FORD F-450 2021 Owners Manual

Manufacturer: FORD, Model Year: 2021, Model line: F-450, Model: FORD F-450 2021Pages: 666, PDF Size: 11.3 MB

Page 431 of 666

12.

Turn the ignition off. If two short horn

beeps are heard, the reset procedure

was unsuccessful and you must

repeat it. If after repeating the

procedure and two short beeps are

heard when the ignition is turned to

off, seek assistance from your

authorized dealer.

13. Set all six tires to the recommended air pressure as indicated on the

Safety Compliance Certification

Label, affixed to either the door hinge

pillar, door-latch post, or the door

edge that meets the door-latch post,

next to the driver seating position or

Tire Label located on the B-Pillar or

the edge of the driver door.

Trailer Tire Pressure Monitoring

System (If Equipped)

Note: Additional equipment may be

required for your vehicle to support trailer

tire pressure monitoring. See your authorized

dealer for more information.

Note: The trailer tire pressure monitoring

system is not a substitute for proper tire

maintenance. It is your responsibility to

maintain correct tire pressures at all times.

Note: If a trailer tire is repaired, replaced or

broken down for service, the screw and valve

on the trailer tire pressure sensor should be

replaced. See your authorized dealer for

details. The trailer tire pressure monitoring system

is an added safety feature that allows you

to view your trailer tire pressures through

the information display.

See General

Information (page 110). Tire pressure

sensors are mounted into each tire on your

trailer. The sensors send a message to your

vehicle indicating the current trailer tire

pressure.

If the trailer tire pressure monitoring

system detects that a tire is low, a warning

message appears in the information

display. The trailer tire pressure status

screen in the information display highlights

the tire with a low pressure.

The main function of the trailer tire

pressure monitoring system is to warn you

when your trailer tires need air. It can also

warn you in the event the system is no

longer capable of functioning as intended.

See

Information Messages (page 121).

When a Temporary Spare or New Tire

is Installed

If you have replaced a trailer tire with a new

or spare tire, a warning message appears

and pressure readings are no longer

displayed for that tire.

To restore the full function of the trailer

tire pressure monitoring system:

• Have the damaged wheel and tire

assembly repaired and remounted to

your trailer.

• Install the trailer tire pressure

monitoring sensor into the new wheel

and tire assembly.

• Perform the trailer tire pressure

monitoring system reset procedure.

Trailer Tire Pressure Monitoring

System Reset Procedure

Note: You need to perform the tire pressure

monitoring system reset procedure after

each tire rotation, or when a new trailer tire

pressure sensor is installed into a trailer tire.

428

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE235807

Page 432 of 666

The trailer tire pressure monitoring system

can be reset through the menu in the

information display. See General

Information (page 110). Performing the

trailer setup process also resets the trailer

tire pressure monitoring system.

CHANGING A ROAD WHEEL WARNING:

If the tire pressure

monitor sensor becomes damaged it

may not function.

Note: If your vehicle is equipped with the

tire pressure monitoring system, the

indicator light illuminates when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

Note: You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

If you get a flat tire when driving, do not

apply the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe

place on the side of the road.

If your vehicle is equipped with the tire

pressure monitoring system, have a flat

serviced by an authorized dealer in order

to prevent damage to the system sensors.

See

Tire Pressure Monitoring System

(page 421). Replace the spare tire with a

road tire as soon as possible. During

repairing or replacing of the flat tire, have

the authorized dealer inspect the system

sensor for damage. Dissimilar Spare Wheel and Tire

Assembly Information WARNING:

Failure to follow these

guidelines could result in an increased

risk of loss of vehicle control, injury or

death.

If you have a dissimilar spare wheel and

tire, then it is intended for temporary use

only. This means that if you need to use it,

you should replace it as soon as possible

with a road wheel and tire assembly that

is the same size and type as the road tires

and wheels that were originally provided

by Ford. If the dissimilar spare tire or wheel

is damaged, it should be replaced rather

than repaired.

A dissimilar spare wheel and tire assembly

is defined as a spare wheel and tire

assembly that is different in brand, size or

appearance from the road tires and

wheels.

Full-size dissimilar spare

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

When driving with the full-size dissimilar

spare wheel and tire assembly, 4WD

functionality may be limited. You may

experience the following:

• Additional noise from the transfer case

or other drive components.

• Difficulty shifting out of a mechanically

locked 4WD mode.

429

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 433 of 666

When driving with the full-size dissimilar

spare wheel and tire assembly, it is

recommended that you do not:

•

Exceed 50 mph (80 km/h) in 4WD.

• Engage 4WD unless the vehicle is

stationary.

• Use 4WD on dry pavement.

The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability. •

Wet weather driving capability.

• Four-wheel drive capability.

When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

• Towing a trailer.

• Driving vehicles equipped with a

camper body.

• Driving vehicles with a load on the

cargo rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly

and seek service as soon as possible.

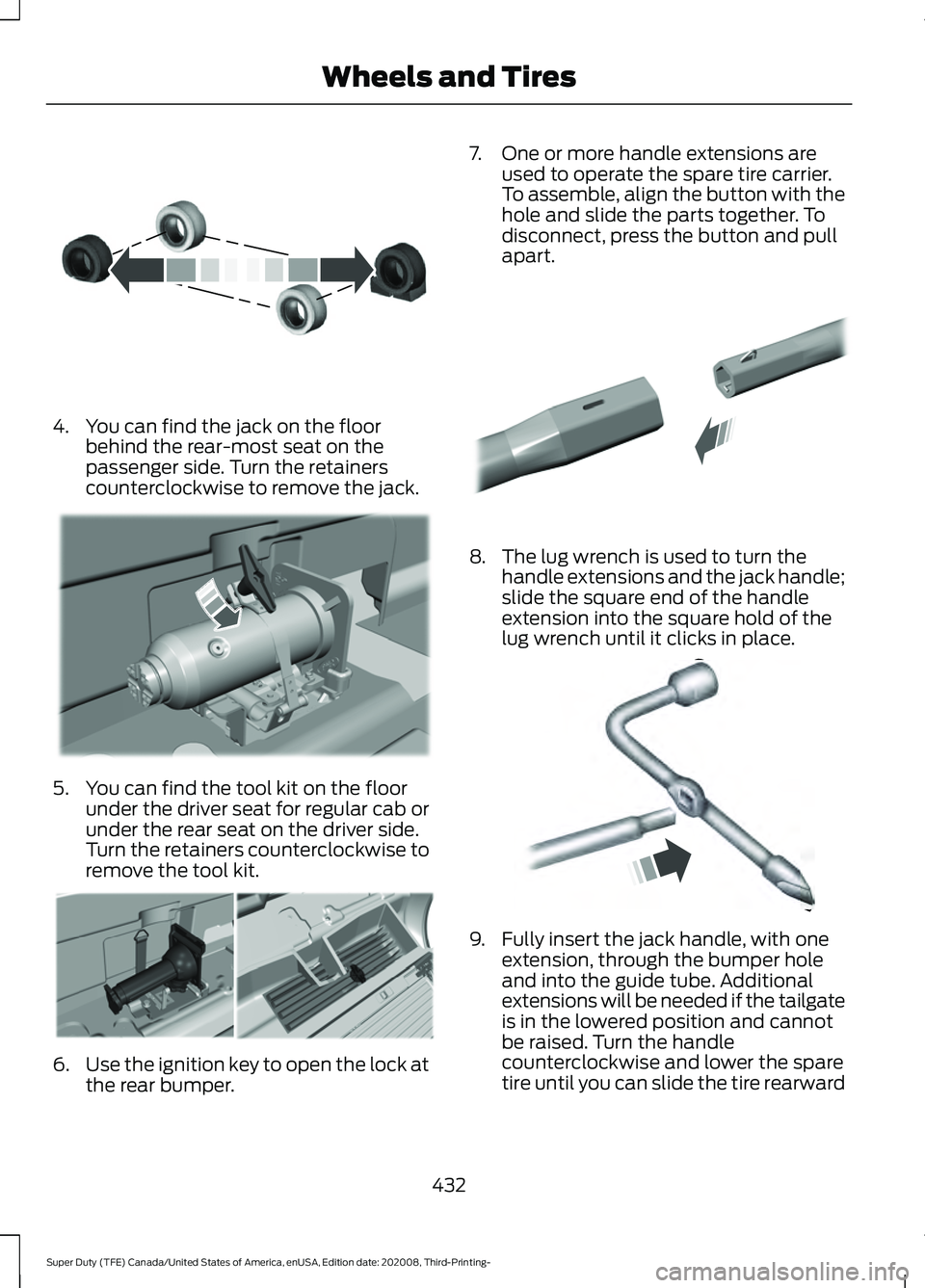

Location of the Spare Tire and

Tools

See the following table for their locations: Location

Item

Under the vehicle, just forward of the rearbumper.

Spare tire - pick-up trucks only

Fastened to the floor pan behind the rear-most seat on the passenger side.

Jack

Regular Cab: Fastened to floor behind thedriver seat.

Jack handle, lug wrench, lug wrench exten-

sion - only provided on dual rear wheel vehicles. Super Cab and Crew Cab: Fastened to the

floor under the rear seat on the driver's side.

Tire Change Procedure WARNING:

The jack supplied with

this vehicle is only intended for changing

wheels. Do not use the vehicle jack other

than when you are changing a wheel in

an emergency. 430

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE166722

Page 434 of 666

WARNING: To help prevent your

vehicle from moving when changing a

wheel, shift the transmission into park

(P), set the parking brake and use an

appropriate block or wheel chock to

secure the wheel diagonally opposite to

the wheel being changed. For example,

when changing the front left wheel,

place an appropriate block or wheel

chock on the right rear wheel. WARNING:

Always use the jack

provided as original equipment with your

vehicle. If using a jack other than the one

provided, make sure the jack capacity is

adequate for the vehicle weight,

including any vehicle cargo or

modifications. If you are unsure if the jack

capacity is adequate, contact the

authorized dealer. WARNING:

Failure to follow these

guidelines could result in an increased

risk of loss of vehicle control, injury or

death. WARNING:

Never place anything

between the vehicle jack and your

vehicle. WARNING:

Never place anything

between the vehicle jack and the ground. WARNING:

Park your vehicle so

that you do not obstruct the flow of

traffic or place yourself in any danger and

set up a warning triangle. WARNING:

Do not work on your

vehicle when the jack is the only support

as your vehicle could slip off the jack.

Failure to follow this instruction could

result in personal injury or death. WARNING:

Do not get under a

vehicle that is only supported by a

vehicle jack. WARNING:

Do not attempt to

change a tire on the side of the vehicle

close to moving traffic. Pull far enough

off the road to avoid the danger of being

hit when operating the jack or changing

the wheel. WARNING:

Only use the spare

wheel carrier to stow the wheel provided

with your vehicle. Other wheel sizes

could cause the spare wheel carrier to

fail if it does not fit securely or is too

heavy.

Note: Do not use impact tools or power

tools operating at over 200 RPM on the

spare wheel carrier winch, which may cause

it to malfunction and prevent a secure fit.

Override the winch at least three times

(there is an audible click each time) to make

sure the wheel and tire fit securely.

Note: Passengers should not remain in the

vehicle when the vehicle is being jacked.

1. Park the vehicle on a level firm ground and activate the hazard flashers.

2. Apply the parking brake, place the transmission in park (P), switch the

engine off.

3. Block the wheel diagonally opposite the flat tire. For example, if the left

front tire is flat, block the right rear

wheel.

431

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and Tires

Page 435 of 666

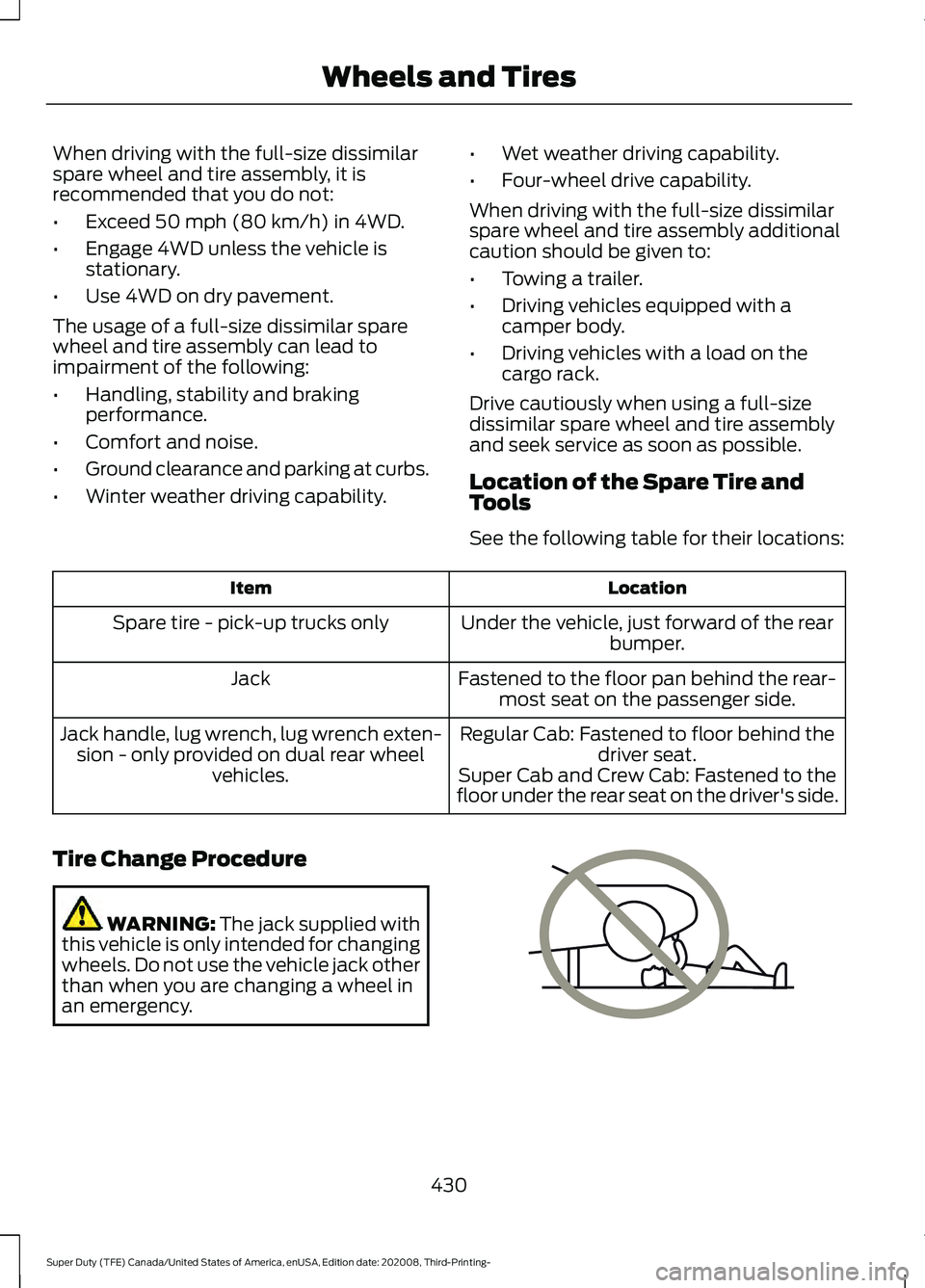

4. You can find the jack on the floor

behind the rear-most seat on the

passenger side. Turn the retainers

counterclockwise to remove the jack. 5. You can find the tool kit on the floor

under the driver seat for regular cab or

under the rear seat on the driver side.

Turn the retainers counterclockwise to

remove the tool kit. 6.

Use the ignition key to open the lock at

the rear bumper. 7. One or more handle extensions are

used to operate the spare tire carrier.

To assemble, align the button with the

hole and slide the parts together. To

disconnect, press the button and pull

apart. 8. The lug wrench is used to turn the

handle extensions and the jack handle;

slide the square end of the handle

extension into the square hold of the

lug wrench until it clicks in place. 9. Fully insert the jack handle, with one

extension, through the bumper hole

and into the guide tube. Additional

extensions will be needed if the tailgate

is in the lowered position and cannot

be raised. Turn the handle

counterclockwise and lower the spare

tire until you can slide the tire rearward

432

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE175447 E309424 E309795 E308882 E162796

Page 436 of 666

and the cable is slack. You will feel

some resistance when you turn the jack

handle assembly. If not replacing the

spare or flat tire to the underbody

storage area, raise the wheel retainer

up into the installed position.

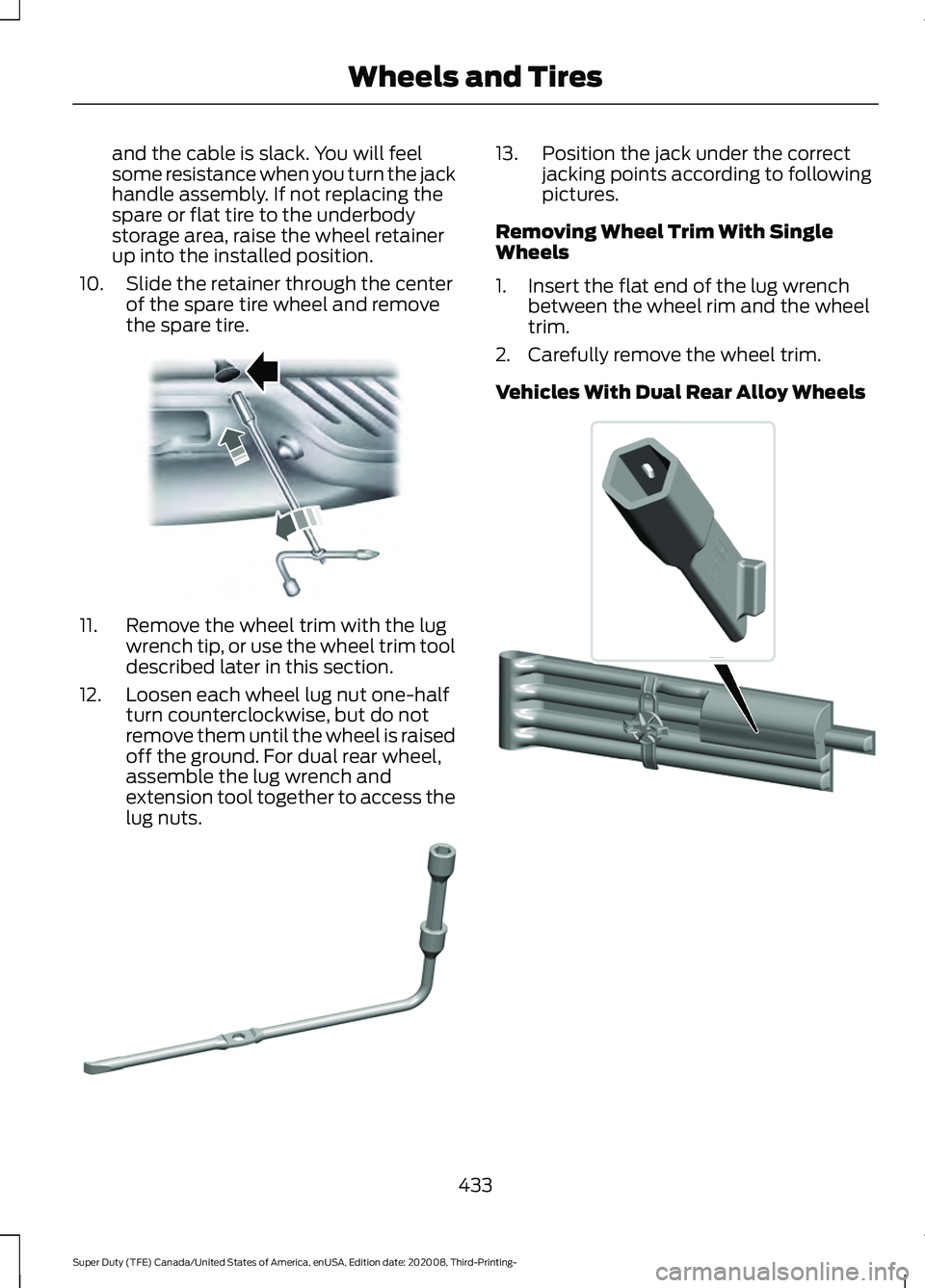

10. Slide the retainer through the center of the spare tire wheel and remove

the spare tire. 11. Remove the wheel trim with the lug

wrench tip, or use the wheel trim tool

described later in this section.

12. Loosen each wheel lug nut one-half turn counterclockwise, but do not

remove them until the wheel is raised

off the ground. For dual rear wheel,

assemble the lug wrench and

extension tool together to access the

lug nuts. 13. Position the jack under the correct

jacking points according to following

pictures.

Removing Wheel Trim With Single

Wheels

1. Insert the flat end of the lug wrench between the wheel rim and the wheel

trim.

2. Carefully remove the wheel trim.

Vehicles With Dual Rear Alloy Wheels 433

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE310417 E309794 E338541

Page 437 of 666

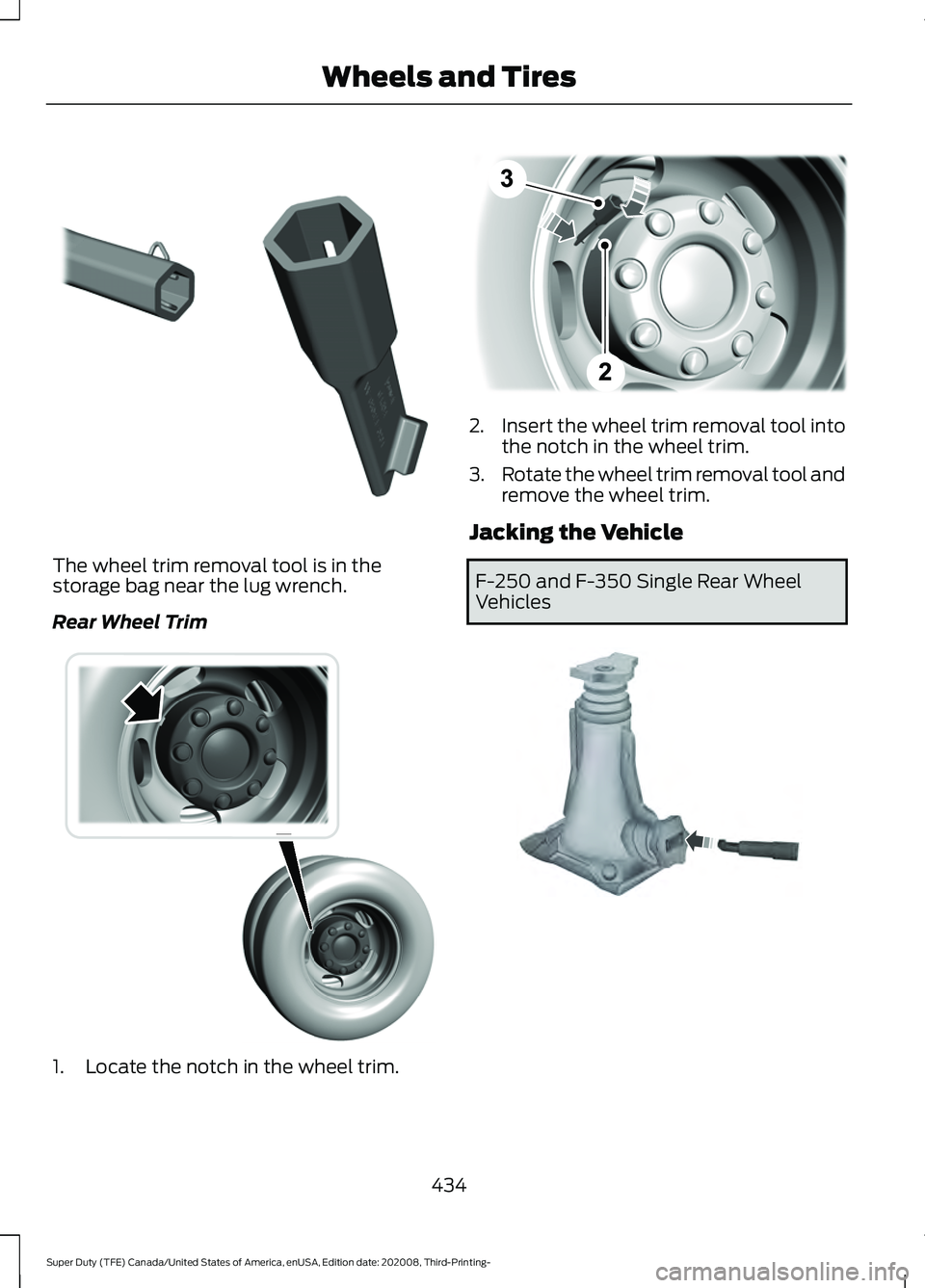

The wheel trim removal tool is in the

storage bag near the lug wrench.

Rear Wheel Trim

1. Locate the notch in the wheel trim. 2.

Insert the wheel trim removal tool into

the notch in the wheel trim.

3. Rotate the wheel trim removal tool and

remove the wheel trim.

Jacking the Vehicle F-250 and F-350 Single Rear Wheel

Vehicles

434

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE338539 E338557 E338552 E162801

Page 438 of 666

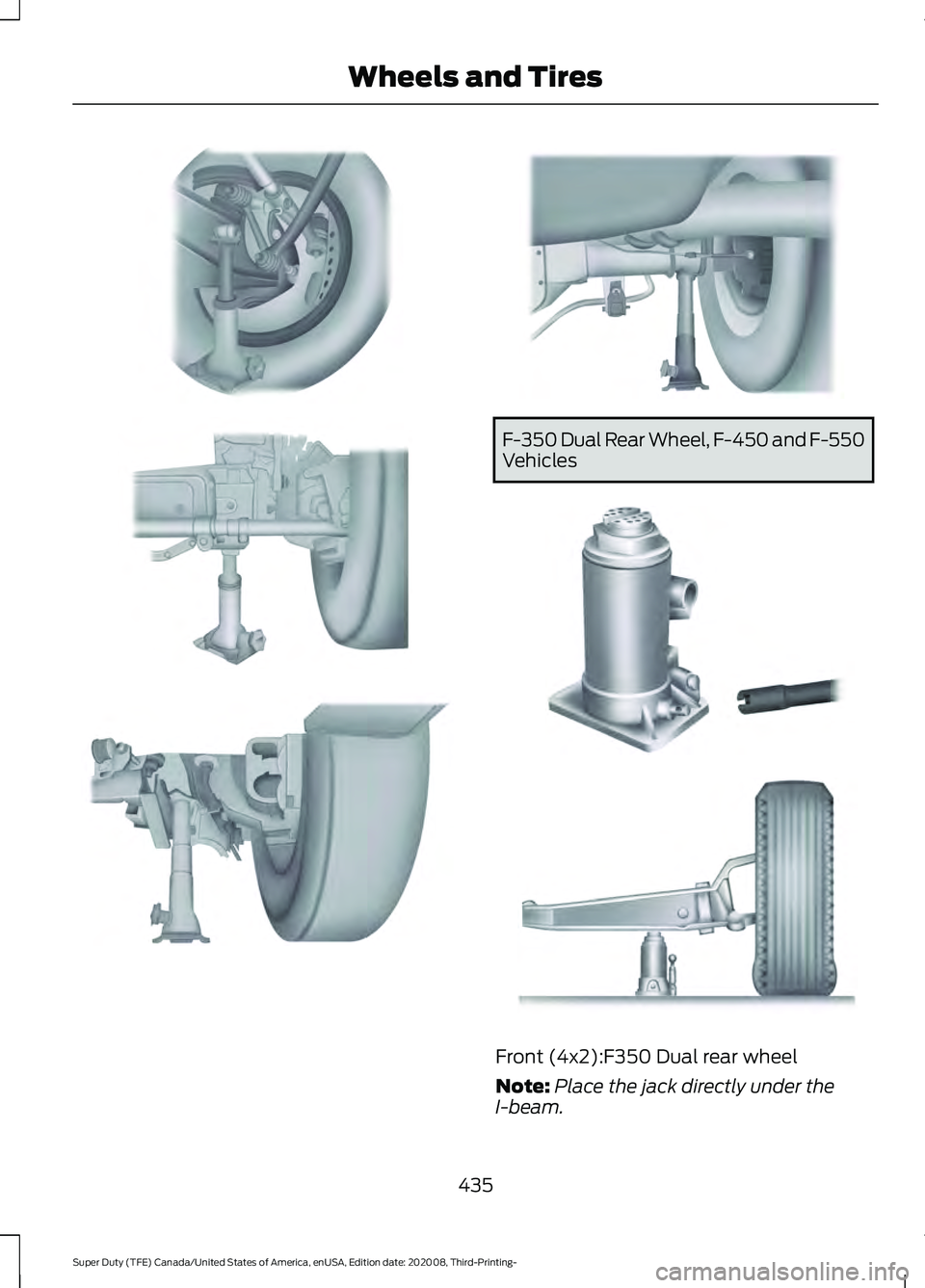

F-350 Dual Rear Wheel, F-450 and F-550

Vehicles

Front (4x2):F350 Dual rear wheel

Note:

Place the jack directly under the

I-beam.

435

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE162802 E162803 E162804 E162805 E162812 E162813

Page 439 of 666

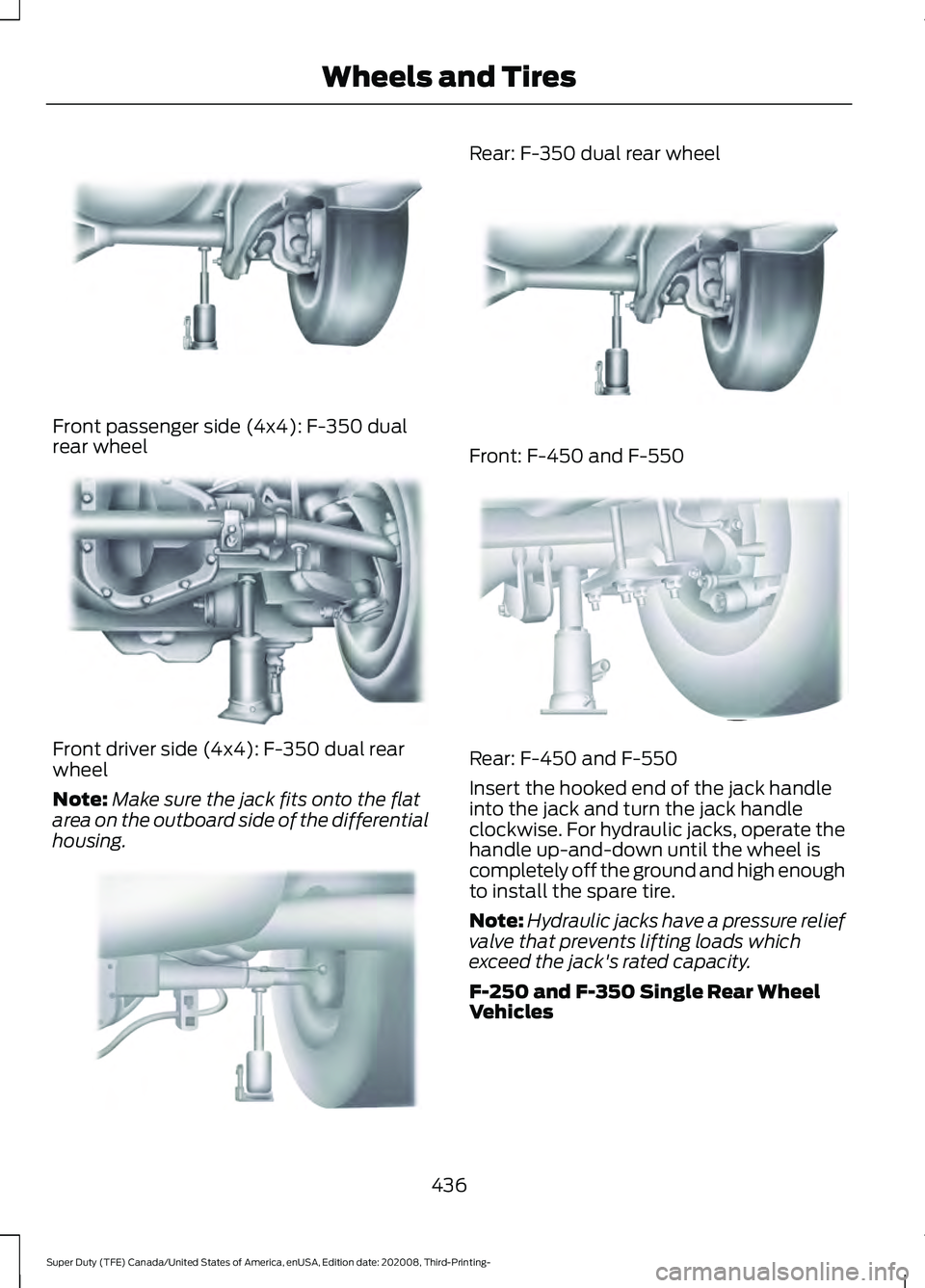

Front passenger side (4x4): F-350 dual

rear wheel

Front driver side (4x4): F-350 dual rear

wheel

Note:

Make sure the jack fits onto the flat

area on the outboard side of the differential

housing. Rear: F-350 dual rear wheel

Front: F-450 and F-550

Rear: F-450 and F-550

Insert the hooked end of the jack handle

into the jack and turn the jack handle

clockwise. For hydraulic jacks, operate the

handle up-and-down until the wheel is

completely off the ground and high enough

to install the spare tire.

Note:

Hydraulic jacks have a pressure relief

valve that prevents lifting loads which

exceed the jack's rated capacity.

F-250 and F-350 Single Rear Wheel

Vehicles

436

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE162815 E162814 E162817 E162816 E162818

Page 440 of 666

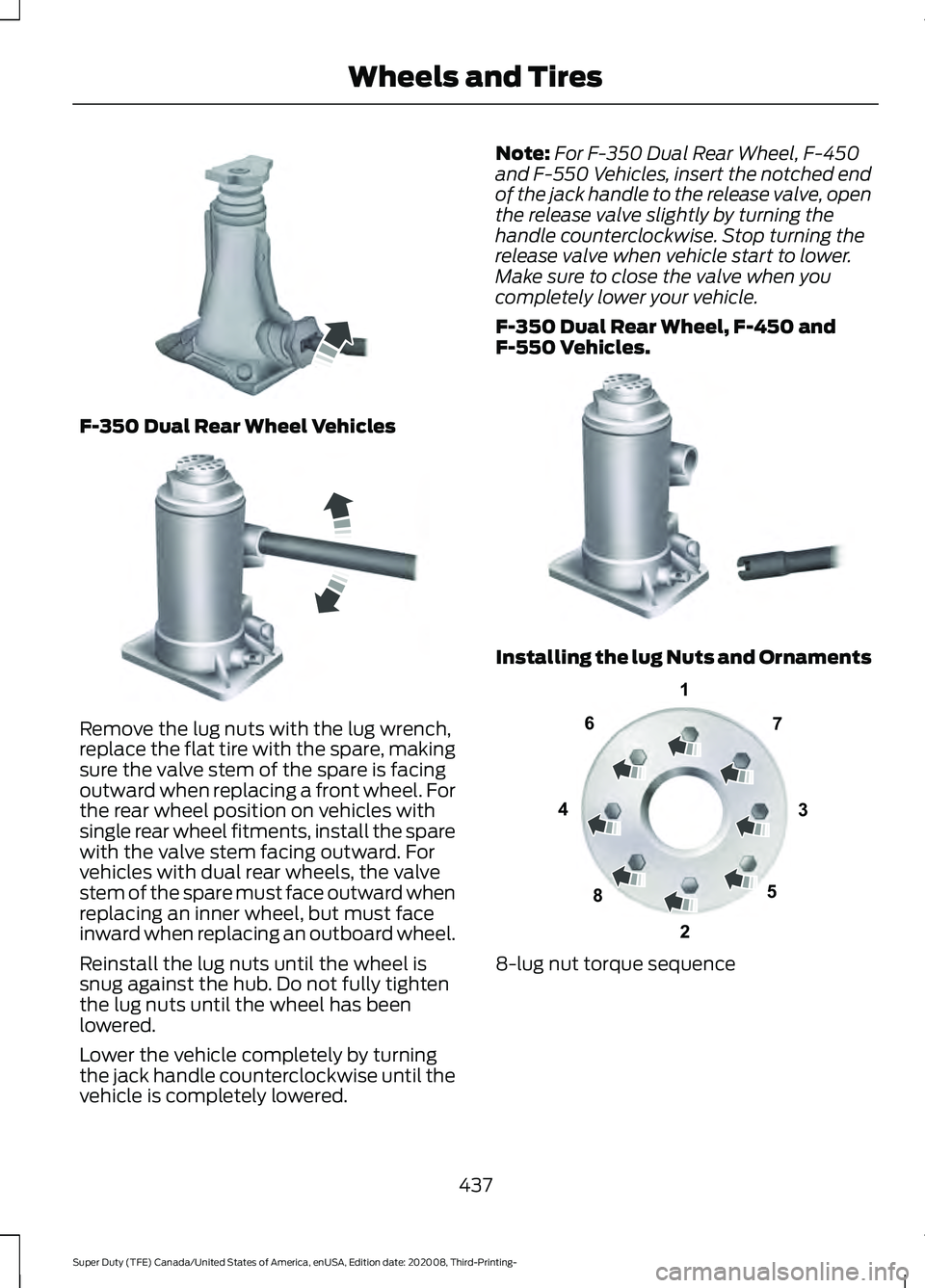

F-350 Dual Rear Wheel Vehicles

Remove the lug nuts with the lug wrench,

replace the flat tire with the spare, making

sure the valve stem of the spare is facing

outward when replacing a front wheel. For

the rear wheel position on vehicles with

single rear wheel fitments, install the spare

with the valve stem facing outward. For

vehicles with dual rear wheels, the valve

stem of the spare must face outward when

replacing an inner wheel, but must face

inward when replacing an outboard wheel.

Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully tighten

the lug nuts until the wheel has been

lowered.

Lower the vehicle completely by turning

the jack handle counterclockwise until the

vehicle is completely lowered. Note:

For F-350 Dual Rear Wheel, F-450

and F-550 Vehicles, insert the notched end

of the jack handle to the release valve, open

the release valve slightly by turning the

handle counterclockwise. Stop turning the

release valve when vehicle start to lower.

Make sure to close the valve when you

completely lower your vehicle.

F-350 Dual Rear Wheel, F-450 and

F-550 Vehicles. Installing the lug Nuts and Ornaments

8-lug nut torque sequence

437

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202008, Third-Printing- Wheels and TiresE162811 E162819 E162812 13

4

27

6

5

8E161441