clock FORD F450 SUPER DUTY 2016 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: F450 SUPER DUTY, Model: FORD F450 SUPER DUTY 2016Pages: 507, PDF Size: 8.13 MB

Page 251 of 507

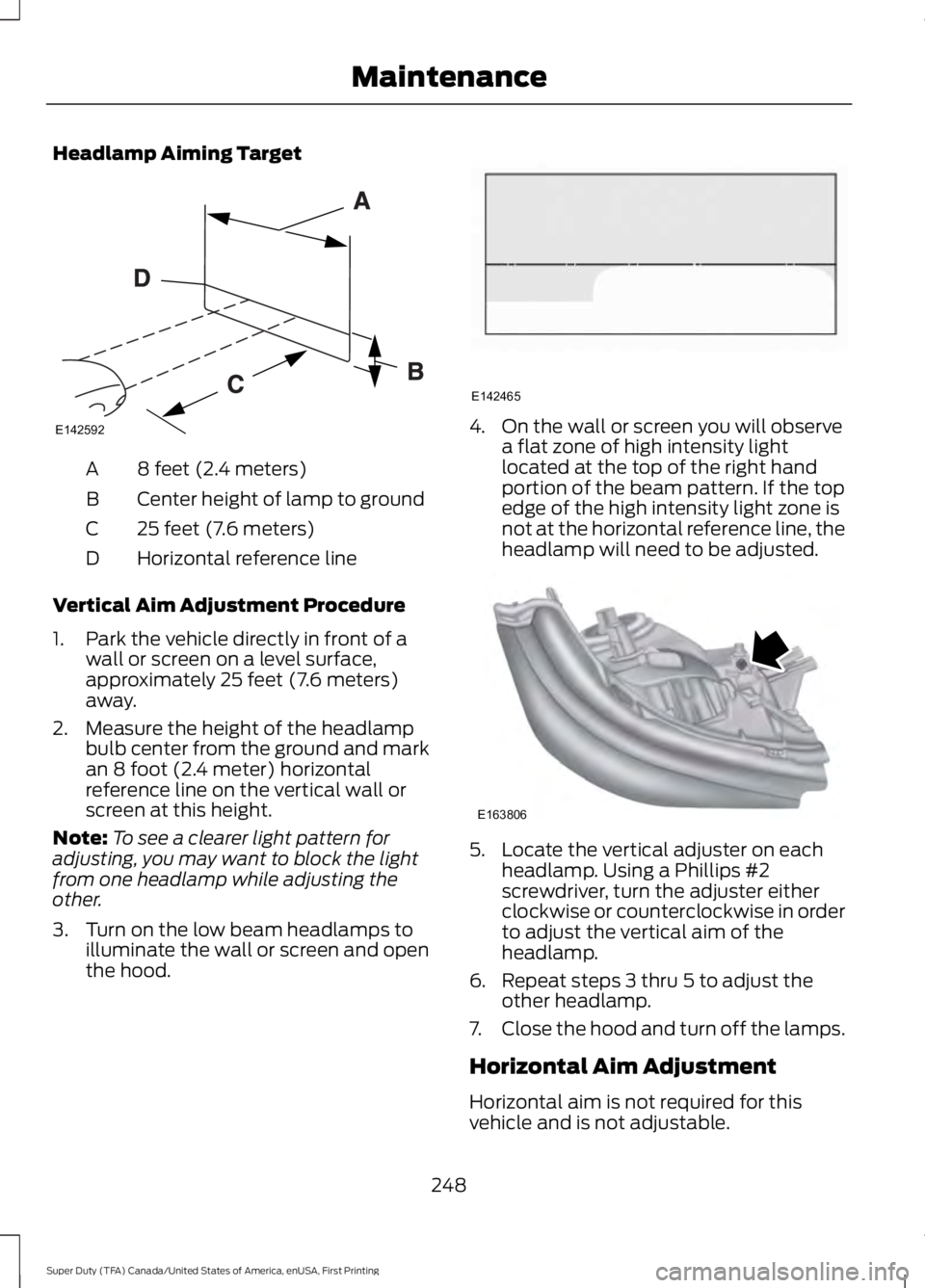

Headlamp Aiming Target

8 feet (2.4 meters)A

Center height of lamp to groundB

25 feet (7.6 meters)C

Horizontal reference lineD

Vertical Aim Adjustment Procedure

1. Park the vehicle directly in front of awall or screen on a level surface,approximately 25 feet (7.6 meters)away.

2. Measure the height of the headlampbulb center from the ground and markan 8 foot (2.4 meter) horizontalreference line on the vertical wall orscreen at this height.

Note:To see a clearer light pattern foradjusting, you may want to block the lightfrom one headlamp while adjusting theother.

3. Turn on the low beam headlamps toilluminate the wall or screen and openthe hood.

4. On the wall or screen you will observea flat zone of high intensity lightlocated at the top of the right handportion of the beam pattern. If the topedge of the high intensity light zone isnot at the horizontal reference line, theheadlamp will need to be adjusted.

5. Locate the vertical adjuster on eachheadlamp. Using a Phillips #2screwdriver, turn the adjuster eitherclockwise or counterclockwise in orderto adjust the vertical aim of theheadlamp.

6. Repeat steps 3 thru 5 to adjust theother headlamp.

7.Close the hood and turn off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for thisvehicle and is not adjustable.

248

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE142592 E142465 E163806

Page 253 of 507

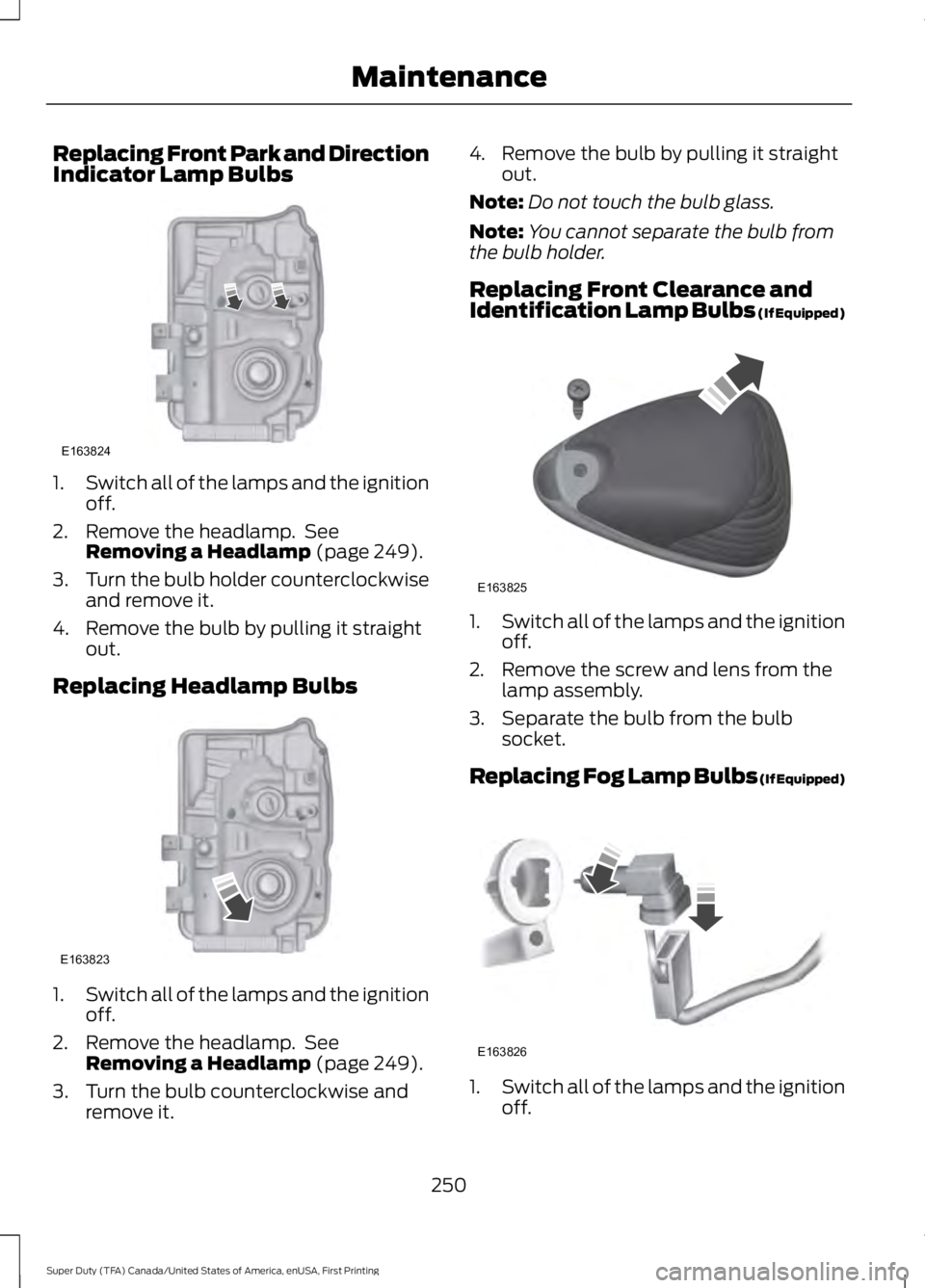

Replacing Front Park and DirectionIndicator Lamp Bulbs

1.Switch all of the lamps and the ignitionoff.

2. Remove the headlamp. SeeRemoving a Headlamp (page 249).

3.Turn the bulb holder counterclockwiseand remove it.

4. Remove the bulb by pulling it straightout.

Replacing Headlamp Bulbs

1.Switch all of the lamps and the ignitionoff.

2. Remove the headlamp. SeeRemoving a Headlamp (page 249).

3. Turn the bulb counterclockwise andremove it.

4. Remove the bulb by pulling it straightout.

Note:Do not touch the bulb glass.

Note:You cannot separate the bulb fromthe bulb holder.

Replacing Front Clearance andIdentification Lamp Bulbs (If Equipped)

1.Switch all of the lamps and the ignitionoff.

2. Remove the screw and lens from thelamp assembly.

3. Separate the bulb from the bulbsocket.

Replacing Fog Lamp Bulbs (If Equipped)

1.Switch all of the lamps and the ignitionoff.

250

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE163824 E163823 E163825 E163826

Page 254 of 507

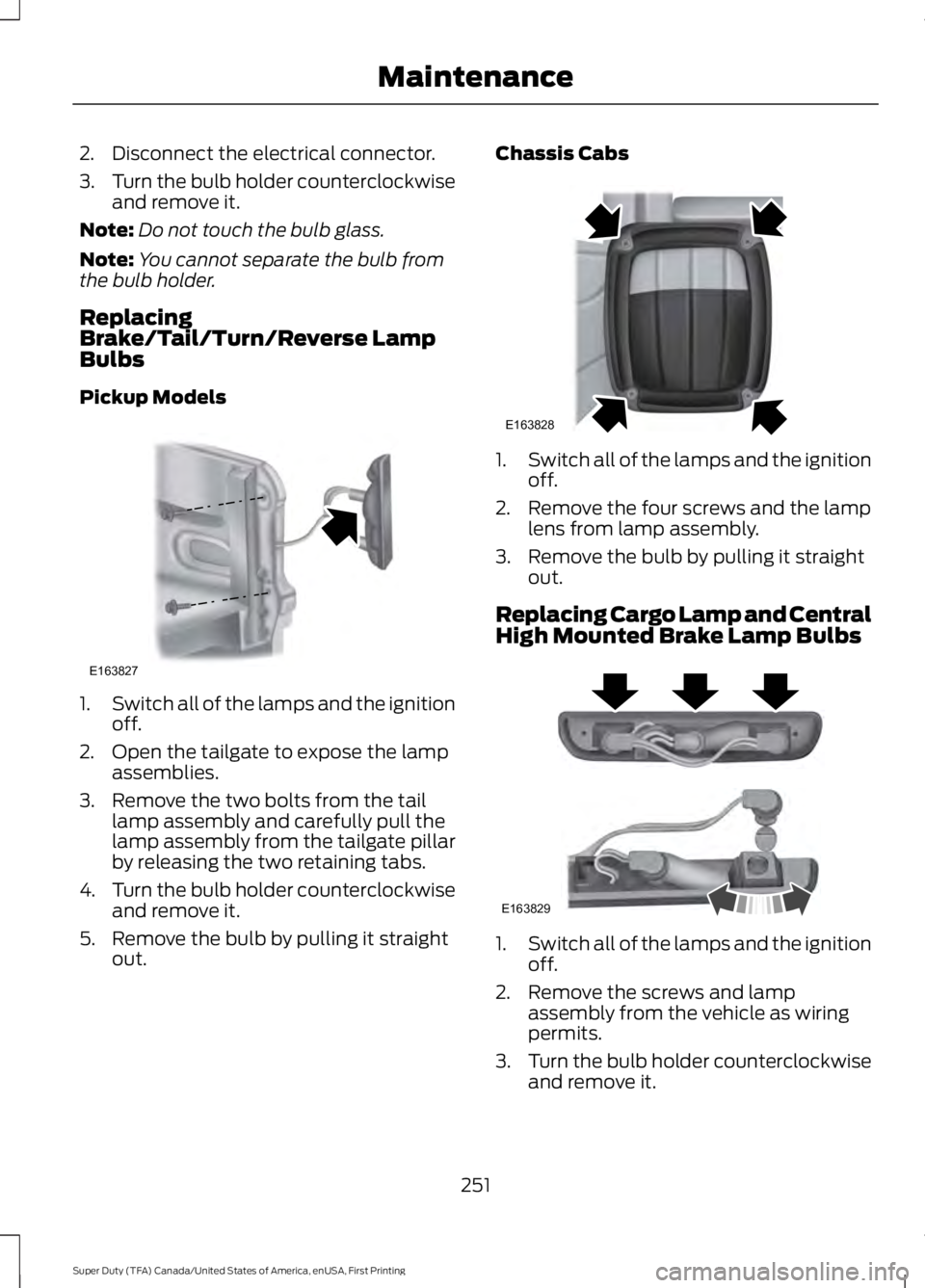

2. Disconnect the electrical connector.

3.Turn the bulb holder counterclockwiseand remove it.

Note:Do not touch the bulb glass.

Note:You cannot separate the bulb fromthe bulb holder.

ReplacingBrake/Tail/Turn/Reverse LampBulbs

Pickup Models

1.Switch all of the lamps and the ignitionoff.

2. Open the tailgate to expose the lampassemblies.

3. Remove the two bolts from the taillamp assembly and carefully pull thelamp assembly from the tailgate pillarby releasing the two retaining tabs.

4.Turn the bulb holder counterclockwiseand remove it.

5. Remove the bulb by pulling it straightout.

Chassis Cabs

1.Switch all of the lamps and the ignitionoff.

2. Remove the four screws and the lamplens from lamp assembly.

3. Remove the bulb by pulling it straightout.

Replacing Cargo Lamp and CentralHigh Mounted Brake Lamp Bulbs

1.Switch all of the lamps and the ignitionoff.

2. Remove the screws and lampassembly from the vehicle as wiringpermits.

3.Turn the bulb holder counterclockwiseand remove it.

251

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE163827 E163828 E163829

Page 255 of 507

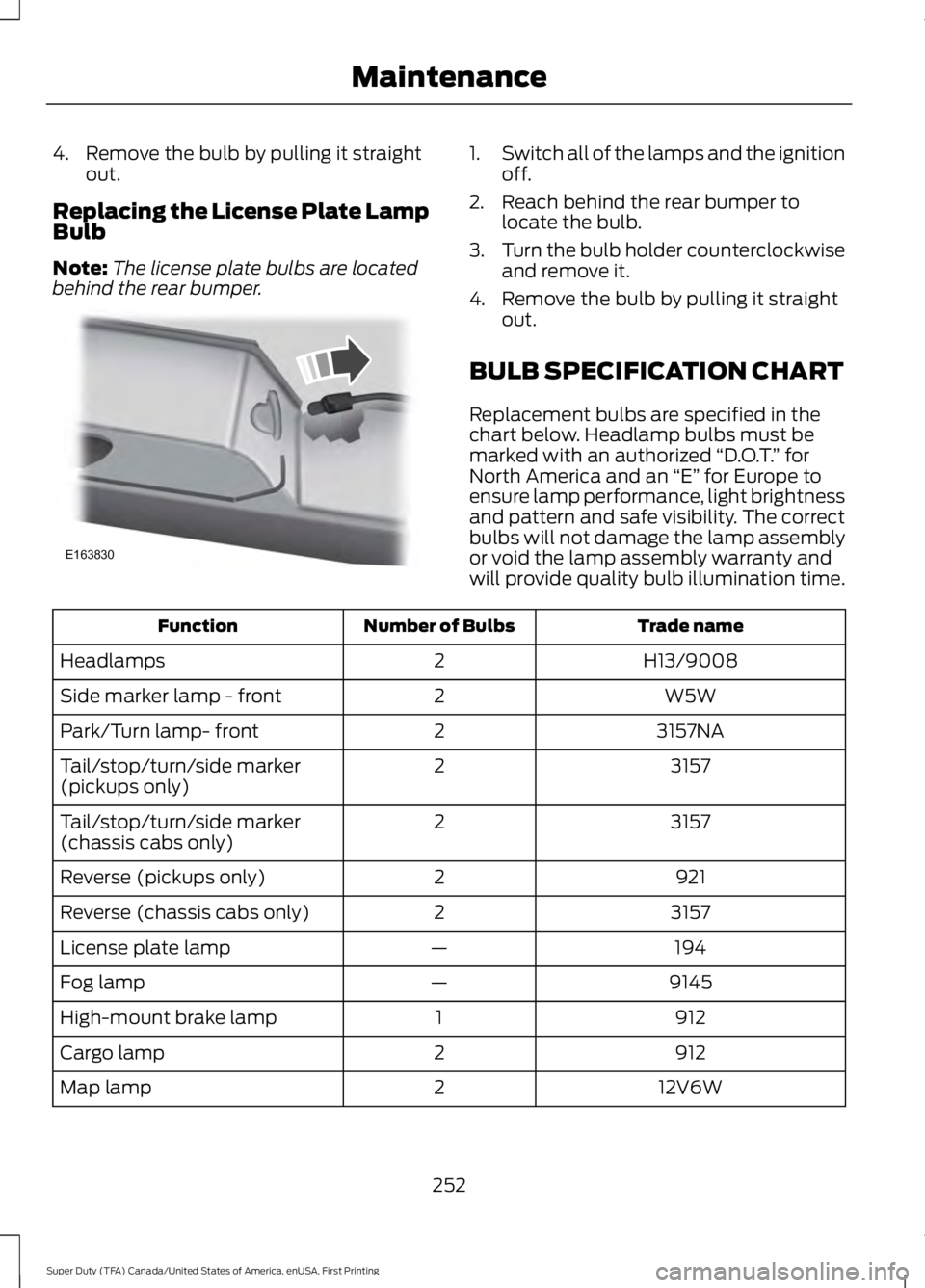

4. Remove the bulb by pulling it straightout.

Replacing the License Plate LampBulb

Note:The license plate bulbs are locatedbehind the rear bumper.

1.Switch all of the lamps and the ignitionoff.

2. Reach behind the rear bumper tolocate the bulb.

3.Turn the bulb holder counterclockwiseand remove it.

4. Remove the bulb by pulling it straightout.

BULB SPECIFICATION CHART

Replacement bulbs are specified in thechart below. Headlamp bulbs must bemarked with an authorized “D.O.T.” forNorth America and an “E” for Europe toensure lamp performance, light brightnessand pattern and safe visibility. The correctbulbs will not damage the lamp assemblyor void the lamp assembly warranty andwill provide quality bulb illumination time.

Trade nameNumber of BulbsFunction

H13/90082Headlamps

W5W2Side marker lamp - front

3157NA2Park/Turn lamp- front

31572Tail/stop/turn/side marker(pickups only)

31572Tail/stop/turn/side marker(chassis cabs only)

9212Reverse (pickups only)

31572Reverse (chassis cabs only)

194—License plate lamp

9145—Fog lamp

9121High-mount brake lamp

9122Cargo lamp

12V6W2Map lamp

252

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE163830

Page 292 of 507

•To reduce the chances of interferencefrom another vehicle, perform thesystem reset procedure at least threefeet (one meter) away from anotherFord Motor Company vehicleundergoing the system reset procedureat the same time.

•Do not wait more than two minutesbetween resetting each tire sensor orthe system will time-out and the entireprocedure will have to be repeated onall four wheels.

•A double horn will sound indicating theneed to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure beforeattempting.

1. Drive the vehicle above 20 mph (32km/h) for at least two minutes, thenpark in a safe location where you caneasily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3. Cycle the ignition to the on positionwith the engine off.

4. Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If the reset modehas been entered successfully, the hornwill sound once, the system indicatorwill flash and a message is shown inthe information display. If this does notoccur, please try again starting at Step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message is shown in theinformation display, seek service fromyour authorized dealer.

5. Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing clockwise order: Left front(driver's side front tire), Right front(passenger's side front tire), Right rear(passenger's side rear tire), Left rear(driver's side rear tire).

6. Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.Note: The single horn chirp confirmsthat the sensor identification code hasbeen learned by the module for thisposition. If a double horn is heard, thereset procedure was unsuccessful, andyou must repeat it.

7. Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8. Remove the valve cap from the valvestem on the right rear tire. Decrease theair pressure until the horn sounds.

9. Remove the valve cap from the valvestem on the left rear tire. Decrease theair pressure until the horn sounds.Training is complete after the hornsounds for the last tire trained (driver'sside rear tire), the system indicatorstops flashing, and a message is shownin the information display.

10.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

289

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 296 of 507

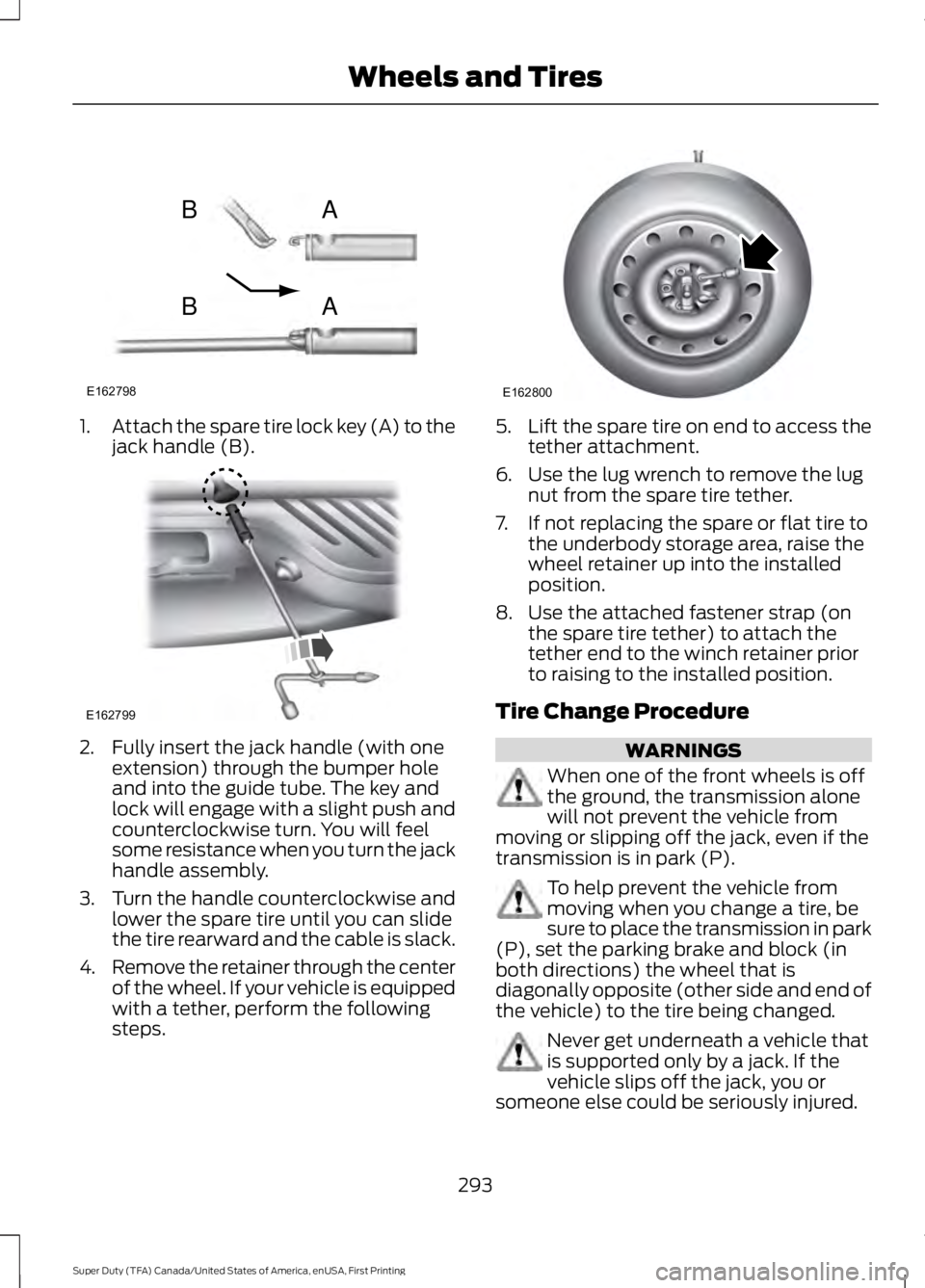

1.Attach the spare tire lock key (A) to thejack handle (B).

2. Fully insert the jack handle (with oneextension) through the bumper holeand into the guide tube. The key andlock will engage with a slight push andcounterclockwise turn. You will feelsome resistance when you turn the jackhandle assembly.

3.Turn the handle counterclockwise andlower the spare tire until you can slidethe tire rearward and the cable is slack.

4.Remove the retainer through the centerof the wheel. If your vehicle is equippedwith a tether, perform the followingsteps.

5.Lift the spare tire on end to access thetether attachment.

6. Use the lug wrench to remove the lugnut from the spare tire tether.

7. If not replacing the spare or flat tire tothe underbody storage area, raise thewheel retainer up into the installedposition.

8. Use the attached fastener strap (onthe spare tire tether) to attach thetether end to the winch retainer priorto raising to the installed position.

Tire Change Procedure

WARNINGS

When one of the front wheels is offthe ground, the transmission alonewill not prevent the vehicle frommoving or slipping off the jack, even if thetransmission is in park (P).

To help prevent the vehicle frommoving when you change a tire, besure to place the transmission in park(P), set the parking brake and block (inboth directions) the wheel that isdiagonally opposite (other side and end ofthe vehicle) to the tire being changed.

Never get underneath a vehicle thatis supported only by a jack. If thevehicle slips off the jack, you orsomeone else could be seriously injured.

293

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and TiresE162798

AB

AB E162799 E162800

Page 297 of 507

WARNINGS

Do not attempt to change a tire onthe side of the vehicle close tomoving traffic. Pull far enough off theroad to avoid the danger of being hit whenoperating the jack or changing the wheel.

Always use the jack provided asoriginal equipment with your vehicle.If using a jack other than the oneprovided as original equipment with yourvehicle, make sure the jack capacity isadequate for the vehicle weight, includingany vehicle cargo or modifications.

Note:Passengers should not remain in thevehicle when the vehicle is being jacked.

Park on a level surface, set the parkingbrake and activate the hazard flashers.

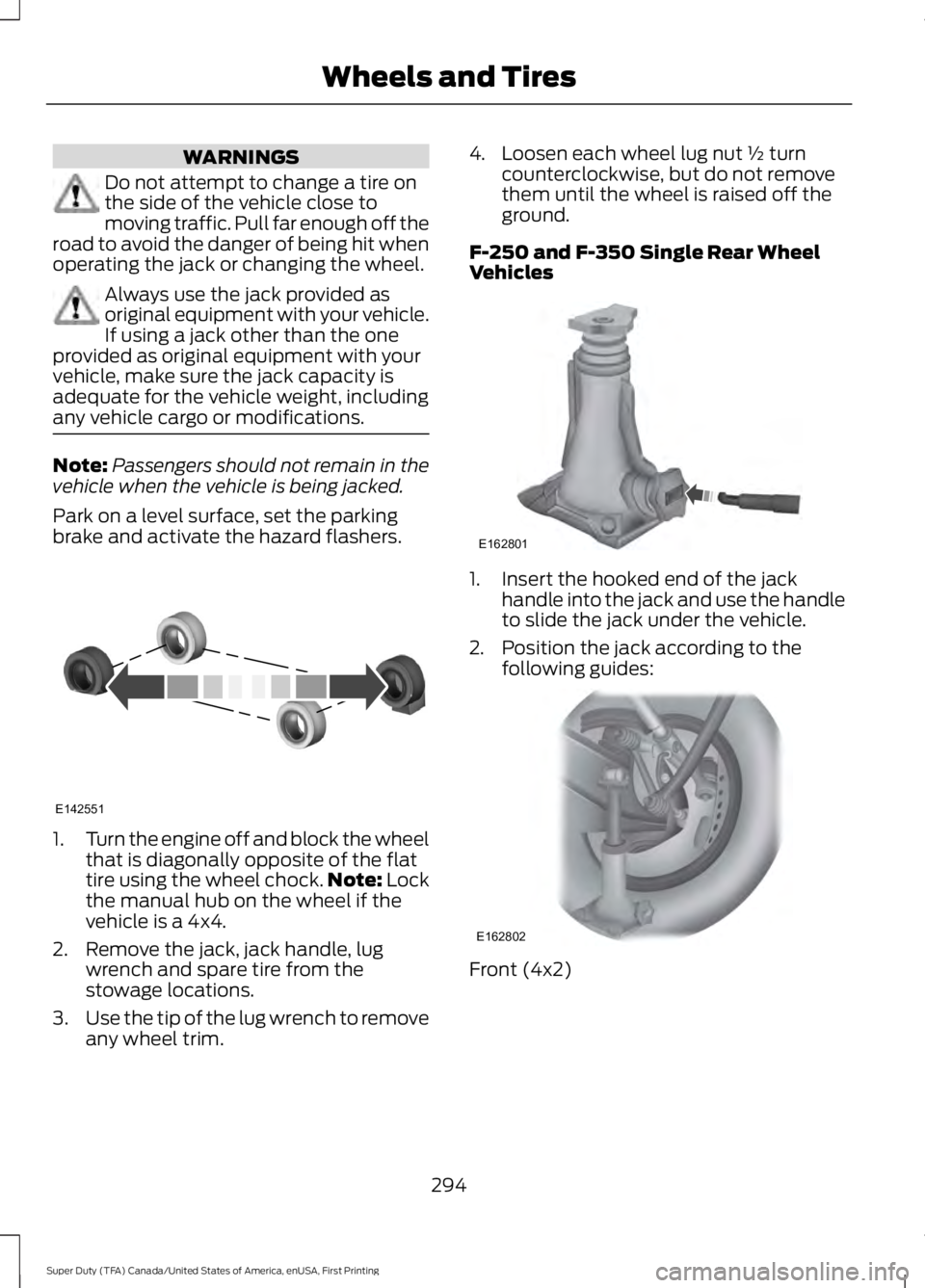

1.Turn the engine off and block the wheelthat is diagonally opposite of the flattire using the wheel chock.Note: Lockthe manual hub on the wheel if thevehicle is a 4x4.

2. Remove the jack, jack handle, lugwrench and spare tire from thestowage locations.

3.Use the tip of the lug wrench to removeany wheel trim.

4. Loosen each wheel lug nut ½ turncounterclockwise, but do not removethem until the wheel is raised off theground.

F-250 and F-350 Single Rear WheelVehicles

1. Insert the hooked end of the jackhandle into the jack and use the handleto slide the jack under the vehicle.

2. Position the jack according to thefollowing guides:

Front (4x2)

294

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and TiresE142551 E162801 E162802

Page 298 of 507

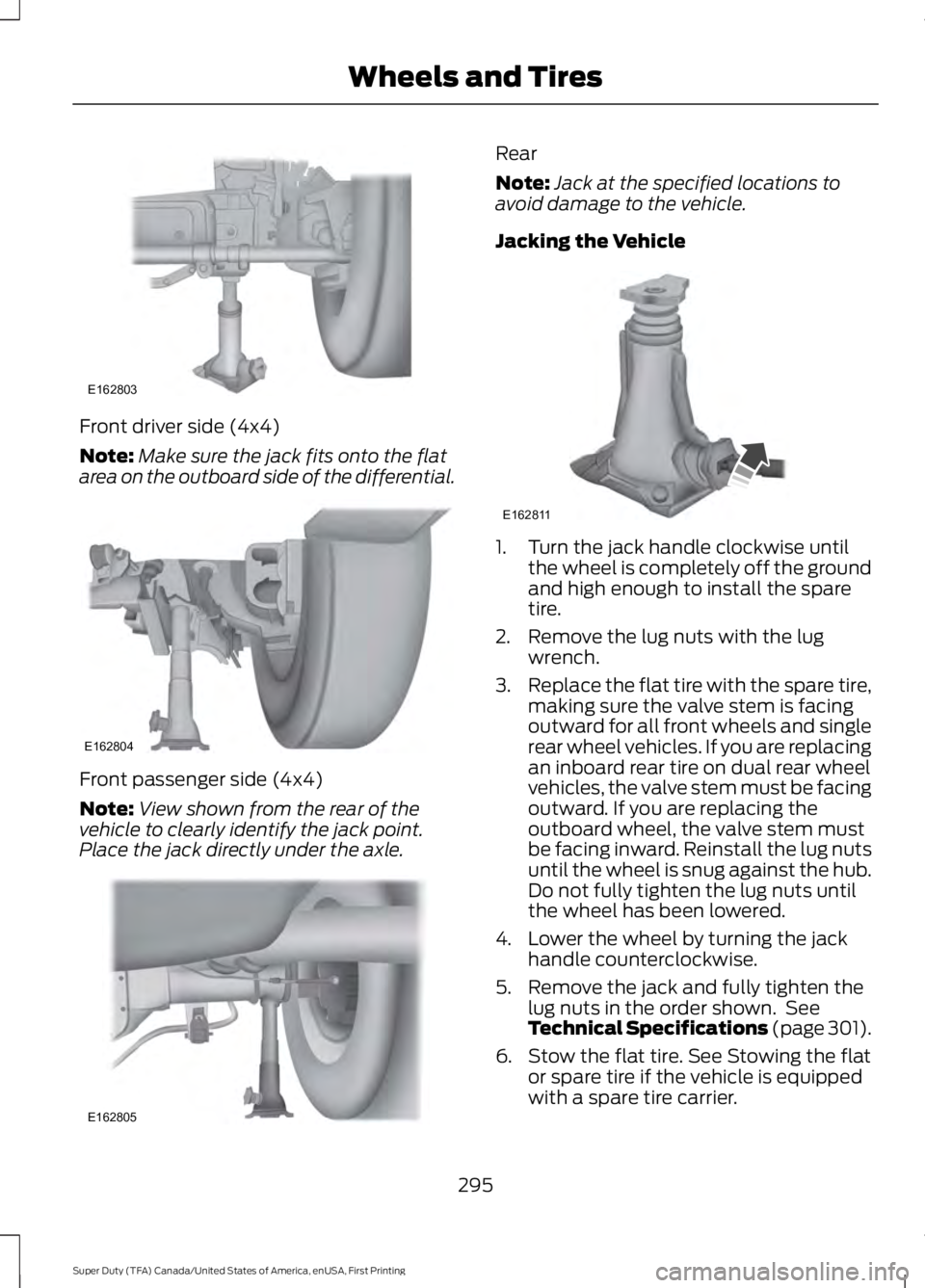

Front driver side (4x4)

Note:Make sure the jack fits onto the flatarea on the outboard side of the differential.

Front passenger side (4x4)

Note:View shown from the rear of thevehicle to clearly identify the jack point.Place the jack directly under the axle.

Rear

Note:Jack at the specified locations toavoid damage to the vehicle.

Jacking the Vehicle

1. Turn the jack handle clockwise untilthe wheel is completely off the groundand high enough to install the sparetire.

2. Remove the lug nuts with the lugwrench.

3.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward for all front wheels and singlerear wheel vehicles. If you are replacingan inboard rear tire on dual rear wheelvehicles, the valve stem must be facingoutward. If you are replacing theoutboard wheel, the valve stem mustbe facing inward. Reinstall the lug nutsuntil the wheel is snug against the hub.Do not fully tighten the lug nuts untilthe wheel has been lowered.

4. Lower the wheel by turning the jackhandle counterclockwise.

5. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 301).

6. Stow the flat tire. See Stowing the flator spare tire if the vehicle is equippedwith a spare tire carrier.

295

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and TiresE162803 E162804 E162805 E162811

Page 300 of 507

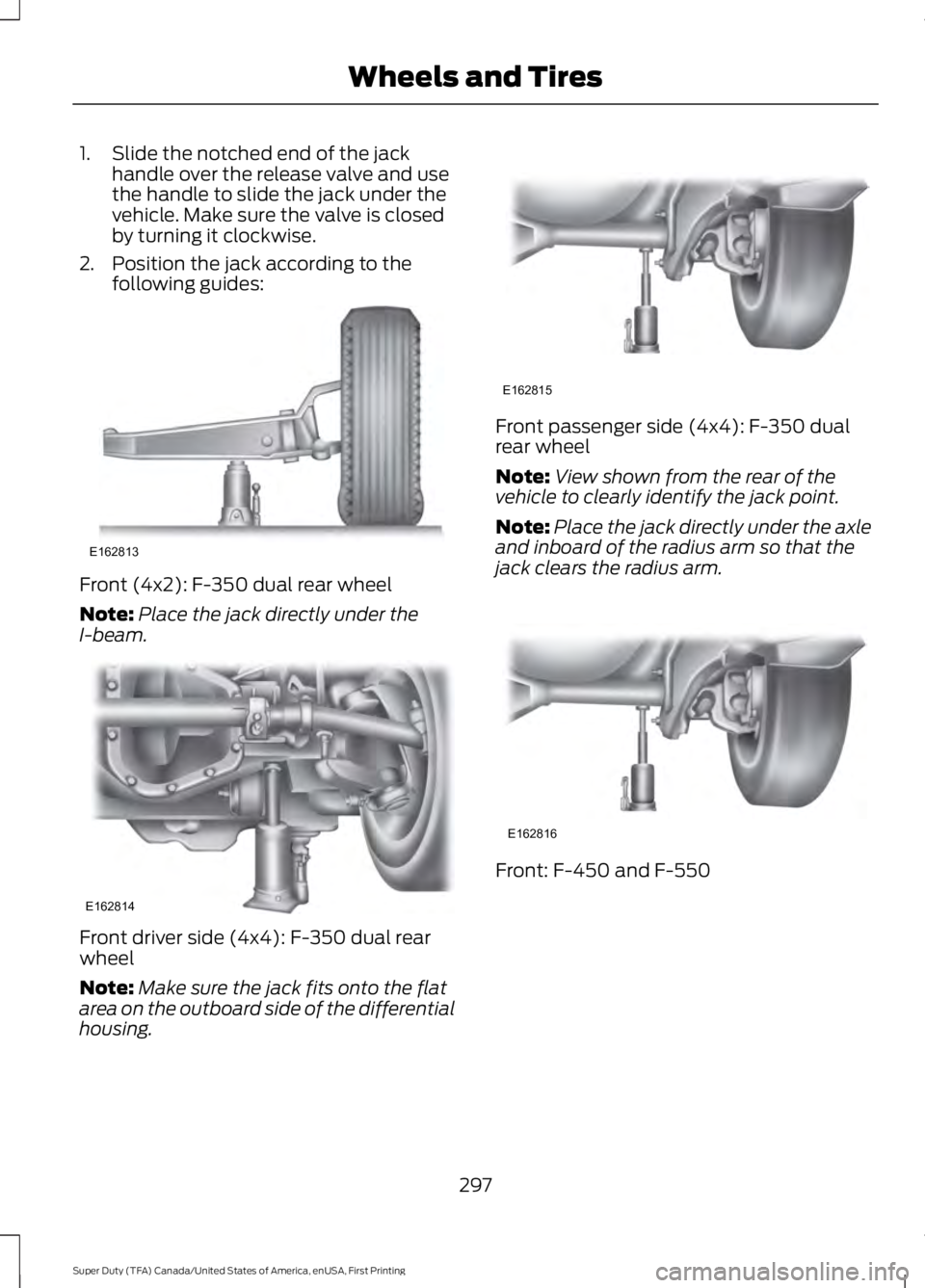

1. Slide the notched end of the jackhandle over the release valve and usethe handle to slide the jack under thevehicle. Make sure the valve is closedby turning it clockwise.

2. Position the jack according to thefollowing guides:

Front (4x2): F-350 dual rear wheel

Note:Place the jack directly under theI-beam.

Front driver side (4x4): F-350 dual rearwheel

Note:Make sure the jack fits onto the flatarea on the outboard side of the differentialhousing.

Front passenger side (4x4): F-350 dualrear wheel

Note:View shown from the rear of thevehicle to clearly identify the jack point.

Note:Place the jack directly under the axleand inboard of the radius arm so that thejack clears the radius arm.

Front: F-450 and F-550

297

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and TiresE162813 E162814 E162815 E162816

Page 301 of 507

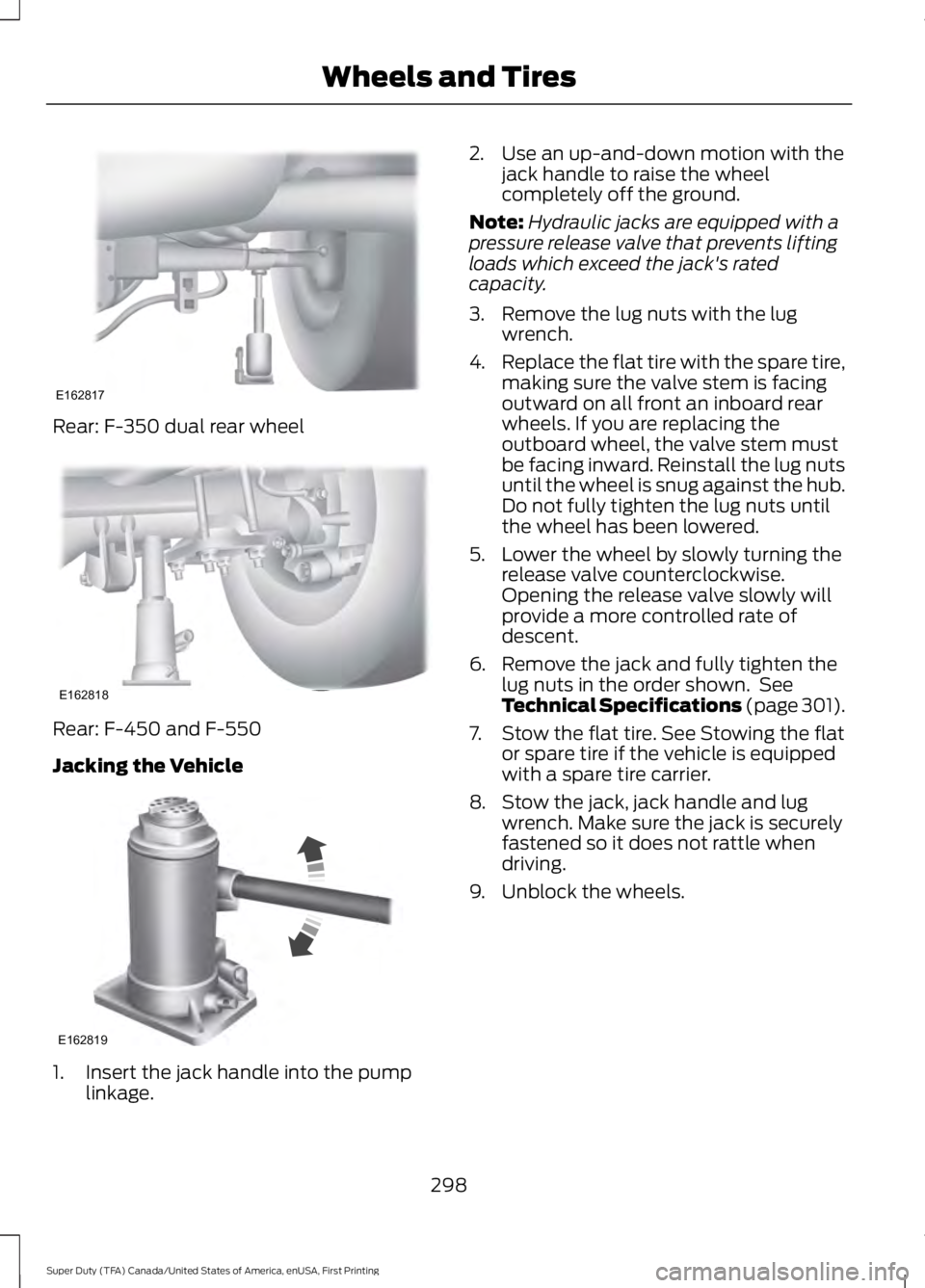

Rear: F-350 dual rear wheel

Rear: F-450 and F-550

Jacking the Vehicle

1. Insert the jack handle into the pumplinkage.

2. Use an up-and-down motion with thejack handle to raise the wheelcompletely off the ground.

Note:Hydraulic jacks are equipped with apressure release valve that prevents liftingloads which exceed the jack's ratedcapacity.

3. Remove the lug nuts with the lugwrench.

4.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward on all front an inboard rearwheels. If you are replacing theoutboard wheel, the valve stem mustbe facing inward. Reinstall the lug nutsuntil the wheel is snug against the hub.Do not fully tighten the lug nuts untilthe wheel has been lowered.

5. Lower the wheel by slowly turning therelease valve counterclockwise.Opening the release valve slowly willprovide a more controlled rate ofdescent.

6. Remove the jack and fully tighten thelug nuts in the order shown. SeeTechnical Specifications (page 301).

7. Stow the flat tire. See Stowing the flator spare tire if the vehicle is equippedwith a spare tire carrier.

8. Stow the jack, jack handle and lugwrench. Make sure the jack is securelyfastened so it does not rattle whendriving.

9. Unblock the wheels.

298

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and TiresE162817 E162818 E162819