FORD F250 SUPER DUTY 2014 Owners Manual

Manufacturer: FORD, Model Year: 2014, Model line: F250 SUPER DUTY, Model: FORD F250 SUPER DUTY 2014Pages: 460, PDF Size: 6.55 MB

Page 241 of 460

2. Release the wiper blade lock (A) andseparate the wiper blade from thewiper arm.

3. Install in the reverse order.

Note:Make sure that the wiper blade locksinto place. Lower the wiper arm and bladeback on the windshield. The wiper arms willautomatically return to their normal positionwhen you turn the ignition on.

•Replace wiper blades at least once peryear for optimum performance.

•You can improve poor wiper quality bycleaning the wiper blades and thewindshield.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle areproperly aimed at the assembly plant. Ifyour vehicle has been in an accident, thealignment of your headlamps should bechecked by your authorized dealer.

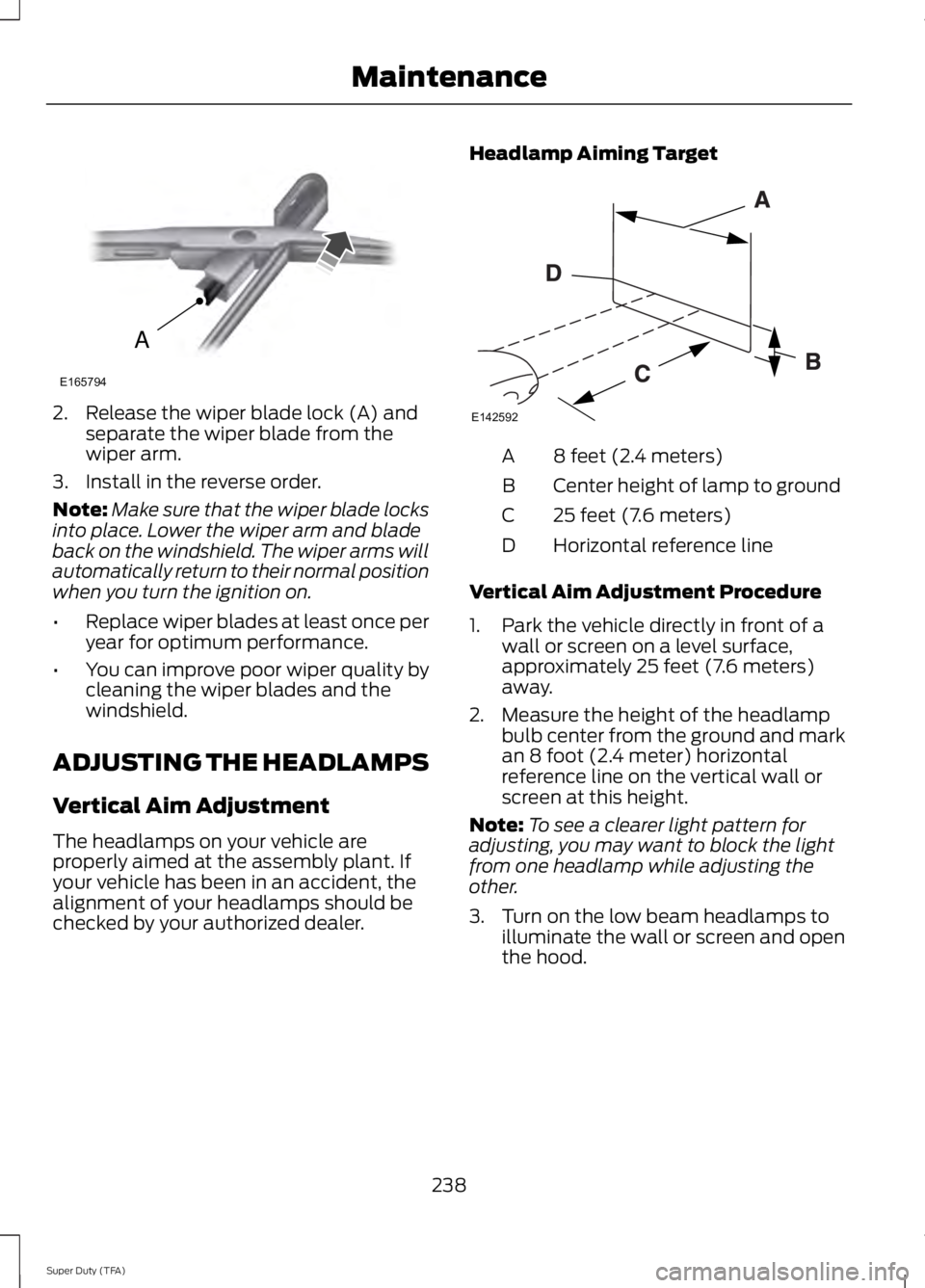

Headlamp Aiming Target

8 feet (2.4 meters)A

Center height of lamp to groundB

25 feet (7.6 meters)C

Horizontal reference lineD

Vertical Aim Adjustment Procedure

1. Park the vehicle directly in front of awall or screen on a level surface,approximately 25 feet (7.6 meters)away.

2. Measure the height of the headlampbulb center from the ground and markan 8 foot (2.4 meter) horizontalreference line on the vertical wall orscreen at this height.

Note:To see a clearer light pattern foradjusting, you may want to block the lightfrom one headlamp while adjusting theother.

3. Turn on the low beam headlamps toilluminate the wall or screen and openthe hood.

238

Super Duty (TFA)

MaintenanceA

E165794 E142592

Page 242 of 460

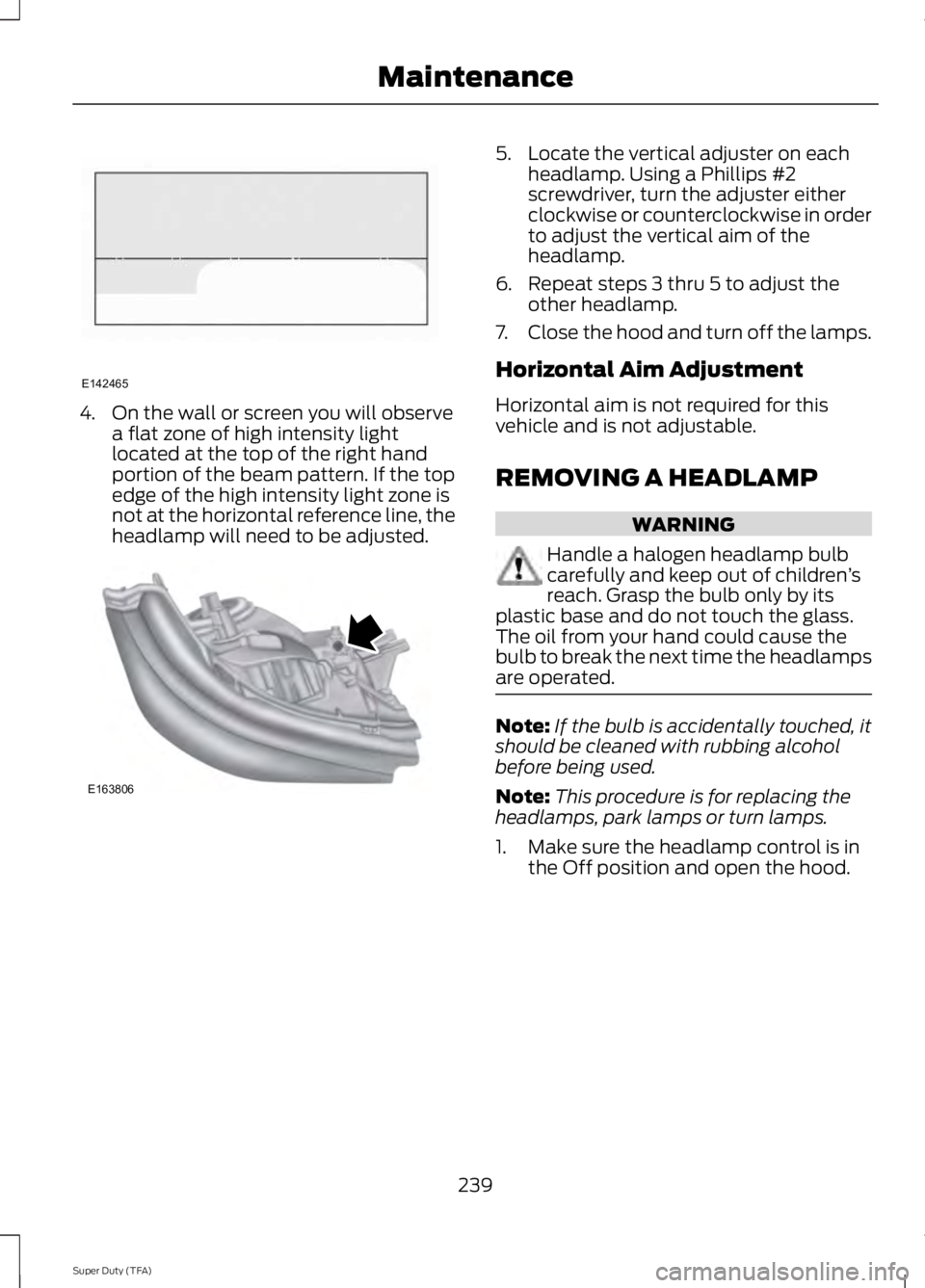

4. On the wall or screen you will observea flat zone of high intensity lightlocated at the top of the right handportion of the beam pattern. If the topedge of the high intensity light zone isnot at the horizontal reference line, theheadlamp will need to be adjusted.

5. Locate the vertical adjuster on eachheadlamp. Using a Phillips #2screwdriver, turn the adjuster eitherclockwise or counterclockwise in orderto adjust the vertical aim of theheadlamp.

6. Repeat steps 3 thru 5 to adjust theother headlamp.

7.Close the hood and turn off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for thisvehicle and is not adjustable.

REMOVING A HEADLAMP

WARNING

Handle a halogen headlamp bulbcarefully and keep out of children’sreach. Grasp the bulb only by itsplastic base and do not touch the glass.The oil from your hand could cause thebulb to break the next time the headlampsare operated.

Note:If the bulb is accidentally touched, itshould be cleaned with rubbing alcoholbefore being used.

Note:This procedure is for replacing theheadlamps, park lamps or turn lamps.

1. Make sure the headlamp control is inthe Off position and open the hood.

239

Super Duty (TFA)

MaintenanceE142465 E163806

Page 243 of 460

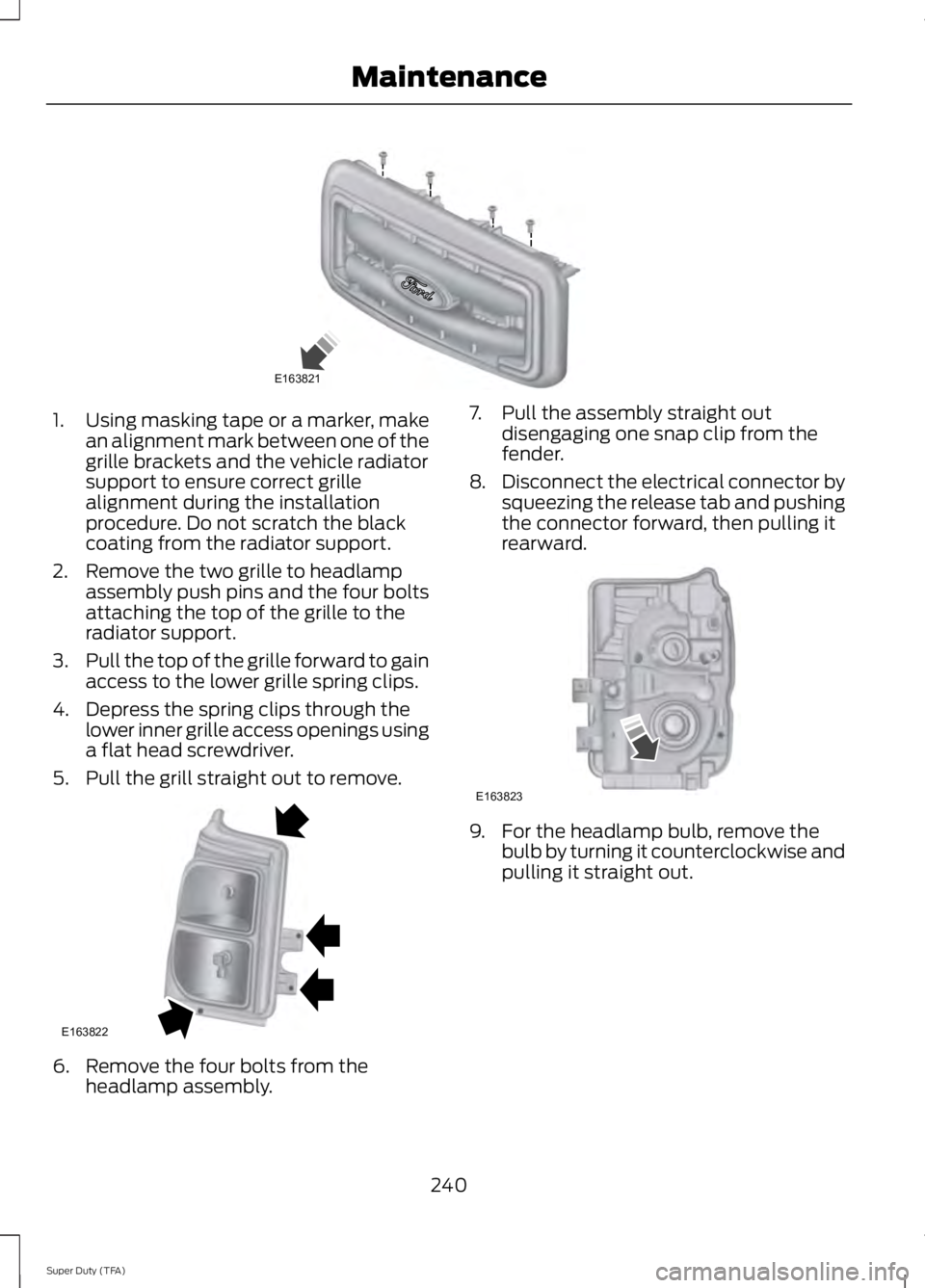

1.Using masking tape or a marker, makean alignment mark between one of thegrille brackets and the vehicle radiatorsupport to ensure correct grillealignment during the installationprocedure. Do not scratch the blackcoating from the radiator support.

2. Remove the two grille to headlampassembly push pins and the four boltsattaching the top of the grille to theradiator support.

3.Pull the top of the grille forward to gainaccess to the lower grille spring clips.

4. Depress the spring clips through thelower inner grille access openings usinga flat head screwdriver.

5. Pull the grill straight out to remove.

6. Remove the four bolts from theheadlamp assembly.

7. Pull the assembly straight outdisengaging one snap clip from thefender.

8.Disconnect the electrical connector bysqueezing the release tab and pushingthe connector forward, then pulling itrearward.

9. For the headlamp bulb, remove thebulb by turning it counterclockwise andpulling it straight out.

240

Super Duty (TFA)

MaintenanceE163821 E163822 E163823

Page 244 of 460

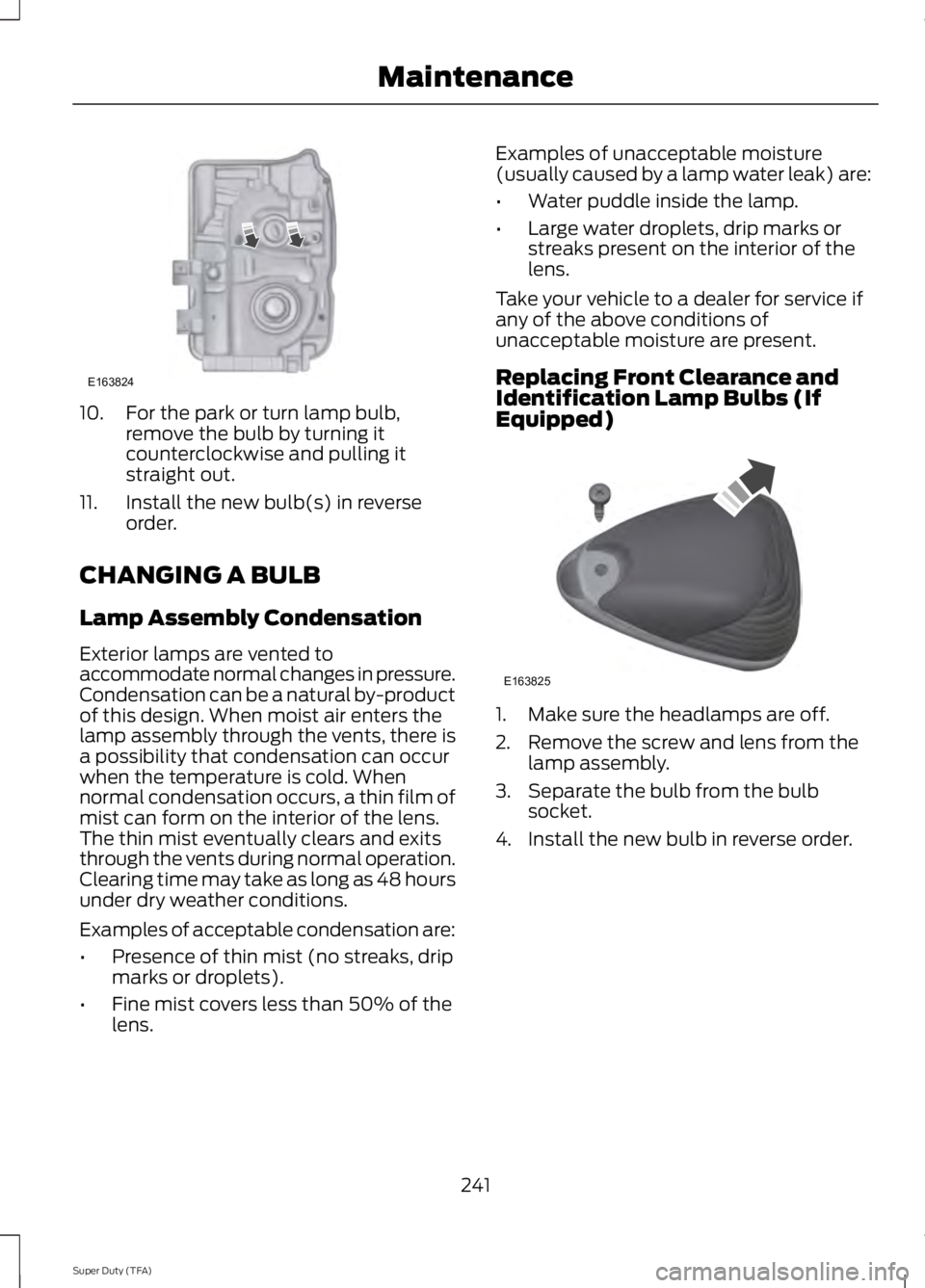

10. For the park or turn lamp bulb,remove the bulb by turning itcounterclockwise and pulling itstraight out.

11. Install the new bulb(s) in reverseorder.

CHANGING A BULB

Lamp Assembly Condensation

Exterior lamps are vented toaccommodate normal changes in pressure.Condensation can be a natural by-productof this design. When moist air enters thelamp assembly through the vents, there isa possibility that condensation can occurwhen the temperature is cold. Whennormal condensation occurs, a thin film ofmist can form on the interior of the lens.The thin mist eventually clears and exitsthrough the vents during normal operation.Clearing time may take as long as 48 hoursunder dry weather conditions.

Examples of acceptable condensation are:

•Presence of thin mist (no streaks, dripmarks or droplets).

•Fine mist covers less than 50% of thelens.

Examples of unacceptable moisture(usually caused by a lamp water leak) are:

•Water puddle inside the lamp.

•Large water droplets, drip marks orstreaks present on the interior of thelens.

Take your vehicle to a dealer for service ifany of the above conditions ofunacceptable moisture are present.

Replacing Front Clearance andIdentification Lamp Bulbs (IfEquipped)

1. Make sure the headlamps are off.

2. Remove the screw and lens from thelamp assembly.

3. Separate the bulb from the bulbsocket.

4. Install the new bulb in reverse order.

241

Super Duty (TFA)

MaintenanceE163824 E163825

Page 245 of 460

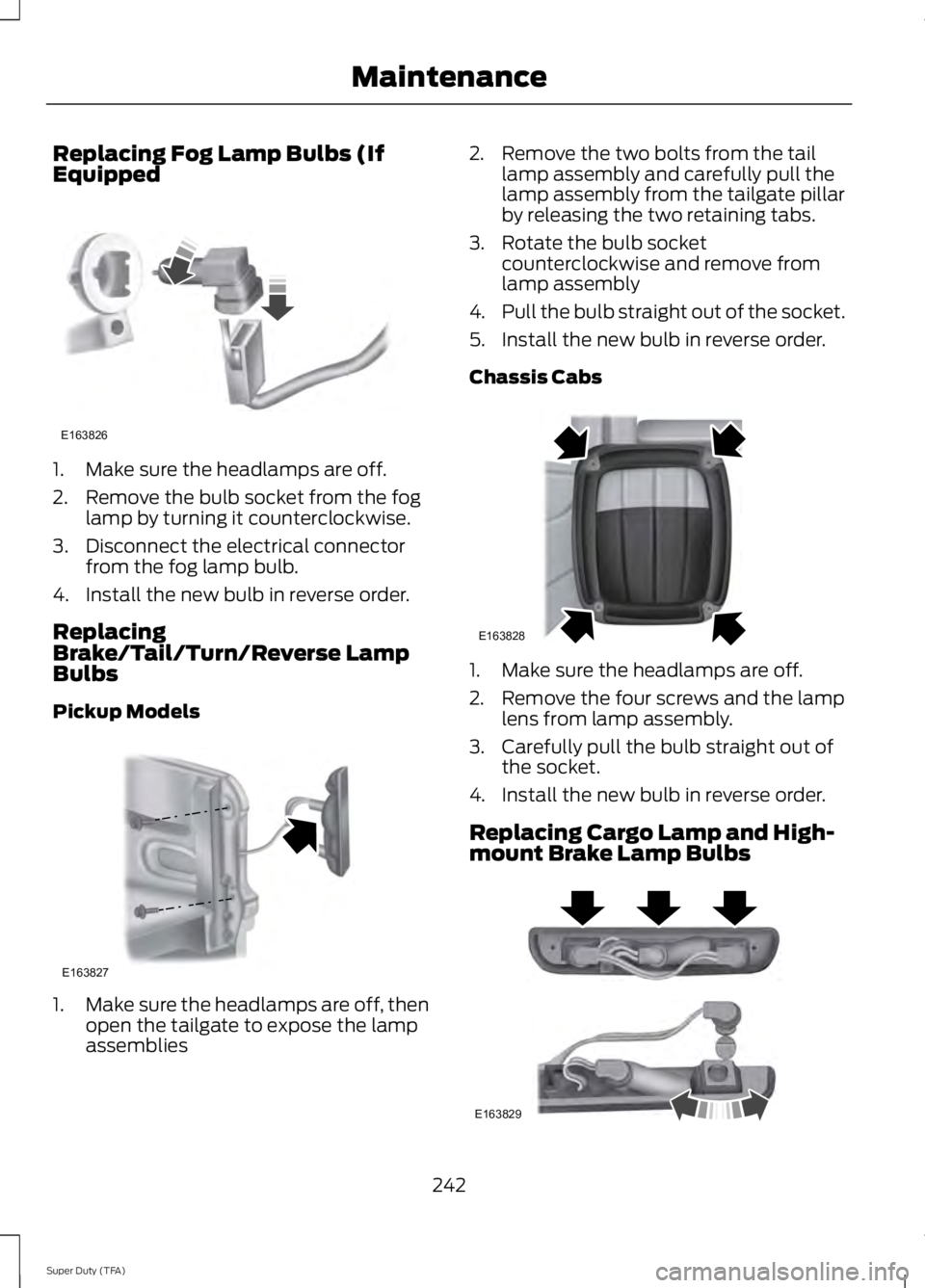

Replacing Fog Lamp Bulbs (IfEquipped

1. Make sure the headlamps are off.

2. Remove the bulb socket from the foglamp by turning it counterclockwise.

3. Disconnect the electrical connectorfrom the fog lamp bulb.

4. Install the new bulb in reverse order.

ReplacingBrake/Tail/Turn/Reverse LampBulbs

Pickup Models

1.Make sure the headlamps are off, thenopen the tailgate to expose the lampassemblies

2. Remove the two bolts from the taillamp assembly and carefully pull thelamp assembly from the tailgate pillarby releasing the two retaining tabs.

3. Rotate the bulb socketcounterclockwise and remove fromlamp assembly

4.Pull the bulb straight out of the socket.

5. Install the new bulb in reverse order.

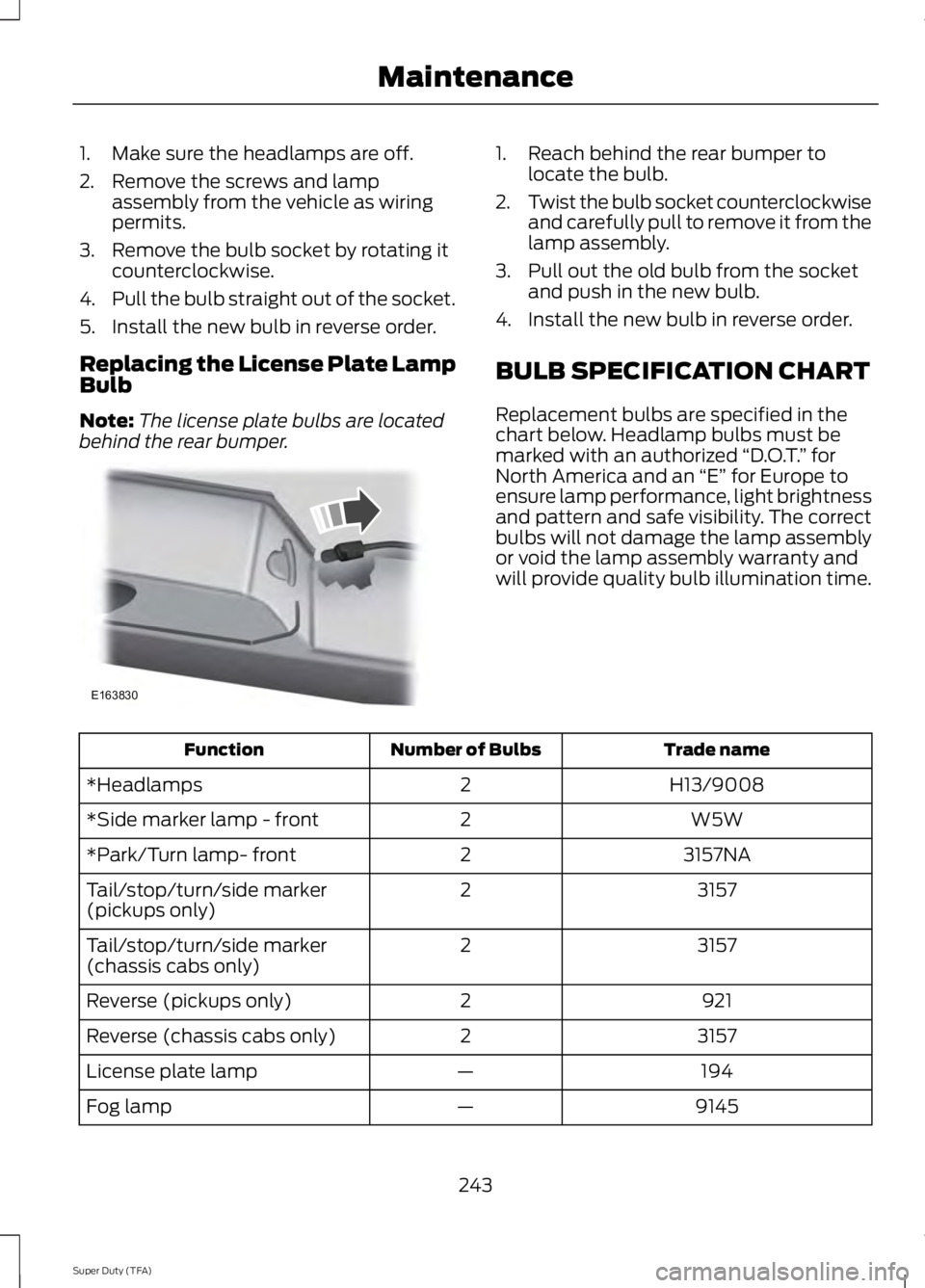

Chassis Cabs

1. Make sure the headlamps are off.

2. Remove the four screws and the lamplens from lamp assembly.

3. Carefully pull the bulb straight out ofthe socket.

4. Install the new bulb in reverse order.

Replacing Cargo Lamp and High-mount Brake Lamp Bulbs

242

Super Duty (TFA)

MaintenanceE163826 E163827 E163828 E163829

Page 246 of 460

1. Make sure the headlamps are off.

2. Remove the screws and lampassembly from the vehicle as wiringpermits.

3. Remove the bulb socket by rotating itcounterclockwise.

4.Pull the bulb straight out of the socket.

5. Install the new bulb in reverse order.

Replacing the License Plate LampBulb

Note:The license plate bulbs are locatedbehind the rear bumper.

1. Reach behind the rear bumper tolocate the bulb.

2.Twist the bulb socket counterclockwiseand carefully pull to remove it from thelamp assembly.

3. Pull out the old bulb from the socketand push in the new bulb.

4. Install the new bulb in reverse order.

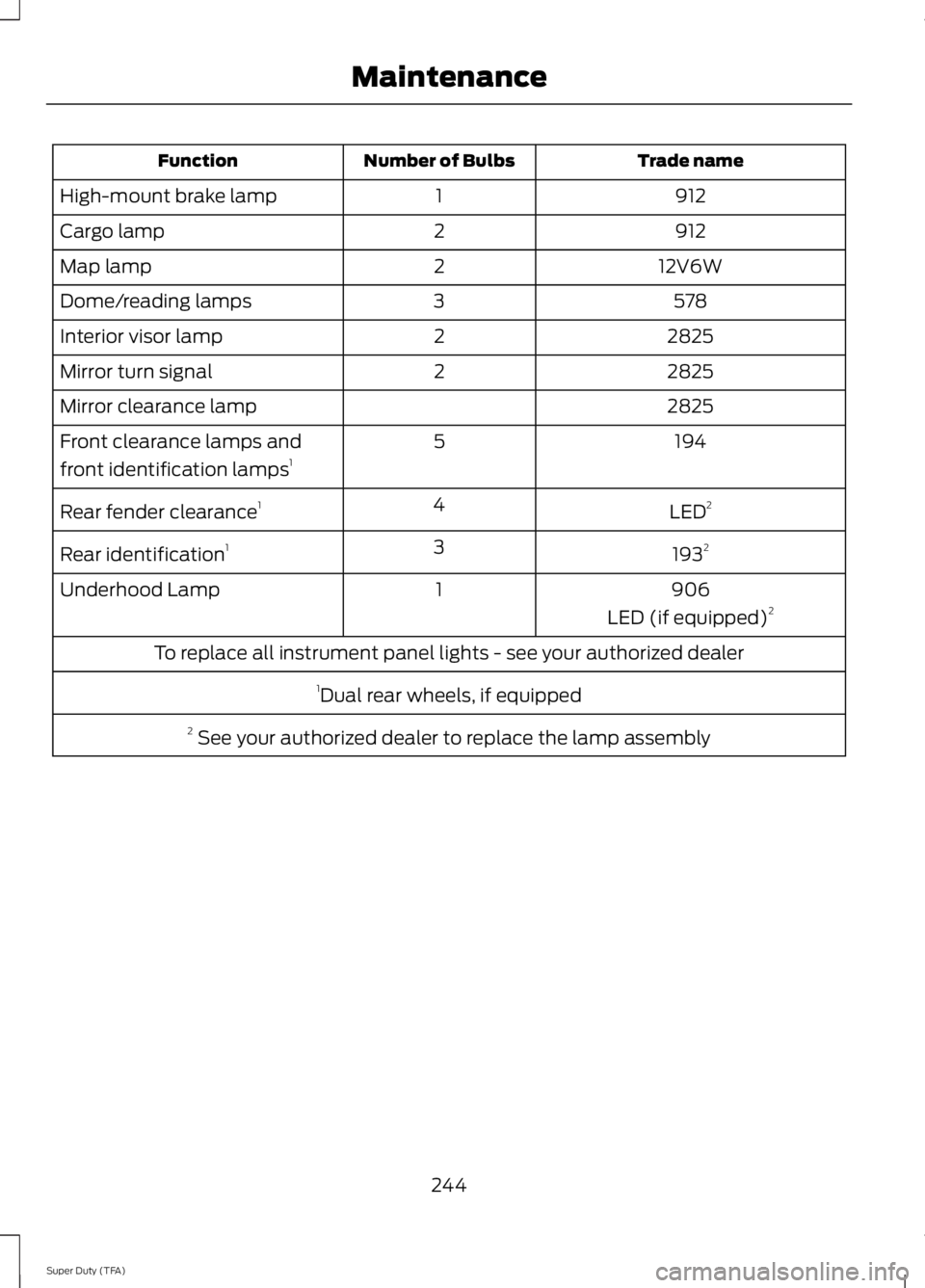

BULB SPECIFICATION CHART

Replacement bulbs are specified in thechart below. Headlamp bulbs must bemarked with an authorized “D.O.T.” forNorth America and an “E” for Europe toensure lamp performance, light brightnessand pattern and safe visibility. The correctbulbs will not damage the lamp assemblyor void the lamp assembly warranty andwill provide quality bulb illumination time.

Trade nameNumber of BulbsFunction

H13/90082*Headlamps

W5W2*Side marker lamp - front

3157NA2*Park/Turn lamp- front

31572Tail/stop/turn/side marker(pickups only)

31572Tail/stop/turn/side marker(chassis cabs only)

9212Reverse (pickups only)

31572Reverse (chassis cabs only)

194—License plate lamp

9145—Fog lamp

243

Super Duty (TFA)

MaintenanceE163830

Page 247 of 460

Trade nameNumber of BulbsFunction

9121High-mount brake lamp

9122Cargo lamp

12V6W2Map lamp

5783Dome/reading lamps

28252Interior visor lamp

28252Mirror turn signal

2825Mirror clearance lamp

1945Front clearance lamps and

front identification lamps1

LED24Rear fender clearance1

19323Rear identification1

9061Underhood Lamp

LED (if equipped)2

To replace all instrument panel lights - see your authorized dealer

1Dual rear wheels, if equipped

2 See your authorized dealer to replace the lamp assembly

244

Super Duty (TFA)

Maintenance

Page 248 of 460

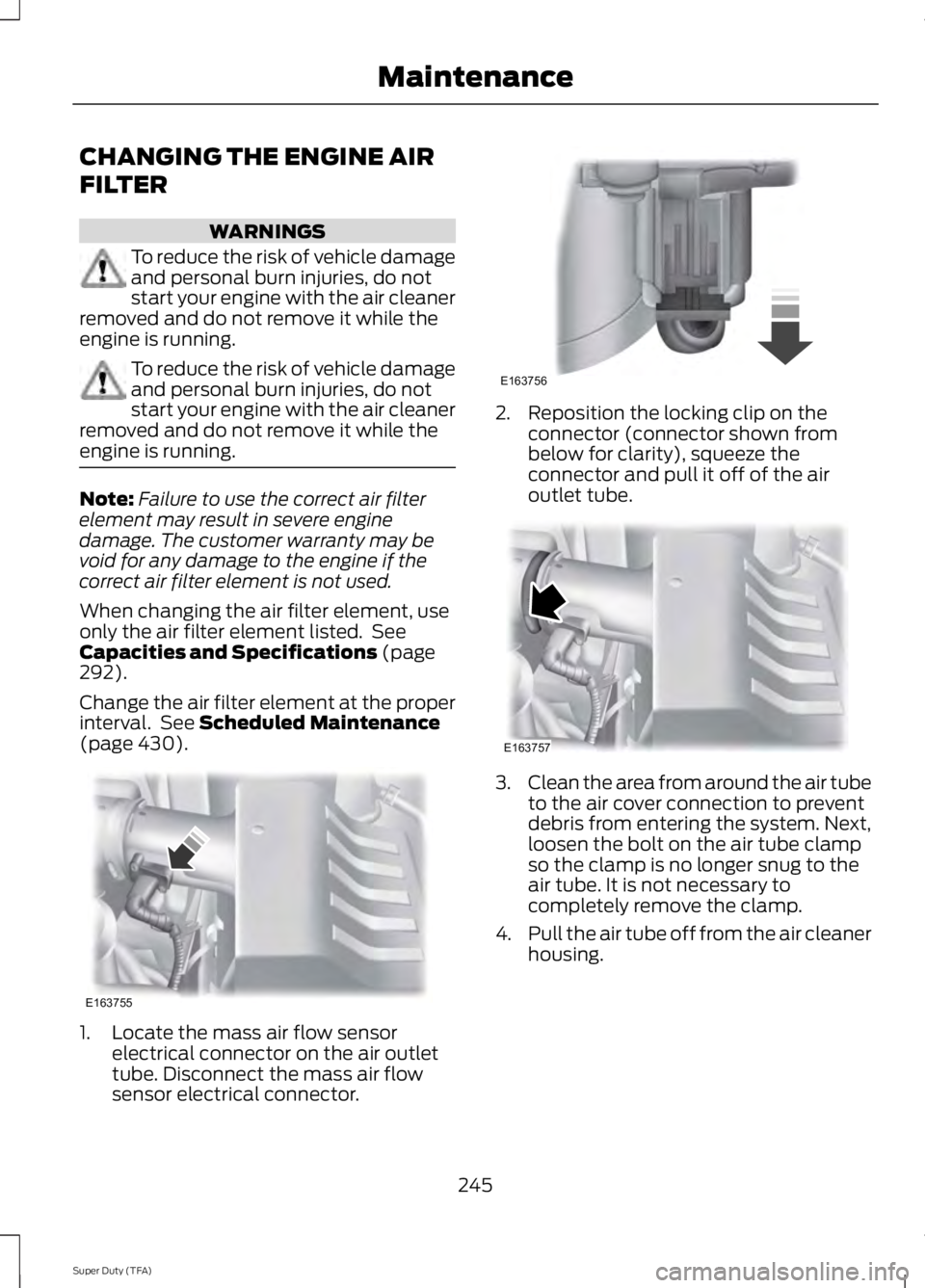

CHANGING THE ENGINE AIR

FILTER

WARNINGS

To reduce the risk of vehicle damageand personal burn injuries, do notstart your engine with the air cleanerremoved and do not remove it while theengine is running.

To reduce the risk of vehicle damageand personal burn injuries, do notstart your engine with the air cleanerremoved and do not remove it while theengine is running.

Note:Failure to use the correct air filterelement may result in severe enginedamage. The customer warranty may bevoid for any damage to the engine if thecorrect air filter element is not used.

When changing the air filter element, useonly the air filter element listed. SeeCapacities and Specifications (page292).

Change the air filter element at the properinterval. See Scheduled Maintenance(page 430).

1. Locate the mass air flow sensorelectrical connector on the air outlettube. Disconnect the mass air flowsensor electrical connector.

2. Reposition the locking clip on theconnector (connector shown frombelow for clarity), squeeze theconnector and pull it off of the airoutlet tube.

3.Clean the area from around the air tubeto the air cover connection to preventdebris from entering the system. Next,loosen the bolt on the air tube clampso the clamp is no longer snug to theair tube. It is not necessary tocompletely remove the clamp.

4.Pull the air tube off from the air cleanerhousing.

245

Super Duty (TFA)

MaintenanceE163755 E163756 E163757

Page 249 of 460

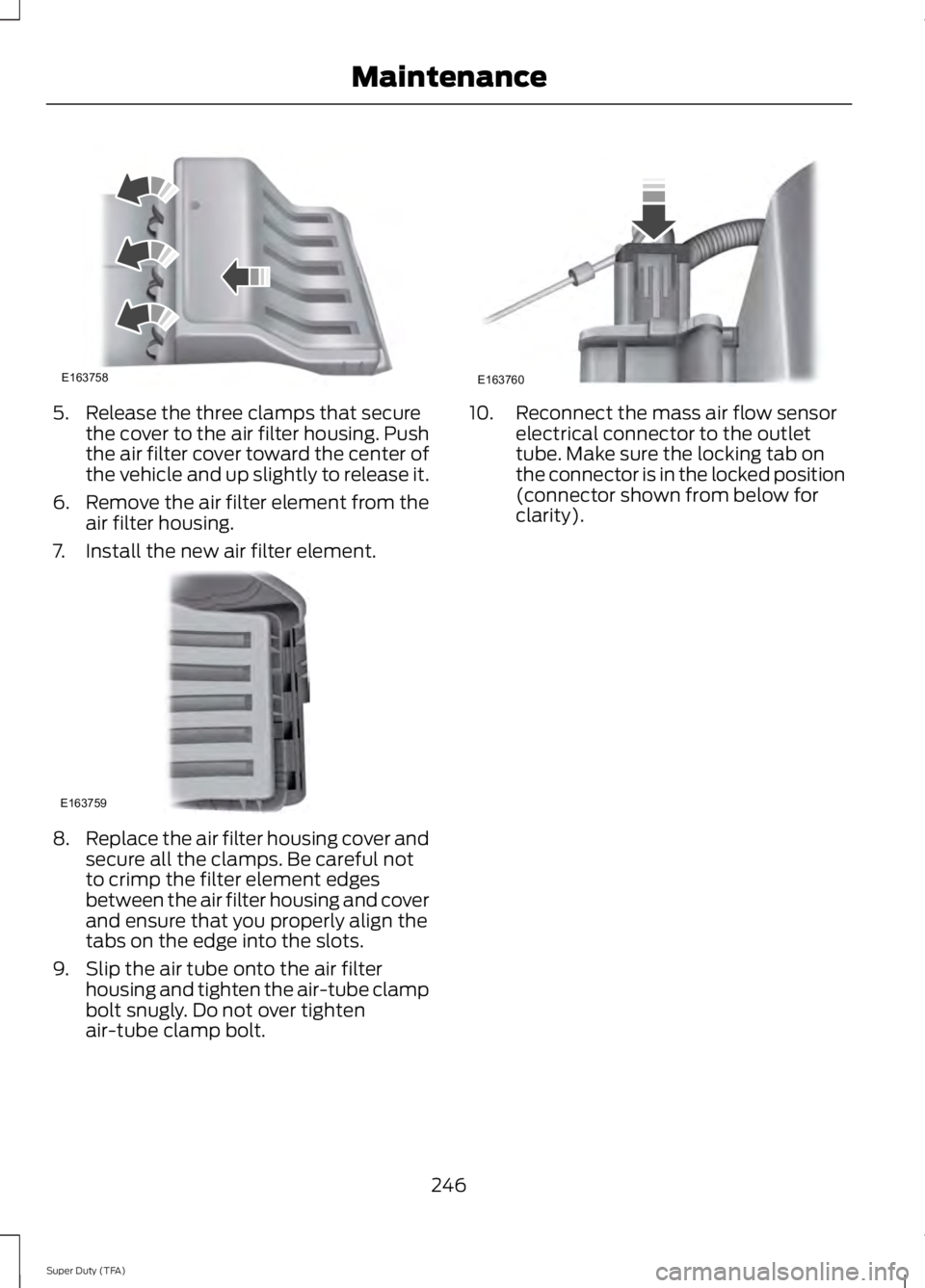

5. Release the three clamps that securethe cover to the air filter housing. Pushthe air filter cover toward the center ofthe vehicle and up slightly to release it.

6.Remove the air filter element from theair filter housing.

7. Install the new air filter element.

8.Replace the air filter housing cover andsecure all the clamps. Be careful notto crimp the filter element edgesbetween the air filter housing and coverand ensure that you properly align thetabs on the edge into the slots.

9. Slip the air tube onto the air filterhousing and tighten the air-tube clampbolt snugly. Do not over tightenair-tube clamp bolt.

10. Reconnect the mass air flow sensorelectrical connector to the outlettube. Make sure the locking tab onthe connector is in the locked position(connector shown from below forclarity).

246

Super Duty (TFA)

MaintenanceE163758 E163759 E163760

Page 250 of 460

GENERAL INFORMATION

Your Ford or Lincoln authorized dealer hasmany quality products available to cleanyour vehicle and protect its finishes.

CLEANING PRODUCTS

For best results, use the following productsor products of equivalent quality:

Motorcraft Bug and Tar Remover (ZC-42)

Motorcraft Custom Bright Metal Cleaner(ZC-15)

Motorcraft Detail Wash (ZC-3-A)

Motorcraft Dusting Cloth (ZC-24)

Motorcraft Engine Shampoo andDegreaser (U.S. only) (ZC-20)

Motorcraft Engine Shampoo (Canadaonly) (CXC-66-A)

Motorcraft Multi-Purpose Cleaner (Canadaonly) (CXC-101)

Motorcraft Premium Glass Cleaner(Canada only) (CXC-100)

Motorcraft Premium Quality WindshieldWasher Fluid (Canada only) [CXC-37-(A,B, D or F)]

Motorcraft Premium Windshield WashConcentrate with Bitterant (U.S. only)(ZC-32-B1)

Motorcraft Professional Strength Carpet& Upholstery Cleaner (ZC-54)

Motorcraft Spot and Stain Remover (U.S.only) (ZC-14)

Motorcraft Ultra-Clear Spray Glass Cleaner(ZC-23)

Motorcraft Wheel and Tire Cleaner(ZC-37-A)

CLEANING THE EXTERIOR

Wash your vehicle regularly with cool orlukewarm water and a neutral pHshampoo, such as Motorcraft Detail Wash.

•Never use strong household detergentsor soap, such as dish washing orlaundry liquid. These products candiscolor and spot painted surfaces.

•Never wash a vehicle that is “hot to thetouch” or during exposure to strong,direct sunlight.

•Dry your vehicle with a chamois or softterry cloth towel in order to eliminatewater spotting.

•Immediately remove items such asgasoline, diesel fuel, bird droppings andinsect deposits because they can causedamage to your vehicle’s paintworkand trim over time. Use Motorcraft Bugand Tar Remover.

•Remove any exterior accessories, suchas antennas, before entering a carwash.

Note:Suntan lotions and insect repellentscan damage any painted surface; if thesesubstances come in contact with yourvehicle, wash off as soon as possible.

Stripes or Graphics (if equipped)

Do not use a commercial or high-pressuresprayer on the surface or edge of stripesand graphics. This can cause damage tothe film and cause the edge of the film topeel away from the vehicle surface.

Exterior Chrome

Note:Never use abrasive materials such assteel wool or plastic pads as they canscratch the chrome surface.

Note:Do not use chrome cleaner, metalcleaner or polish on wheels and wheelcovers

247

Super Duty (TFA)

Vehicle Care