clock FORD F250 SUPER DUTY 2017 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F250 SUPER DUTY, Model: FORD F250 SUPER DUTY 2017Pages: 642, PDF Size: 12.35 MB

Page 355 of 642

1.Switch all of the lamps and the ignitionoff.

2. To access the bulb, reach behind thebumper.

3. Disconnect the electrical connector.

4.Turn the bulb holder counterclockwiseand remove it.

Note:You cannot separate the bulb fromthe bulb holder.

Note:Handle a halogen bulb carefully andkeep out of children’s reach. Grasp the bulbonly by its plastic base and do not touch theglass. The oil from your hand could causethe bulb to break the next time the foglamps are operated.

Rear Lamps, Brake Lamps, RearDirection Indicator and ReversingLamp Bulbs

Pickup Models - Vehicles without BlindSpot Information System

1.Switch all of the lamps and the ignitionoff.

2. Open the tailgate to expose the lampassemblies.

3. Remove the bolts from the tail lampassembly and carefully pull the lampassembly from the tailgate pillar byreleasing the two retaining tabs.

4.Turn the bulb holder counterclockwiseand remove it.

5. Remove the bulb by pulling it straightout.

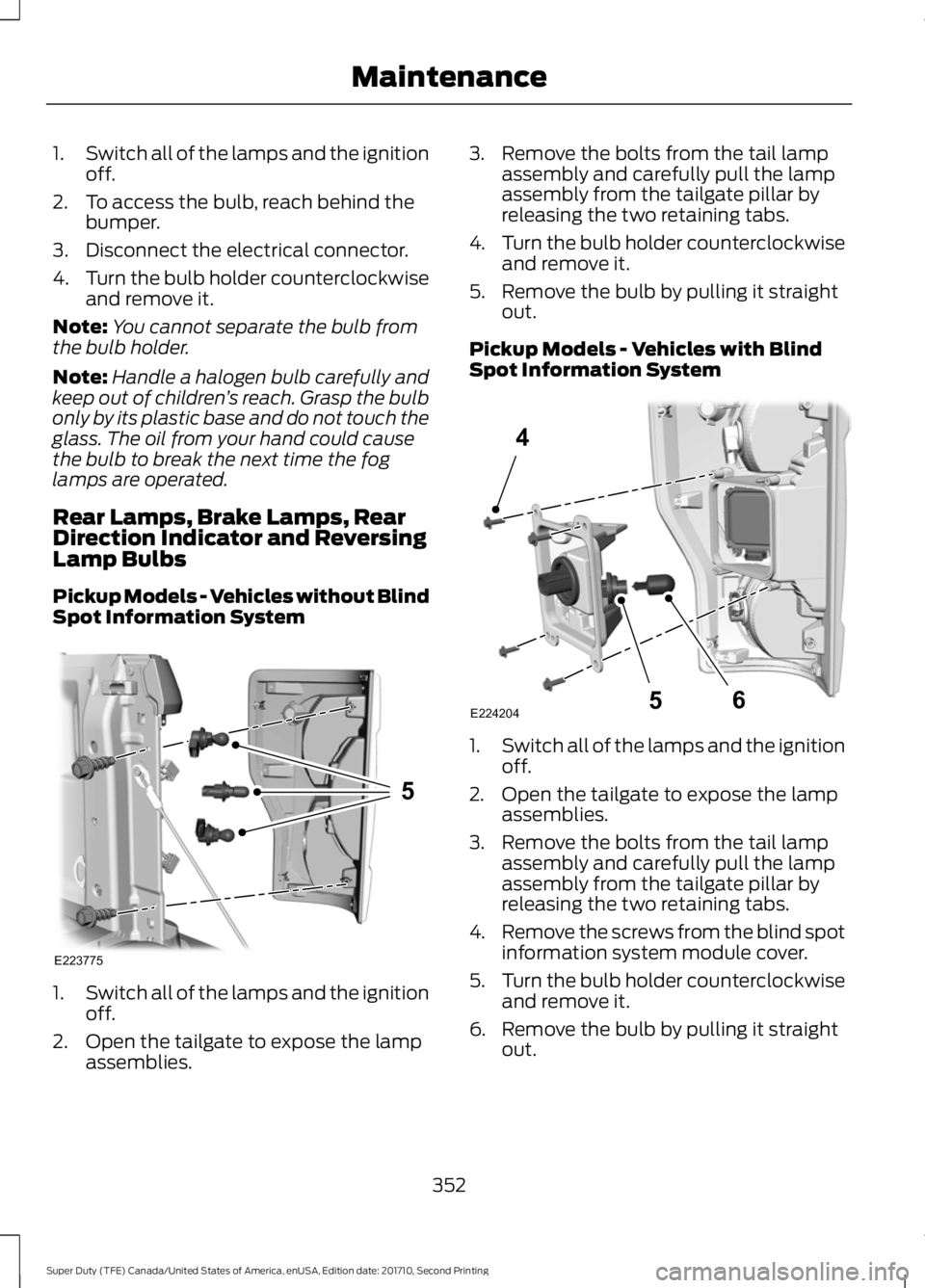

Pickup Models - Vehicles with BlindSpot Information System

1.Switch all of the lamps and the ignitionoff.

2. Open the tailgate to expose the lampassemblies.

3. Remove the bolts from the tail lampassembly and carefully pull the lampassembly from the tailgate pillar byreleasing the two retaining tabs.

4.Remove the screws from the blind spotinformation system module cover.

5.Turn the bulb holder counterclockwiseand remove it.

6. Remove the bulb by pulling it straightout.

352

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

MaintenanceE223775

5 E224204

4

65

Page 356 of 642

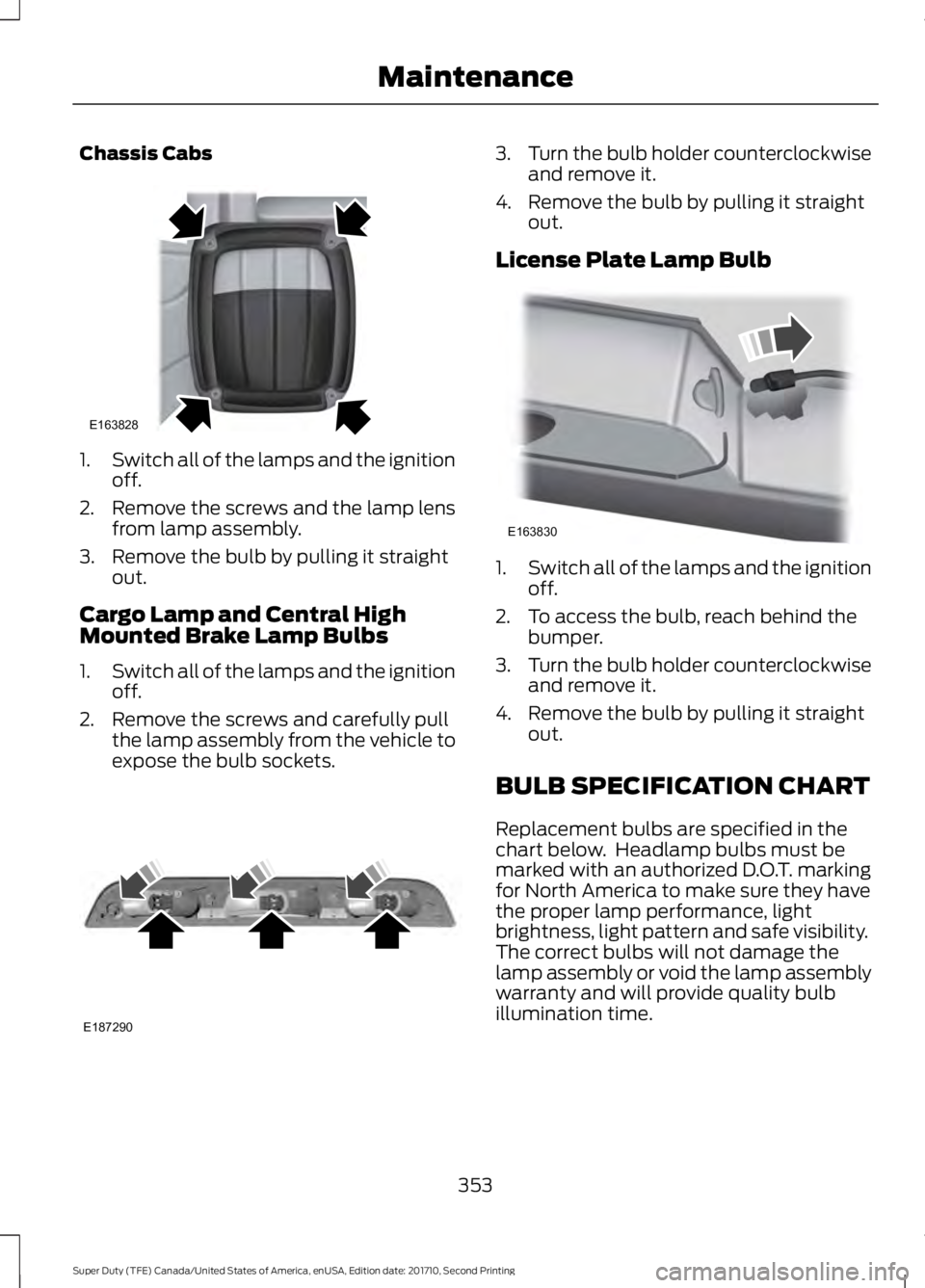

Chassis Cabs

1.Switch all of the lamps and the ignitionoff.

2. Remove the screws and the lamp lensfrom lamp assembly.

3. Remove the bulb by pulling it straightout.

Cargo Lamp and Central HighMounted Brake Lamp Bulbs

1.Switch all of the lamps and the ignitionoff.

2. Remove the screws and carefully pullthe lamp assembly from the vehicle toexpose the bulb sockets.

3.Turn the bulb holder counterclockwiseand remove it.

4. Remove the bulb by pulling it straightout.

License Plate Lamp Bulb

1.Switch all of the lamps and the ignitionoff.

2. To access the bulb, reach behind thebumper.

3.Turn the bulb holder counterclockwiseand remove it.

4. Remove the bulb by pulling it straightout.

BULB SPECIFICATION CHART

Replacement bulbs are specified in thechart below. Headlamp bulbs must bemarked with an authorized D.O.T. markingfor North America to make sure they havethe proper lamp performance, lightbrightness, light pattern and safe visibility.The correct bulbs will not damage thelamp assembly or void the lamp assemblywarranty and will provide quality bulbillumination time.

353

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

MaintenanceE163828 E187290 E163830

Page 364 of 642

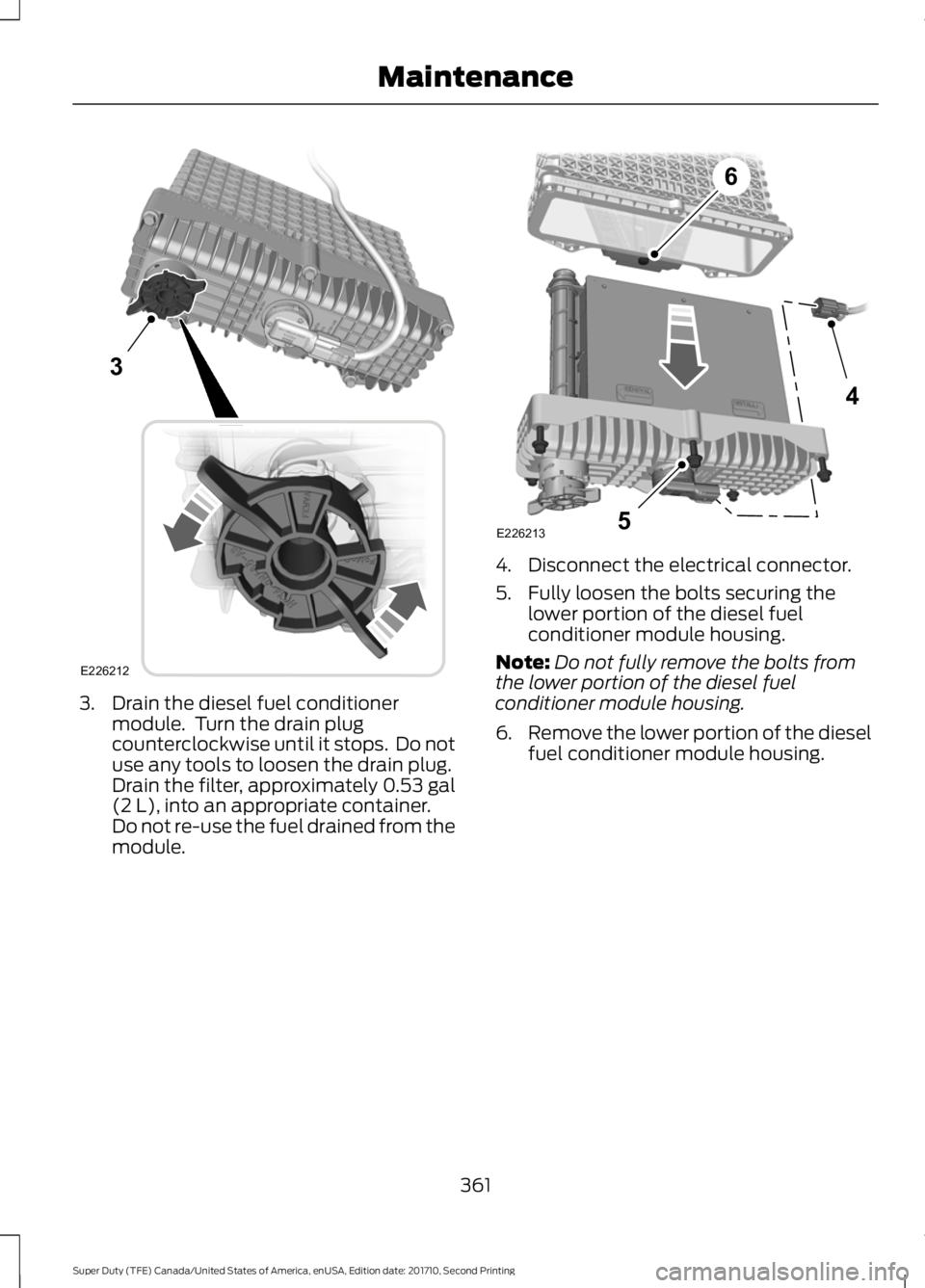

3. Drain the diesel fuel conditionermodule. Turn the drain plugcounterclockwise until it stops. Do notuse any tools to loosen the drain plug.Drain the filter, approximately 0.53 gal(2 L), into an appropriate container.Do not re-use the fuel drained from themodule.

4. Disconnect the electrical connector.

5. Fully loosen the bolts securing thelower portion of the diesel fuelconditioner module housing.

Note:Do not fully remove the bolts fromthe lower portion of the diesel fuelconditioner module housing.

6.Remove the lower portion of the dieselfuel conditioner module housing.

361

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Maintenance3

E226212 4

5

6

E226213

Page 365 of 642

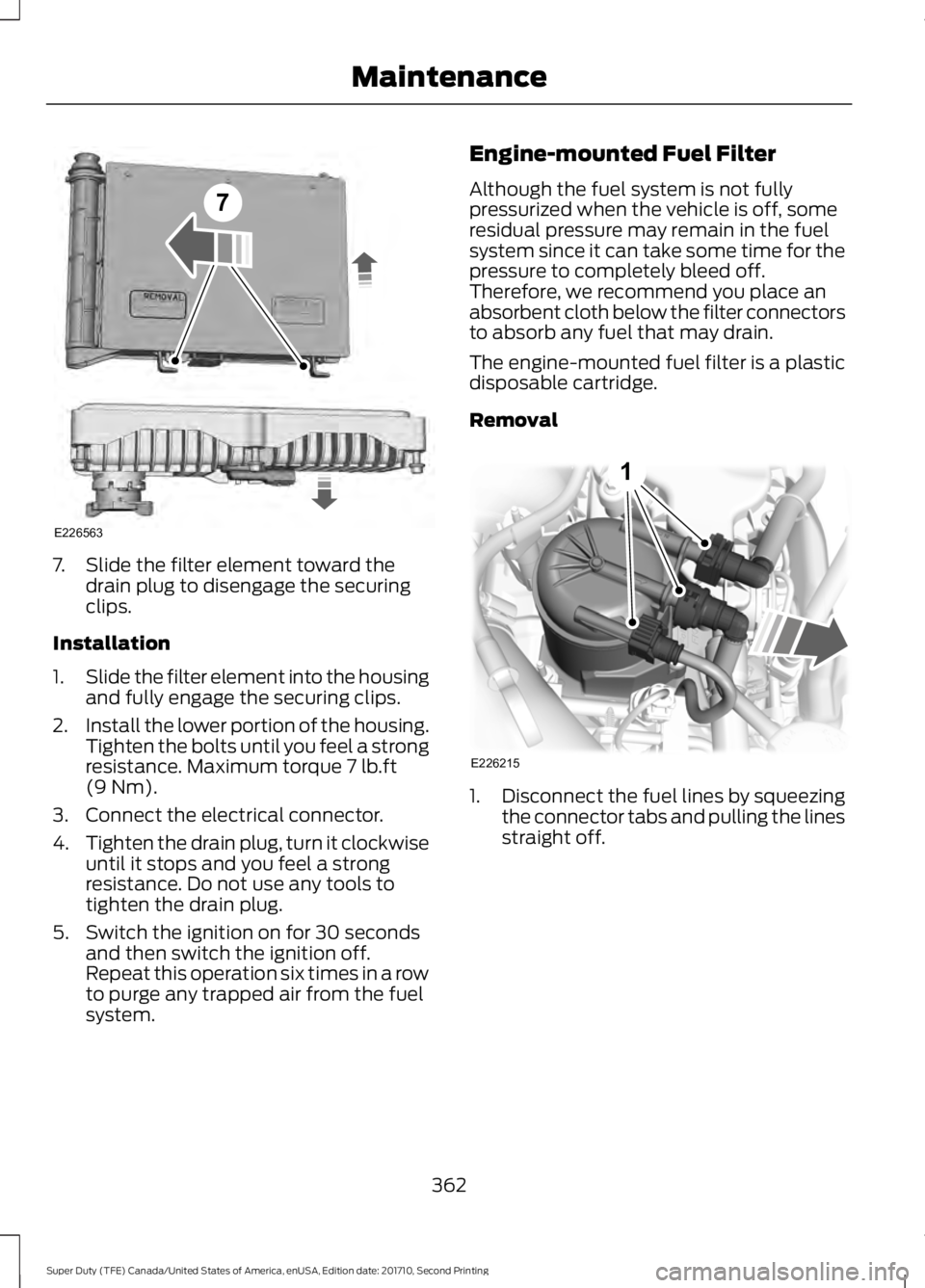

7. Slide the filter element toward thedrain plug to disengage the securingclips.

Installation

1.Slide the filter element into the housingand fully engage the securing clips.

2.Install the lower portion of the housing.Tighten the bolts until you feel a strongresistance. Maximum torque 7 lb.ft(9 Nm).

3. Connect the electrical connector.

4.Tighten the drain plug, turn it clockwiseuntil it stops and you feel a strongresistance. Do not use any tools totighten the drain plug.

5. Switch the ignition on for 30 secondsand then switch the ignition off.Repeat this operation six times in a rowto purge any trapped air from the fuelsystem.

Engine-mounted Fuel Filter

Although the fuel system is not fullypressurized when the vehicle is off, someresidual pressure may remain in the fuelsystem since it can take some time for thepressure to completely bleed off.Therefore, we recommend you place anabsorbent cloth below the filter connectorsto absorb any fuel that may drain.

The engine-mounted fuel filter is a plasticdisposable cartridge.

Removal

1.Disconnect the fuel lines by squeezingthe connector tabs and pulling the linesstraight off.

362

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Maintenance7

E226563 E226215

1

Page 366 of 642

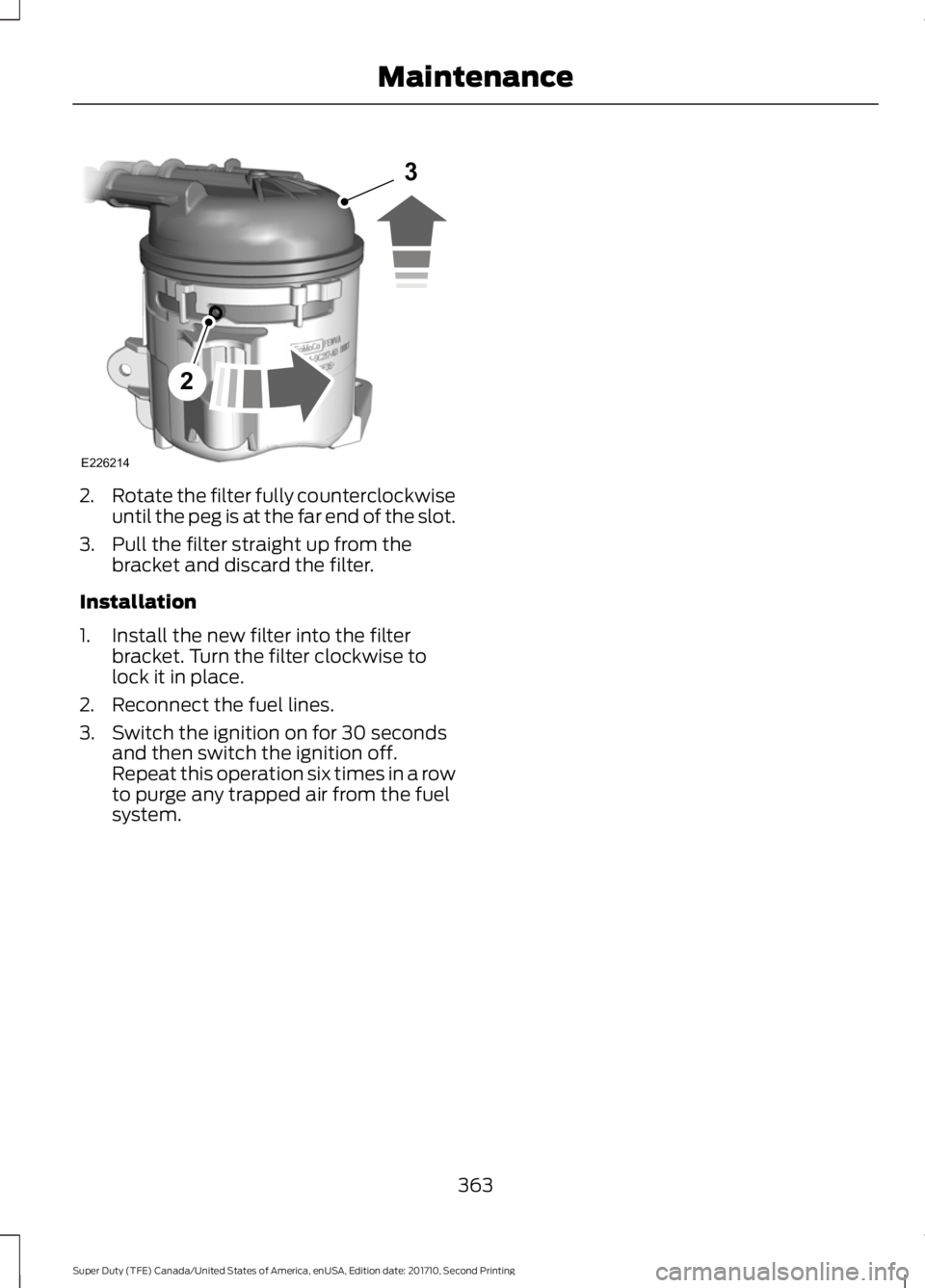

2.Rotate the filter fully counterclockwiseuntil the peg is at the far end of the slot.

3. Pull the filter straight up from thebracket and discard the filter.

Installation

1. Install the new filter into the filterbracket. Turn the filter clockwise tolock it in place.

2. Reconnect the fuel lines.

3. Switch the ignition on for 30 secondsand then switch the ignition off.Repeat this operation six times in a rowto purge any trapped air from the fuelsystem.

363

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

MaintenanceE226214

2

3

Page 402 of 642

•To reduce the chances of interferencefrom another vehicle, perform thesystem reset procedure at least threefeet (one meter) away from anotherFord Motor Company vehicleundergoing the system reset procedureat the same time.

•Do not wait more than two minutesbetween resetting each tire sensor orthe system will time-out and the entireprocedure will have to be repeated onall four wheels.

•A double horn will sound indicating theneed to repeat the procedure.

Performing the System Reset Procedure(Single Rear Wheel)

Read the entire procedure beforeattempting.

1. Drive the vehicle above 20 mph(32 km/h) for at least two minutes,then park in a safe location where youcan easily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3. Cycle the ignition to the on positionwith the engine off.

4. Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If the reset modehas been entered successfully, the hornwill sound once, the system indicatorwill flash and a message is shown inthe information display. If this does notoccur, please try again starting at Step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message is shown in theinformation display, seek service fromyour authorized dealer.

5. Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing clockwise order: Left front(driver's side front tire), Right front(passenger's side front tire), Right rear(passenger's side rear tire), Left rear(driver's side rear tire).

6. Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.

Note:The single horn chirp confirms thatthe sensor identification code has beenlearned by the module for this position. If adouble horn is heard, the reset procedurewas unsuccessful, and you must repeat it.

7. Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8. Remove the valve cap from the valvestem on the right rear tire. Decrease theair pressure until the horn sounds.

9. Remove the valve cap from the valvestem on the left rear tire. Decrease theair pressure until the horn sounds.Training is complete after the hornsounds for the last tire trained (driver'sside rear tire), the system indicatorstops flashing, and a message is shownin the information display.

10.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

399

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and Tires

Page 408 of 642

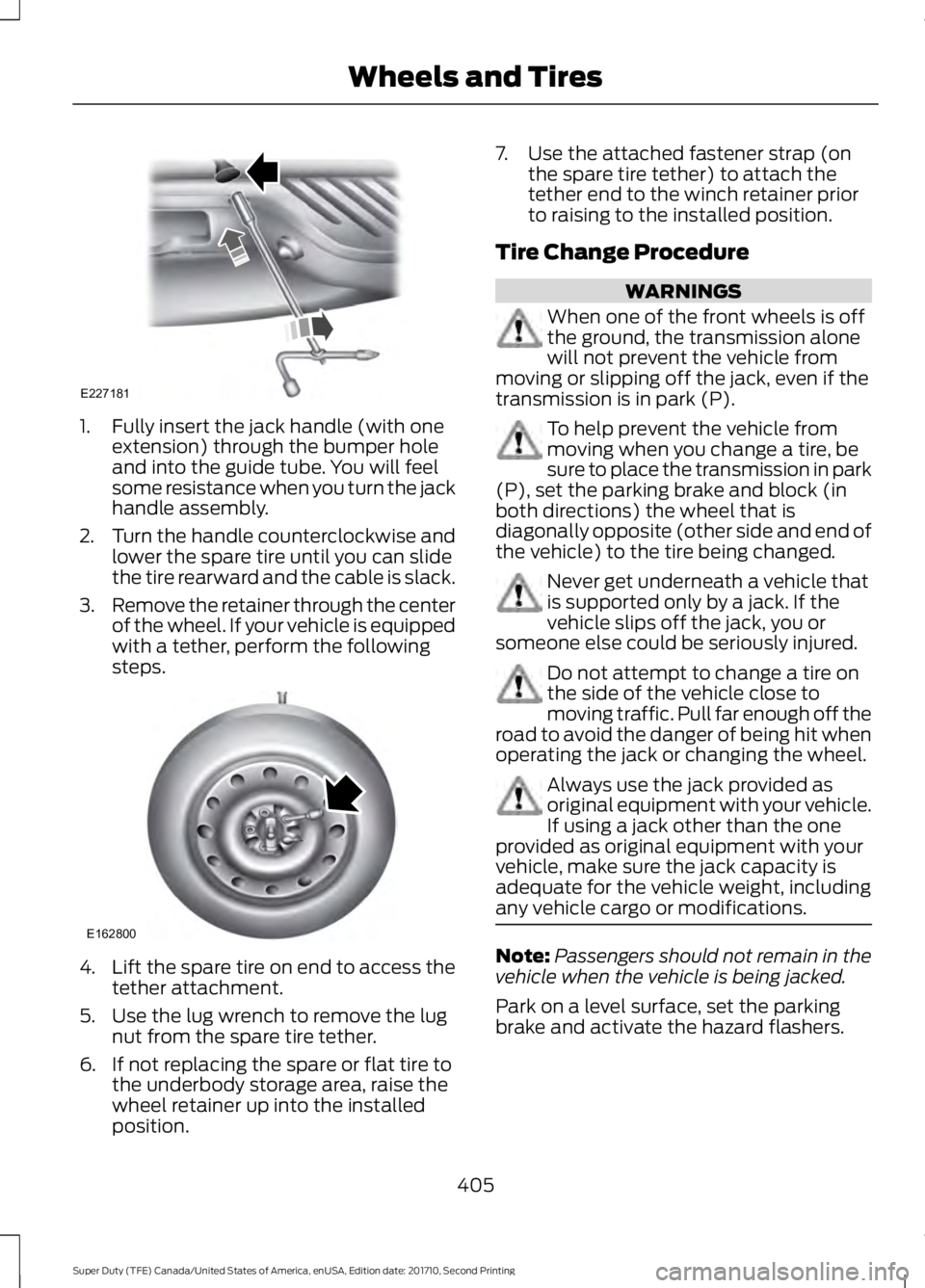

1. Fully insert the jack handle (with oneextension) through the bumper holeand into the guide tube. You will feelsome resistance when you turn the jackhandle assembly.

2.Turn the handle counterclockwise andlower the spare tire until you can slidethe tire rearward and the cable is slack.

3.Remove the retainer through the centerof the wheel. If your vehicle is equippedwith a tether, perform the followingsteps.

4.Lift the spare tire on end to access thetether attachment.

5. Use the lug wrench to remove the lugnut from the spare tire tether.

6. If not replacing the spare or flat tire tothe underbody storage area, raise thewheel retainer up into the installedposition.

7. Use the attached fastener strap (onthe spare tire tether) to attach thetether end to the winch retainer priorto raising to the installed position.

Tire Change Procedure

WARNINGS

When one of the front wheels is offthe ground, the transmission alonewill not prevent the vehicle frommoving or slipping off the jack, even if thetransmission is in park (P).

To help prevent the vehicle frommoving when you change a tire, besure to place the transmission in park(P), set the parking brake and block (inboth directions) the wheel that isdiagonally opposite (other side and end ofthe vehicle) to the tire being changed.

Never get underneath a vehicle thatis supported only by a jack. If thevehicle slips off the jack, you orsomeone else could be seriously injured.

Do not attempt to change a tire onthe side of the vehicle close tomoving traffic. Pull far enough off theroad to avoid the danger of being hit whenoperating the jack or changing the wheel.

Always use the jack provided asoriginal equipment with your vehicle.If using a jack other than the oneprovided as original equipment with yourvehicle, make sure the jack capacity isadequate for the vehicle weight, includingany vehicle cargo or modifications.

Note:Passengers should not remain in thevehicle when the vehicle is being jacked.

Park on a level surface, set the parkingbrake and activate the hazard flashers.

405

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and TiresE227181 E162800

Page 409 of 642

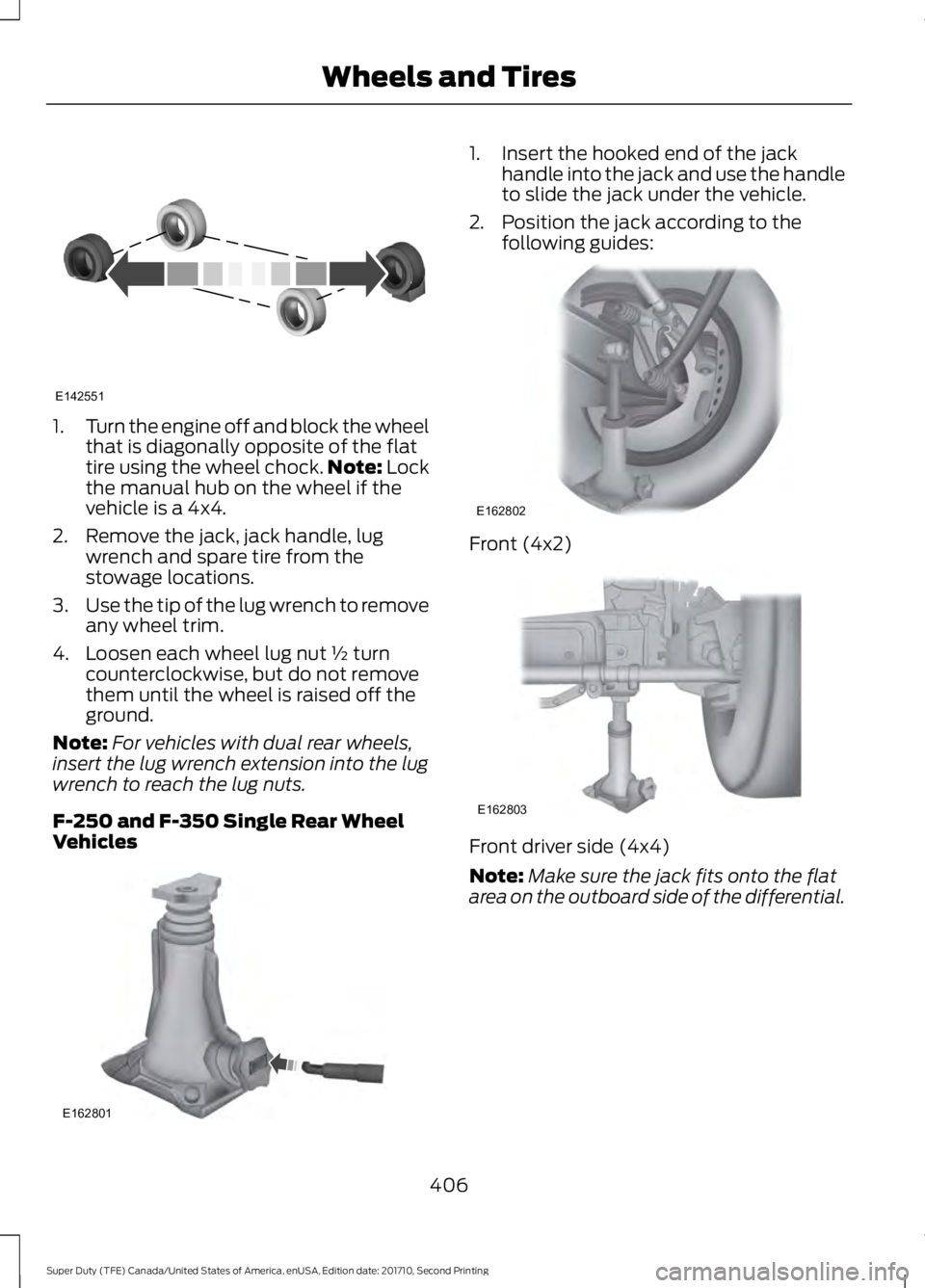

1.Turn the engine off and block the wheelthat is diagonally opposite of the flattire using the wheel chock.Note: Lockthe manual hub on the wheel if thevehicle is a 4x4.

2. Remove the jack, jack handle, lugwrench and spare tire from thestowage locations.

3.Use the tip of the lug wrench to removeany wheel trim.

4. Loosen each wheel lug nut ½ turncounterclockwise, but do not removethem until the wheel is raised off theground.

Note:For vehicles with dual rear wheels,insert the lug wrench extension into the lugwrench to reach the lug nuts.

F-250 and F-350 Single Rear WheelVehicles

1. Insert the hooked end of the jackhandle into the jack and use the handleto slide the jack under the vehicle.

2. Position the jack according to thefollowing guides:

Front (4x2)

Front driver side (4x4)

Note:Make sure the jack fits onto the flatarea on the outboard side of the differential.

406

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and TiresE142551 E162801 E162802 E162803

Page 410 of 642

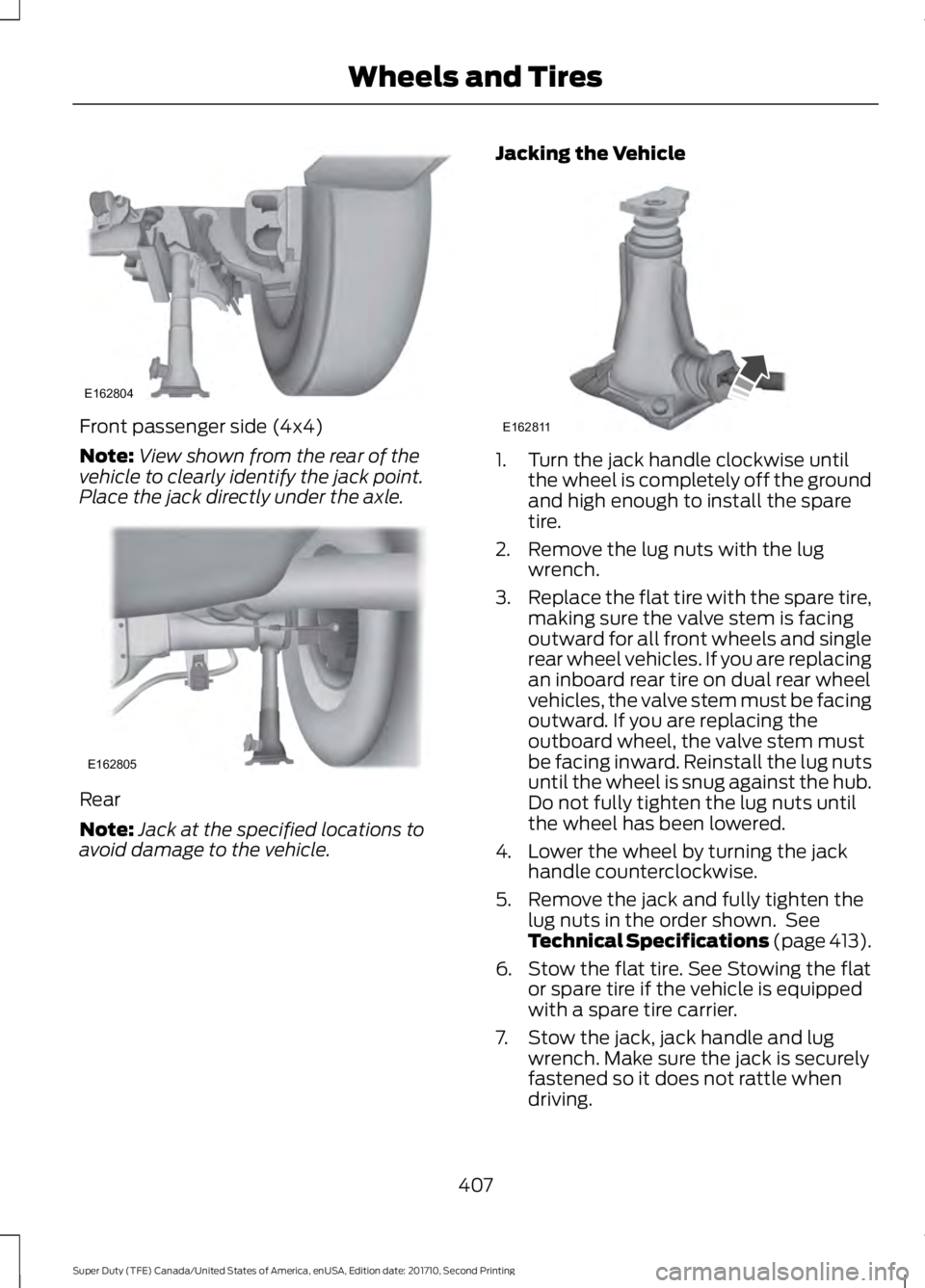

Front passenger side (4x4)

Note:View shown from the rear of thevehicle to clearly identify the jack point.Place the jack directly under the axle.

Rear

Note:Jack at the specified locations toavoid damage to the vehicle.

Jacking the Vehicle

1. Turn the jack handle clockwise untilthe wheel is completely off the groundand high enough to install the sparetire.

2. Remove the lug nuts with the lugwrench.

3.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward for all front wheels and singlerear wheel vehicles. If you are replacingan inboard rear tire on dual rear wheelvehicles, the valve stem must be facingoutward. If you are replacing theoutboard wheel, the valve stem mustbe facing inward. Reinstall the lug nutsuntil the wheel is snug against the hub.Do not fully tighten the lug nuts untilthe wheel has been lowered.

4. Lower the wheel by turning the jackhandle counterclockwise.

5. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 413).

6. Stow the flat tire. See Stowing the flator spare tire if the vehicle is equippedwith a spare tire carrier.

7. Stow the jack, jack handle and lugwrench. Make sure the jack is securelyfastened so it does not rattle whendriving.

407

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and TiresE162804 E162805 E162811

Page 412 of 642

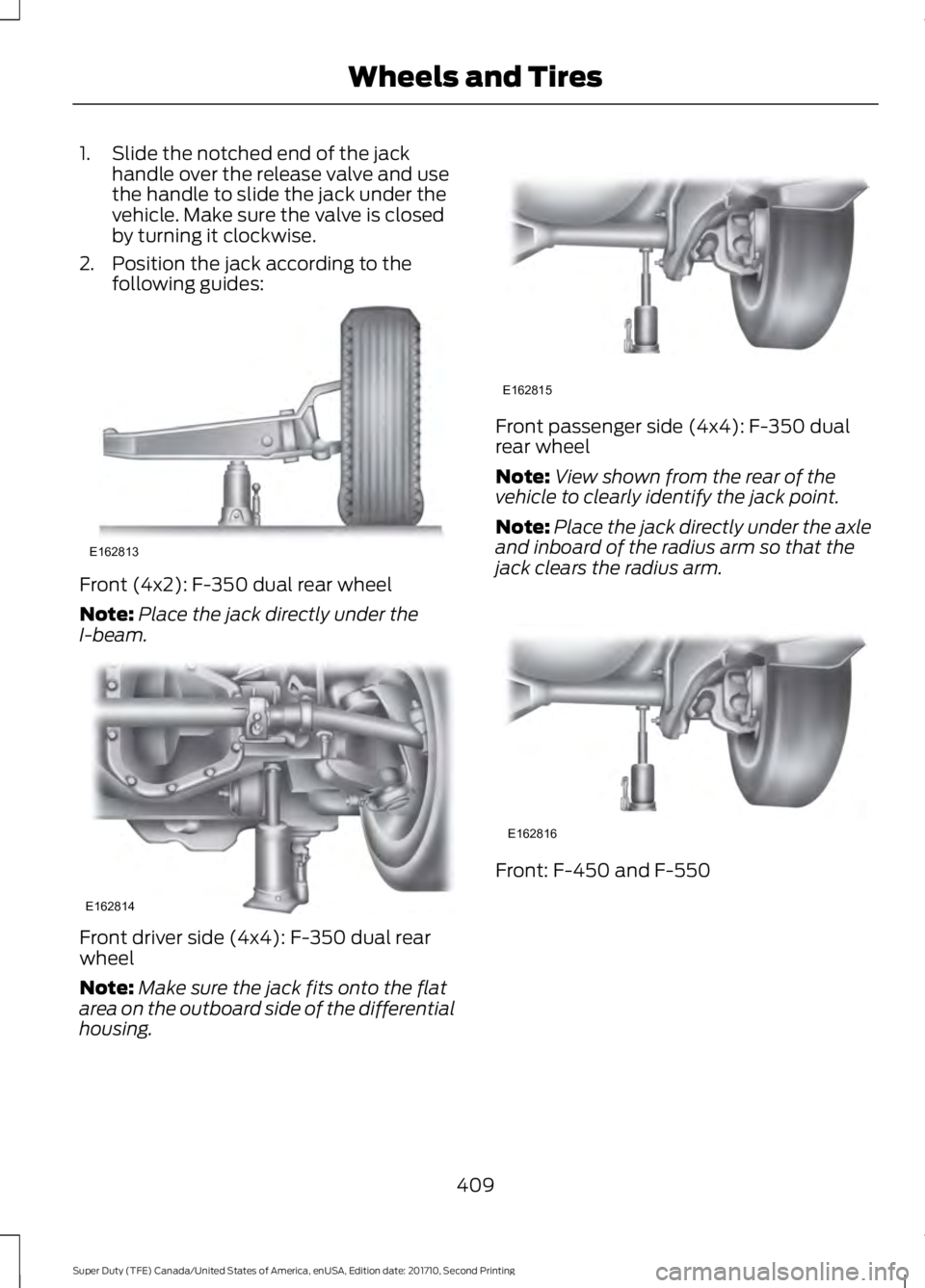

1. Slide the notched end of the jackhandle over the release valve and usethe handle to slide the jack under thevehicle. Make sure the valve is closedby turning it clockwise.

2. Position the jack according to thefollowing guides:

Front (4x2): F-350 dual rear wheel

Note:Place the jack directly under theI-beam.

Front driver side (4x4): F-350 dual rearwheel

Note:Make sure the jack fits onto the flatarea on the outboard side of the differentialhousing.

Front passenger side (4x4): F-350 dualrear wheel

Note:View shown from the rear of thevehicle to clearly identify the jack point.

Note:Place the jack directly under the axleand inboard of the radius arm so that thejack clears the radius arm.

Front: F-450 and F-550

409

Super Duty (TFE) Canada/United States of America, enUSA, Edition date: 201710, Second Printing

Wheels and TiresE162813 E162814 E162815 E162816