lock FORD F-350 2018 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2018, Model line: F-350, Model: FORD F-350 2018Pages: 660, PDF Size: 11.64 MB

Page 416 of 660

Rear

Note:

Jack at the specified locations to

avoid damage to the vehicle.

Jacking the Vehicle 1. Turn the jack handle clockwise until

the wheel is completely off the ground

and high enough to install the spare

tire.

2. Remove the lug nuts with the lug wrench.

3. Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward for all front wheels and single

rear wheel vehicles. If you are replacing

an inboard rear tire on dual rear wheel

vehicles, the valve stem must be facing

outward. If you are replacing the

outboard wheel, the valve stem must

be facing inward. Reinstall the lug nuts

until the wheel is snug against the hub.

Do not fully tighten the lug nuts until

the wheel has been lowered.

4. Lower the wheel by turning the jack handle counterclockwise.

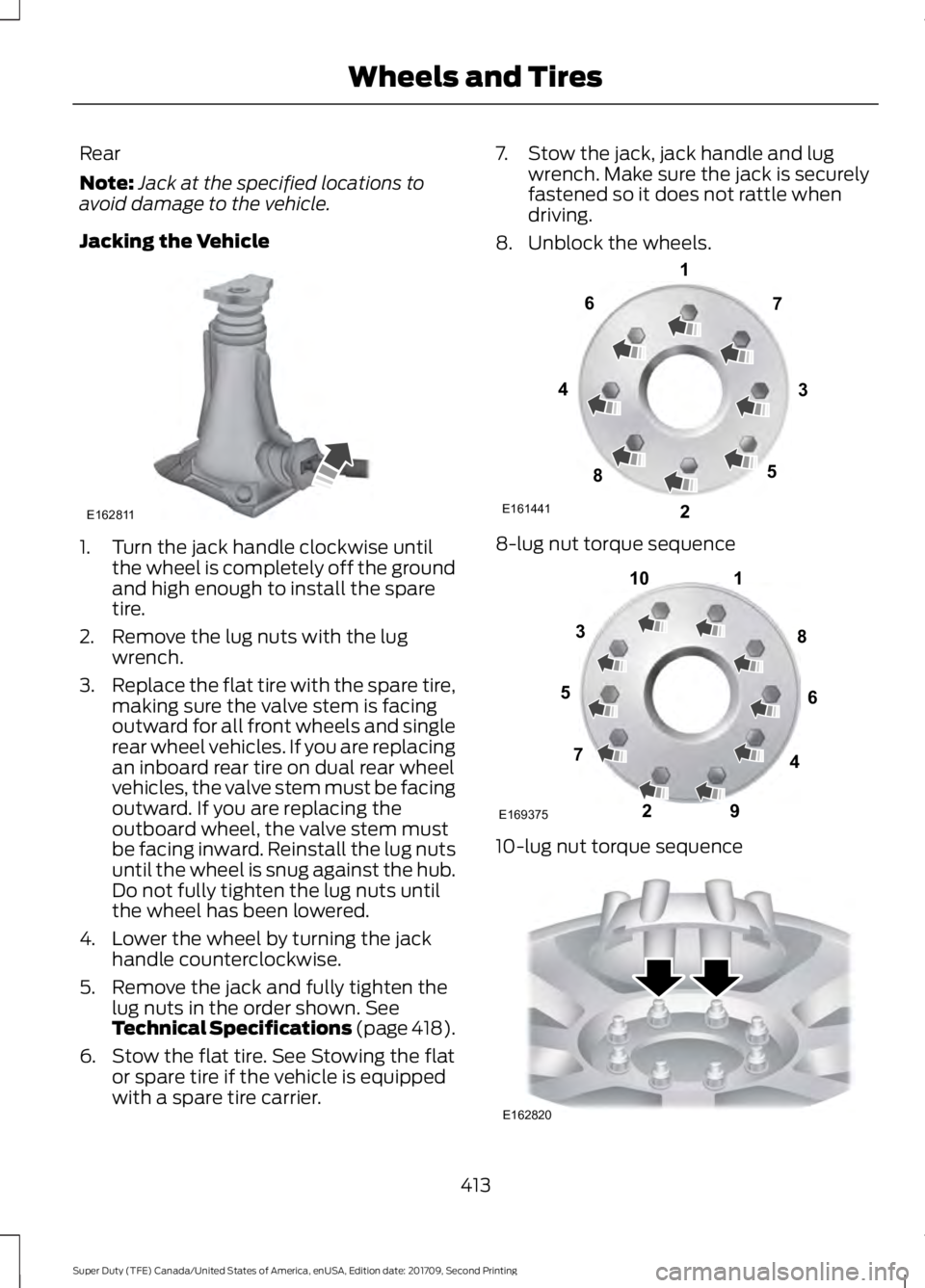

5. Remove the jack and fully tighten the lug nuts in the order shown. See

Technical Specifications (page 418).

6. Stow the flat tire. See Stowing the flat or spare tire if the vehicle is equipped

with a spare tire carrier. 7. Stow the jack, jack handle and lug

wrench. Make sure the jack is securely

fastened so it does not rattle when

driving.

8. Unblock the wheels. 8-lug nut torque sequence

10-lug nut torque sequence

413

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Wheels and TiresE162811 E161441

13

4

27

6

5

8 1

2

3

4

5

6

7 8

9

10

E169375 E162820

Page 417 of 660

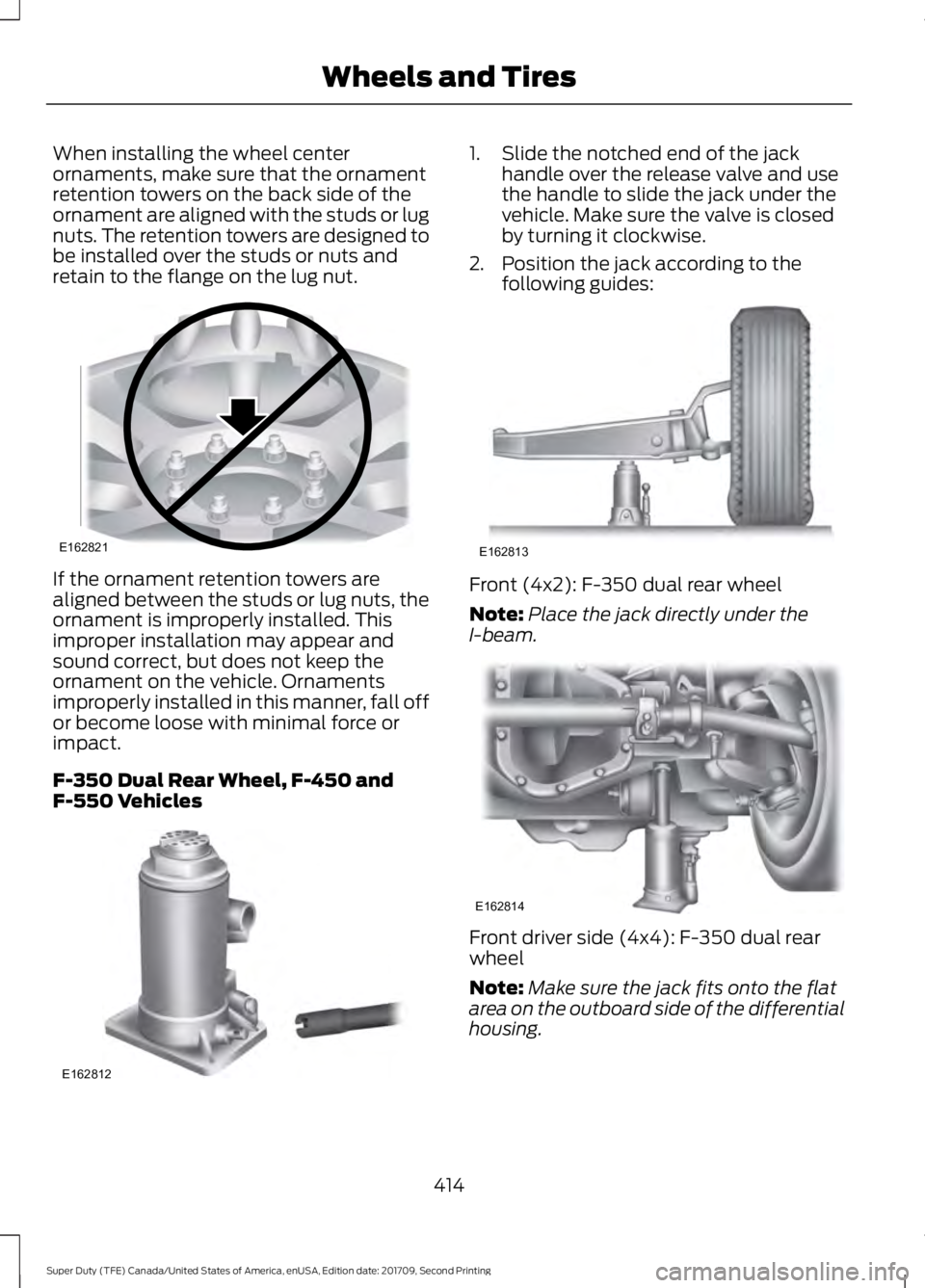

When installing the wheel center

ornaments, make sure that the ornament

retention towers on the back side of the

ornament are aligned with the studs or lug

nuts. The retention towers are designed to

be installed over the studs or nuts and

retain to the flange on the lug nut.

If the ornament retention towers are

aligned between the studs or lug nuts, the

ornament is improperly installed. This

improper installation may appear and

sound correct, but does not keep the

ornament on the vehicle. Ornaments

improperly installed in this manner, fall off

or become loose with minimal force or

impact.

F-350 Dual Rear Wheel, F-450 and

F-550 Vehicles 1. Slide the notched end of the jack

handle over the release valve and use

the handle to slide the jack under the

vehicle. Make sure the valve is closed

by turning it clockwise.

2. Position the jack according to the following guides: Front (4x2): F-350 dual rear wheel

Note:

Place the jack directly under the

I-beam. Front driver side (4x4): F-350 dual rear

wheel

Note:

Make sure the jack fits onto the flat

area on the outboard side of the differential

housing.

414

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Wheels and TiresE162821 E162812 E162813 E162814

Page 419 of 660

2. Use an up-and-down motion with the

jack handle to raise the wheel

completely off the ground.

Note: Hydraulic jacks are equipped with a

pressure release valve that prevents lifting

loads which exceed the jack's rated

capacity.

3. Remove the lug nuts with the lug wrench.

4. Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward on all front an inboard rear

wheels. If you are replacing the

outboard wheel, the valve stem must

be facing inward. Reinstall the lug nuts

until the wheel is snug against the hub.

Do not fully tighten the lug nuts until

the wheel has been lowered.

5. Lower the wheel by slowly turning the release valve counterclockwise.

Opening the release valve slowly

provides a more controlled rate of

descent.

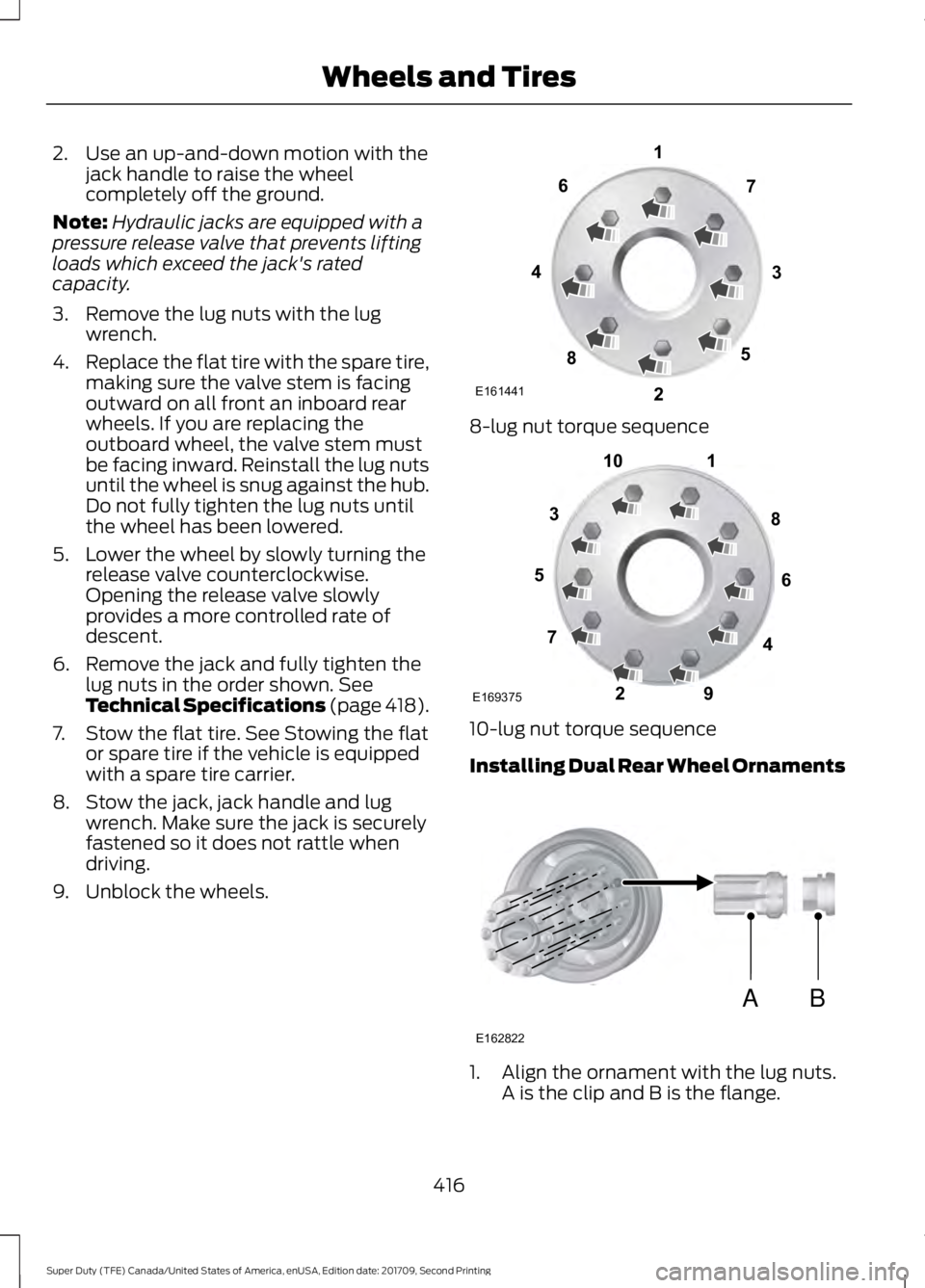

6. Remove the jack and fully tighten the lug nuts in the order shown. See

Technical Specifications (page 418).

7. Stow the flat tire. See Stowing the flat or spare tire if the vehicle is equipped

with a spare tire carrier.

8. Stow the jack, jack handle and lug wrench. Make sure the jack is securely

fastened so it does not rattle when

driving.

9. Unblock the wheels. 8-lug nut torque sequence

10-lug nut torque sequence

Installing Dual Rear Wheel Ornaments

1. Align the ornament with the lug nuts.

A is the clip and B is the flange.

416

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Wheels and TiresE161441

13

4

27

6

5

8 1

2

3

4

5

6

7 8

9

10

E169375 AB

E162822

Page 421 of 660

2. Lay the tire on the ground with the

valve stem facing up.

3. Slide the wheel partially under the vehicle and install the retainer through

the wheel center. Pull on the cable to

align the components at the end of the

cable.

4. Turn the jack handle clockwise until the tire is raised to its stowed position

underneath the vehicle. The effort to

turn the jack handle increases

significantly and the spare tire carrier

ratchets or slips when the tire is raised

to the maximum tightness. Tighten to

the best of your ability, to the point

where the ratchet/slip occurs, if

possible. The spare tire carrier does not

allow you to overtighten. If the spare

tire carrier ratchets or slips with little

effort, take the vehicle to your

authorized dealer for assistance at your

earliest convenience. 5. Check that the tire lies flat against the

frame and is properly tightened. Try to

push or pull, then turn the tire to be

sure it does not move. Loosen and

retighten, if necessary. Failure to

properly stow the spare tire may result

in failure of the winch cable and loss

of the tire.

6. Repeat this tightness check procedure

when servicing the spare tire pressure,

every six months, per scheduled

maintenance information, or at any

time that the spare tire is disturbed

through service of other components.

TECHNICAL SPECIFICATIONS

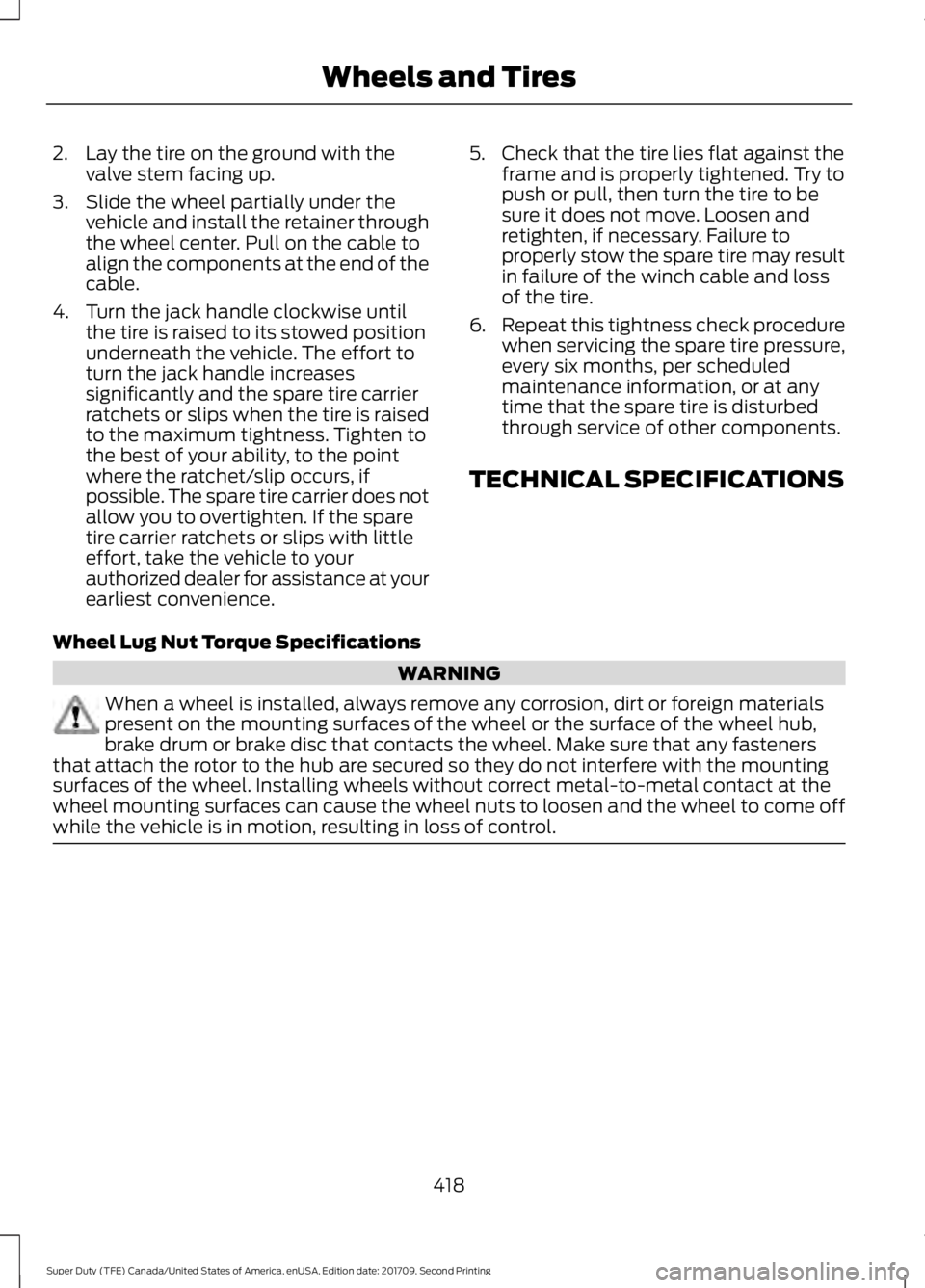

Wheel Lug Nut Torque Specifications WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign materials

present on the mounting surfaces of the wheel or the surface of the wheel hub,

brake drum or brake disc that contacts the wheel. Make sure that any fasteners

that attach the rotor to the hub are secured so they do not interfere with the mounting

surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off

while the vehicle is in motion, resulting in loss of control. 418

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Wheels and Tires

Page 430 of 660

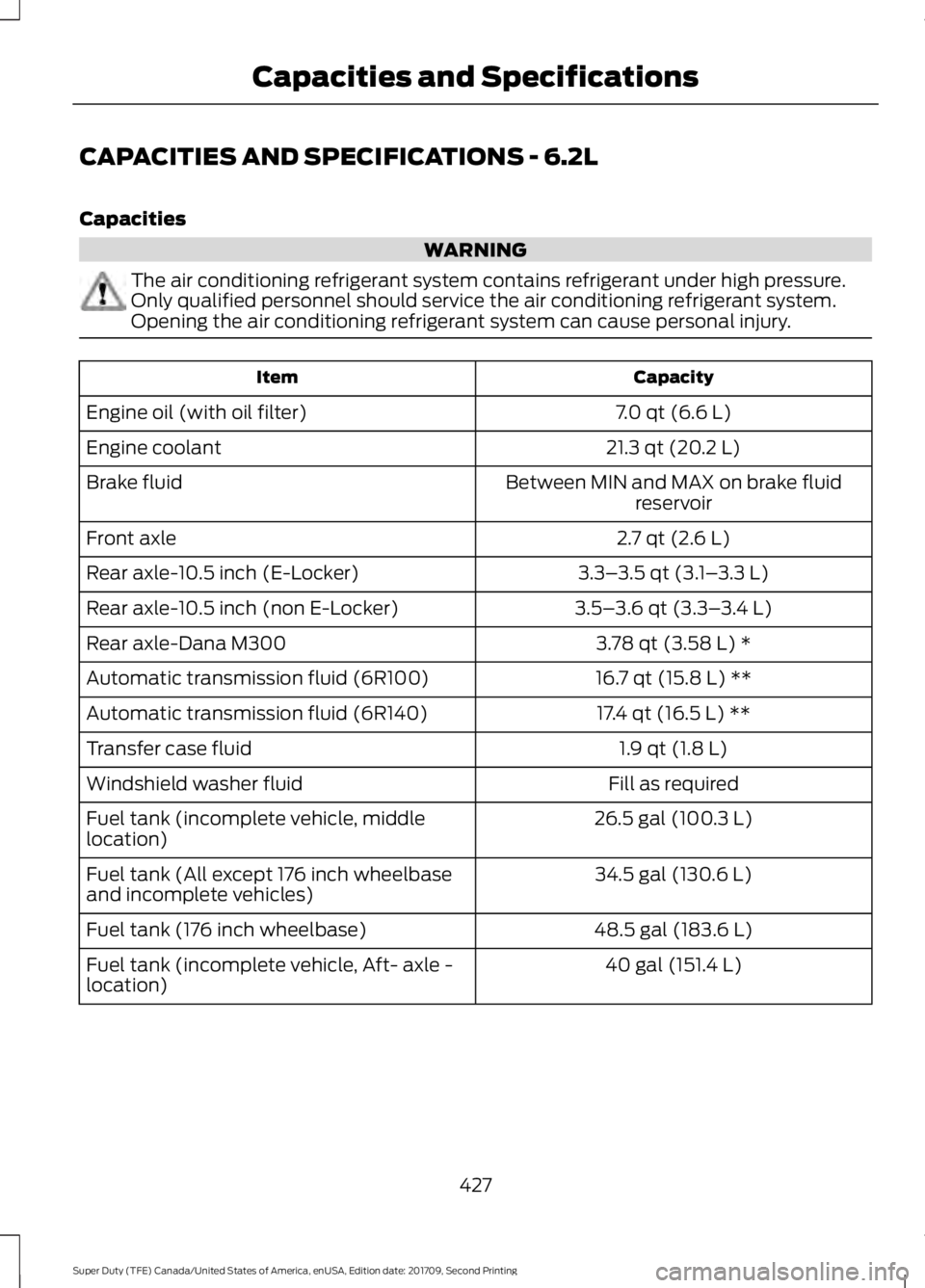

CAPACITIES AND SPECIFICATIONS - 6.2L

Capacities

WARNING

The air conditioning refrigerant system contains refrigerant under high pressure.

Only qualified personnel should service the air conditioning refrigerant system.

Opening the air conditioning refrigerant system can cause personal injury.

Capacity

Item

7.0 qt (6.6 L)

Engine oil (with oil filter)

21.3 qt (20.2 L)

Engine coolant

Between MIN and MAX on brake fluidreservoir

Brake fluid

2.7 qt (2.6 L)

Front axle

3.3–3.5 qt (3.1– 3.3 L)

Rear axle-10.5 inch (E-Locker)

3.5–3.6 qt (3.3– 3.4 L)

Rear axle-10.5 inch (non E-Locker)

3.78 qt (3.58 L) *

Rear axle-Dana M300

16.7 qt (15.8 L)

**

Automatic transmission fluid (6R100)

17.4 qt (16.5 L)

**

Automatic transmission fluid (6R140)

1.9 qt (1.8 L)

Transfer case fluid

Fill as required

Windshield washer fluid

26.5 gal (100.3 L)

Fuel tank (incomplete vehicle, middle

location)

34.5 gal (130.6 L)

Fuel tank (All except 176 inch wheelbase

and incomplete vehicles)

48.5 gal (183.6 L)

Fuel tank (176 inch wheelbase)

40 gal (151.4 L)

Fuel tank (incomplete vehicle, Aft- axle -

location)

427

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Capacities and Specifications

Page 432 of 660

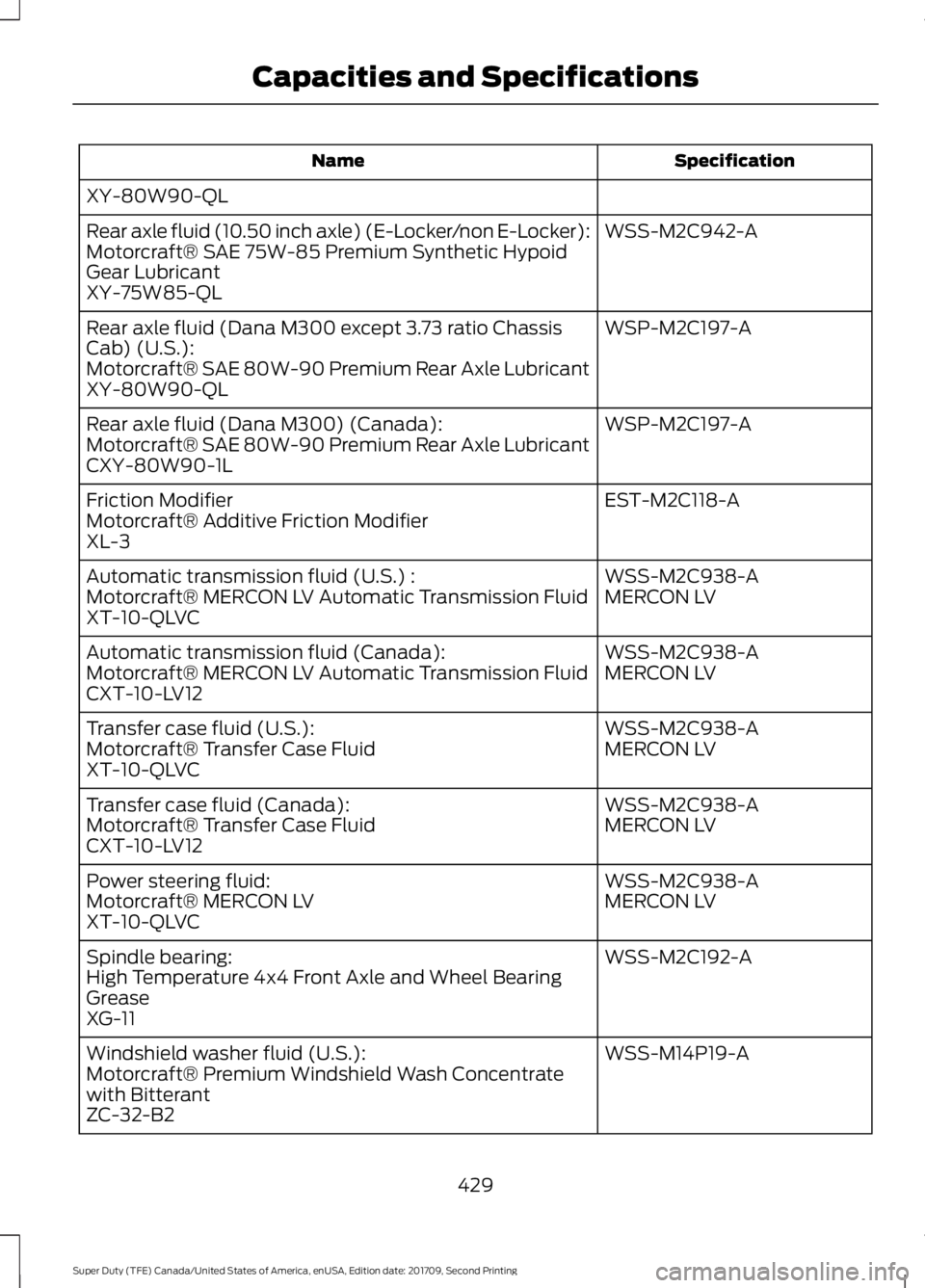

Specification

Name

XY-80W90-QL WSS-M2C942-A

Rear axle fluid (10.50 inch axle) (E-Locker/non E-Locker):

Motorcraft® SAE 75W-85 Premium Synthetic Hypoid

Gear Lubricant

XY-75W85-QL

WSP-M2C197-A

Rear axle fluid (Dana M300 except 3.73 ratio Chassis

Cab) (U.S.):

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

XY-80W90-QL

WSP-M2C197-A

Rear axle fluid (Dana M300) (Canada):

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

CXY-80W90-1L

EST-M2C118-A

Friction Modifier

Motorcraft® Additive Friction Modifier

XL-3

WSS-M2C938-A

Automatic transmission fluid (U.S.) :

MERCON LV

Motorcraft® MERCON LV Automatic Transmission Fluid

XT-10-QLVC

WSS-M2C938-A

Automatic transmission fluid (Canada):

MERCON LV

Motorcraft® MERCON LV Automatic Transmission Fluid

CXT-10-LV12

WSS-M2C938-A

Transfer case fluid (U.S.):

MERCON LV

Motorcraft® Transfer Case Fluid

XT-10-QLVC

WSS-M2C938-A

Transfer case fluid (Canada):

MERCON LV

Motorcraft® Transfer Case Fluid

CXT-10-LV12

WSS-M2C938-A

Power steering fluid:

MERCON LV

Motorcraft® MERCON LV

XT-10-QLVC

WSS-M2C192-A

Spindle bearing:

High Temperature 4x4 Front Axle and Wheel Bearing

Grease

XG-11

WSS-M14P19-A

Windshield washer fluid (U.S.):

Motorcraft® Premium Windshield Wash Concentrate

with Bitterant

ZC-32-B2

429

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Capacities and Specifications

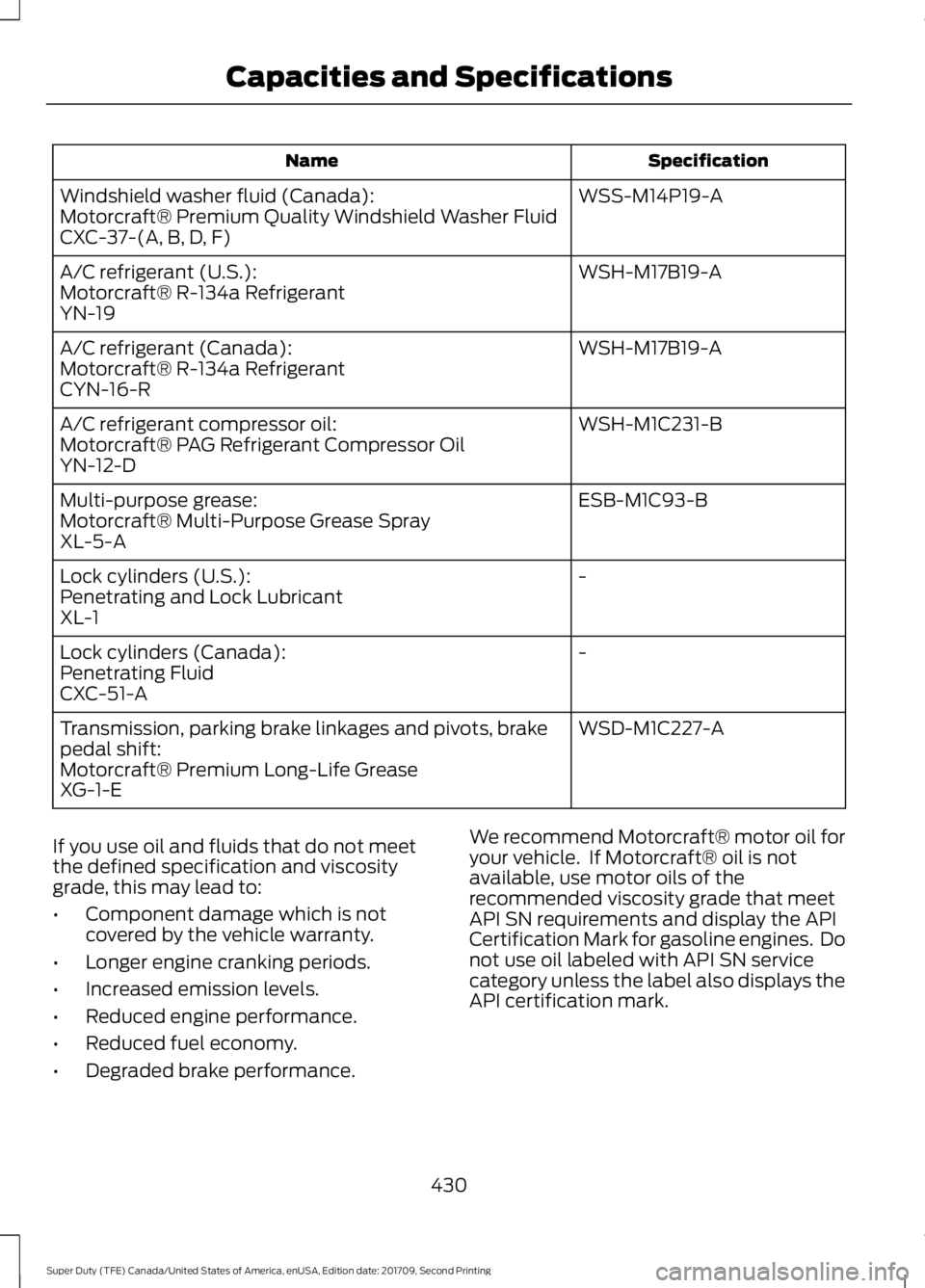

Page 433 of 660

Specification

Name

WSS-M14P19-A

Windshield washer fluid (Canada):

Motorcraft® Premium Quality Windshield Washer Fluid

CXC-37-(A, B, D, F)

WSH-M17B19-A

A/C refrigerant (U.S.):

Motorcraft® R-134a Refrigerant

YN-19

WSH-M17B19-A

A/C refrigerant (Canada):

Motorcraft® R-134a Refrigerant

CYN-16-R

WSH-M1C231-B

A/C refrigerant compressor oil:

Motorcraft® PAG Refrigerant Compressor Oil

YN-12-D

ESB-M1C93-B

Multi-purpose grease:

Motorcraft® Multi-Purpose Grease Spray

XL-5-A

-

Lock cylinders (U.S.):

Penetrating and Lock Lubricant

XL-1

-

Lock cylinders (Canada):

Penetrating Fluid

CXC-51-A

WSD-M1C227-A

Transmission, parking brake linkages and pivots, brake

pedal shift:

Motorcraft® Premium Long-Life Grease

XG-1-E

If you use oil and fluids that do not meet

the defined specification and viscosity

grade, this may lead to:

• Component damage which is not

covered by the vehicle warranty.

• Longer engine cranking periods.

• Increased emission levels.

• Reduced engine performance.

• Reduced fuel economy.

• Degraded brake performance. We recommend Motorcraft® motor oil for

your vehicle. If Motorcraft® oil is not

available, use motor oils of the

recommended viscosity grade that meet

API SN requirements and display the API

Certification Mark for gasoline engines. Do

not use oil labeled with API SN service

category unless the label also displays the

API certification mark.

430

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Capacities and Specifications

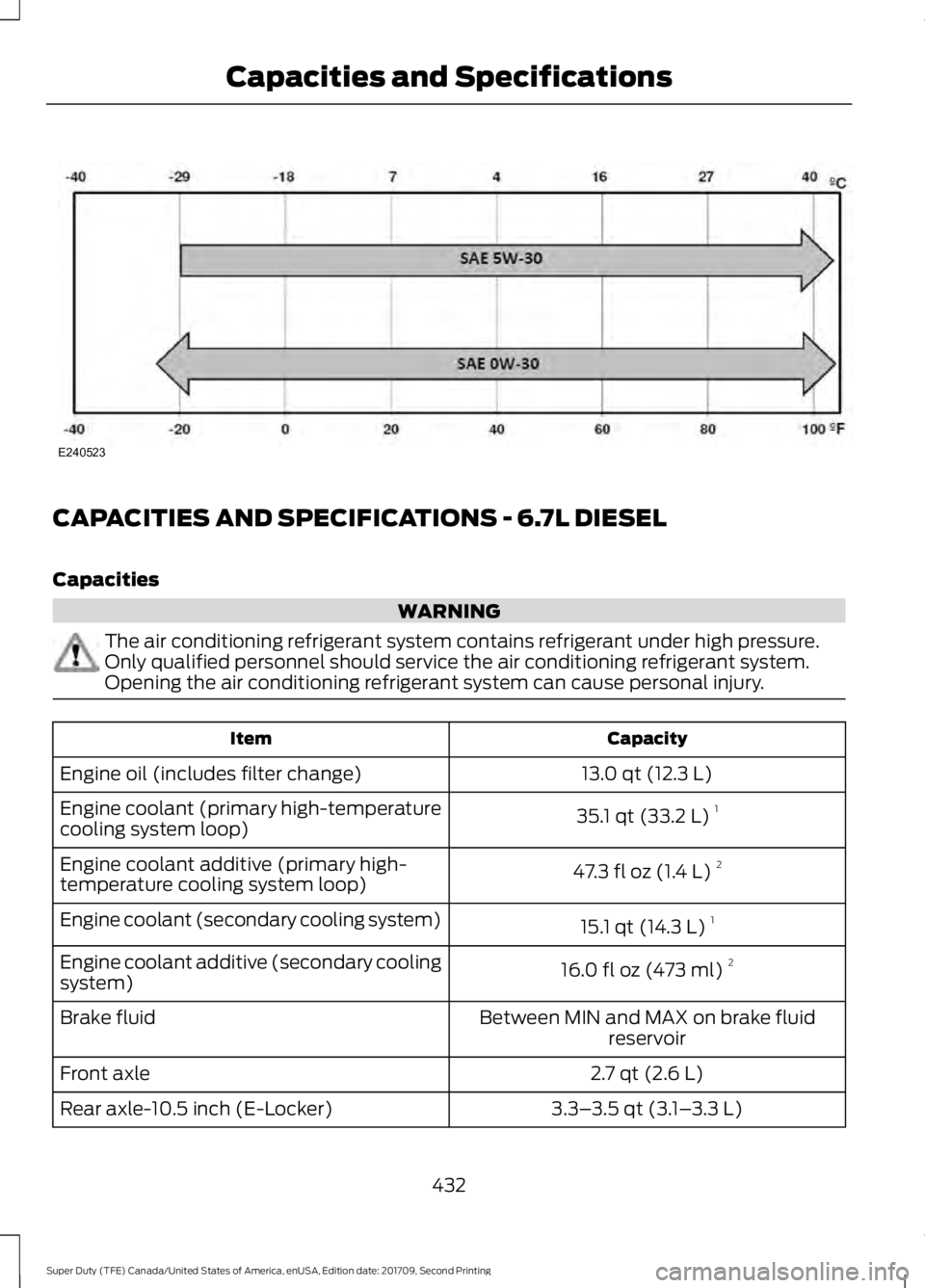

Page 435 of 660

CAPACITIES AND SPECIFICATIONS - 6.7L DIESEL

Capacities

WARNING

The air conditioning refrigerant system contains refrigerant under high pressure.

Only qualified personnel should service the air conditioning refrigerant system.

Opening the air conditioning refrigerant system can cause personal injury.

Capacity

Item

13.0 qt (12.3 L)

Engine oil (includes filter change)

35.1 qt (33.2 L)1

Engine coolant (primary high-temperature

cooling system loop)

47.3 fl oz (1.4 L)2

Engine coolant additive (primary high-

temperature cooling system loop)

15.1 qt (14.3 L)1

Engine coolant (secondary cooling system)

16.0 fl oz (473 ml)2

Engine coolant additive (secondary cooling

system)

Between MIN and MAX on brake fluidreservoir

Brake fluid

2.7 qt (2.6 L)

Front axle

3.3–3.5 qt (3.1– 3.3 L)

Rear axle-10.5 inch (E-Locker)

432

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Capacities and SpecificationsE240523

Page 436 of 660

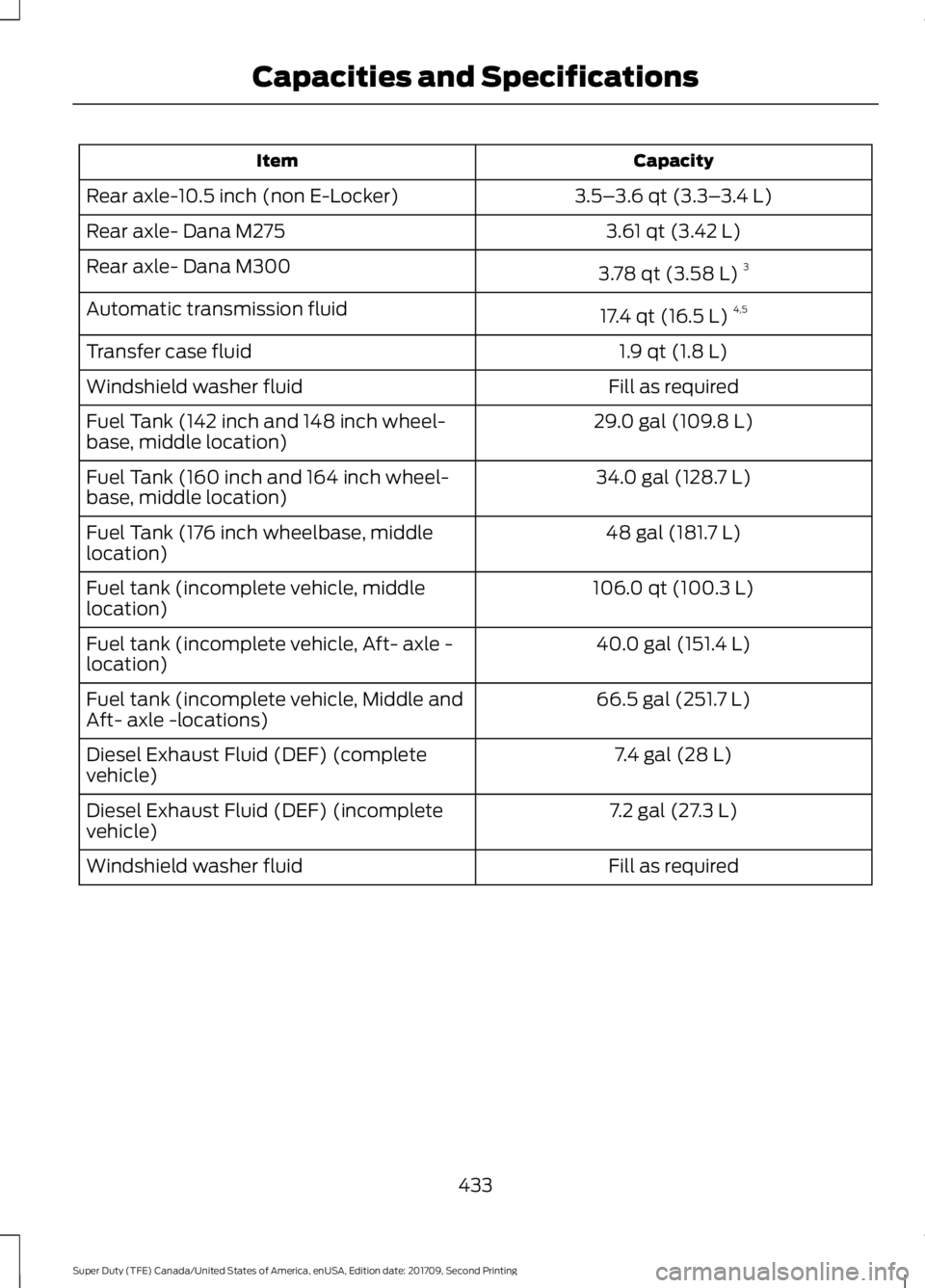

Capacity

Item

3.5–3.6 qt (3.3– 3.4 L)

Rear axle-10.5 inch (non E-Locker)

3.61 qt (3.42 L)

Rear axle- Dana M275

3.78 qt (3.58 L)3

Rear axle- Dana M300

17.4 qt (16.5 L)4,5

Automatic transmission fluid

1.9 qt (1.8 L)

Transfer case fluid

Fill as required

Windshield washer fluid

29.0 gal (109.8 L)

Fuel Tank (142 inch and 148 inch wheel-

base, middle location)

34.0 gal (128.7 L)

Fuel Tank (160 inch and 164 inch wheel-

base, middle location)

48 gal (181.7 L)

Fuel Tank (176 inch wheelbase, middle

location)

106.0 qt (100.3 L)

Fuel tank (incomplete vehicle, middle

location)

40.0 gal (151.4 L)

Fuel tank (incomplete vehicle, Aft- axle -

location)

66.5 gal (251.7 L)

Fuel tank (incomplete vehicle, Middle and

Aft- axle -locations)

7.4 gal (28 L)

Diesel Exhaust Fluid (DEF) (complete

vehicle)

7.2 gal (27.3 L)

Diesel Exhaust Fluid (DEF) (incomplete

vehicle)

Fill as required

Windshield washer fluid

433

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Capacities and Specifications

Page 438 of 660

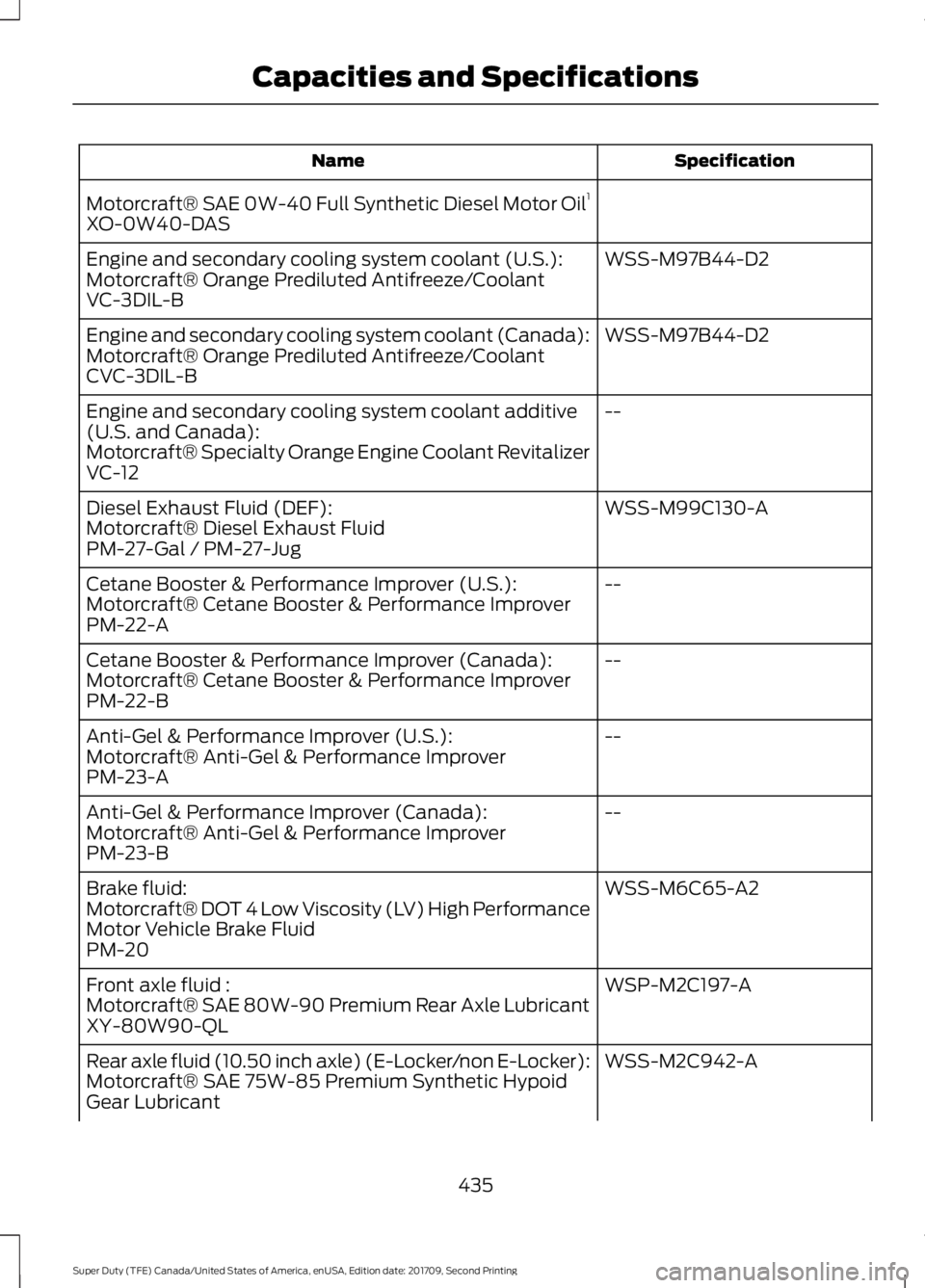

Specification

Name

Motorcraft® SAE 0W-40 Full Synthetic Diesel Motor Oil 1

XO-0W40-DAS

WSS-M97B44-D2

Engine and secondary cooling system coolant (U.S.):

Motorcraft® Orange Prediluted Antifreeze/Coolant

VC-3DIL-B

WSS-M97B44-D2

Engine and secondary cooling system coolant (Canada):

Motorcraft® Orange Prediluted Antifreeze/Coolant

CVC-3DIL-B

--

Engine and secondary cooling system coolant additive

(U.S. and Canada):

Motorcraft® Specialty Orange Engine Coolant Revitalizer

VC-12

WSS-M99C130-A

Diesel Exhaust Fluid (DEF):

Motorcraft® Diesel Exhaust Fluid

PM-27-Gal / PM-27-Jug

--

Cetane Booster & Performance Improver (U.S.):

Motorcraft® Cetane Booster & Performance Improver

PM-22-A

--

Cetane Booster & Performance Improver (Canada):

Motorcraft® Cetane Booster & Performance Improver

PM-22-B

--

Anti-Gel & Performance Improver (U.S.):

Motorcraft® Anti-Gel & Performance Improver

PM-23-A

--

Anti-Gel & Performance Improver (Canada):

Motorcraft® Anti-Gel & Performance Improver

PM-23-B

WSS-M6C65-A2

Brake fluid:

Motorcraft® DOT 4 Low Viscosity (LV) High Performance

Motor Vehicle Brake Fluid

PM-20

WSP-M2C197-A

Front axle fluid :

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

XY-80W90-QL

WSS-M2C942-A

Rear axle fluid (10.50 inch axle) (E-Locker/non E-Locker):

Motorcraft® SAE 75W-85 Premium Synthetic Hypoid

Gear Lubricant

435

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201709, Second Printing Capacities and Specifications