fuel pressure FORD F150 2002 10.G Bi Fuel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2002, Model line: F150, Model: FORD F150 2002 10.GPages: 32, PDF Size: 0.51 MB

Page 3 of 32

GASEOUS FUEL INJECTION

YourBi-fuelvehicle is equipped with two fuel injection systems, an

unleaded gasoline fuel system and a gaseous fuel injection system.

Two types of gaseous fuel injection systems are available:

²Compressed Natural Gas (CNG)

²Liquefied Petroleum Gas (LPG)

The two available gaseous fuel injection systems operate in somewhat

similar manners. However, differences in operating pressures and

gaseous fuel properties make itimportantthat you understand which

system you are using.

If you are unsure as to which fuel system you have, contact your dealer.

Your new Gaseous Fuel Injection System is a result of years of research

and technical experience. It employes the latest solid state electronics to

provide excellent driveability, emissions control and fuel economy.

Compressed natural gas (CNG)

Compressed natural gas (CNG) is a mixture of hydrocarbon gases with a

high concentration of methane that is stored under high pressure.

Abundant reserves of natural gas in the United States and Canada allow

natural gas to be used as a very cost-efficient fuel. Natural gas is a clean

burning fuel, making it a highly suitable fuel to meet automotive emission

standards.

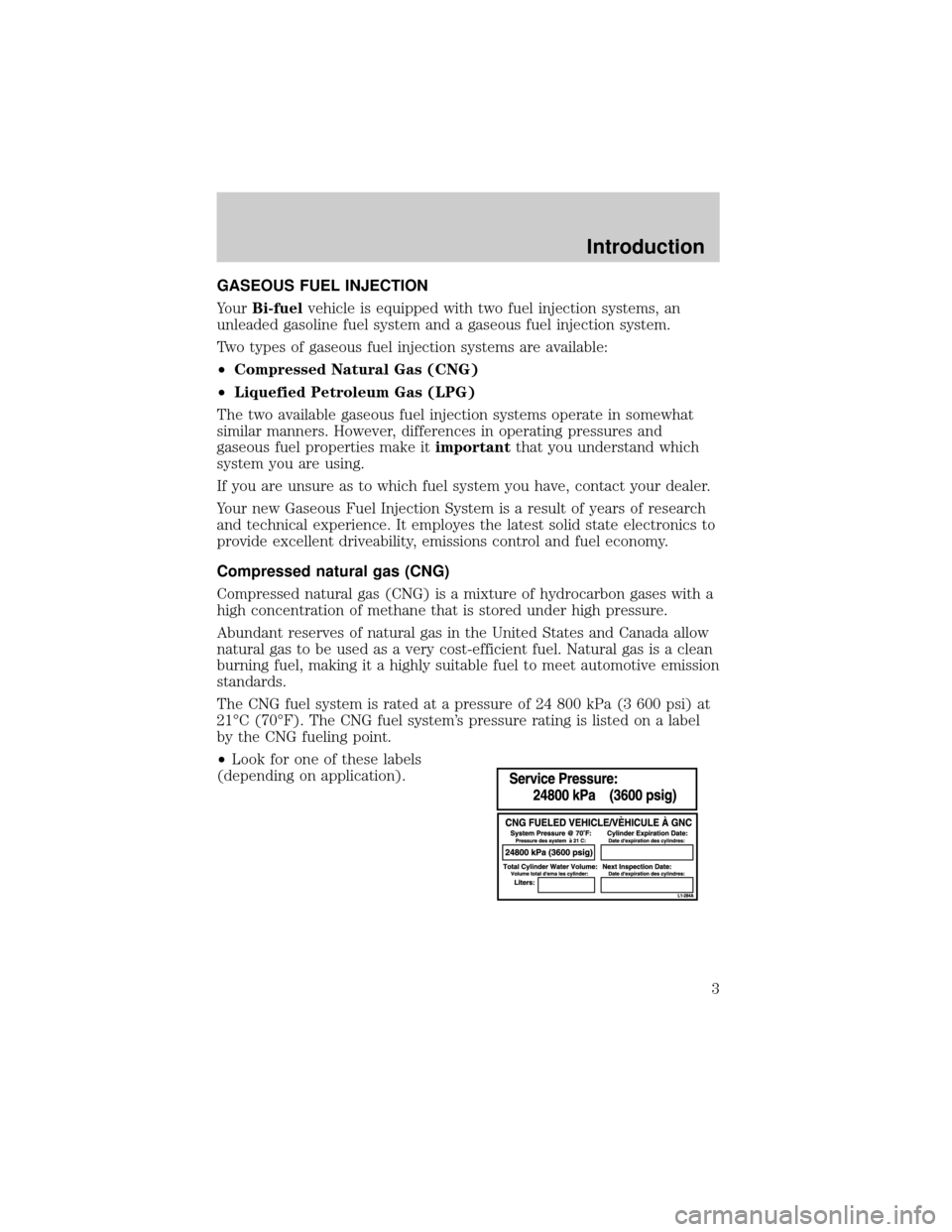

The CNG fuel system is rated at a pressure of 24 800 kPa (3 600 psi) at

21ÉC (70ÉF). The CNG fuel system's pressure rating is listed on a label

by the CNG fueling point.

²Look for one of these labels

(depending on application).

Introduction

3

Page 4 of 32

Use caution when servicing or maintaining any of the components of the

CNG fuel system. Failure to provide adequate ventilation could result in

gas vapor build up over time potentially resulting in a combustible

mixture.

Service to CNG fuel system must be conducted only at qualified

dealerships by qualified technicians. Failure to do so may cause

damage to components or cause bodily harm.

Liquefied petroleum gas (LPG)

Liquefied Petroleum Gas (LPG) is a mixture of hydrocarbon gases

consisting mostly of propane with smaller amounts of ethane and butane,

which when under low pressure, are stored in a liquefied state.

LPG is a clean burning fuel, making it a highly suitable fuel to meet

automotive emission standards.

Automotive grade LPG is typically referred to as HD-5 Propane (HD-10

Propane in California) and contains at least 90% propane.

Use caution when servicing or maintaining any of the components of the

LPG fuel system. Failure to provide adequate ventilation could result in

gas vapor build up over time potentially resulting in a combustible

mixture.

Service to LPG fuel system components must be conducted only

at qualified dealerships by qualified technicians. Failure to do so

may cause damage to components or cause bodily harm.

PRECAUTIONARY INFORMATION

In certain localities, local authorities have established guidelines and

regulations that directly affect the operation and storage of yourBi-fuel

vehicle.

These established guidelines and regulations include:

²refueling.

²underground parking.

²operating your vehicle under bridges or in tunnels.

More information on established guidelines and regulations are available

from your qualified Ford dealership.

Introduction

4

Page 6 of 32

If yourBi-fuelvehicle is to be painted, the CNG or propane fuel tank(s)

and fuel lines must be emptied before the vehicle is placed in a heated

room, known as a ªpaint ovenº, for the new paint to cure. These ªpaint

ovensº typically operate at temperatures up to 60É C (140É F). The high

temperatures in the ªpaint ovenº could cause the fuel in the fuel tanks to

expand, which may cause an overpressure condition within the fuel tanks

that can be hazardous to personal safety and property. Contact your

qualified Ford dealership for assistance.

Do not use paint drying ovens for propane-fueled vehicles. The

heat of paint drying ovens will increase the pressure in the fuel

tanks. This could cause venting of propane fuel vapor into the oven

and result in a fire from the heat or sparks in the electrical equipment.

If the fuel is confined inside an oven, an explosion may occur. When

refinishing the body panels of a propane-fueled vehicle, use spot

painting and drying methods.

Failure to empty (vent) the CNG or propane fuel tank(s) and

fuel lines prior to vehicle being placed in a ªpaint ovenº may

cause an overpressure condition within the fuel tanks that can be

hazardous to personal safety and property.

On F-Series Bi-fuel vehicles, do notmodify or replace the cargo bed

with any non-OEM components. Should the cargo bed need to be

removed for service or replacement, it should be done at a qualified

dealership using qualified service technicians. Do not sit, stand or place

heavy loads on the in-bed fuel tank cover. Any cap added to the cargo

bed on this vehicle must be vented to the outside (consult your local

regulations). Failure to provide adequate ventilation could result in gas

vapor build up over time, potentially resulting in a combustible mixture.

Introduction

6

Page 11 of 32

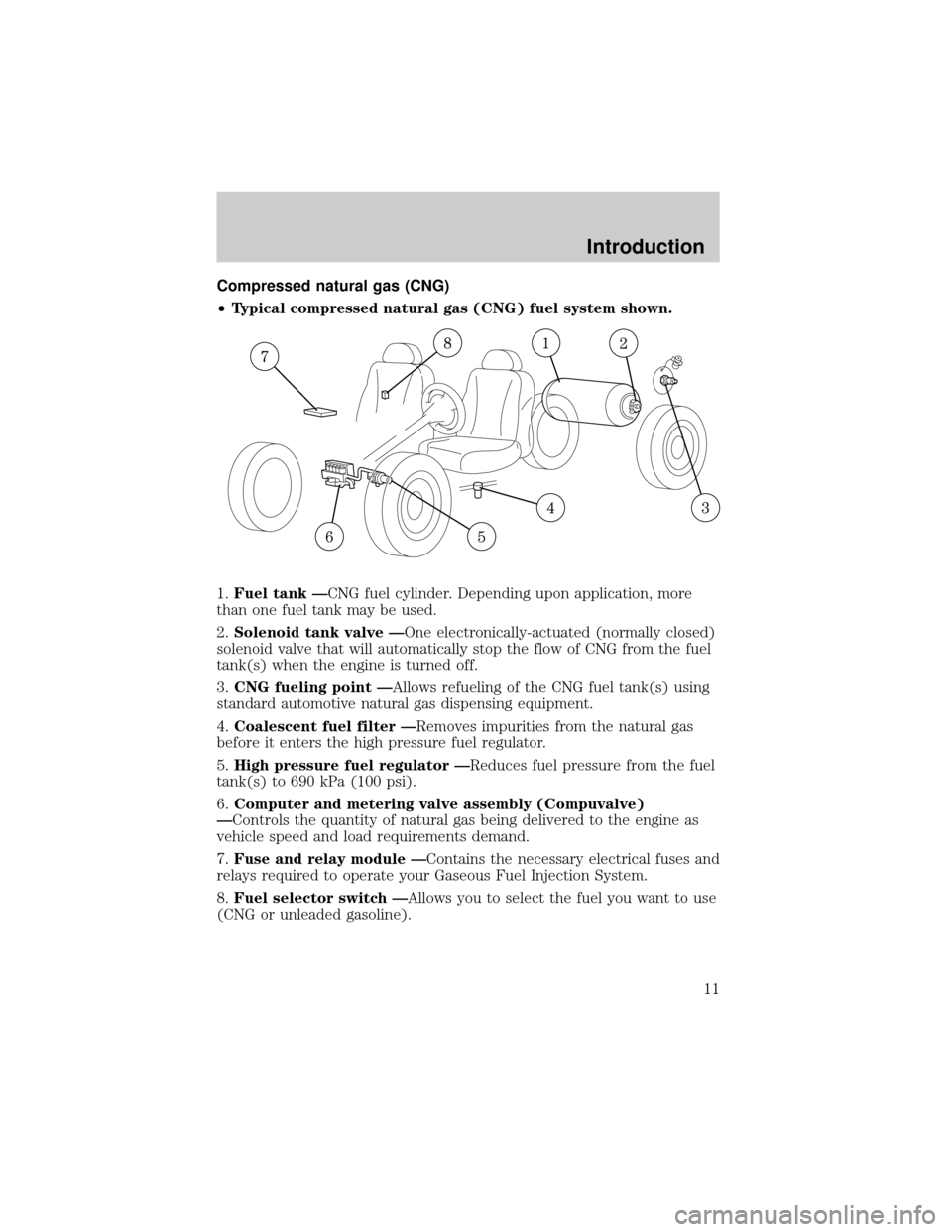

Compressed natural gas (CNG)

²Typical compressed natural gas (CNG) fuel system shown.

1.Fuel tank ÐCNG fuel cylinder. Depending upon application, more

than one fuel tank may be used.

2.Solenoid tank valve ÐOne electronically-actuated (normally closed)

solenoid valve that will automatically stop the flow of CNG from the fuel

tank(s) when the engine is turned off.

3.CNG fueling point ÐAllows refueling of the CNG fuel tank(s) using

standard automotive natural gas dispensing equipment.

4.Coalescent fuel filter ÐRemoves impurities from the natural gas

before it enters the high pressure fuel regulator.

5.High pressure fuel regulator ÐReduces fuel pressure from the fuel

tank(s) to 690 kPa (100 psi).

6.Computer and metering valve assembly (Compuvalve)

ÐControls the quantity of natural gas being delivered to the engine as

vehicle speed and load requirements demand.

7.Fuse and relay module ÐContains the necessary electrical fuses and

relays required to operate your Gaseous Fuel Injection System.

8.Fuel selector switch ÐAllows you to select the fuel you want to use

(CNG or unleaded gasoline).

Introduction

11

Page 12 of 32

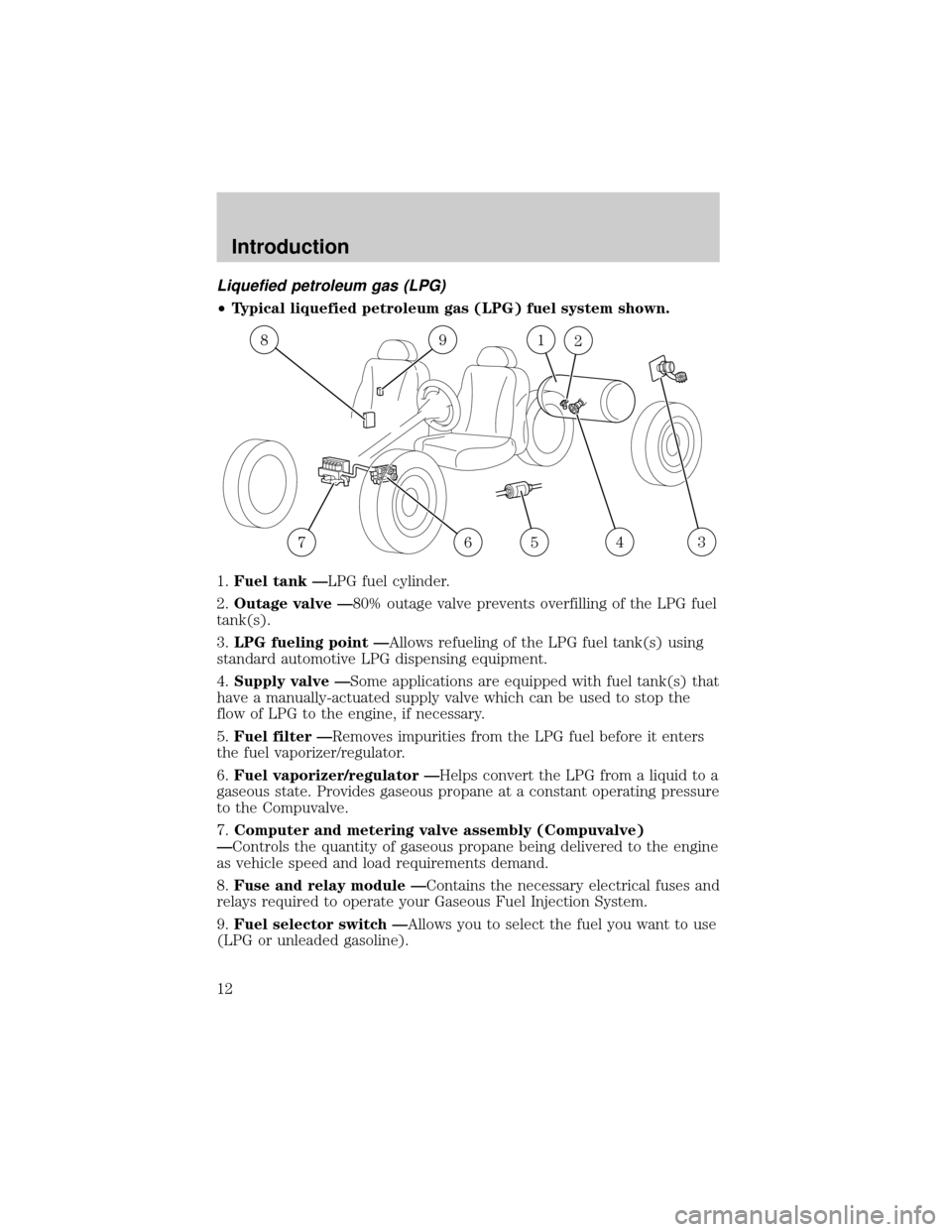

Liquefied petroleum gas (LPG)

²Typical liquefied petroleum gas (LPG) fuel system shown.

1.Fuel tank ÐLPG fuel cylinder.

2.Outage valve Ð80% outage valve prevents overfilling of the LPG fuel

tank(s).

3.LPG fueling point ÐAllows refueling of the LPG fuel tank(s) using

standard automotive LPG dispensing equipment.

4.Supply valve ÐSome applications are equipped with fuel tank(s) that

have a manually-actuated supply valve which can be used to stop the

flow of LPG to the engine, if necessary.

5.Fuel filter ÐRemoves impurities from the LPG fuel before it enters

the fuel vaporizer/regulator.

6.Fuel vaporizer/regulator ÐHelps convert the LPG from a liquid to a

gaseous state. Provides gaseous propane at a constant operating pressure

to the Compuvalve.

7.Computer and metering valve assembly (Compuvalve)

ÐControls the quantity of gaseous propane being delivered to the engine

as vehicle speed and load requirements demand.

8.Fuse and relay module ÐContains the necessary electrical fuses and

relays required to operate your Gaseous Fuel Injection System.

9.Fuel selector switch ÐAllows you to select the fuel you want to use

(LPG or unleaded gasoline).

192

35467

8

Introduction

12

Page 14 of 32

When the selector switch is placed

in the GAS position, your engine will

operate in the unleaded gasoline

mode.

If the CNG or LPG (depending upon application) runs low during the

operation of the vehicle in the gaseous fuel mode, the gaseous fuel

injection system will automatically change to the unleaded gasoline

operating mode. The green indicator light on the fuel selector switch will

turn off to show the vehicle has changed to the unleaded gasoline

operating mode.

The vehicle's fuel system will NOT automatically change to the

gaseous fuel mode (CNG or LPG, depending upon application),

if the level of the unleaded gasoline runs low.

FUEL GAUGE

The fuel gauge in your CNG or LPGBi-fuelvehicle (depending upon

application) behaves similarly to a standard gasoline fuel gauge. The fuel

gauge will provide a linear reading from Full down to Empty.

²Fuel gauge operation for aLPG Bi-fuelvehicle is based on a float

type sensor measuring the level of the liquid propane in the fuel

tank(s).

²Fuel gauge operation for aCNG Bi-fuelvehicle is based on the

pressure and temperature of the natural gas in the fuel tank(s).

Depending upon the application, a full fuel gauge reading will occur at

a pressure of approximately 20 700 kPa (3 000 psi) or 24 800 kPa

(3 600 psi) at a temperature of approximately 21ÉC (70ÉF). For more

information on fuel gauge performance during the fast-fill method of

CNG fueling, refer toRefueling your Bi-fuel vehiclein the

Maintenance and carechapter of this supplement.

ALT

GAS

Instrumentation and controls

14

Page 25 of 32

Many localities have restrictions on refueling CNG and LPG fueled

vehicles. In these localities, only qualified technicians at designated

refueling stations are allowed to refuel your vehicle. Refer to your

local authorized Ford dealer for more information.

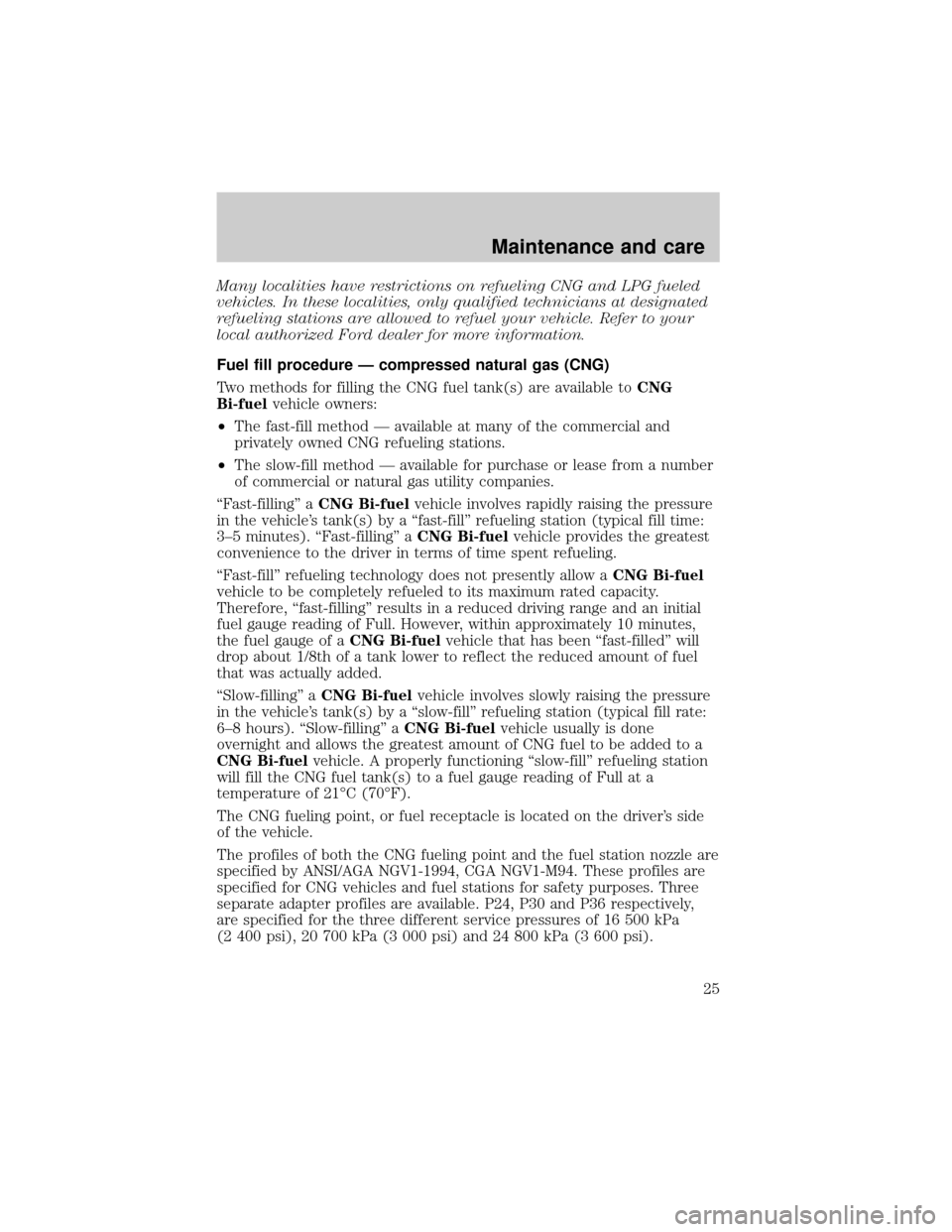

Fuel fill procedure Ð compressed natural gas (CNG)

Two methods for filling the CNG fuel tank(s) are available toCNG

Bi-fuelvehicle owners:

²The fast-fill method Ð available at many of the commercial and

privately owned CNG refueling stations.

²The slow-fill method Ð available for purchase or lease from a number

of commercial or natural gas utility companies.

ªFast-fillingº aCNG Bi-fuelvehicle involves rapidly raising the pressure

in the vehicle's tank(s) by a ªfast-fillº refueling station (typical fill time:

3±5 minutes). ªFast-fillingº aCNG Bi-fuelvehicle provides the greatest

convenience to the driver in terms of time spent refueling.

ªFast-fillº refueling technology does not presently allow aCNG Bi-fuel

vehicle to be completely refueled to its maximum rated capacity.

Therefore, ªfast-fillingº results in a reduced driving range and an initial

fuel gauge reading of Full. However, within approximately 10 minutes,

the fuel gauge of aCNG Bi-fuelvehicle that has been ªfast-filledº will

drop about 1/8th of a tank lower to reflect the reduced amount of fuel

that was actually added.

ªSlow-fillingº aCNG Bi-fuelvehicle involves slowly raising the pressure

in the vehicle's tank(s) by a ªslow-fillº refueling station (typical fill rate:

6±8 hours). ªSlow-fillingº aCNG Bi-fuelvehicle usually is done

overnight and allows the greatest amount of CNG fuel to be added to a

CNG Bi-fuelvehicle. A properly functioning ªslow-fillº refueling station

will fill the CNG fuel tank(s) to a fuel gauge reading of Full at a

temperature of 21ÉC (70ÉF).

The CNG fueling point, or fuel receptacle is located on the driver's side

of the vehicle.

The profiles of both the CNG fueling point and the fuel station nozzle are

specified by ANSI/AGA NGV1-1994, CGA NGV1-M94. These profiles are

specified for CNG vehicles and fuel stations for safety purposes. Three

separate adapter profiles are available. P24, P30 and P36 respectively,

are specified for the three different service pressures of 16 500 kPa

(2 400 psi), 20 700 kPa (3 000 psi) and 24 800 kPa (3 600 psi).

Maintenance and care

25

Page 26 of 32

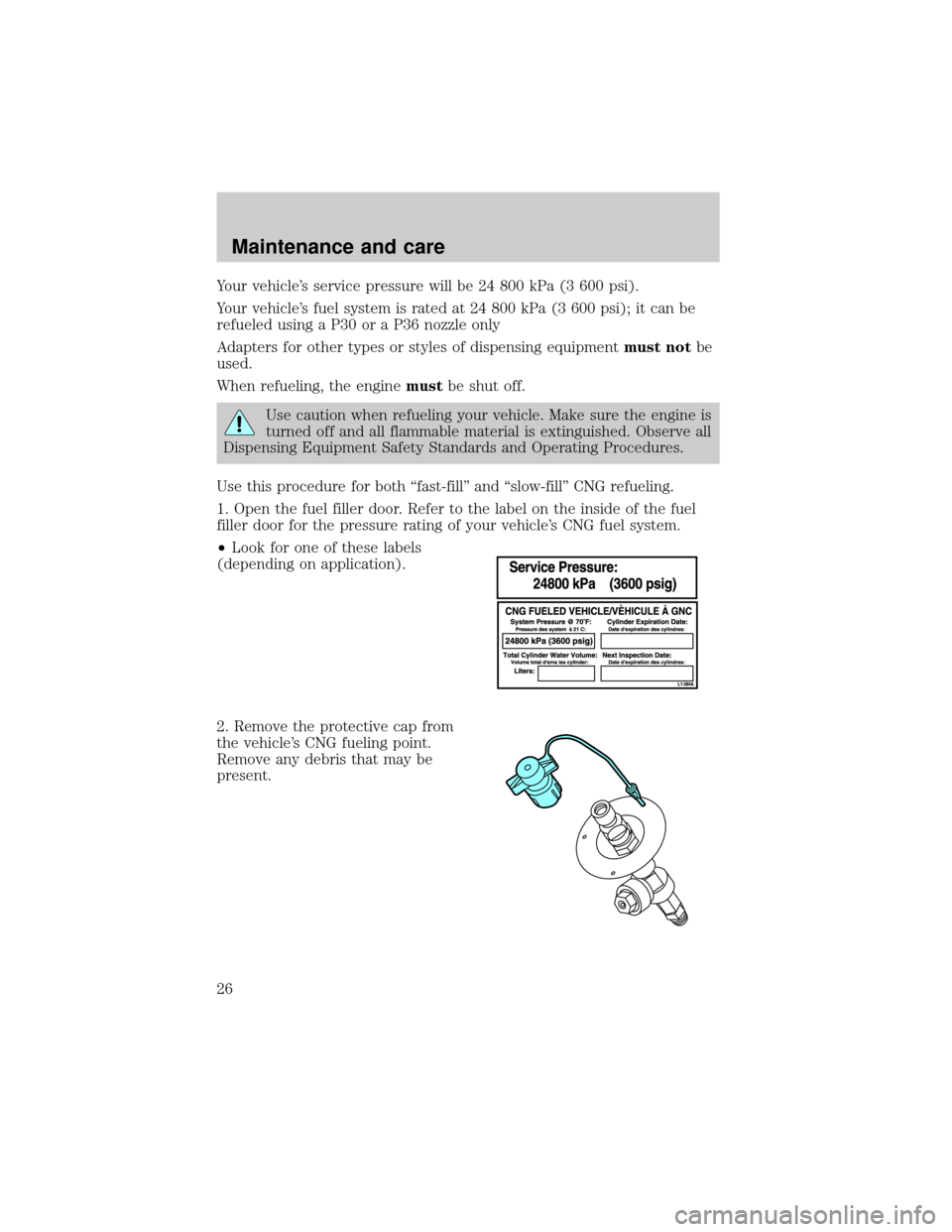

Your vehicle's service pressure will be 24 800 kPa (3 600 psi).

Your vehicle's fuel system is rated at 24 800 kPa (3 600 psi); it can be

refueled using a P30 or a P36 nozzle only

Adapters for other types or styles of dispensing equipmentmust notbe

used.

When refueling, the enginemustbe shut off.

Use caution when refueling your vehicle. Make sure the engine is

turned off and all flammable material is extinguished. Observe all

Dispensing Equipment Safety Standards and Operating Procedures.

Use this procedure for both ªfast-fillº and ªslow-fillº CNG refueling.

1. Open the fuel filler door. Refer to the label on the inside of the fuel

filler door for the pressure rating of your vehicle's CNG fuel system.

²Look for one of these labels

(depending on application).

2. Remove the protective cap from

the vehicle's CNG fueling point.

Remove any debris that may be

present.

Maintenance and care

26

Page 30 of 32

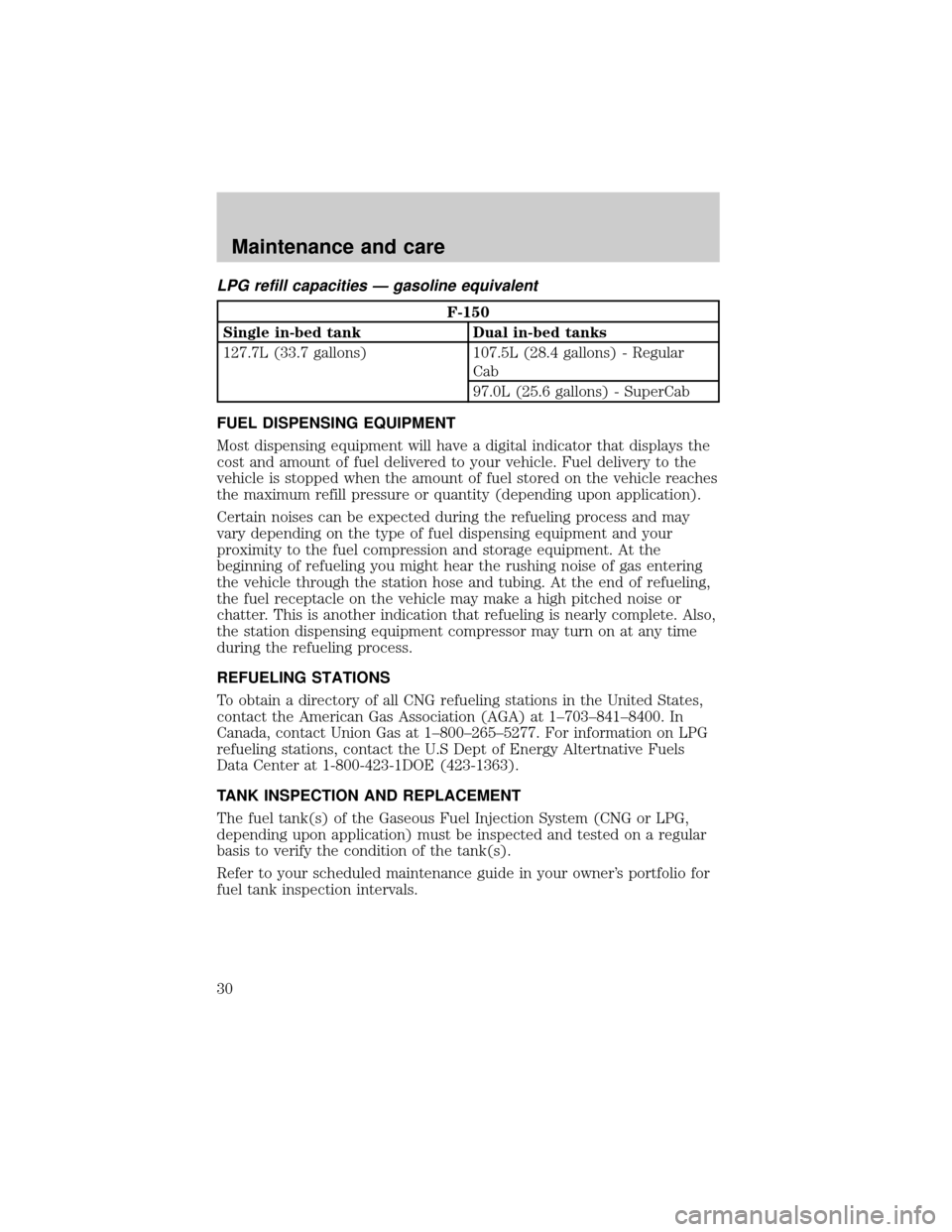

LPG refill capacities Ð gasoline equivalent

F-150

Single in-bed tank Dual in-bed tanks

127.7L (33.7 gallons) 107.5L (28.4 gallons) - Regular

Cab

97.0L (25.6 gallons) - SuperCab

FUEL DISPENSING EQUIPMENT

Most dispensing equipment will have a digital indicator that displays the

cost and amount of fuel delivered to your vehicle. Fuel delivery to the

vehicle is stopped when the amount of fuel stored on the vehicle reaches

the maximum refill pressure or quantity (depending upon application).

Certain noises can be expected during the refueling process and may

vary depending on the type of fuel dispensing equipment and your

proximity to the fuel compression and storage equipment. At the

beginning of refueling you might hear the rushing noise of gas entering

the vehicle through the station hose and tubing. At the end of refueling,

the fuel receptacle on the vehicle may make a high pitched noise or

chatter. This is another indication that refueling is nearly complete. Also,

the station dispensing equipment compressor may turn on at any time

during the refueling process.

REFUELING STATIONS

To obtain a directory of all CNG refueling stations in the United States,

contact the American Gas Association (AGA) at 1±703±841±8400. In

Canada, contact Union Gas at 1±800±265±5277. For information on LPG

refueling stations, contact the U.S Dept of Energy Altertnative Fuels

Data Center at 1-800-423-1DOE (423-1363).

TANK INSPECTION AND REPLACEMENT

The fuel tank(s) of the Gaseous Fuel Injection System (CNG or LPG,

depending upon application) must be inspected and tested on a regular

basis to verify the condition of the tank(s).

Refer to your scheduled maintenance guide in your owner's portfolio for

fuel tank inspection intervals.

Maintenance and care

30