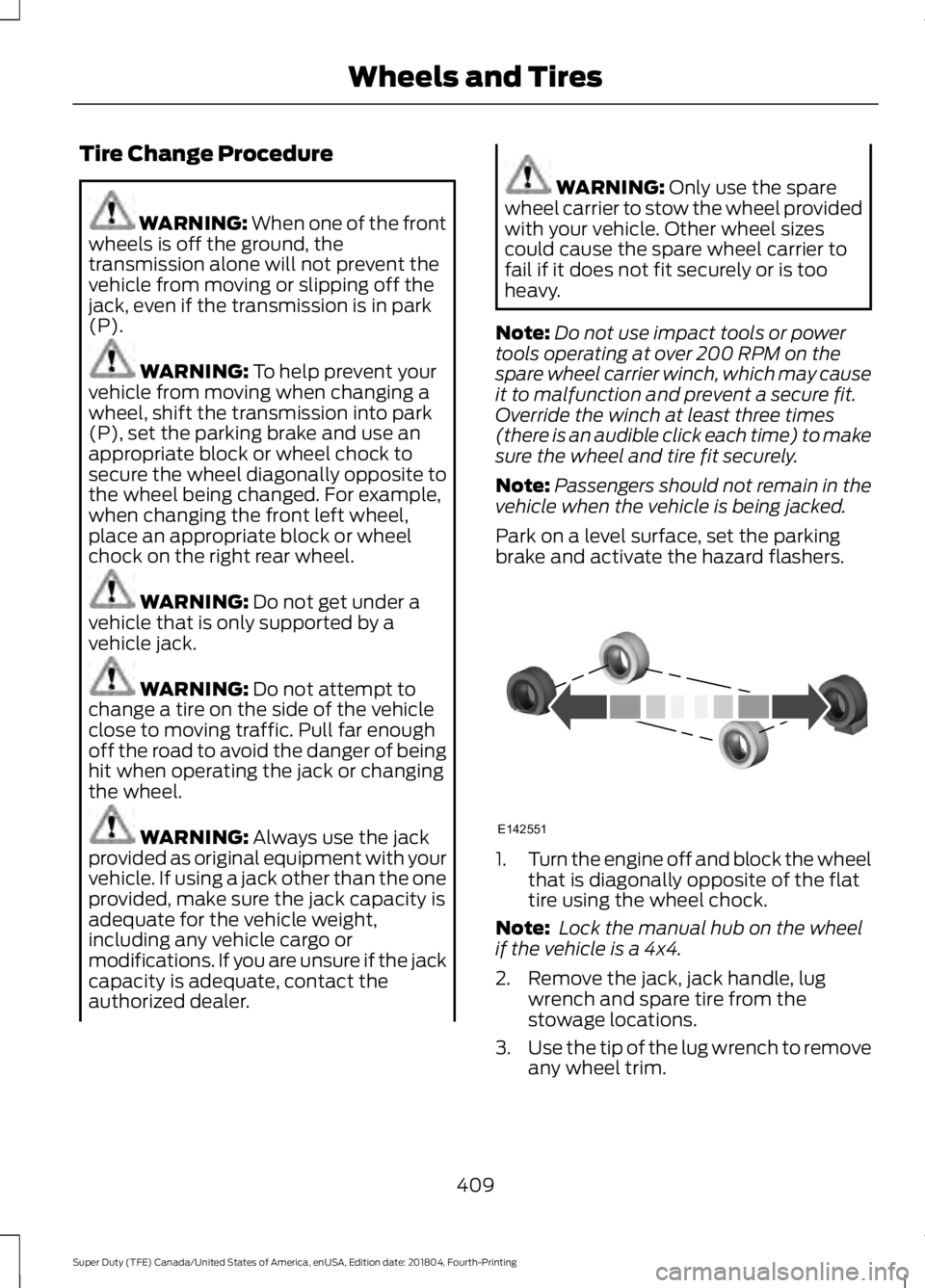

Tire Change Procedure

WARNING: When one of the front

wheels is off the ground, the

transmission alone will not prevent the

vehicle from moving or slipping off the

jack, even if the transmission is in park

(P). WARNING:

To help prevent your

vehicle from moving when changing a

wheel, shift the transmission into park

(P), set the parking brake and use an

appropriate block or wheel chock to

secure the wheel diagonally opposite to

the wheel being changed. For example,

when changing the front left wheel,

place an appropriate block or wheel

chock on the right rear wheel. WARNING:

Do not get under a

vehicle that is only supported by a

vehicle jack. WARNING:

Do not attempt to

change a tire on the side of the vehicle

close to moving traffic. Pull far enough

off the road to avoid the danger of being

hit when operating the jack or changing

the wheel. WARNING:

Always use the jack

provided as original equipment with your

vehicle. If using a jack other than the one

provided, make sure the jack capacity is

adequate for the vehicle weight,

including any vehicle cargo or

modifications. If you are unsure if the jack

capacity is adequate, contact the

authorized dealer. WARNING:

Only use the spare

wheel carrier to stow the wheel provided

with your vehicle. Other wheel sizes

could cause the spare wheel carrier to

fail if it does not fit securely or is too

heavy.

Note: Do not use impact tools or power

tools operating at over 200 RPM on the

spare wheel carrier winch, which may cause

it to malfunction and prevent a secure fit.

Override the winch at least three times

(there is an audible click each time) to make

sure the wheel and tire fit securely.

Note: Passengers should not remain in the

vehicle when the vehicle is being jacked.

Park on a level surface, set the parking

brake and activate the hazard flashers. 1.

Turn the engine off and block the wheel

that is diagonally opposite of the flat

tire using the wheel chock.

Note: Lock the manual hub on the wheel

if the vehicle is a 4x4.

2. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

3. Use the tip of the lug wrench to remove

any wheel trim.

409

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Wheels and TiresE142551

Page 413 of 666

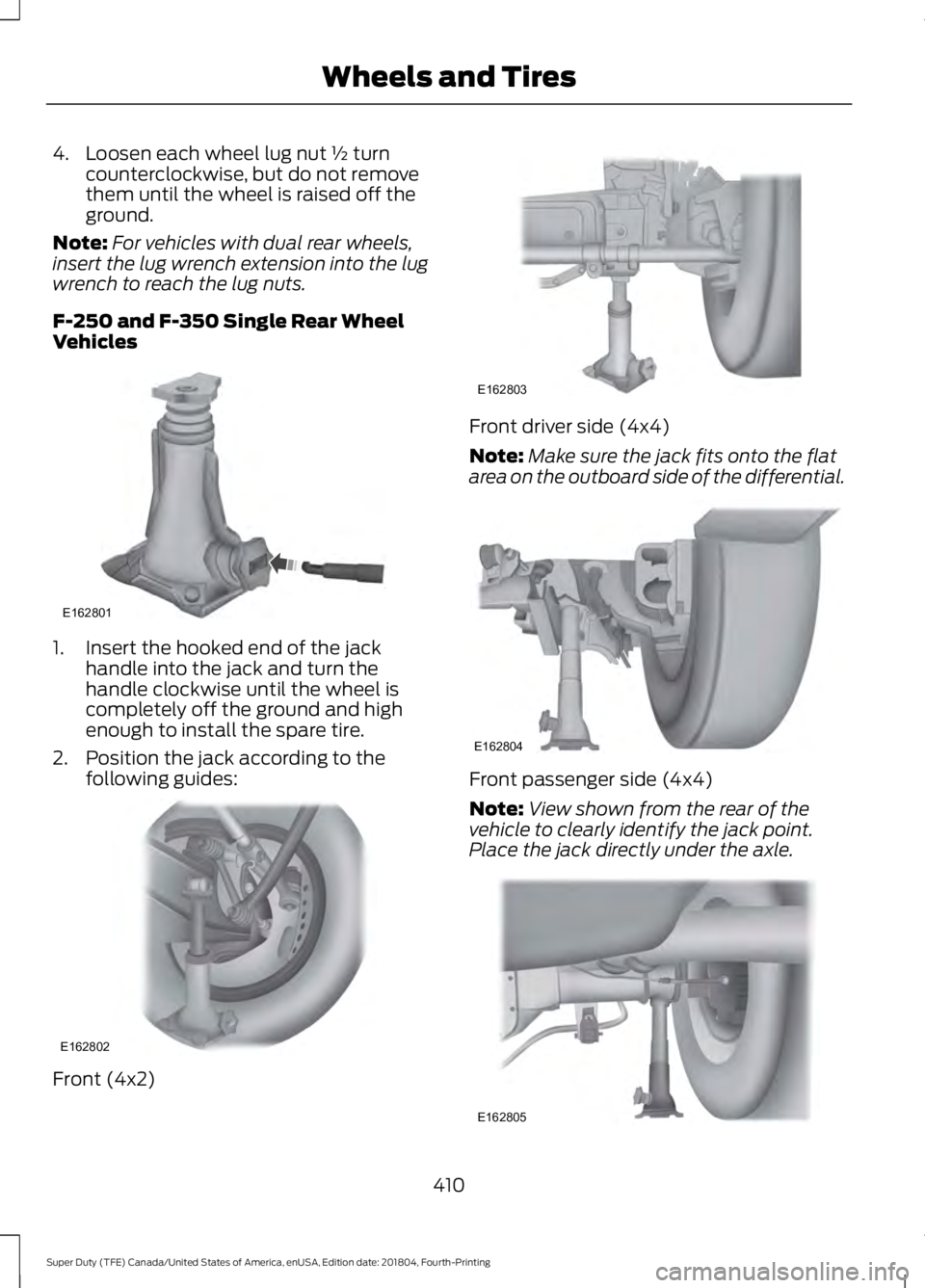

4. Loosen each wheel lug nut ½ turn

counterclockwise, but do not remove

them until the wheel is raised off the

ground.

Note: For vehicles with dual rear wheels,

insert the lug wrench extension into the lug

wrench to reach the lug nuts.

F-250 and F-350 Single Rear Wheel

Vehicles 1. Insert the hooked end of the jack

handle into the jack and turn the

handle clockwise until the wheel is

completely off the ground and high

enough to install the spare tire.

2. Position the jack according to the following guides: Front (4x2) Front driver side (4x4)

Note:

Make sure the jack fits onto the flat

area on the outboard side of the differential. Front passenger side (4x4)

Note:

View shown from the rear of the

vehicle to clearly identify the jack point.

Place the jack directly under the axle. 410

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Wheels and TiresE162801 E162802 E162803 E162804 E162805

Page 414 of 666

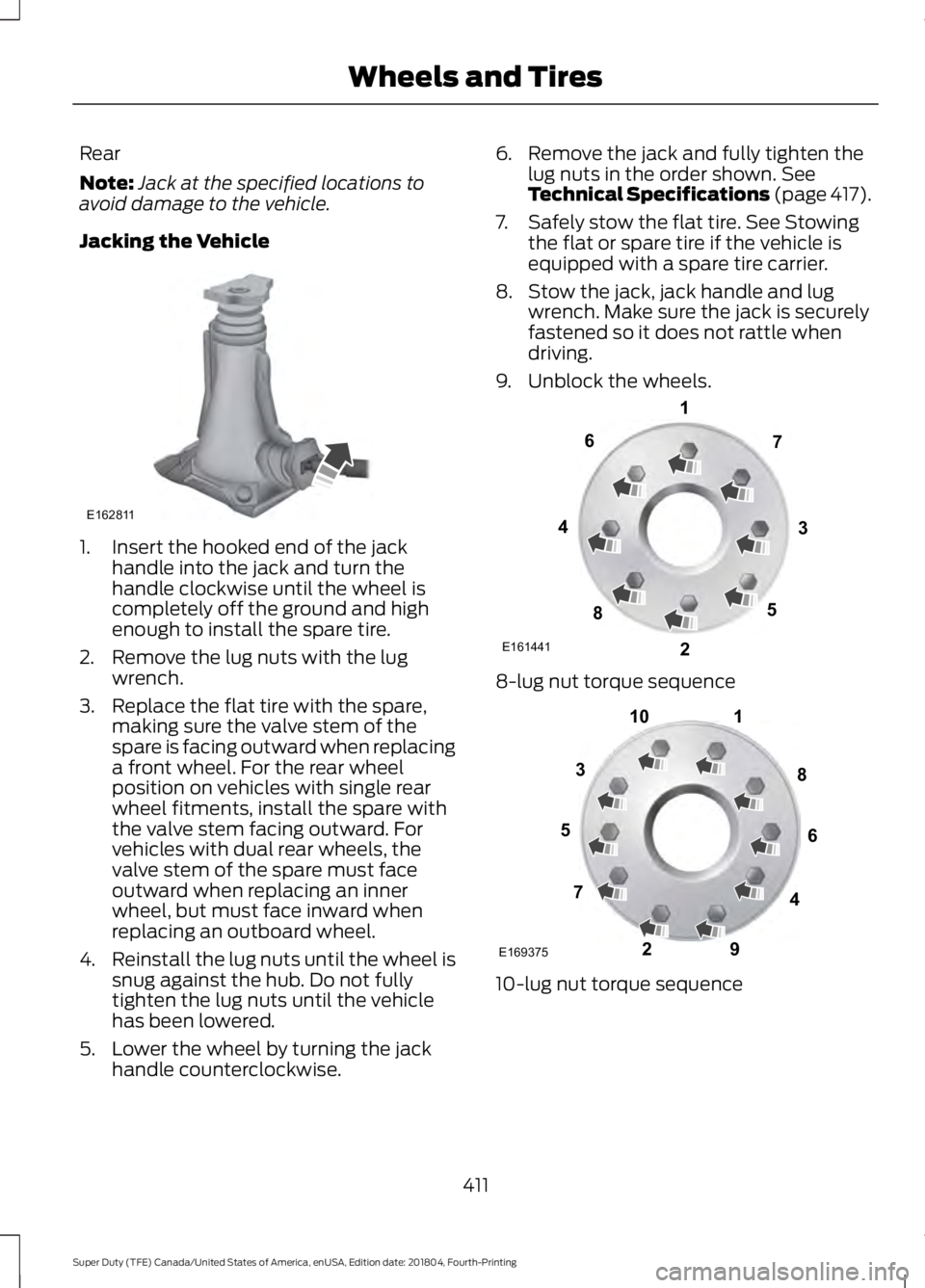

Rear

Note:

Jack at the specified locations to

avoid damage to the vehicle.

Jacking the Vehicle 1. Insert the hooked end of the jack

handle into the jack and turn the

handle clockwise until the wheel is

completely off the ground and high

enough to install the spare tire.

2. Remove the lug nuts with the lug wrench.

3. Replace the flat tire with the spare, making sure the valve stem of the

spare is facing outward when replacing

a front wheel. For the rear wheel

position on vehicles with single rear

wheel fitments, install the spare with

the valve stem facing outward. For

vehicles with dual rear wheels, the

valve stem of the spare must face

outward when replacing an inner

wheel, but must face inward when

replacing an outboard wheel.

4. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully

tighten the lug nuts until the vehicle

has been lowered.

5. Lower the wheel by turning the jack handle counterclockwise. 6. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page 417).

7. Safely stow the flat tire. See Stowing the flat or spare tire if the vehicle is

equipped with a spare tire carrier.

8. Stow the jack, jack handle and lug wrench. Make sure the jack is securely

fastened so it does not rattle when

driving.

9. Unblock the wheels. 8-lug nut torque sequence

10-lug nut torque sequence

411

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Wheels and TiresE162811 E161441

13

4

27

6

5

8 1

2

3

4

5

6

7 8

9

10

E169375

Page 415 of 666

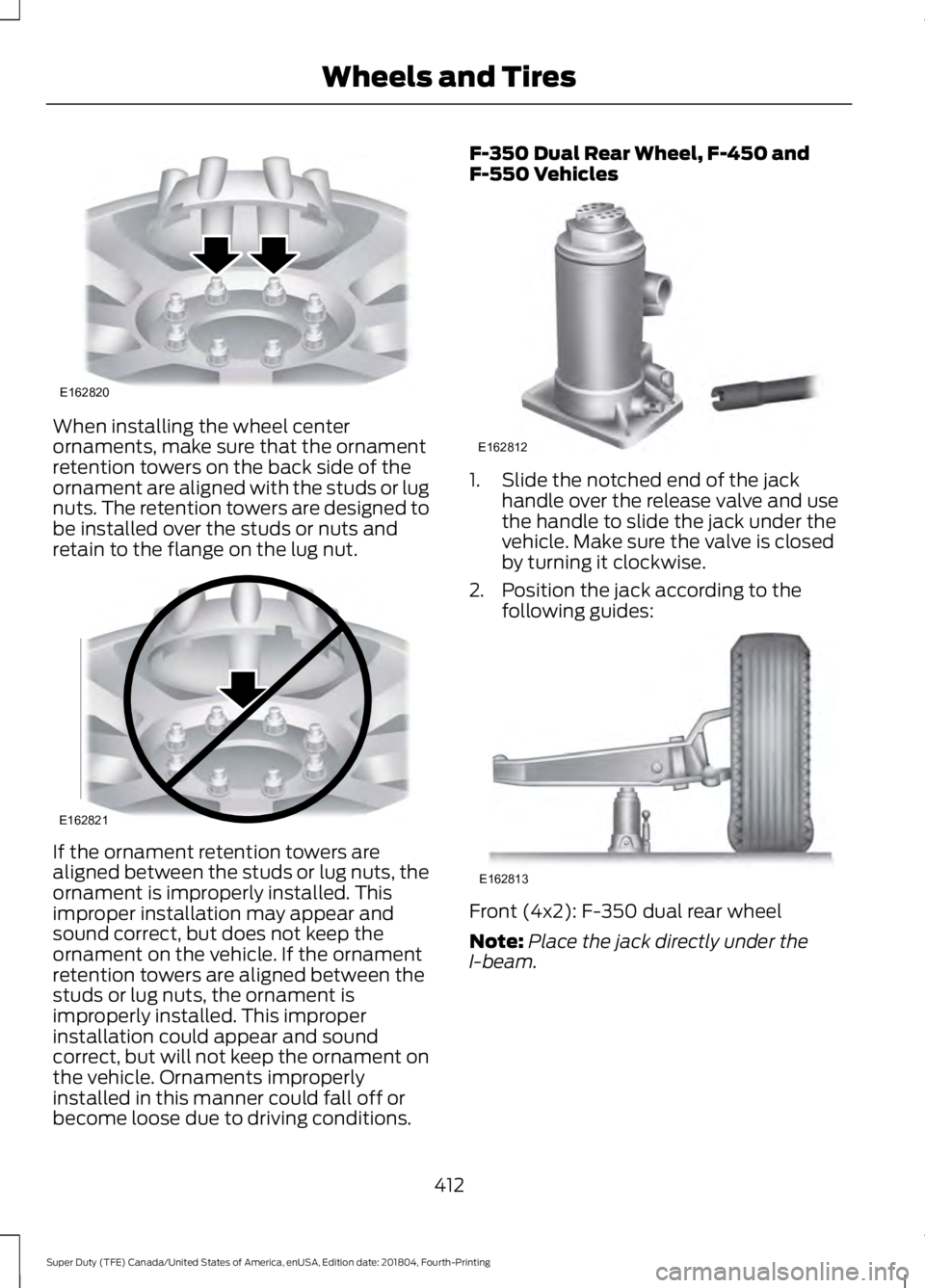

When installing the wheel center

ornaments, make sure that the ornament

retention towers on the back side of the

ornament are aligned with the studs or lug

nuts. The retention towers are designed to

be installed over the studs or nuts and

retain to the flange on the lug nut.

If the ornament retention towers are

aligned between the studs or lug nuts, the

ornament is improperly installed. This

improper installation may appear and

sound correct, but does not keep the

ornament on the vehicle. If the ornament

retention towers are aligned between the

studs or lug nuts, the ornament is

improperly installed. This improper

installation could appear and sound

correct, but will not keep the ornament on

the vehicle. Ornaments improperly

installed in this manner could fall off or

become loose due to driving conditions. F-350 Dual Rear Wheel, F-450 and

F-550 Vehicles

1. Slide the notched end of the jack

handle over the release valve and use

the handle to slide the jack under the

vehicle. Make sure the valve is closed

by turning it clockwise.

2. Position the jack according to the following guides: Front (4x2): F-350 dual rear wheel

Note:

Place the jack directly under the

I-beam.

412

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Wheels and TiresE162820 E162821 E162812 E162813

Page 417 of 666

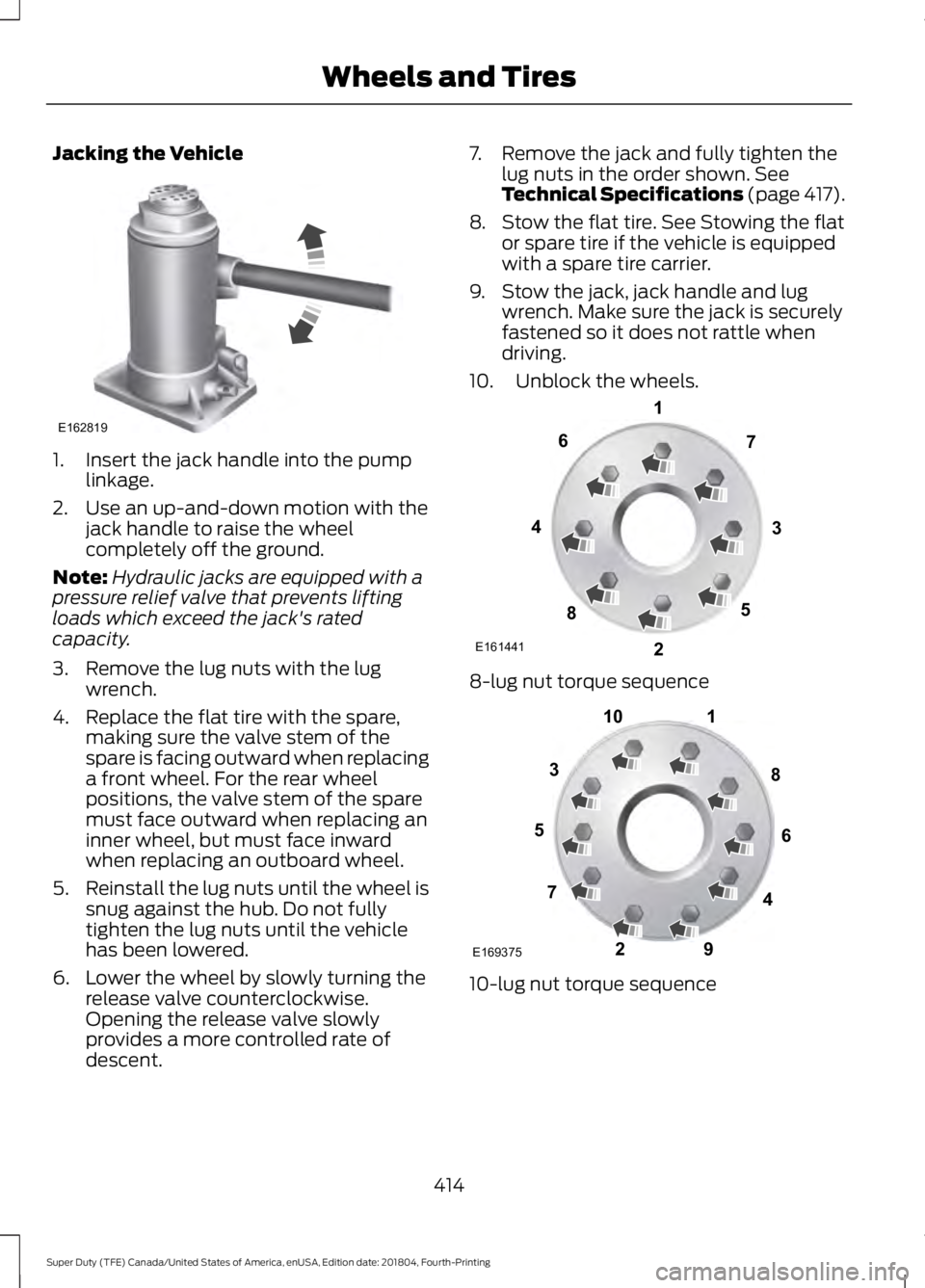

Jacking the Vehicle

1. Insert the jack handle into the pump

linkage.

2. Use an up-and-down motion with the jack handle to raise the wheel

completely off the ground.

Note: Hydraulic jacks are equipped with a

pressure relief valve that prevents lifting

loads which exceed the jack's rated

capacity.

3. Remove the lug nuts with the lug wrench.

4. Replace the flat tire with the spare, making sure the valve stem of the

spare is facing outward when replacing

a front wheel. For the rear wheel

positions, the valve stem of the spare

must face outward when replacing an

inner wheel, but must face inward

when replacing an outboard wheel.

5. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully

tighten the lug nuts until the vehicle

has been lowered.

6. Lower the wheel by slowly turning the release valve counterclockwise.

Opening the release valve slowly

provides a more controlled rate of

descent. 7. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page 417).

8. Stow the flat tire. See Stowing the flat or spare tire if the vehicle is equipped

with a spare tire carrier.

9. Stow the jack, jack handle and lug wrench. Make sure the jack is securely

fastened so it does not rattle when

driving.

10. Unblock the wheels. 8-lug nut torque sequence

10-lug nut torque sequence

414

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Wheels and TiresE162819 E161441

13

4

27

6

5

8 1

2

3

4

5

6

7 8

9

10

E169375

Page 419 of 666

2. Lay the tire on the ground with the

valve stem facing up.

3. Slide the wheel partially under the vehicle and install the retainer through

the wheel center. Pull on the cable to

align the components at the end of the

cable.

4. Turn the jack handle clockwise until the tire is raised to its stowed position

underneath the vehicle. The effort to

turn the jack handle increases

significantly and the spare tire carrier

ratchets or slips when the tire is raised to the maximum tightness. Tighten to

the best of your ability, to the point

where the ratchet/slip occurs, if

possible. The spare tire carrier does not

allow you to overtighten. If the spare

tire carrier ratchets or slips with little

effort, take the vehicle to your

authorized dealer for assistance at your

earliest convenience.

5. Check that the tire lies flat against the frame and is properly tightened. Try to

push or pull, then turn the tire to be

sure it does not move. Loosen and

retighten, if necessary. Failure to

properly stow the spare tire may result

in failure of the winch cable and loss

of the tire.

6. Repeat this tightness check procedure

when servicing the spare tire pressure,

every six months, per scheduled

maintenance information, or at any

time that the spare tire is disturbed

through service of other components.

416

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Wheels and TiresE162800

Page 429 of 666

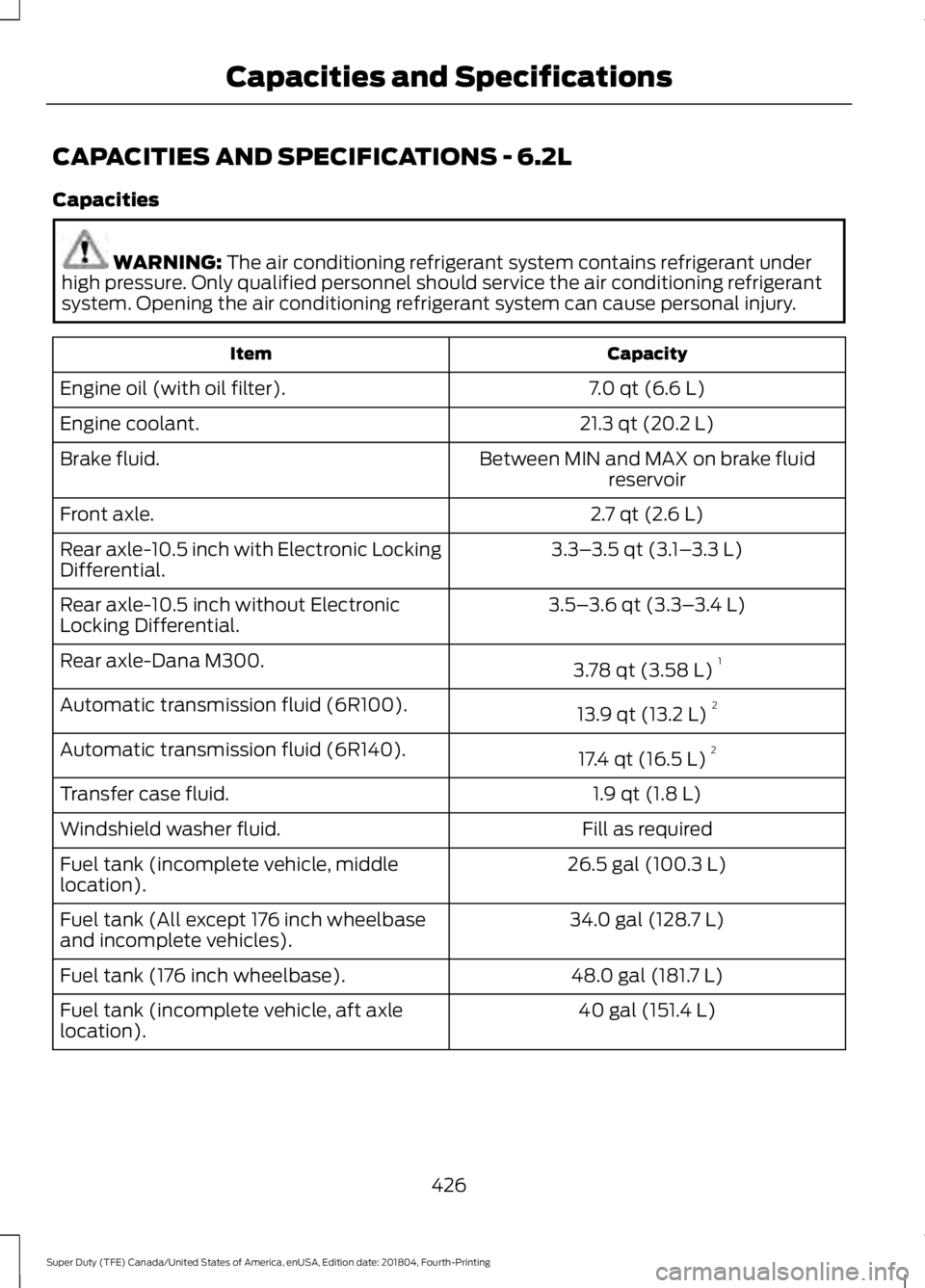

CAPACITIES AND SPECIFICATIONS - 6.2L

Capacities

WARNING: The air conditioning refrigerant system contains refrigerant under

high pressure. Only qualified personnel should service the air conditioning refrigerant

system. Opening the air conditioning refrigerant system can cause personal injury. Capacity

Item

7.0 qt (6.6 L)

Engine oil (with oil filter).

21.3 qt (20.2 L)

Engine coolant.

Between MIN and MAX on brake fluidreservoir

Brake fluid.

2.7 qt (2.6 L)

Front axle.

3.3–3.5 qt (3.1– 3.3 L)

Rear axle-10.5 inch with Electronic Locking

Differential.

3.5–3.6 qt (3.3– 3.4 L)

Rear axle-10.5 inch without Electronic

Locking Differential.

3.78 qt (3.58 L)1

Rear axle-Dana M300.

13.9 qt (13.2 L)2

Automatic transmission fluid (6R100).

17.4 qt (16.5 L)2

Automatic transmission fluid (6R140).

1.9 qt (1.8 L)

Transfer case fluid.

Fill as required

Windshield washer fluid.

26.5 gal (100.3 L)

Fuel tank (incomplete vehicle, middle

location).

34.0 gal (128.7 L)

Fuel tank (All except 176 inch wheelbase

and incomplete vehicles).

48.0 gal (181.7 L)

Fuel tank (176 inch wheelbase).

40 gal (151.4 L)

Fuel tank (incomplete vehicle, aft axle

location).

426

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201804, Fourth-Printing Capacities and Specifications