engine FORD F350 2003 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2003, Model line: F350, Model: FORD F350 2003Pages: 280, PDF Size: 4.18 MB

Page 179 of 280

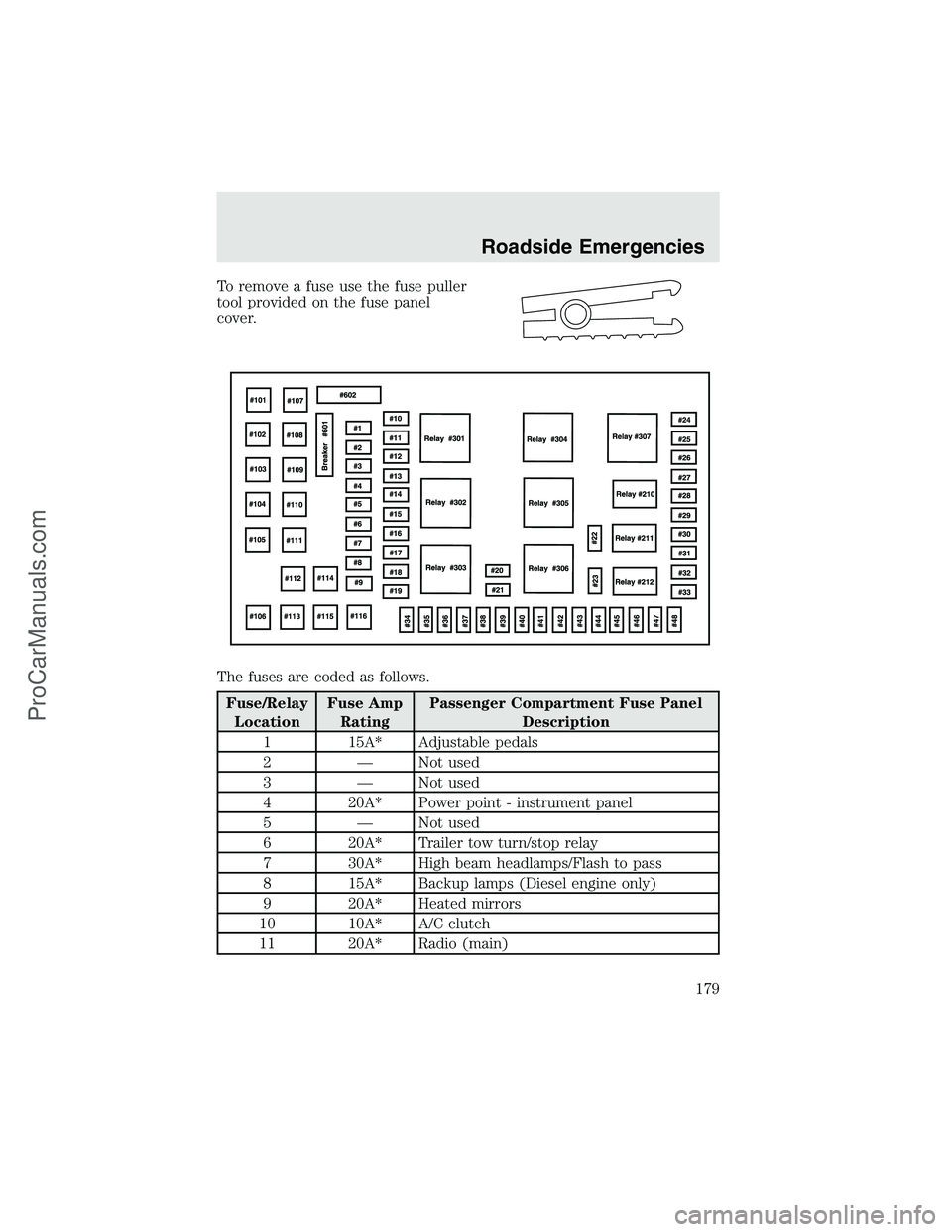

To remove a fuse use the fuse puller

tool provided on the fuse panel

cover.

The fuses are coded as follows.

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse Panel

Description

1 15A* Adjustable pedals

2—Not used

3—Not used

4 20A* Power point - instrument panel

5—Not used

6 20A* Trailer tow turn/stop relay

7 30A* High beam headlamps/Flash to pass

8 15A* Backup lamps (Diesel engine only)

9 20A* Heated mirrors

10 10A* A/C clutch

11 20A* Radio (main)

Roadside Emergencies

179

ProCarManuals.com

Page 180 of 280

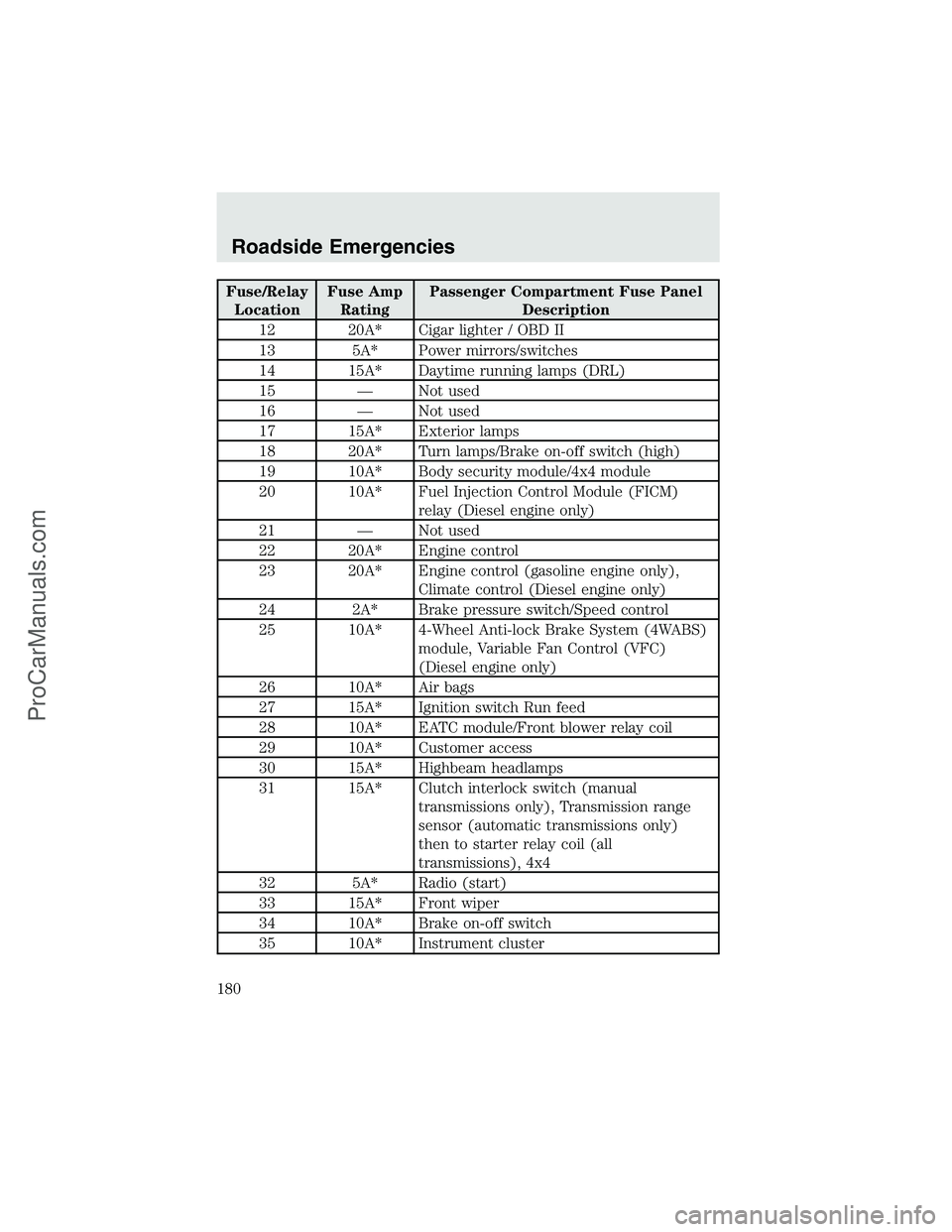

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse Panel

Description

12 20A* Cigar lighter / OBD II

13 5A* Power mirrors/switches

14 15A* Daytime running lamps (DRL)

15—Not used

16—Not used

17 15A* Exterior lamps

18 20A* Turn lamps/Brake on-off switch (high)

19 10A* Body security module/4x4 module

20 10A* Fuel Injection Control Module (FICM)

relay (Diesel engine only)

21—Not used

22 20A* Engine control

23 20A* Engine control (gasoline engine only),

Climate control (Diesel engine only)

24 2A* Brake pressure switch/Speed control

25 10A* 4-Wheel Anti-lock Brake System (4WABS)

module, Variable Fan Control (VFC)

(Diesel engine only)

26 10A* Air bags

27 15A* Ignition switch Run feed

28 10A* EATC module/Front blower relay coil

29 10A* Customer access

30 15A* Highbeam headlamps

31 15A* Clutch interlock switch (manual

transmissions only), Transmission range

sensor (automatic transmissions only)

then to starter relay coil (all

transmissions), 4x4

32 5A* Radio (start)

33 15A* Front wiper

34 10A* Brake on-off switch

35 10A* Instrument cluster

Roadside Emergencies

180

ProCarManuals.com

Page 181 of 280

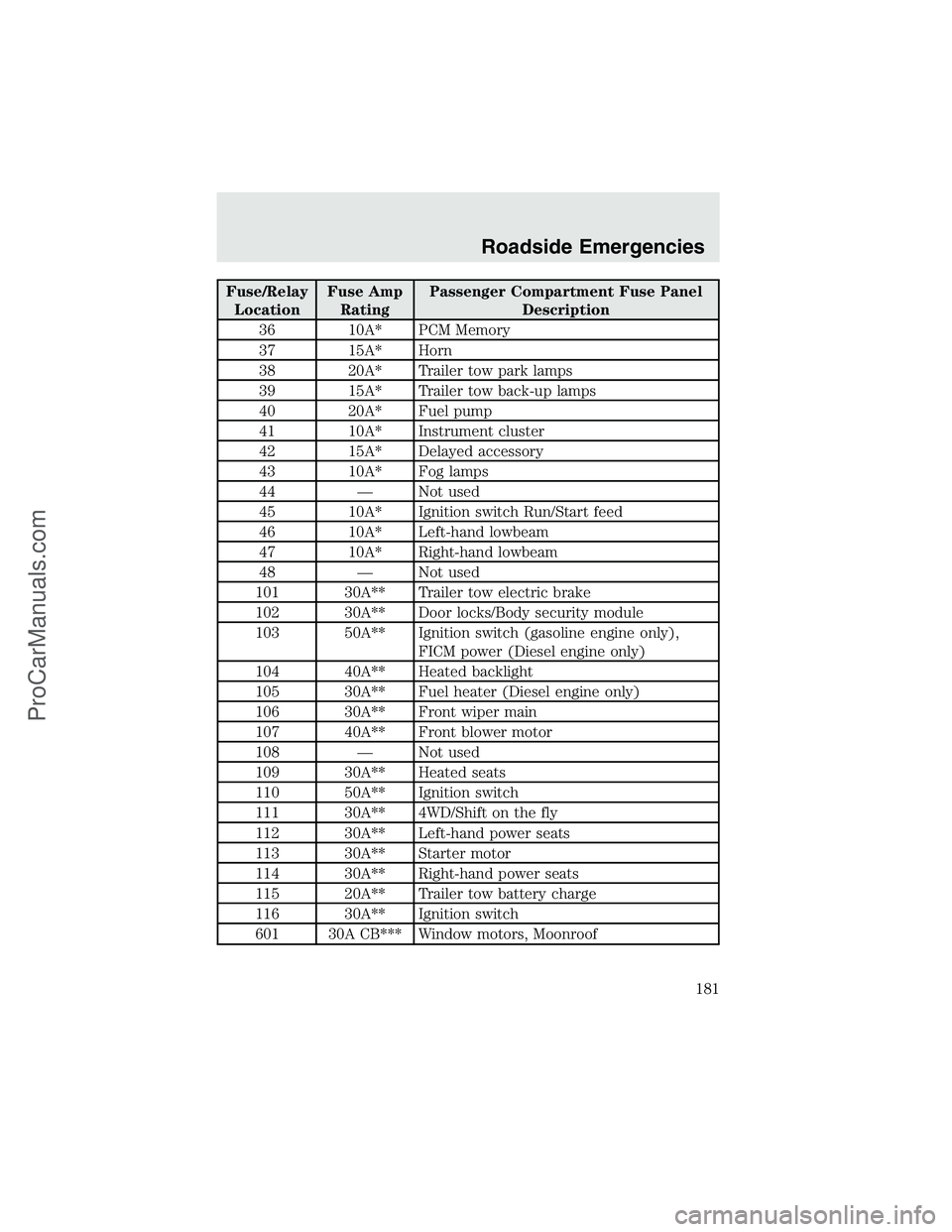

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse Panel

Description

36 10A* PCM Memory

37 15A* Horn

38 20A* Trailer tow park lamps

39 15A* Trailer tow back-up lamps

40 20A* Fuel pump

41 10A* Instrument cluster

42 15A* Delayed accessory

43 10A* Fog lamps

44—Not used

45 10A* Ignition switch Run/Start feed

46 10A* Left-hand lowbeam

47 10A* Right-hand lowbeam

48—Not used

101 30A** Trailer tow electric brake

102 30A** Door locks/Body security module

103 50A** Ignition switch (gasoline engine only),

FICM power (Diesel engine only)

104 40A** Heated backlight

105 30A** Fuel heater (Diesel engine only)

106 30A** Front wiper main

107 40A** Front blower motor

108—Not used

109 30A** Heated seats

110 50A** Ignition switch

111 30A** 4WD/Shift on the fly

112 30A** Left-hand power seats

113 30A** Starter motor

114 30A** Right-hand power seats

115 20A** Trailer tow battery charge

116 30A** Ignition switch

601 30A CB*** Window motors, Moonroof

Roadside Emergencies

181

ProCarManuals.com

Page 182 of 280

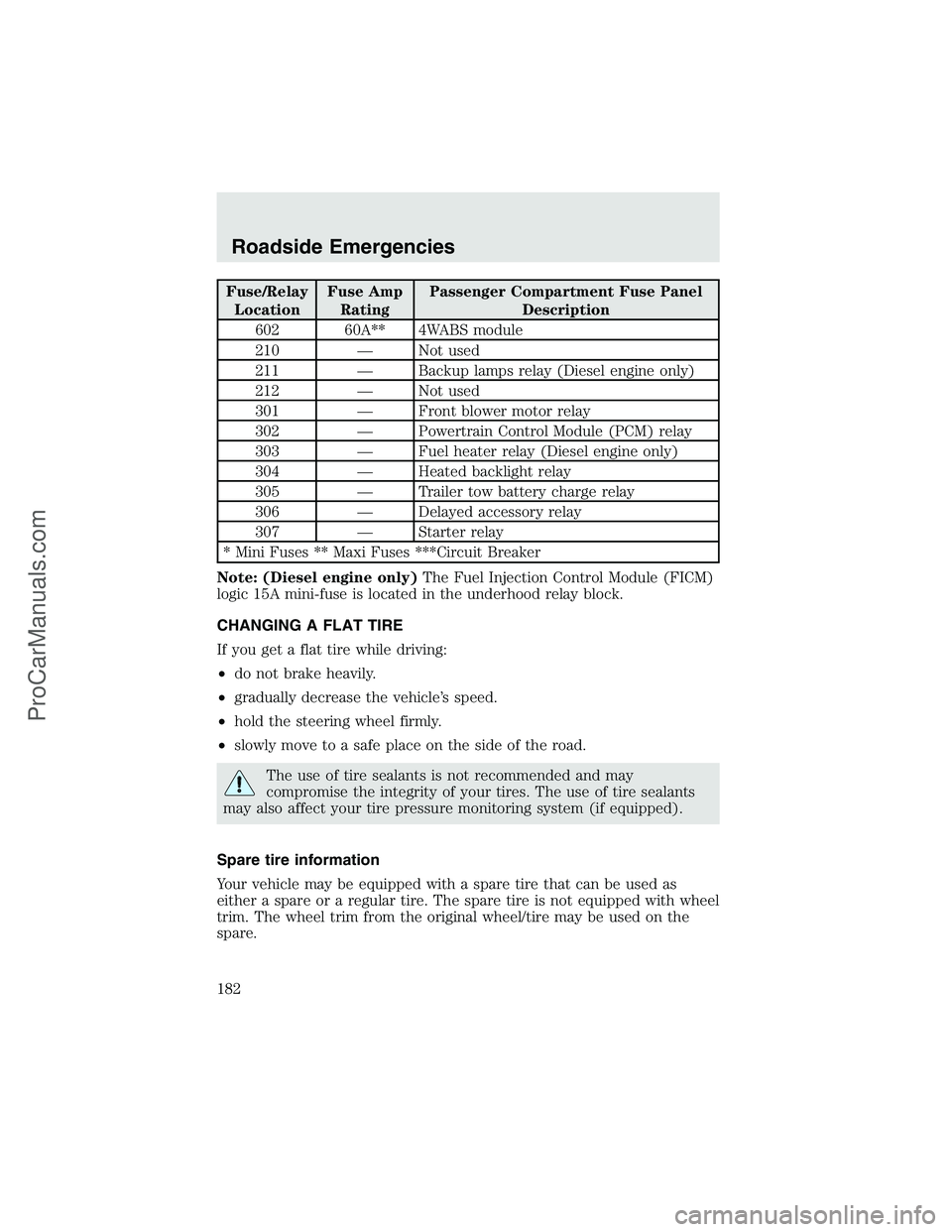

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse Panel

Description

602 60A** 4WABS module

210—Not used

211—Backup lamps relay (Diesel engine only)

212—Not used

301—Front blower motor relay

302—Powertrain Control Module (PCM) relay

303—Fuel heater relay (Diesel engine only)

304—Heated backlight relay

305—Trailer tow battery charge relay

306—Delayed accessory relay

307—Starter relay

* Mini Fuses ** Maxi Fuses ***Circuit Breaker

Note: (Diesel engine only)The Fuel Injection Control Module (FICM)

logic 15A mini-fuse is located in the underhood relay block.

CHANGING A FLAT TIRE

If you get a flat tire while driving:

•do not brake heavily.

•gradually decrease the vehicle’s speed.

•hold the steering wheel firmly.

•slowly move to a safe place on the side of the road.

The use of tire sealants is not recommended and may

compromise the integrity of your tires. The use of tire sealants

may also affect your tire pressure monitoring system (if equipped).

Spare tire information

Your vehicle may be equipped with a spare tire that can be used as

either a spare or a regular tire. The spare tire is not equipped with wheel

trim. The wheel trim from the original wheel/tire may be used on the

spare.

Roadside Emergencies

182

ProCarManuals.com

Page 185 of 280

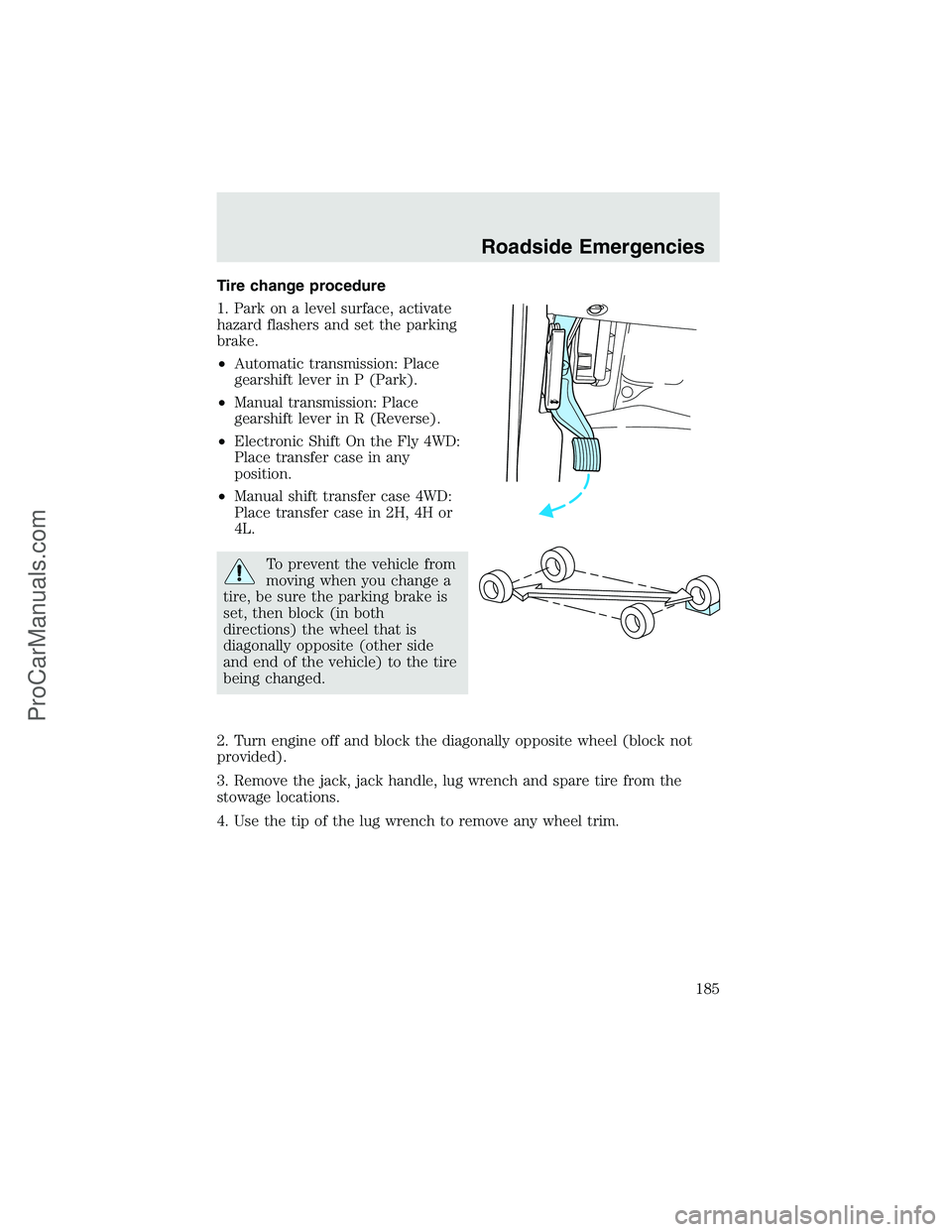

Tire change procedure

1. Park on a level surface, activate

hazard flashers and set the parking

brake.

•Automatic transmission: Place

gearshift lever in P (Park).

•Manual transmission: Place

gearshift lever in R (Reverse).

•Electronic Shift On the Fly 4WD:

Place transfer case in any

position.

•Manual shift transfer case 4WD:

Place transfer case in 2H, 4H or

4L.

To prevent the vehicle from

moving when you change a

tire, be sure the parking brake is

set, then block (in both

directions) the wheel that is

diagonally opposite (other side

and end of the vehicle) to the tire

being changed.

2. Turn engine off and block the diagonally opposite wheel (block not

provided).

3. Remove the jack, jack handle, lug wrench and spare tire from the

stowage locations.

4. Use the tip of the lug wrench to remove any wheel trim.

Roadside Emergencies

185

ProCarManuals.com

Page 188 of 280

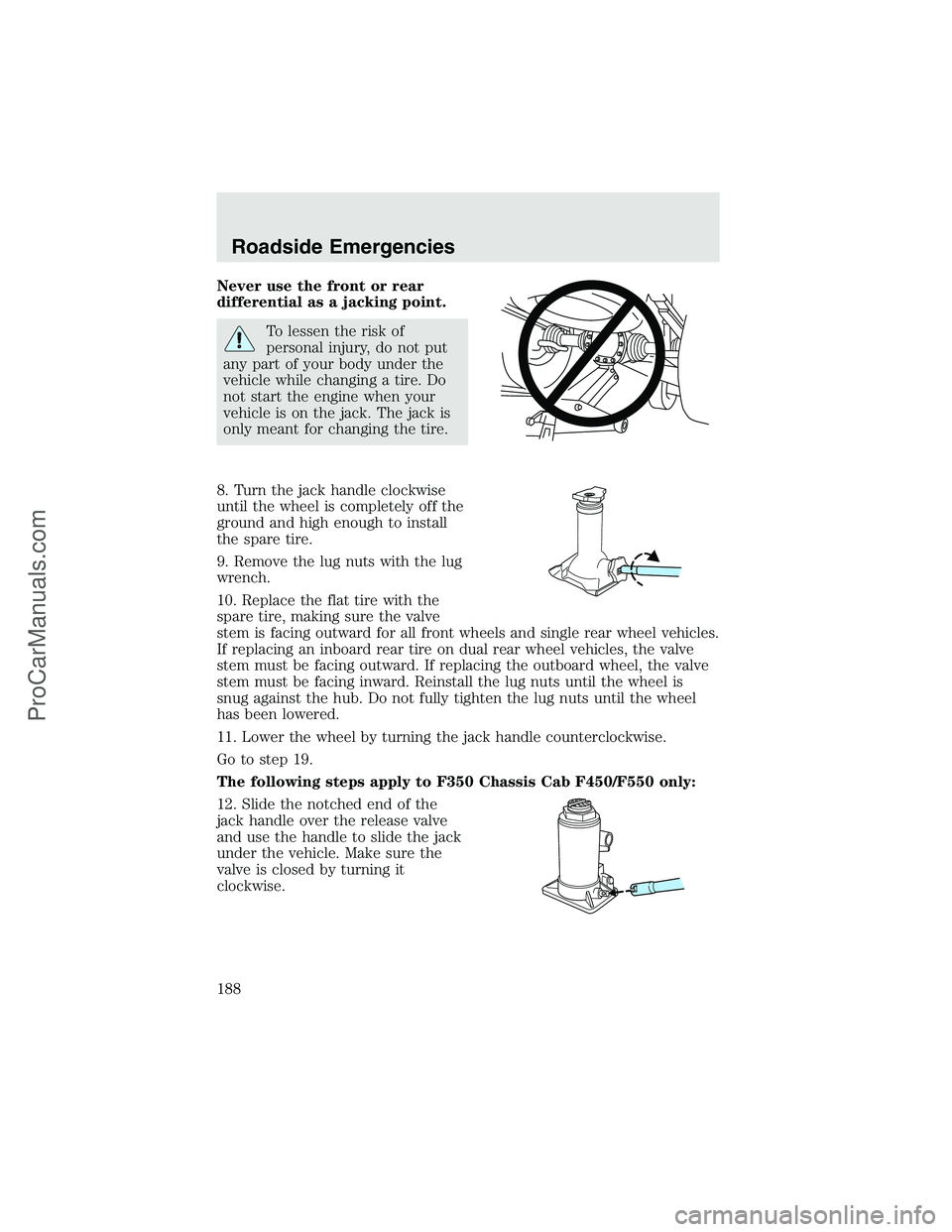

Never use the front or rear

differential as a jacking point.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

8. Turn the jack handle clockwise

until the wheel is completely off the

ground and high enough to install

the spare tire.

9. Remove the lug nuts with the lug

wrench.

10. Replace the flat tire with the

spare tire, making sure the valve

stem is facing outward for all front wheels and single rear wheel vehicles.

If replacing an inboard rear tire on dual rear wheel vehicles, the valve

stem must be facing outward. If replacing the outboard wheel, the valve

stem must be facing inward. Reinstall the lug nuts until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

11. Lower the wheel by turning the jack handle counterclockwise.

Go to step 19.

The following steps apply to F350 Chassis Cab F450/F550 only:

12. Slide the notched end of the

jack handle over the release valve

and use the handle to slide the jack

under the vehicle. Make sure the

valve is closed by turning it

clockwise.

Roadside Emergencies

188

ProCarManuals.com

Page 193 of 280

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; also, the

catalytic converter may become damaged.

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Roadside Emergencies

193

ProCarManuals.com

Page 195 of 280

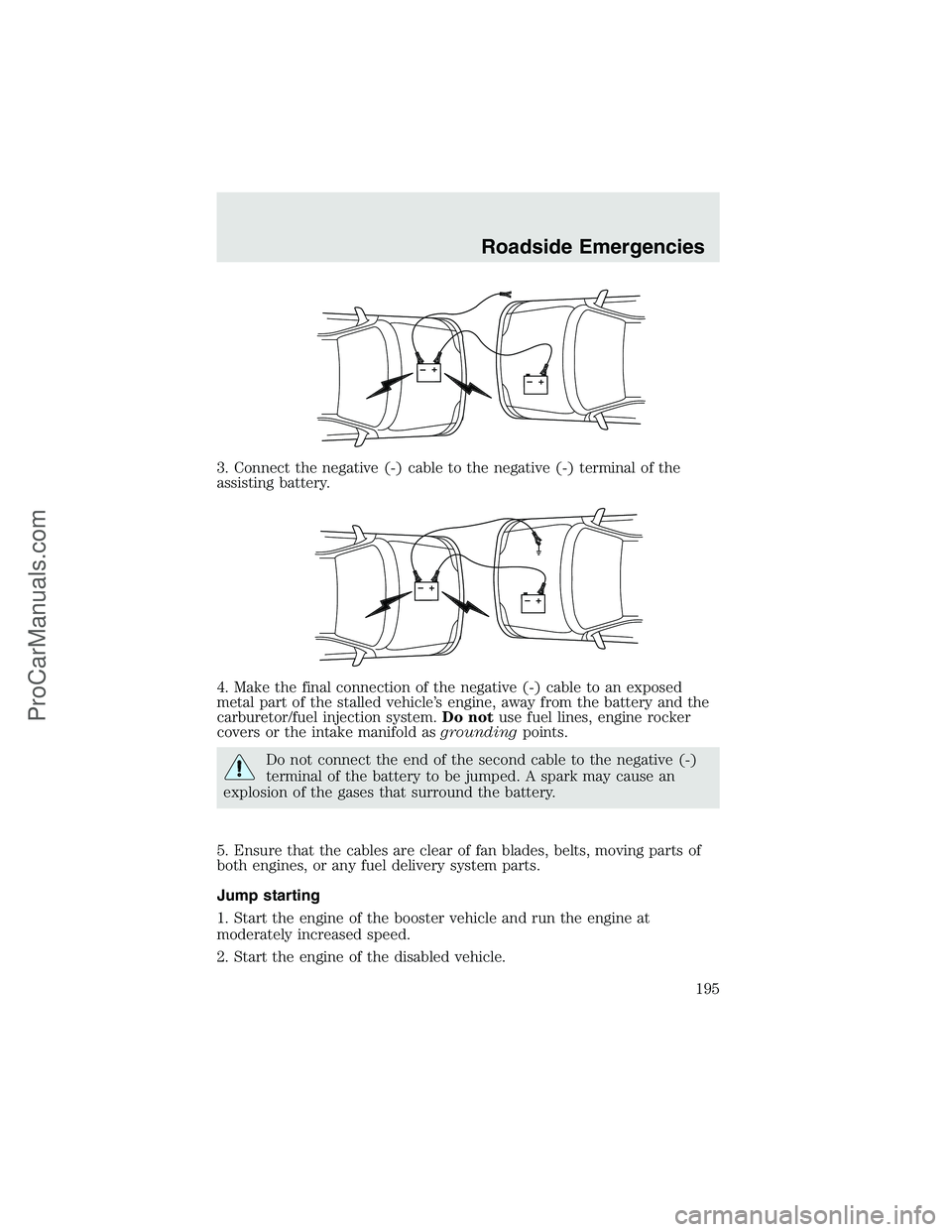

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle’s engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

+–+–

+–+–

Roadside Emergencies

195

ProCarManuals.com

Page 196 of 280

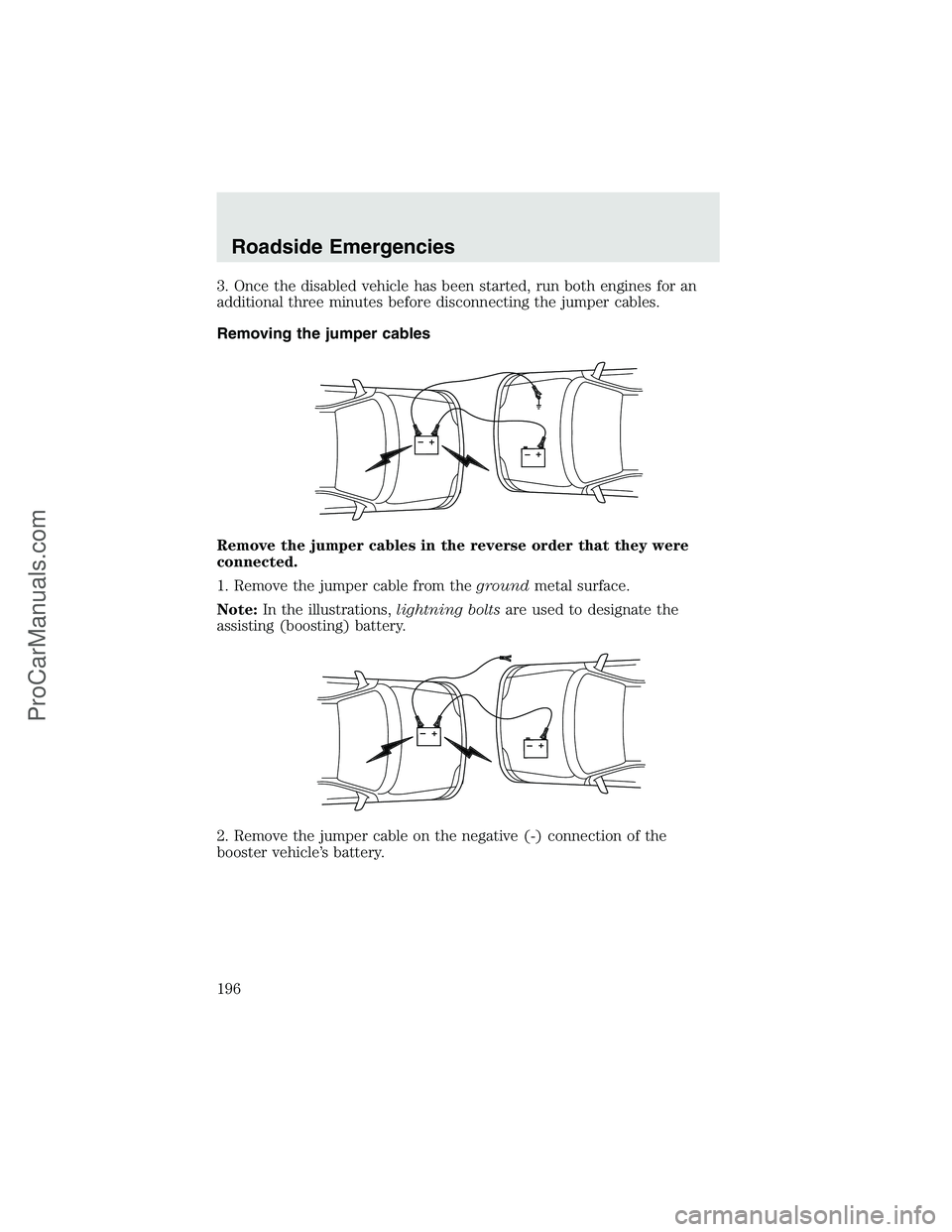

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

+–+–

+–+–

Roadside Emergencies

196

ProCarManuals.com

Page 197 of 280

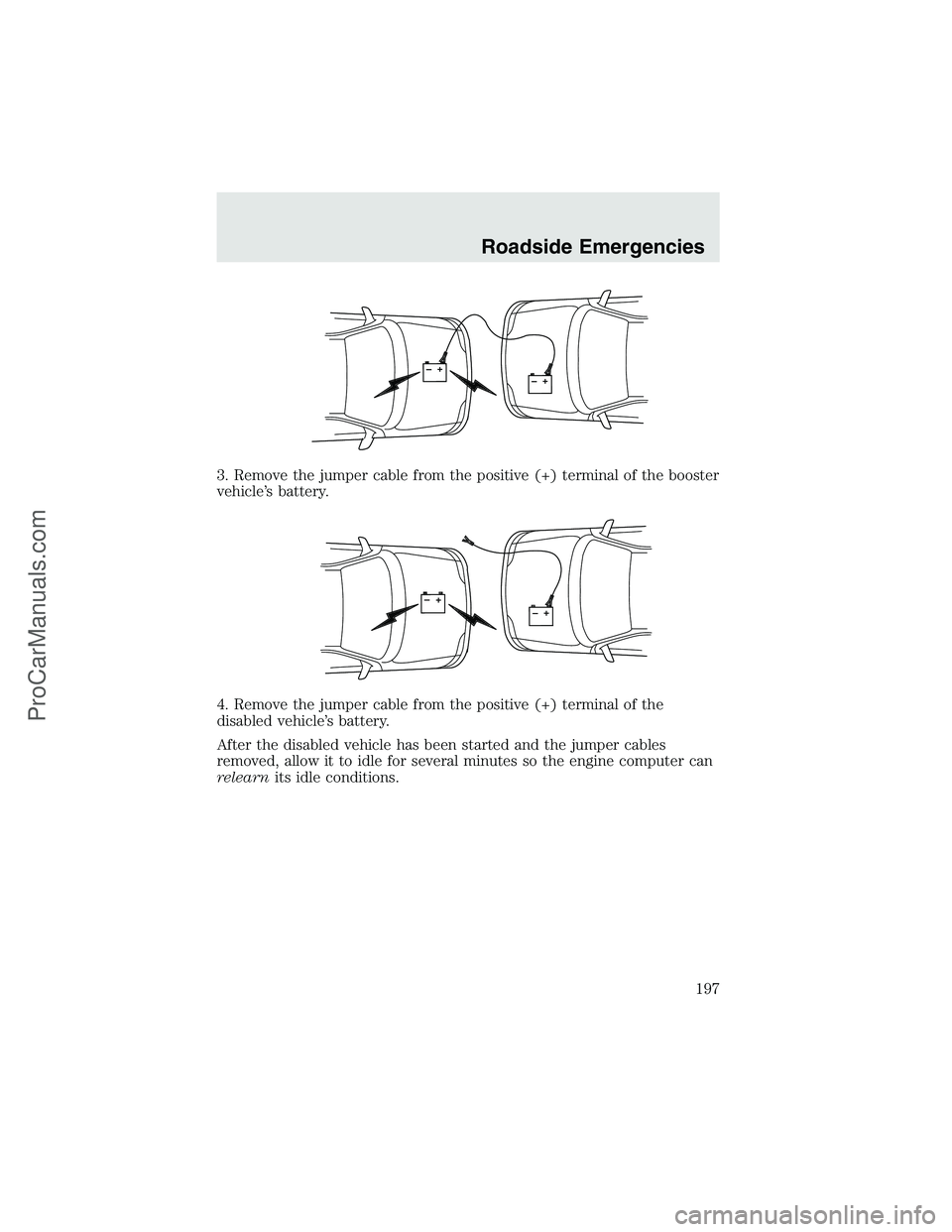

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

Roadside Emergencies

197

ProCarManuals.com