fuel FORD F SERIES MOTORHOME AND COMMERCIAL CHASSIS 1999 10.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1999, Model line: F SERIES MOTORHOME AND COMMERCIAL CHASSIS, Model: FORD F SERIES MOTORHOME AND COMMERCIAL CHASSIS 1999 10.GPages: 96, PDF Size: 0.57 MB

Page 36 of 96

Separate functioning brake systems are required for safe control of

towed vehicles and trailers weighing more than 680 kg (1 500 lbs) when

loaded.

Trailer lamps

Trailer lamps are required on most towed vehicles. Make sure your

trailer lamps conform to local and Federal regulations. See your dealer or

trailer rental agency for proper instructions and equipment for hooking

up trailer lamps.

Driving while you tow

Do not drive faster than 88 km/h (55 mph) when towing a trailer.

Speed control may shut off if you are towing on long, steep grades.

When towing a trailer:

•Use a lower gear when towing up or down steep hills. This will

eliminate excessive downshifting and upshifting for optimum fuel

economy and transmission cooling.

•Anticipate stops and brake gradually.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your maintenance guide and or

service guide for more information.

Trailer towing tips

•Practice turning, stopping and backing up in an area before starting on

a trip to get the feel of the vehicle trailer combination. When turning,

make wider turns so the trailer wheels will clear curbs and other

obstacles.

•Allow more distance for stopping with a trailer attached.

•The trailer tongue weight should be 10% of the loaded trailer weight.

•After you have traveled 80 km (50 miles), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

•When stopped in traffic for long periods of time in hot weather, place

the gearshift in P (Park) and increase idle speed. This aids engine

cooling and air conditioner efficiency.

•Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer’s wheels.

Driving

36

Page 37 of 96

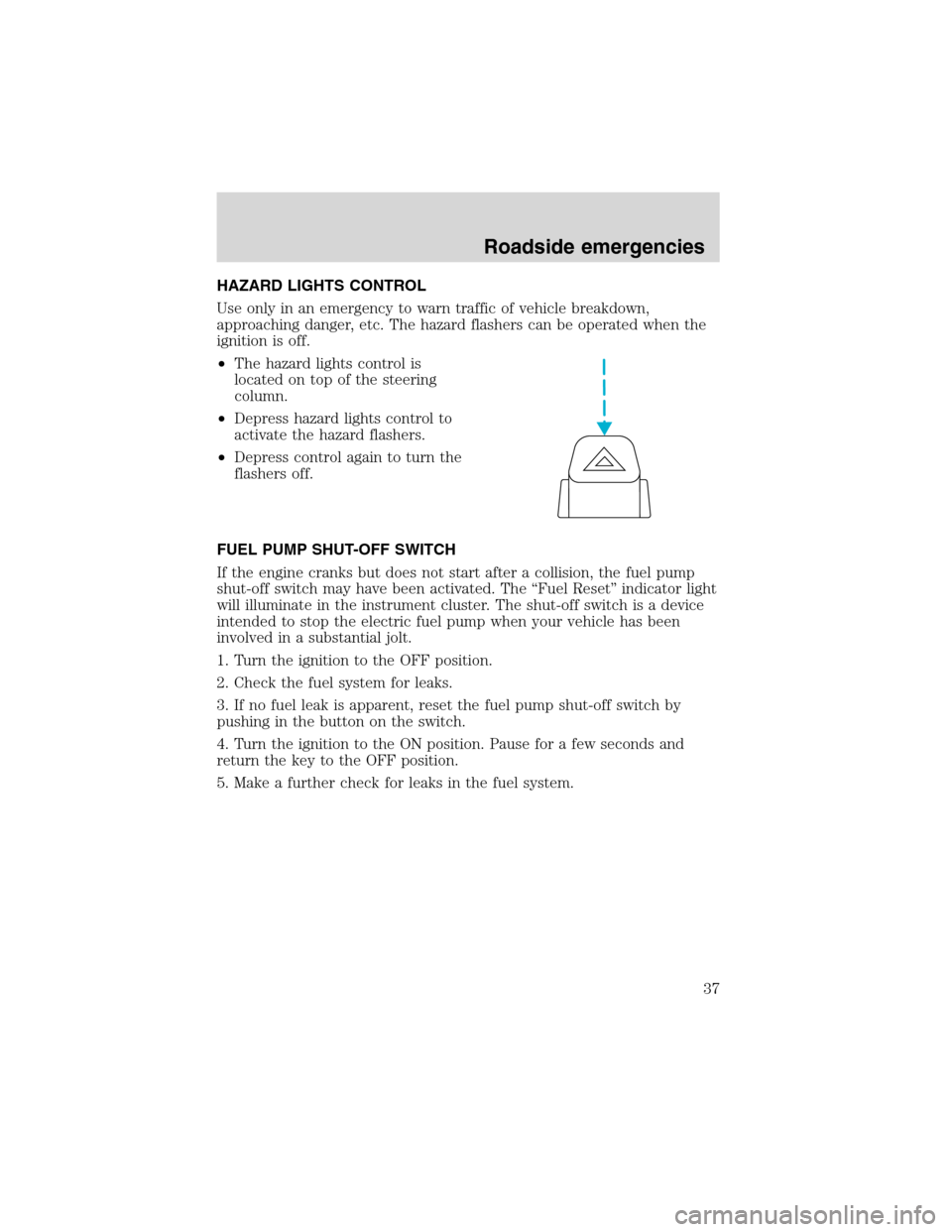

HAZARD LIGHTS CONTROL

Use only in an emergency to warn traffic of vehicle breakdown,

approaching danger, etc. The hazard flashers can be operated when the

ignition is off.

•The hazard lights control is

located on top of the steering

column.

•Depress hazard lights control to

activate the hazard flashers.

•Depress control again to turn the

flashers off.

FUEL PUMP SHUT-OFF SWITCH

If the engine cranks but does not start after a collision, the fuel pump

shut-off switch may have been activated. The “Fuel Reset” indicator light

will illuminate in the instrument cluster. The shut-off switch is a device

intended to stop the electric fuel pump when your vehicle has been

involved in a substantial jolt.

1. Turn the ignition to the OFF position.

2. Check the fuel system for leaks.

3. If no fuel leak is apparent, reset the fuel pump shut-off switch by

pushing in the button on the switch.

4. Turn the ignition to the ON position. Pause for a few seconds and

return the key to the OFF position.

5. Make a further check for leaks in the fuel system.

Roadside emergencies

37

Page 38 of 96

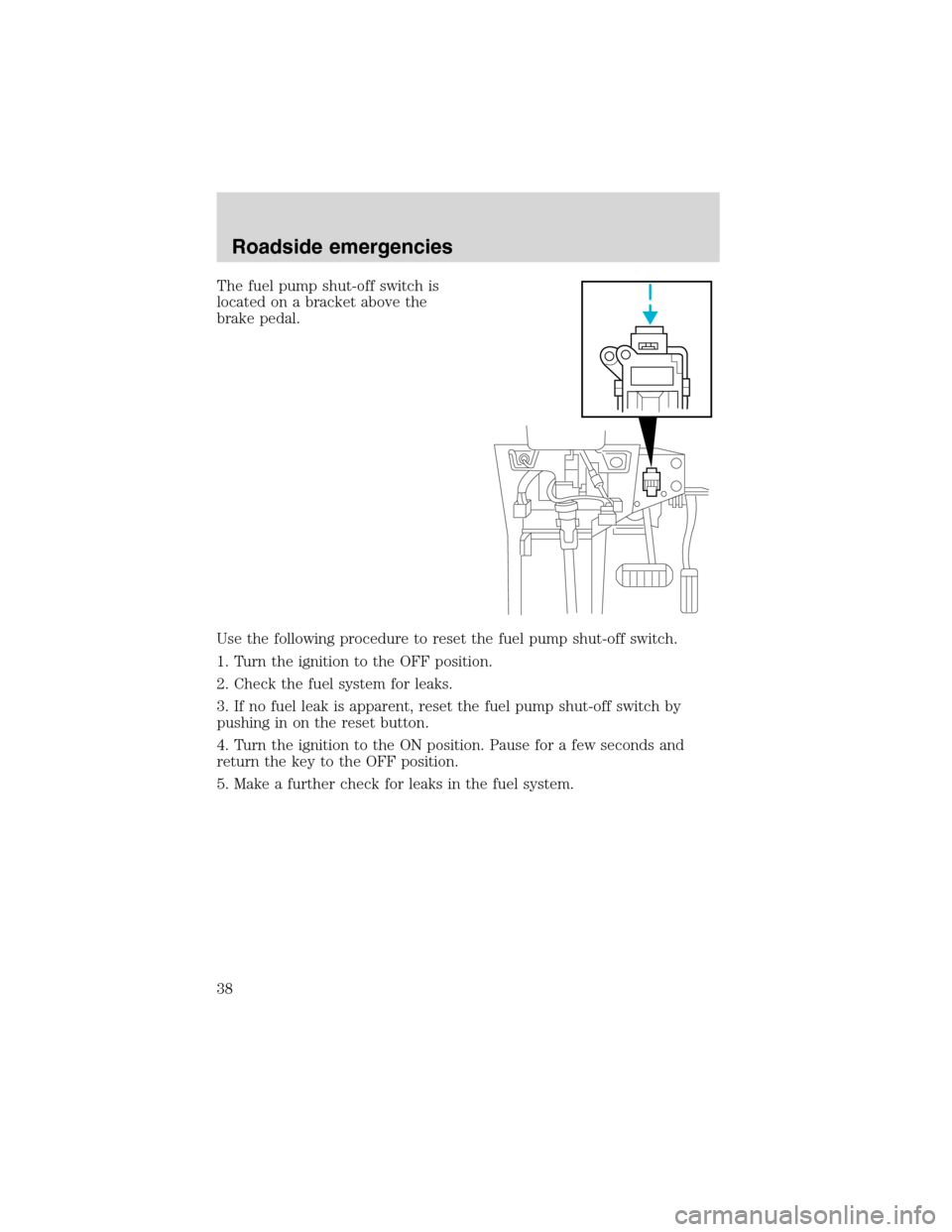

The fuel pump shut-off switch is

located on a bracket above the

brake pedal.

Use the following procedure to reset the fuel pump shut-off switch.

1. Turn the ignition to the OFF position.

2. Check the fuel system for leaks.

3. If no fuel leak is apparent, reset the fuel pump shut-off switch by

pushing in on the reset button.

4. Turn the ignition to the ON position. Pause for a few seconds and

return the key to the OFF position.

5. Make a further check for leaks in the fuel system.

Roadside emergencies

38

Page 43 of 96

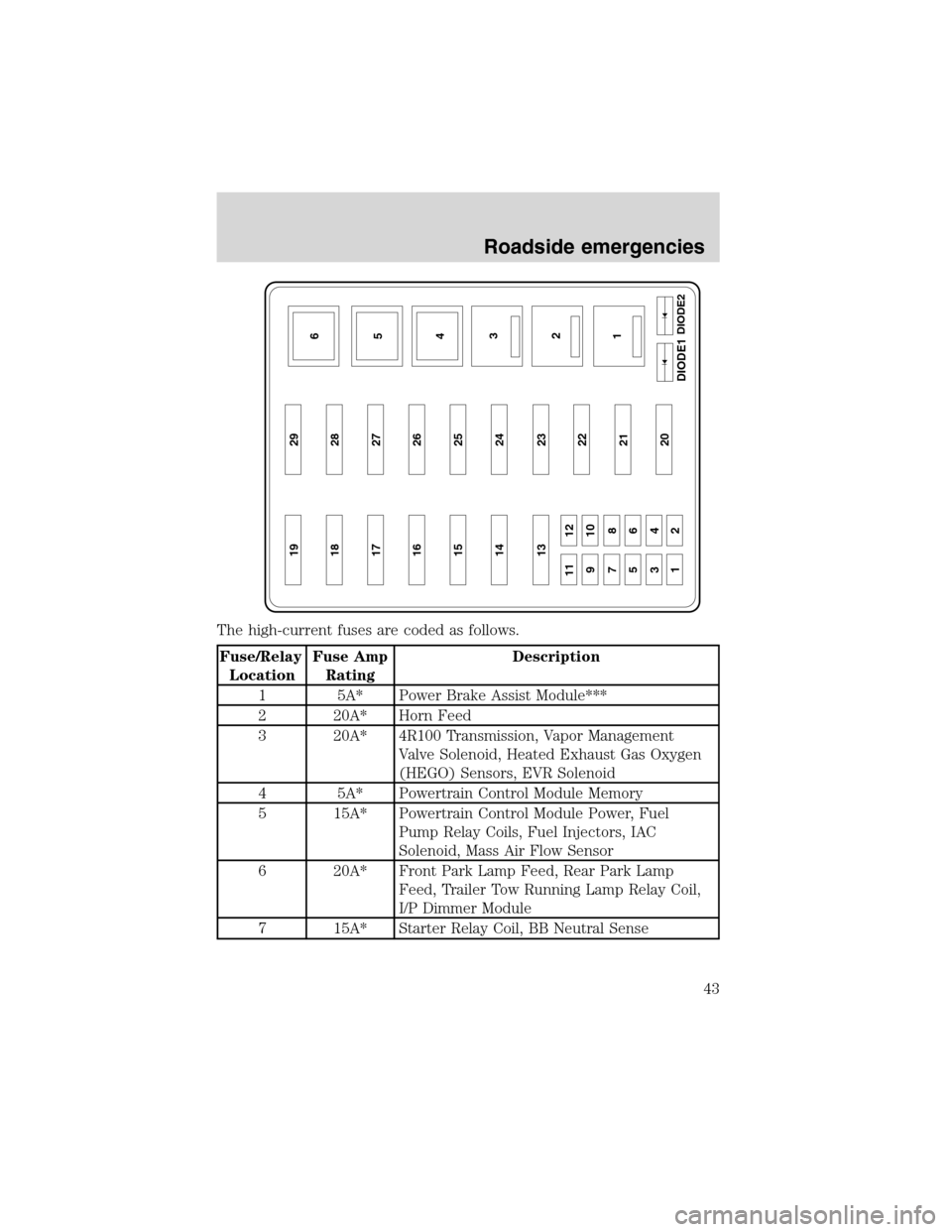

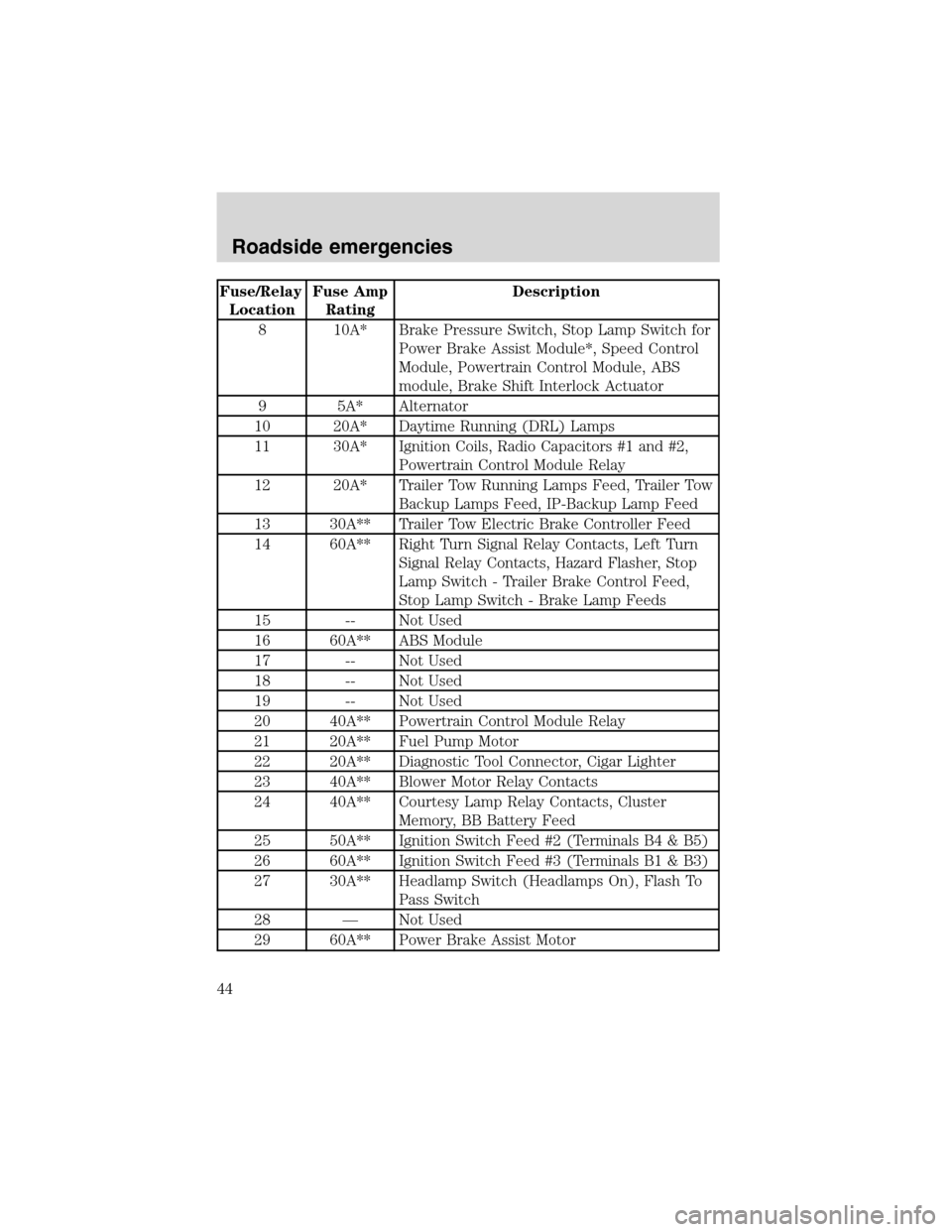

The high-current fuses are coded as follows.

Fuse/Relay

LocationFuse Amp

RatingDescription

1 5A* Power Brake Assist Module***

2 20A* Horn Feed

3 20A* 4R100 Transmission, Vapor Management

Valve Solenoid, Heated Exhaust Gas Oxygen

(HEGO) Sensors, EVR Solenoid

4 5A* Powertrain Control Module Memory

5 15A* Powertrain Control Module Power, Fuel

Pump Relay Coils, Fuel Injectors, IAC

Solenoid, Mass Air Flow Sensor

6 20A* Front Park Lamp Feed, Rear Park Lamp

Feed, Trailer Tow Running Lamp Relay Coil,

I/P Dimmer Module

7 15A* Starter Relay Coil, BB Neutral Sense

19 29

18 28

17 27

16 26

15 25

14 24

13

11 12

910

78

56

34

1223

22

21

20

6

5

4

3

2

1DIODE2

DIODE1

Roadside emergencies

43

Page 44 of 96

Fuse/Relay

LocationFuse Amp

RatingDescription

8 10A* Brake Pressure Switch, Stop Lamp Switch for

Power Brake Assist Module*, Speed Control

Module, Powertrain Control Module, ABS

module, Brake Shift Interlock Actuator

9 5A* Alternator

10 20A* Daytime Running (DRL) Lamps

11 30A* Ignition Coils, Radio Capacitors #1 and #2,

Powertrain Control Module Relay

12 20A* Trailer Tow Running Lamps Feed, Trailer Tow

Backup Lamps Feed, IP-Backup Lamp Feed

13 30A** Trailer Tow Electric Brake Controller Feed

14 60A** Right Turn Signal Relay Contacts, Left Turn

Signal Relay Contacts, Hazard Flasher, Stop

Lamp Switch - Trailer Brake Control Feed,

Stop Lamp Switch - Brake Lamp Feeds

15 -- Not Used

16 60A** ABS Module

17 -- Not Used

18 -- Not Used

19 -- Not Used

20 40A** Powertrain Control Module Relay

21 20A** Fuel Pump Motor

22 20A** Diagnostic Tool Connector, Cigar Lighter

23 40A** Blower Motor Relay Contacts

24 40A** Courtesy Lamp Relay Contacts, Cluster

Memory, BB Battery Feed

25 50A** Ignition Switch Feed #2 (Terminals B4 & B5)

26 60A** Ignition Switch Feed #3 (Terminals B1 & B3)

27 30A** Headlamp Switch (Headlamps On), Flash To

Pass Switch

28 — Not Used

29 60A** Power Brake Assist Motor

Roadside emergencies

44

Page 45 of 96

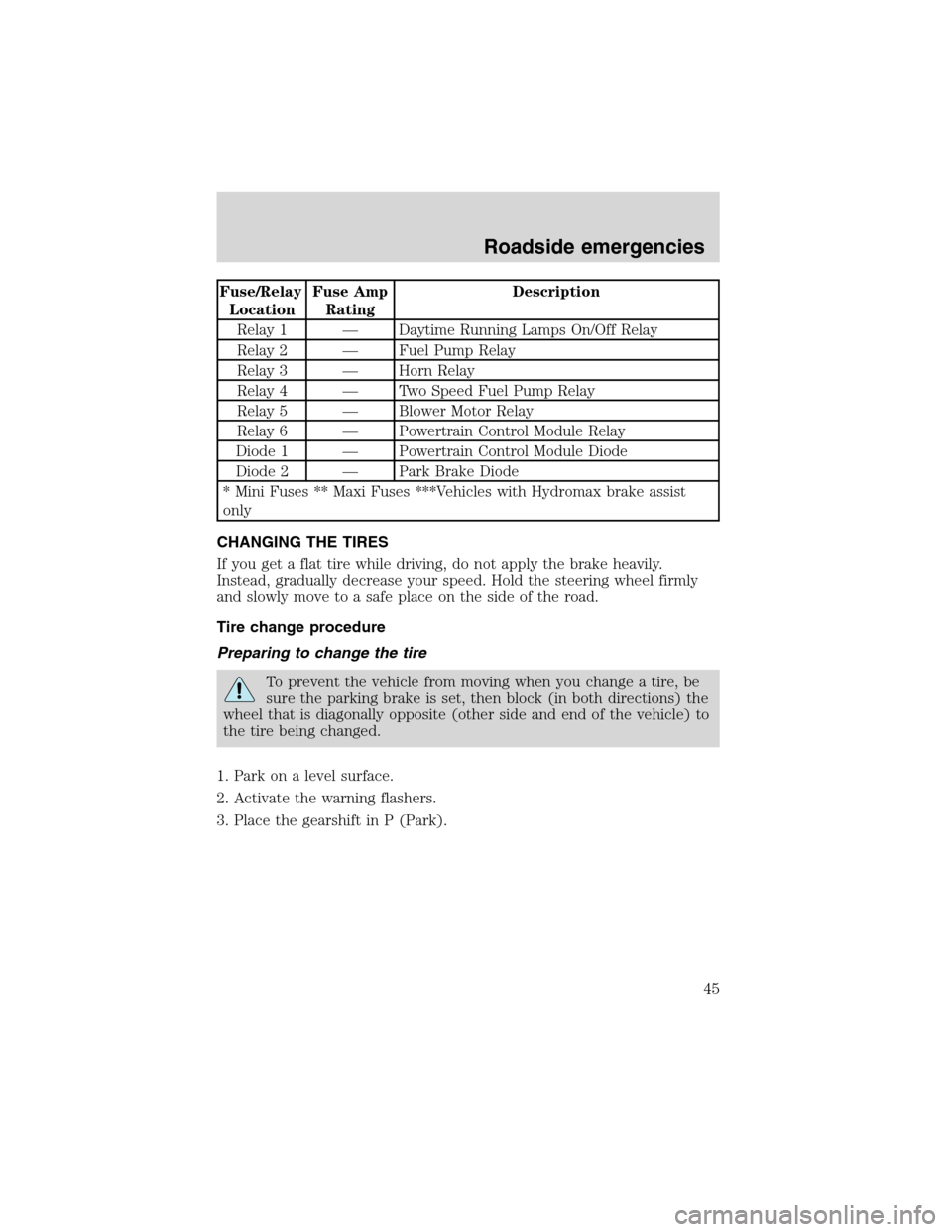

Fuse/Relay

LocationFuse Amp

RatingDescription

Relay 1 — Daytime Running Lamps On/Off Relay

Relay 2 — Fuel Pump Relay

Relay 3 — Horn Relay

Relay 4 — Two Speed Fuel Pump Relay

Relay 5 — Blower Motor Relay

Relay 6 — Powertrain Control Module Relay

Diode 1 — Powertrain Control Module Diode

Diode 2 — Park Brake Diode

* Mini Fuses ** Maxi Fuses ***Vehicles with Hydromax brake assist

only

CHANGING THE TIRES

If you get a flat tire while driving, do not apply the brake heavily.

Instead, gradually decrease your speed. Hold the steering wheel firmly

and slowly move to a safe place on the side of the road.

Tire change procedure

Preparing to change the tire

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block (in both directions) the

wheel that is diagonally opposite (other side and end of the vehicle) to

the tire being changed.

1. Park on a level surface.

2. Activate the warning flashers.

3. Place the gearshift in P (Park).

Roadside emergencies

45

Page 50 of 96

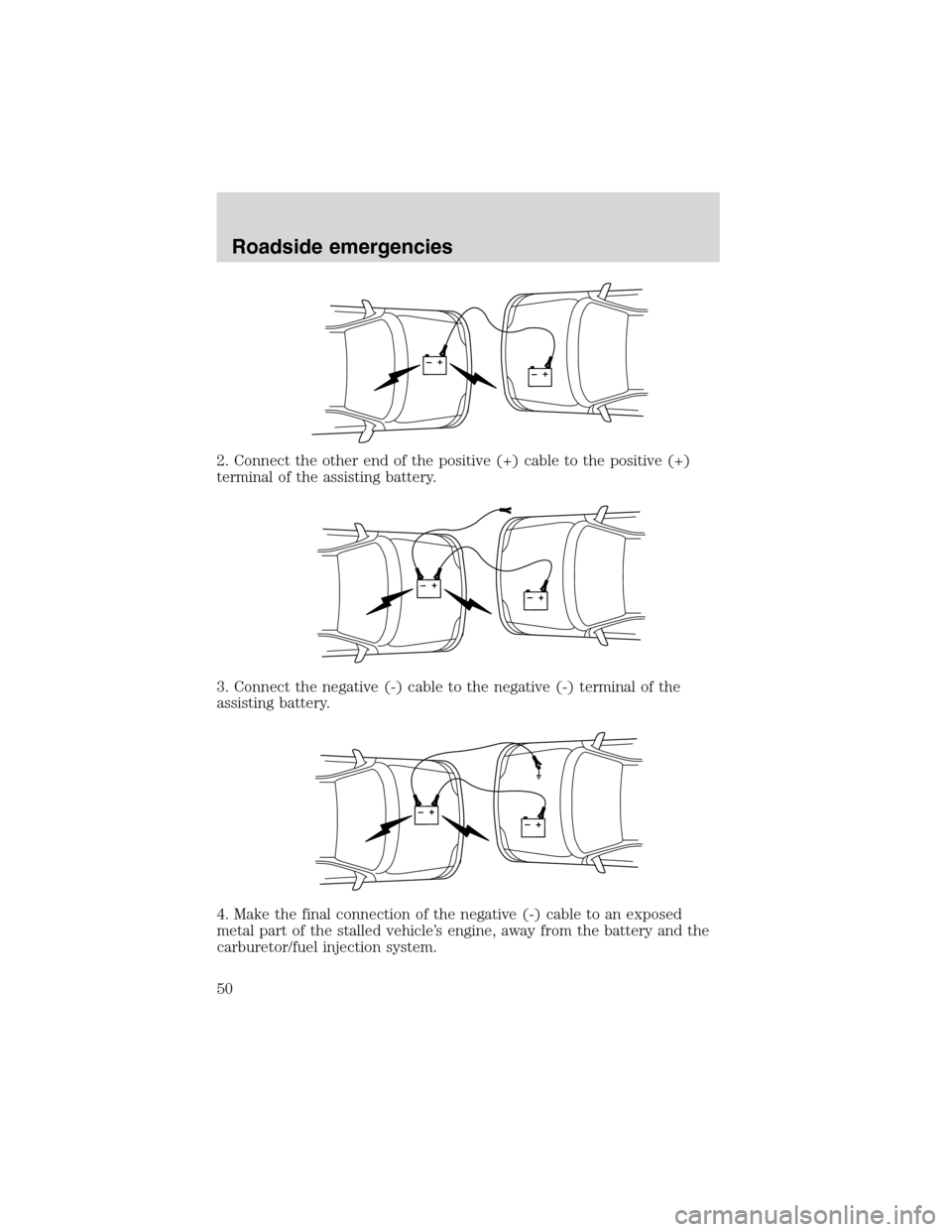

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle’s engine, away from the battery and the

carburetor/fuel injection system.

+–+–

+–+–

+–+–

Roadside emergencies

50

Page 51 of 96

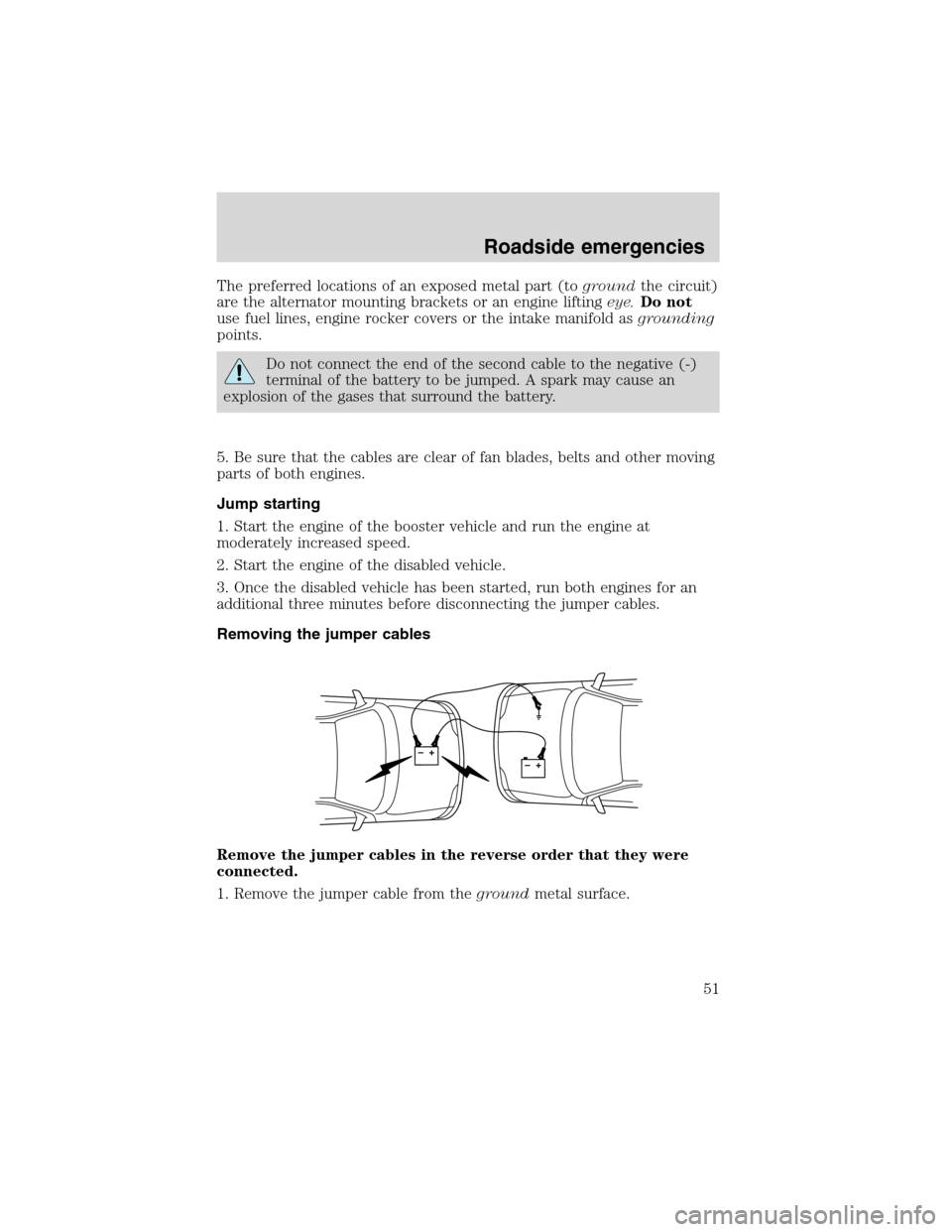

The preferred locations of an exposed metal part (togroundthe circuit)

are the alternator mounting brackets or an engine liftingeye.Do not

use fuel lines, engine rocker covers or the intake manifold asgrounding

points.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Be sure that the cables are clear of fan blades, belts and other moving

parts of both engines.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

+–+–

Roadside emergencies

51

Page 54 of 96

SERVICE RECOMMENDATIONS

To help you service your vehicle:

•We highlight do-it-yourself items in the engine compartment for easy

location.

•We provide a Scheduled Maintenance Guide which makes tracking

routine service easy.

If your vehicle requires professional service, your dealership can provide

necessary parts and service. Check your “Warranty Guide” to find out

which parts and services are covered.

Use only recommended fuels, lubricants, fluids and service parts

conforming to specifications. Motorcraft parts are designed and built to

provide the best performance in your vehicle.

PRECAUTIONS WHEN SERVICING YOUR VEHICLE

Be especially careful when inspecting or servicing your vehicle.

•Do not work on a hot engine.

•When the engine is running, make sure that loose clothing, jewelry or

long hair does not get caught up in moving parts.

•Do not work on a vehicle with the engine running in an enclosed

space, unless you are sure you have enough ventilation.

•Keep all lit cigarettes, open flames and other lit material away from

the battery and all fuel related parts.

If you disconnect the battery, the engine must “relearn” its idle

conditions before your vehicle will drive properly, as explained inBattery

in this chapter.

Working with the engine off

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Turn off the engine and remove the key.

3. Block the wheels to prevent the vehicle from moving unexpectedly.

Working with the engine on

1. Set the parking brake and ensure the gearshift is securely latched in P

(Park).

2. Block the wheels to prevent the vehicle from moving unexpectedly.

Maintenance and care

54

Page 68 of 96

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

When lifting a plastic-cased battery, excessive pressure on the

end walls could cause acid to flow through the vent caps,

resulting in personal injury and/or damage to the vehicle or battery.

Lift the battery with a battery carrier or with your hands on opposite

corners.

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

To account for customer driving habits and conditions, your automatic

transmission electronically controls the shift quality by using an adaptive

learning strategy. The adaptive learning strategy is maintained by power

from the battery. When the battery is disconnected or a new battery is

installed, the transmission must relearn its adaptive strategy. Optimal

shifting will resume within a few hundred kilometers (miles) of

operation.

If the shift quality does not improve within a few hundred

kilometers (miles) of operation, or if the downshifts and other

throttle conditions do not function normally, see your dealer or a

qualified service technician as soon as possible.

Because your vehicle’s engine is also electronically controlled by a

computer, some control conditions are maintained by power from the

battery. When the battery is disconnected or a new battery is installed,

the engine must relearn its idle and fuel trim strategy for optimum

driveability and performance. To begin this process:

1. Set your parking brake.

Maintenance and care

68