FORD F-450 2022 Owners Manual

Manufacturer: FORD, Model Year: 2022, Model line: F-450, Model: FORD F-450 2022Pages: 740, PDF Size: 12.6 MB

Page 461 of 740

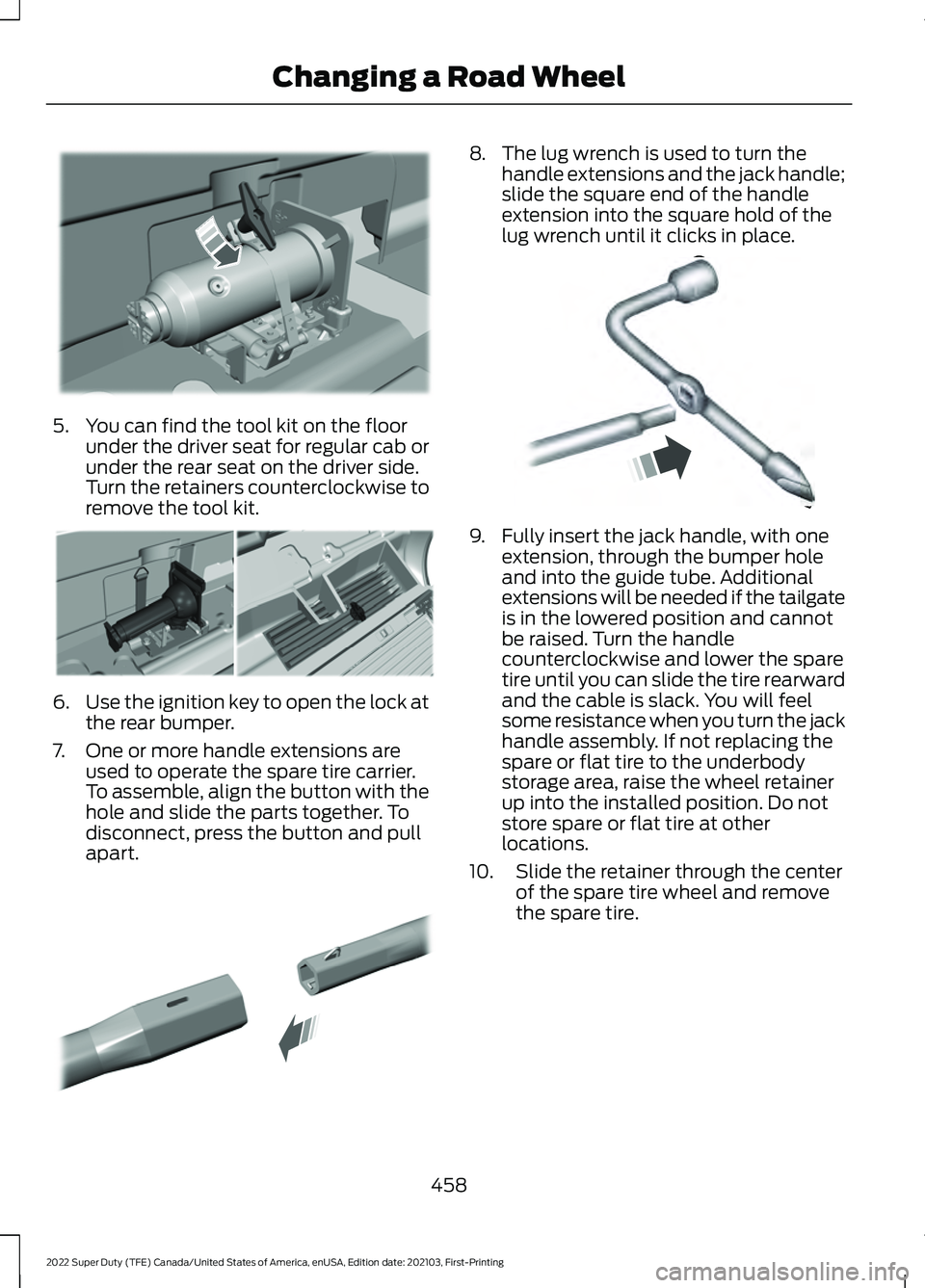

5. You can find the tool kit on the floor

under the driver seat for regular cab or

under the rear seat on the driver side.

Turn the retainers counterclockwise to

remove the tool kit. 6.

Use the ignition key to open the lock at

the rear bumper.

7. One or more handle extensions are used to operate the spare tire carrier.

To assemble, align the button with the

hole and slide the parts together. To

disconnect, press the button and pull

apart. 8. The lug wrench is used to turn the

handle extensions and the jack handle;

slide the square end of the handle

extension into the square hold of the

lug wrench until it clicks in place. 9. Fully insert the jack handle, with one

extension, through the bumper hole

and into the guide tube. Additional

extensions will be needed if the tailgate

is in the lowered position and cannot

be raised. Turn the handle

counterclockwise and lower the spare

tire until you can slide the tire rearward

and the cable is slack. You will feel

some resistance when you turn the jack

handle assembly. If not replacing the

spare or flat tire to the underbody

storage area, raise the wheel retainer

up into the installed position. Do not

store spare or flat tire at other

locations.

10. Slide the retainer through the center of the spare tire wheel and remove

the spare tire.

458

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE309424 E309795 E308882 E162796

Page 462 of 740

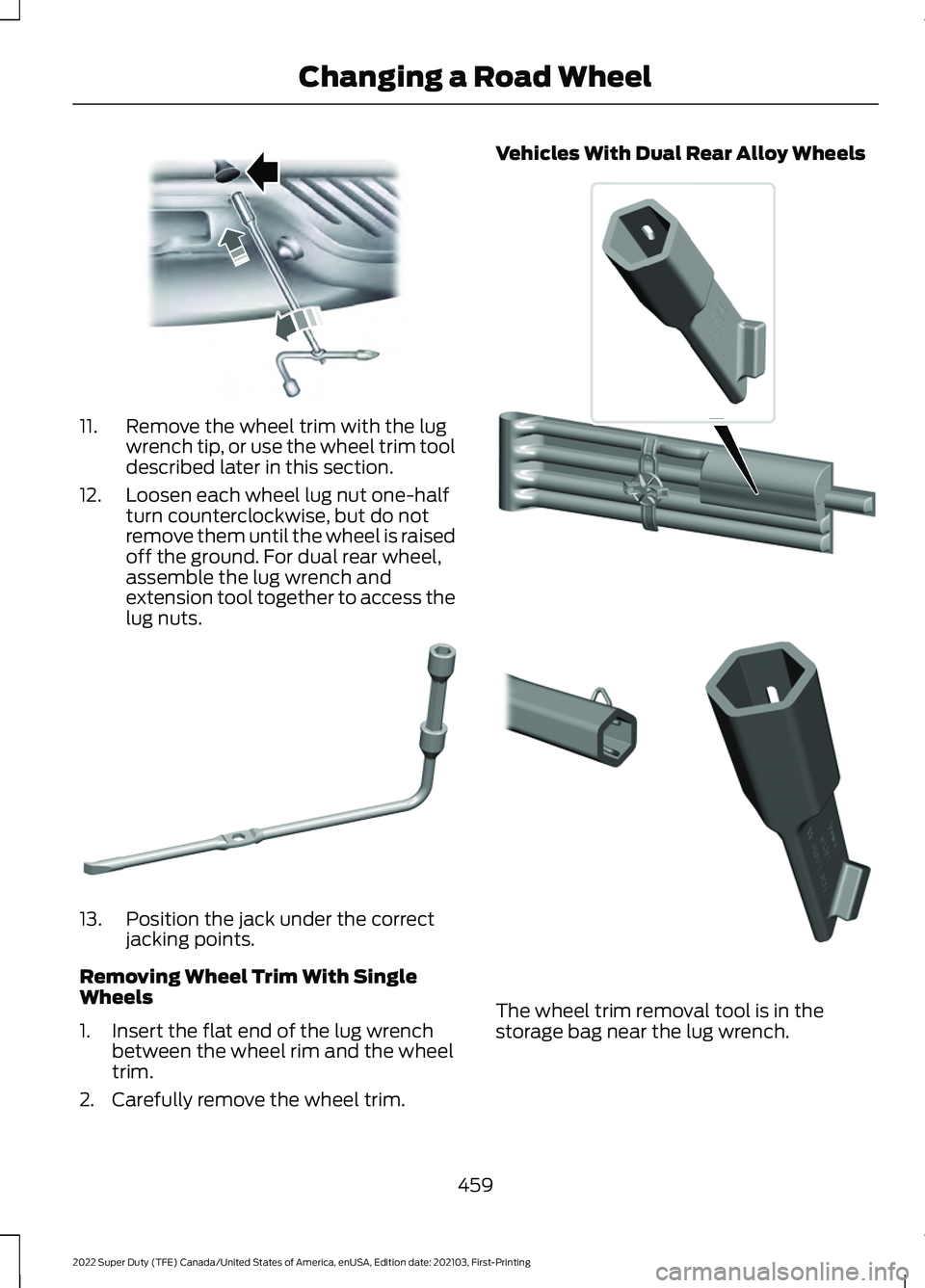

11. Remove the wheel trim with the lug

wrench tip, or use the wheel trim tool

described later in this section.

12. Loosen each wheel lug nut one-half turn counterclockwise, but do not

remove them until the wheel is raised

off the ground. For dual rear wheel,

assemble the lug wrench and

extension tool together to access the

lug nuts. 13. Position the jack under the correct

jacking points.

Removing Wheel Trim With Single

Wheels

1. Insert the flat end of the lug wrench between the wheel rim and the wheel

trim.

2. Carefully remove the wheel trim. Vehicles With Dual Rear Alloy Wheels

The wheel trim removal tool is in the

storage bag near the lug wrench.

459

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE310417 E309794 E338541 E338539

Page 463 of 740

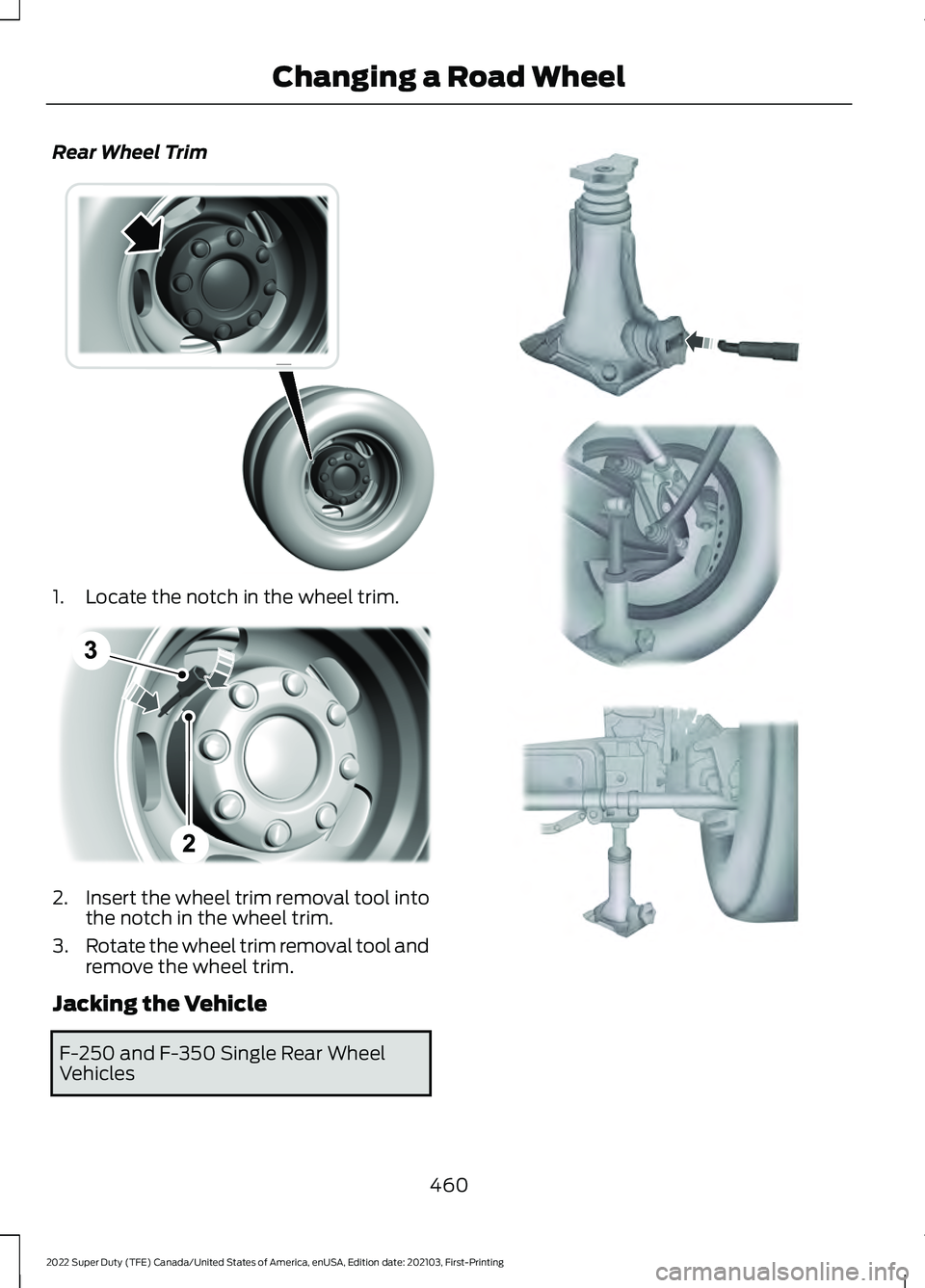

Rear Wheel Trim

1. Locate the notch in the wheel trim.

2.

Insert the wheel trim removal tool into

the notch in the wheel trim.

3. Rotate the wheel trim removal tool and

remove the wheel trim.

Jacking the Vehicle F-250 and F-350 Single Rear Wheel

Vehicles

460

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE338557 E338552 E162801 E162802 E162803

Page 464 of 740

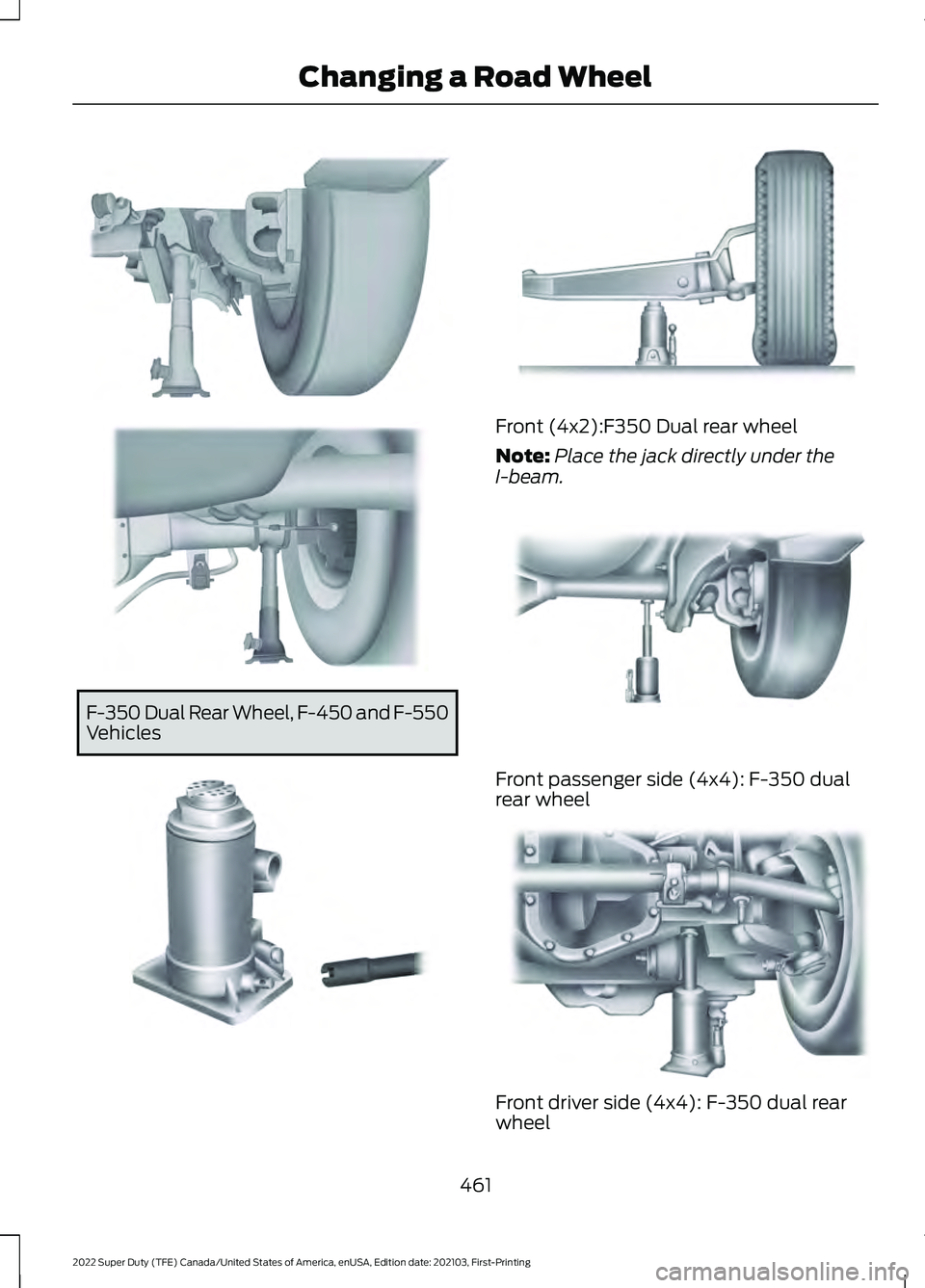

F-350 Dual Rear Wheel, F-450 and F-550

Vehicles Front (4x2):F350 Dual rear wheel

Note:

Place the jack directly under the

I-beam. Front passenger side (4x4): F-350 dual

rear wheel

Front driver side (4x4): F-350 dual rear

wheel

461

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE162804 E162805 E162812 E162813 E162815 E162814

Page 465 of 740

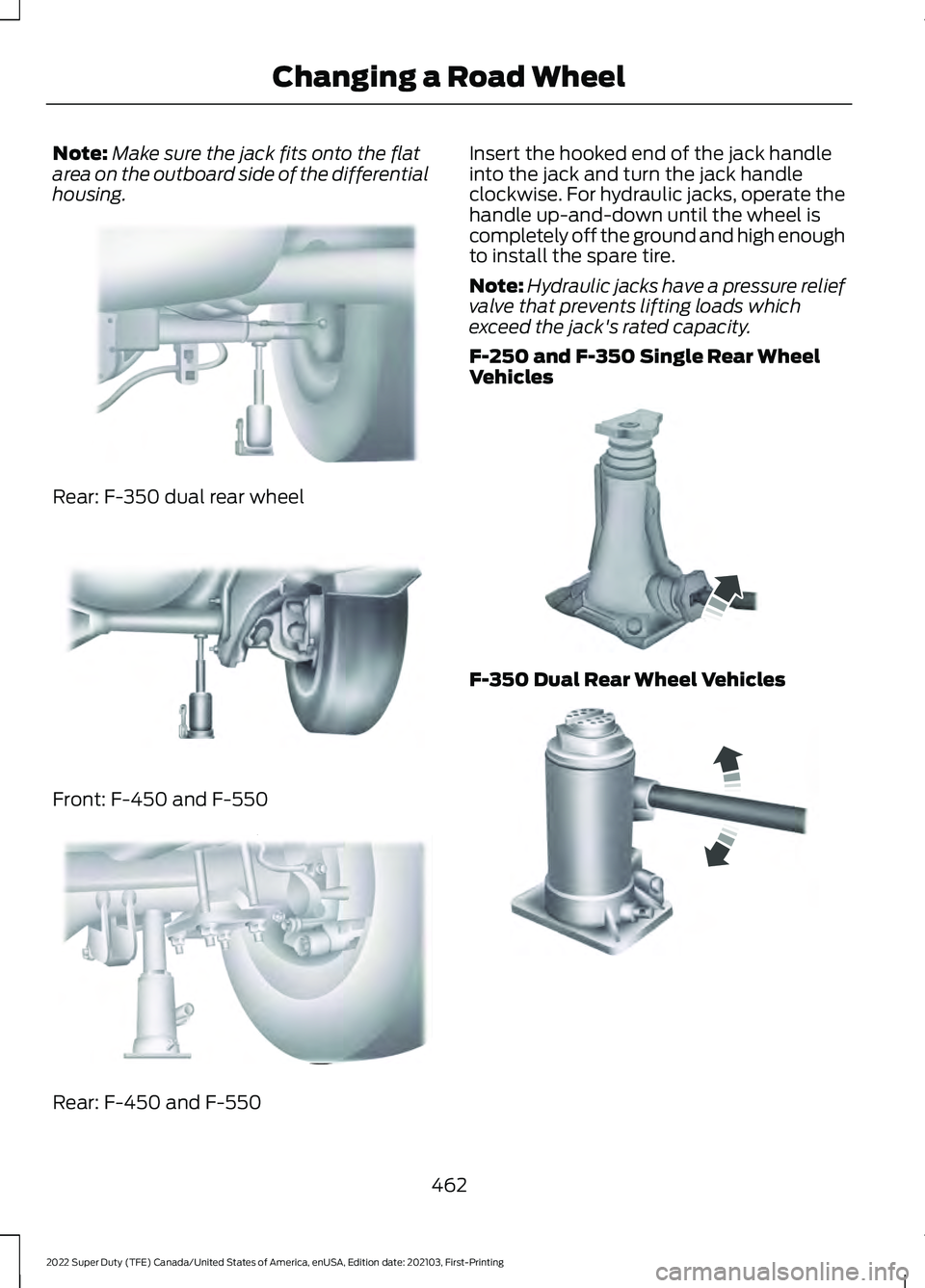

Note:

Make sure the jack fits onto the flat

area on the outboard side of the differential

housing. Rear: F-350 dual rear wheel

Front: F-450 and F-550

Rear: F-450 and F-550 Insert the hooked end of the jack handle

into the jack and turn the jack handle

clockwise. For hydraulic jacks, operate the

handle up-and-down until the wheel is

completely off the ground and high enough

to install the spare tire.

Note:

Hydraulic jacks have a pressure relief

valve that prevents lifting loads which

exceed the jack's rated capacity.

F-250 and F-350 Single Rear Wheel

Vehicles F-350 Dual Rear Wheel Vehicles

462

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE162817 E162816 E162818 E162811 E162819

Page 466 of 740

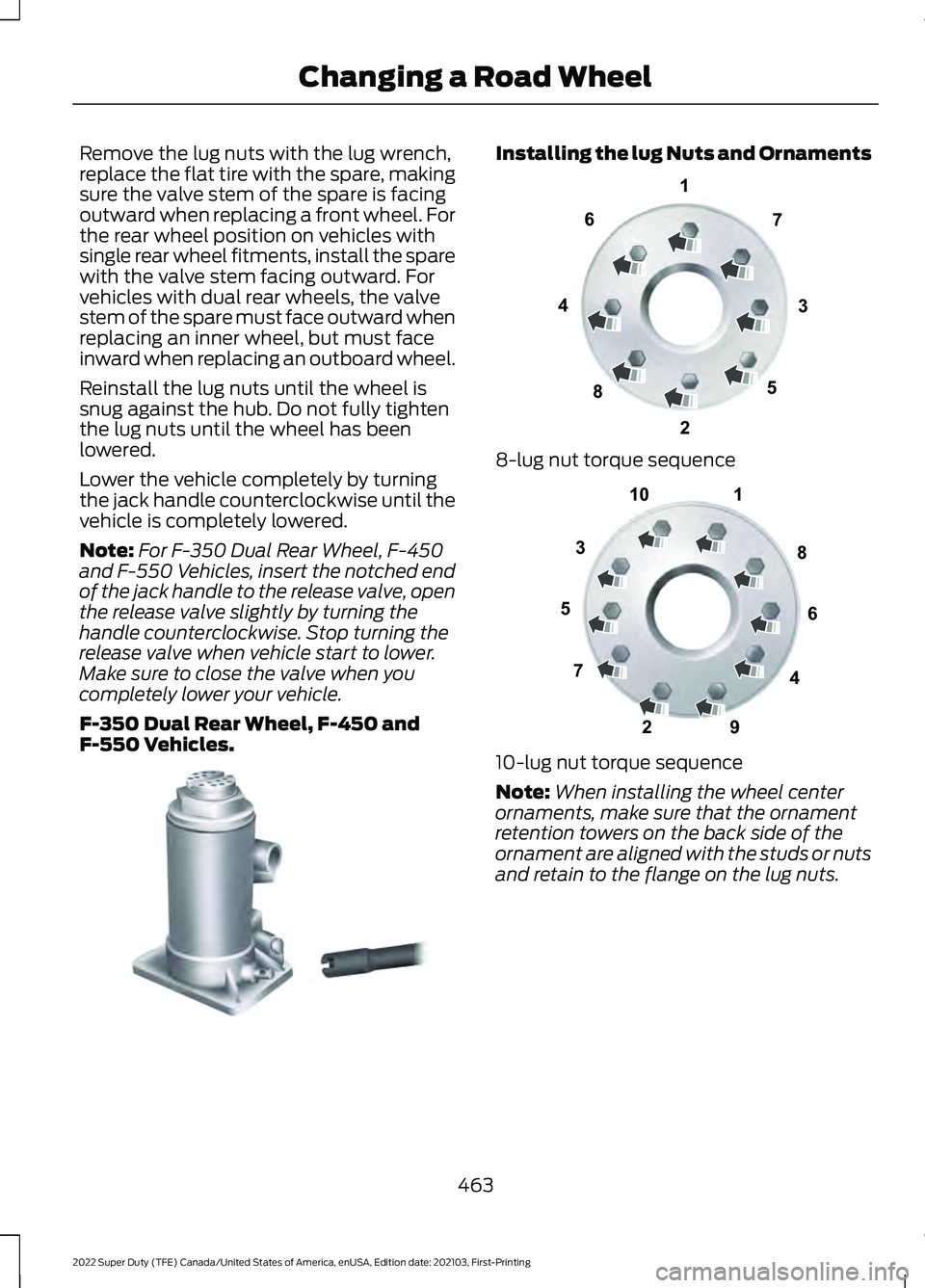

Remove the lug nuts with the lug wrench,

replace the flat tire with the spare, making

sure the valve stem of the spare is facing

outward when replacing a front wheel. For

the rear wheel position on vehicles with

single rear wheel fitments, install the spare

with the valve stem facing outward. For

vehicles with dual rear wheels, the valve

stem of the spare must face outward when

replacing an inner wheel, but must face

inward when replacing an outboard wheel.

Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully tighten

the lug nuts until the wheel has been

lowered.

Lower the vehicle completely by turning

the jack handle counterclockwise until the

vehicle is completely lowered.

Note:

For F-350 Dual Rear Wheel, F-450

and F-550 Vehicles, insert the notched end

of the jack handle to the release valve, open

the release valve slightly by turning the

handle counterclockwise. Stop turning the

release valve when vehicle start to lower.

Make sure to close the valve when you

completely lower your vehicle.

F-350 Dual Rear Wheel, F-450 and

F-550 Vehicles. Installing the lug Nuts and Ornaments

8-lug nut torque sequence

10-lug nut torque sequence

Note:

When installing the wheel center

ornaments, make sure that the ornament

retention towers on the back side of the

ornament are aligned with the studs or nuts

and retain to the flange on the lug nuts.

463

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE162812 13

4

27

6

5

8E161441 1

2

3

4

5

6

7 8

9

10E169375

Page 467 of 740

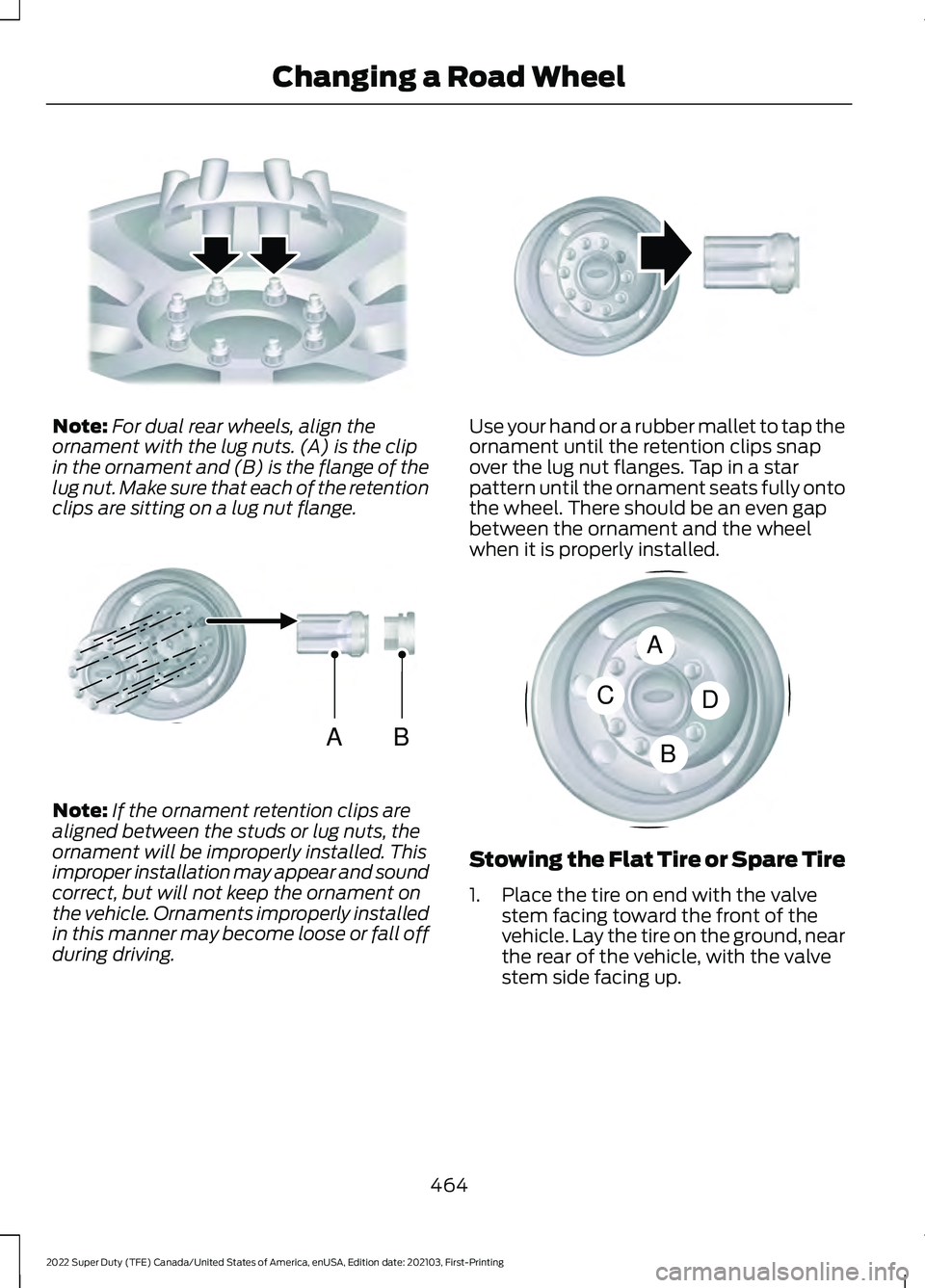

Note:

For dual rear wheels, align the

ornament with the lug nuts. (A) is the clip

in the ornament and (B) is the flange of the

lug nut. Make sure that each of the retention

clips are sitting on a lug nut flange. Note:

If the ornament retention clips are

aligned between the studs or lug nuts, the

ornament will be improperly installed. This

improper installation may appear and sound

correct, but will not keep the ornament on

the vehicle. Ornaments improperly installed

in this manner may become loose or fall off

during driving. Use your hand or a rubber mallet to tap the

ornament until the retention clips snap

over the lug nut flanges. Tap in a star

pattern until the ornament seats fully onto

the wheel. There should be an even gap

between the ornament and the wheel

when it is properly installed.

Stowing the Flat Tire or Spare Tire

1. Place the tire on end with the valve

stem facing toward the front of the

vehicle. Lay the tire on the ground, near

the rear of the vehicle, with the valve

stem side facing up.

464

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE162820 ABE162822 E162823 A

C

B

DE162824

Page 468 of 740

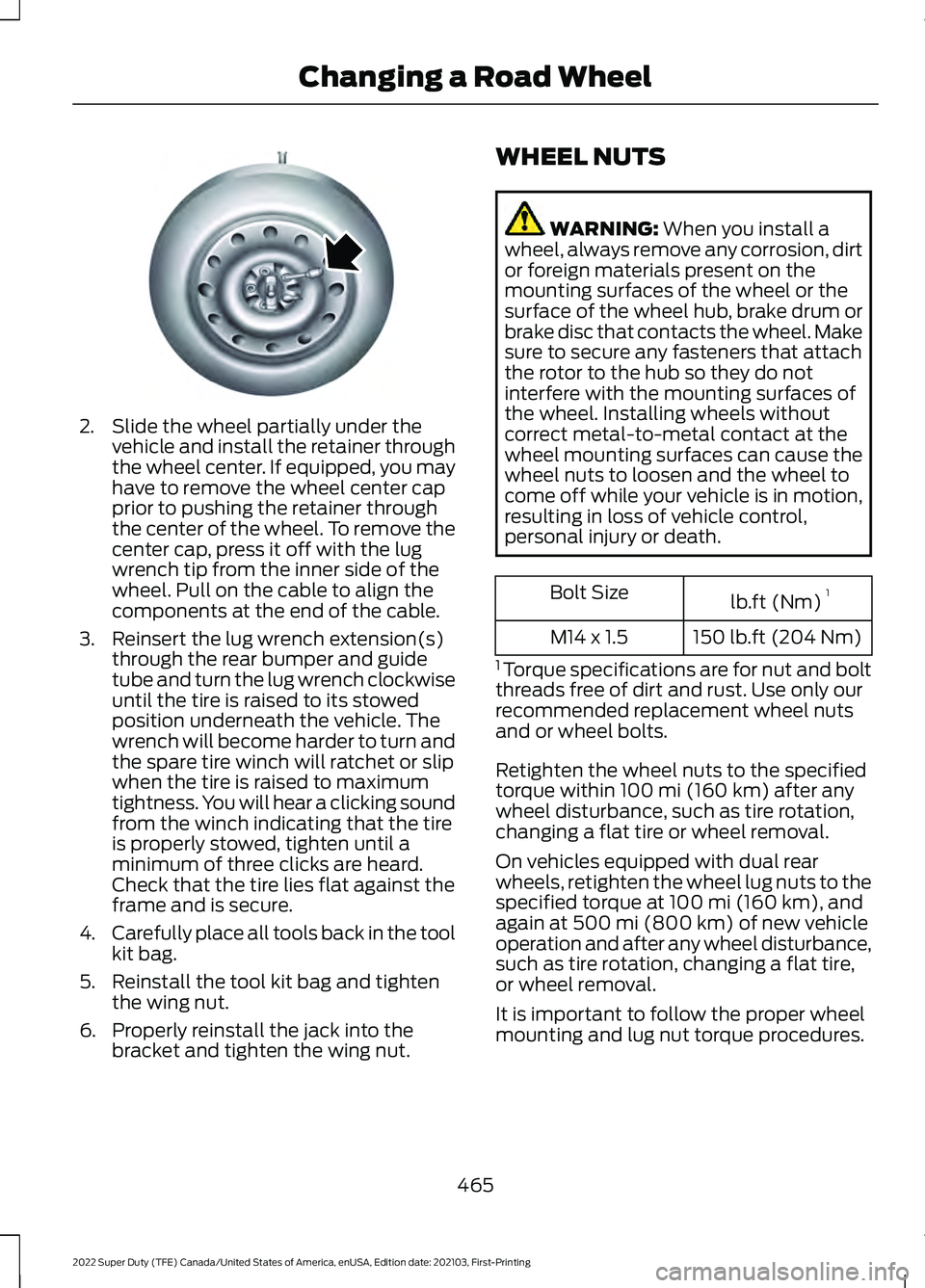

2. Slide the wheel partially under the

vehicle and install the retainer through

the wheel center. If equipped, you may

have to remove the wheel center cap

prior to pushing the retainer through

the center of the wheel. To remove the

center cap, press it off with the lug

wrench tip from the inner side of the

wheel. Pull on the cable to align the

components at the end of the cable.

3. Reinsert the lug wrench extension(s) through the rear bumper and guide

tube and turn the lug wrench clockwise

until the tire is raised to its stowed

position underneath the vehicle. The

wrench will become harder to turn and

the spare tire winch will ratchet or slip

when the tire is raised to maximum

tightness. You will hear a clicking sound

from the winch indicating that the tire

is properly stowed, tighten until a

minimum of three clicks are heard.

Check that the tire lies flat against the

frame and is secure.

4. Carefully place all tools back in the tool

kit bag.

5. Reinstall the tool kit bag and tighten the wing nut.

6. Properly reinstall the jack into the bracket and tighten the wing nut. WHEEL NUTS WARNING: When you install a

wheel, always remove any corrosion, dirt

or foreign materials present on the

mounting surfaces of the wheel or the

surface of the wheel hub, brake drum or

brake disc that contacts the wheel. Make

sure to secure any fasteners that attach

the rotor to the hub so they do not

interfere with the mounting surfaces of

the wheel. Installing wheels without

correct metal-to-metal contact at the

wheel mounting surfaces can cause the

wheel nuts to loosen and the wheel to

come off while your vehicle is in motion,

resulting in loss of vehicle control,

personal injury or death. lb.ft (Nm)

1

Bolt Size

150 lb.ft (204 Nm)

M14 x 1.5

1 Torque specifications are for nut and bolt

threads free of dirt and rust. Use only our

recommended replacement wheel nuts

and or wheel bolts.

Retighten the wheel nuts to the specified

torque within

100 mi (160 km) after any

wheel disturbance, such as tire rotation,

changing a flat tire or wheel removal.

On vehicles equipped with dual rear

wheels, retighten the wheel lug nuts to the

specified torque at

100 mi (160 km), and

again at 500 mi (800 km) of new vehicle

operation and after any wheel disturbance,

such as tire rotation, changing a flat tire,

or wheel removal.

It is important to follow the proper wheel

mounting and lug nut torque procedures.

465

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE162800

Page 469 of 740

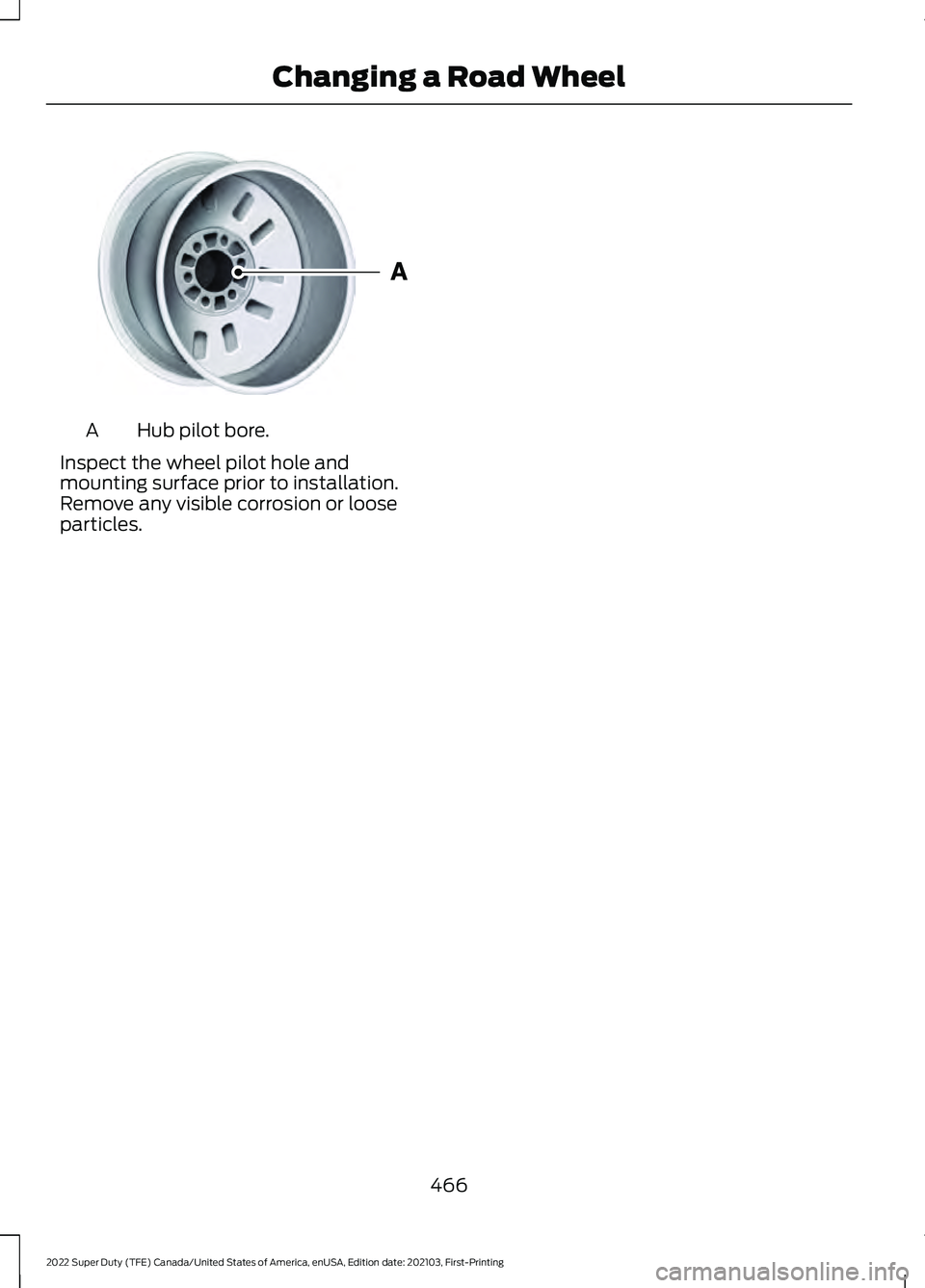

Hub pilot bore.

A

Inspect the wheel pilot hole and

mounting surface prior to installation.

Remove any visible corrosion or loose

particles.

466

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Changing a Road WheelE145950

Page 470 of 740

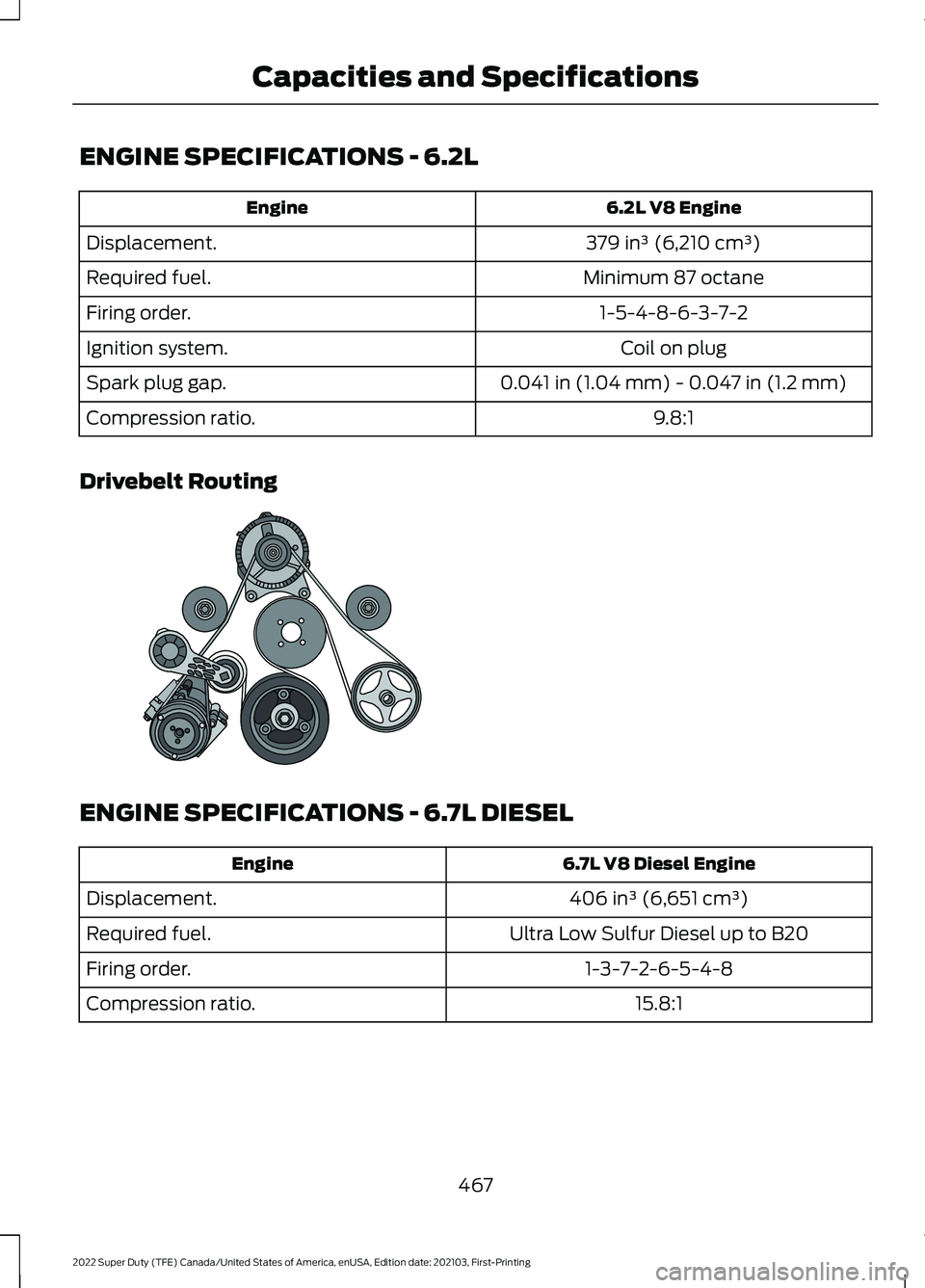

ENGINE SPECIFICATIONS - 6.2L

6.2L V8 Engine

Engine

379 in³ (6,210 cm³)

Displacement.

Minimum 87 octane

Required fuel.

1-5-4-8-6-3-7-2

Firing order.

Coil on plug

Ignition system.

0.041 in (1.04 mm) - 0.047 in (1.2 mm)

Spark plug gap.

9.8:1

Compression ratio.

Drivebelt Routing ENGINE SPECIFICATIONS - 6.7L DIESEL

6.7L V8 Diesel Engine

Engine

406 in³ (6,651 cm³)

Displacement.

Ultra Low Sulfur Diesel up to B20

Required fuel.

1-3-7-2-6-5-4-8

Firing order.

15.8:1

Compression ratio.

467

2022 Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 202103, First-Printing Capacities and Specifications E163761