ignition FORD F450 SUPER DUTY 2016 Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2016, Model line: F450 SUPER DUTY, Model: FORD F450 SUPER DUTY 2016Pages: 507, PDF Size: 8.13 MB

Page 233 of 507

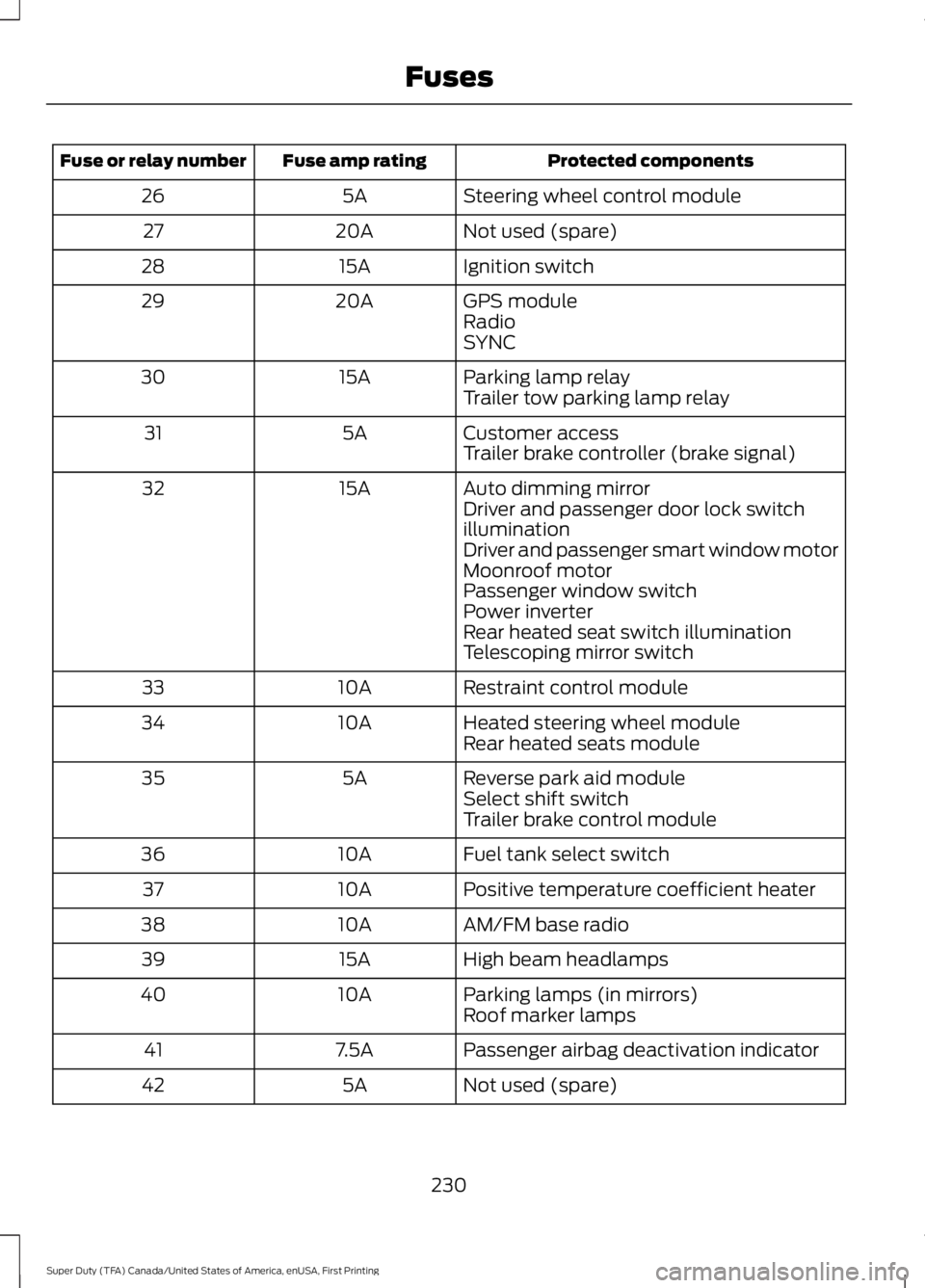

Protected componentsFuse amp ratingFuse or relay number

Steering wheel control module5A26

Not used (spare)20A27

Ignition switch15A28

GPS module20A29RadioSYNC

Parking lamp relay15A30Trailer tow parking lamp relay

Customer access5A31Trailer brake controller (brake signal)

Auto dimming mirror15A32Driver and passenger door lock switchilluminationDriver and passenger smart window motorMoonroof motorPassenger window switchPower inverterRear heated seat switch illuminationTelescoping mirror switch

Restraint control module10A33

Heated steering wheel module10A34Rear heated seats module

Reverse park aid module5A35Select shift switchTrailer brake control module

Fuel tank select switch10A36

Positive temperature coefficient heater10A37

AM/FM base radio10A38

High beam headlamps15A39

Parking lamps (in mirrors)10A40Roof marker lamps

Passenger airbag deactivation indicator7.5A41

Not used (spare)5A42

230

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Fuses

Page 239 of 507

Only use oils certified for gasoline enginesby the American Petroleum Institute (API).An oil with this trademark symbolconforms to the current engine andemission system protection standards andfuel economy requirements of theInternational Lubricants SpecificationAdvisory Council (ILSAC), comprised ofU.S. and Japanese automobilemanufacturers.

1. Check the engine oil level.

2. If the engine oil level is not within thenormal range, add engine oil thatmeets Ford specifications. SeeCapacities and Specifications for moreinformation.

3. Remove the engine oil filler cap anduse a funnel to pour the engine oil intothe opening.

4.Recheck the engine oil level. Make surethe oil level is not above the normaloperating range on the engine oil leveldipstick.

5. Install the engine oil level dipstick andensure it is fully seated.

6. Fully install the engine oil filler cap byturning the filler cap clockwise untilthree clicks are heard or until the capis fully seated.

OIL CHANGE INDICATOR

RESET

Resetting the Oil Life MonitoringSystem

Only reset the oil life monitoring systemafter changing the engine oil and oil filter.

1.Switch the ignition on. Do not start theengine. For vehicles with push-buttonstart, press and hold the start buttonfor two seconds without pressing thebrake pedal. Do not start the engine.

2.Press the accelerator and brake pedalsat the same time.

3.Keep the accelerator and brake pedalsfully pressed.

4. After three seconds, a messageconfirming that the reset is in progresswill be displayed.

5. After 25 seconds, a messageconfirming that the reset is completewill be displayed.

6. Release the accelerator and brakepedals.

7.The message confirming that the resetis complete will no longer be displayed.

8.Switch the ignition off. For vehicles withpush-button start, press the startbutton to switch the ignition off.

ENGINE COOLANT CHECK

WARNINGS

Do not add engine coolant when theengine is hot. Steam and scaldingliquids released from a hot coolingsystem can burn you badly. Also, you canbe burned if you spill coolant on hot engineparts.

236

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE142732

Page 250 of 507

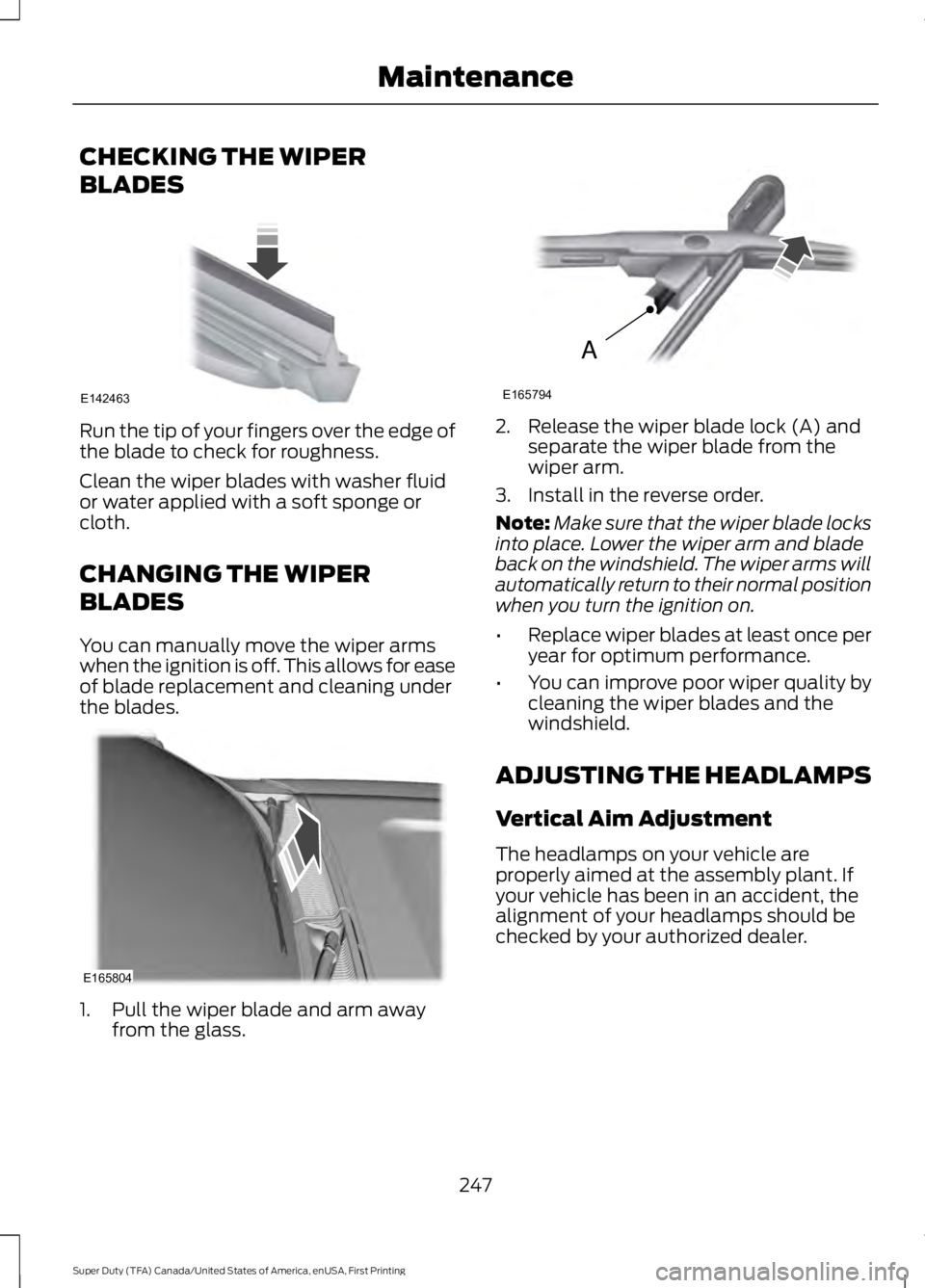

CHECKING THE WIPER

BLADES

Run the tip of your fingers over the edge ofthe blade to check for roughness.

Clean the wiper blades with washer fluidor water applied with a soft sponge orcloth.

CHANGING THE WIPER

BLADES

You can manually move the wiper armswhen the ignition is off. This allows for easeof blade replacement and cleaning underthe blades.

1. Pull the wiper blade and arm awayfrom the glass.

2. Release the wiper blade lock (A) andseparate the wiper blade from thewiper arm.

3. Install in the reverse order.

Note:Make sure that the wiper blade locksinto place. Lower the wiper arm and bladeback on the windshield. The wiper arms willautomatically return to their normal positionwhen you turn the ignition on.

•Replace wiper blades at least once peryear for optimum performance.

•You can improve poor wiper quality bycleaning the wiper blades and thewindshield.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle areproperly aimed at the assembly plant. Ifyour vehicle has been in an accident, thealignment of your headlamps should bechecked by your authorized dealer.

247

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE142463 E165804 A

E165794

Page 252 of 507

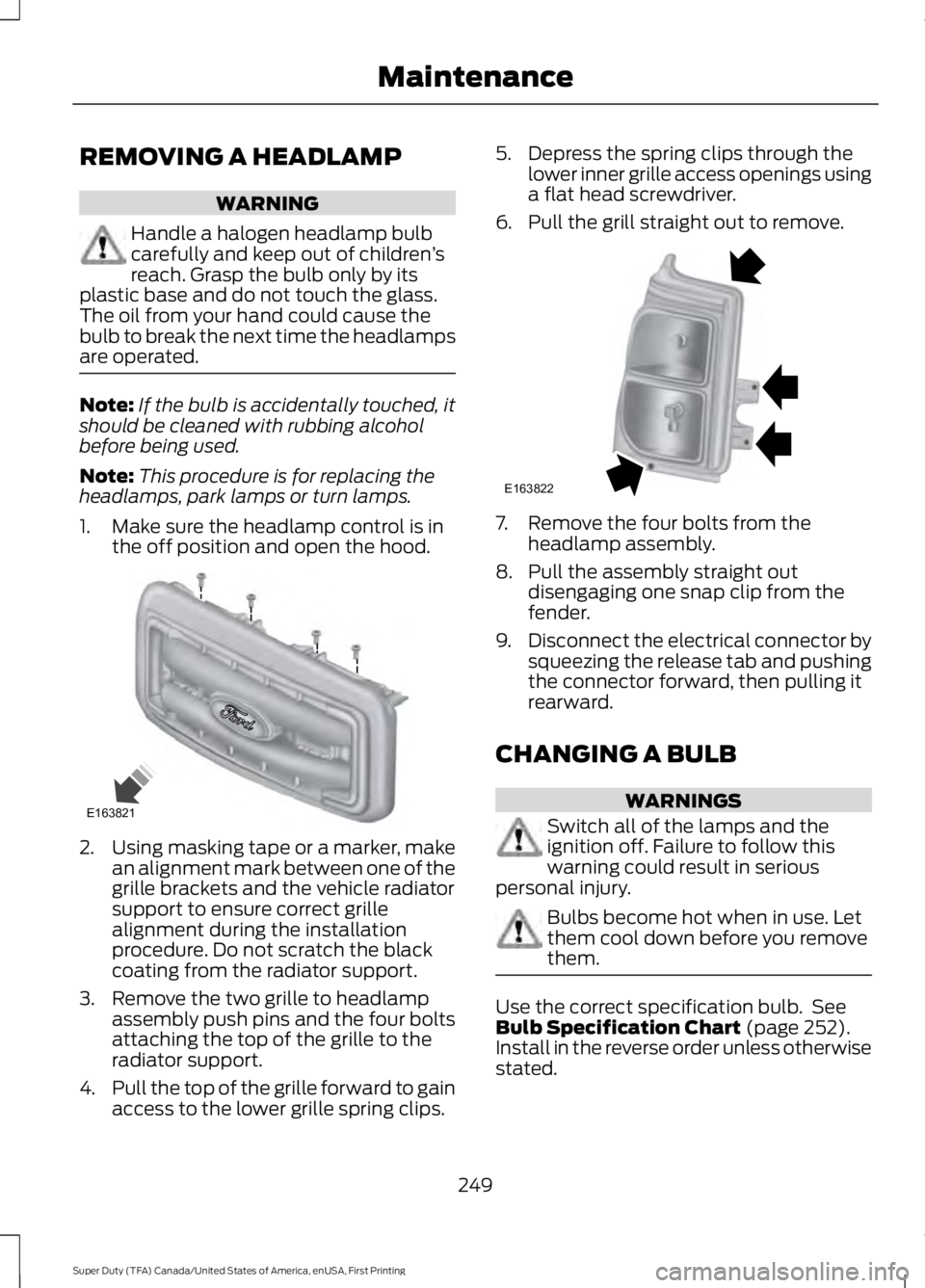

REMOVING A HEADLAMP

WARNING

Handle a halogen headlamp bulbcarefully and keep out of children’sreach. Grasp the bulb only by itsplastic base and do not touch the glass.The oil from your hand could cause thebulb to break the next time the headlampsare operated.

Note:If the bulb is accidentally touched, itshould be cleaned with rubbing alcoholbefore being used.

Note:This procedure is for replacing theheadlamps, park lamps or turn lamps.

1. Make sure the headlamp control is inthe off position and open the hood.

2.Using masking tape or a marker, makean alignment mark between one of thegrille brackets and the vehicle radiatorsupport to ensure correct grillealignment during the installationprocedure. Do not scratch the blackcoating from the radiator support.

3. Remove the two grille to headlampassembly push pins and the four boltsattaching the top of the grille to theradiator support.

4.Pull the top of the grille forward to gainaccess to the lower grille spring clips.

5. Depress the spring clips through thelower inner grille access openings usinga flat head screwdriver.

6. Pull the grill straight out to remove.

7. Remove the four bolts from theheadlamp assembly.

8. Pull the assembly straight outdisengaging one snap clip from thefender.

9.Disconnect the electrical connector bysqueezing the release tab and pushingthe connector forward, then pulling itrearward.

CHANGING A BULB

WARNINGS

Switch all of the lamps and theignition off. Failure to follow thiswarning could result in seriouspersonal injury.

Bulbs become hot when in use. Letthem cool down before you removethem.

Use the correct specification bulb. SeeBulb Specification Chart (page 252).Install in the reverse order unless otherwisestated.

249

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE163821 E163822

Page 253 of 507

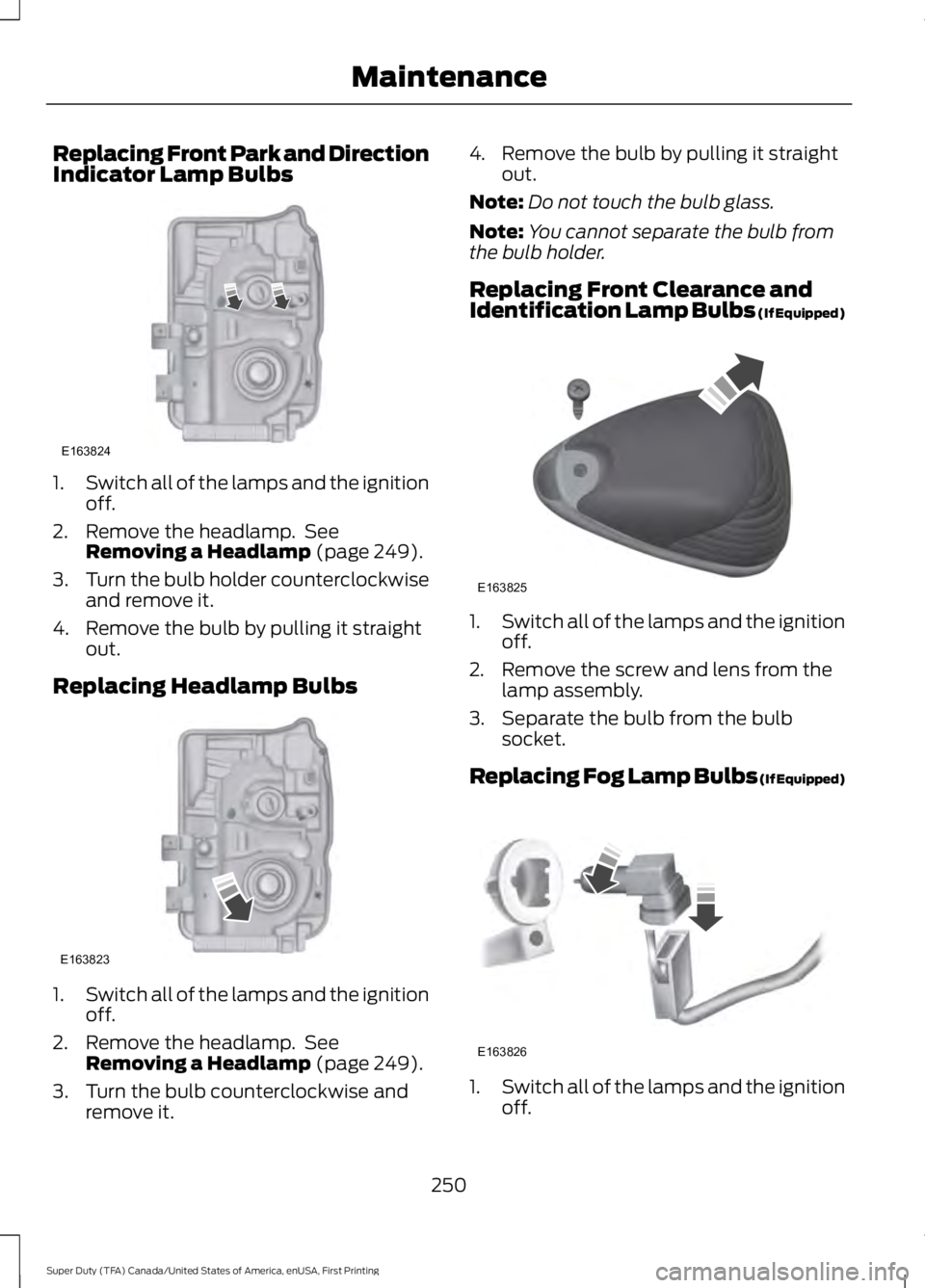

Replacing Front Park and DirectionIndicator Lamp Bulbs

1.Switch all of the lamps and the ignitionoff.

2. Remove the headlamp. SeeRemoving a Headlamp (page 249).

3.Turn the bulb holder counterclockwiseand remove it.

4. Remove the bulb by pulling it straightout.

Replacing Headlamp Bulbs

1.Switch all of the lamps and the ignitionoff.

2. Remove the headlamp. SeeRemoving a Headlamp (page 249).

3. Turn the bulb counterclockwise andremove it.

4. Remove the bulb by pulling it straightout.

Note:Do not touch the bulb glass.

Note:You cannot separate the bulb fromthe bulb holder.

Replacing Front Clearance andIdentification Lamp Bulbs (If Equipped)

1.Switch all of the lamps and the ignitionoff.

2. Remove the screw and lens from thelamp assembly.

3. Separate the bulb from the bulbsocket.

Replacing Fog Lamp Bulbs (If Equipped)

1.Switch all of the lamps and the ignitionoff.

250

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE163824 E163823 E163825 E163826

Page 254 of 507

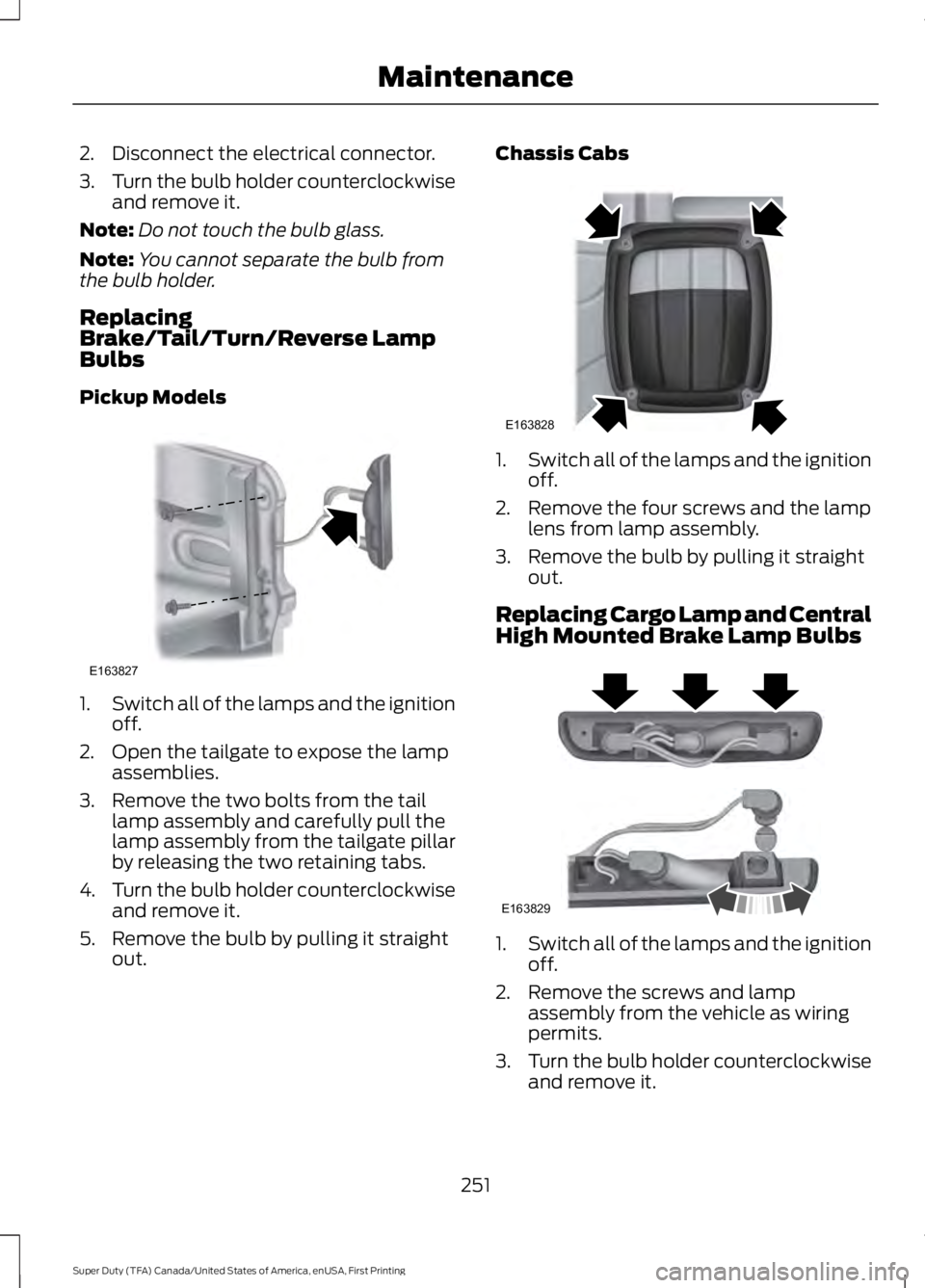

2. Disconnect the electrical connector.

3.Turn the bulb holder counterclockwiseand remove it.

Note:Do not touch the bulb glass.

Note:You cannot separate the bulb fromthe bulb holder.

ReplacingBrake/Tail/Turn/Reverse LampBulbs

Pickup Models

1.Switch all of the lamps and the ignitionoff.

2. Open the tailgate to expose the lampassemblies.

3. Remove the two bolts from the taillamp assembly and carefully pull thelamp assembly from the tailgate pillarby releasing the two retaining tabs.

4.Turn the bulb holder counterclockwiseand remove it.

5. Remove the bulb by pulling it straightout.

Chassis Cabs

1.Switch all of the lamps and the ignitionoff.

2. Remove the four screws and the lamplens from lamp assembly.

3. Remove the bulb by pulling it straightout.

Replacing Cargo Lamp and CentralHigh Mounted Brake Lamp Bulbs

1.Switch all of the lamps and the ignitionoff.

2. Remove the screws and lampassembly from the vehicle as wiringpermits.

3.Turn the bulb holder counterclockwiseand remove it.

251

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE163827 E163828 E163829

Page 255 of 507

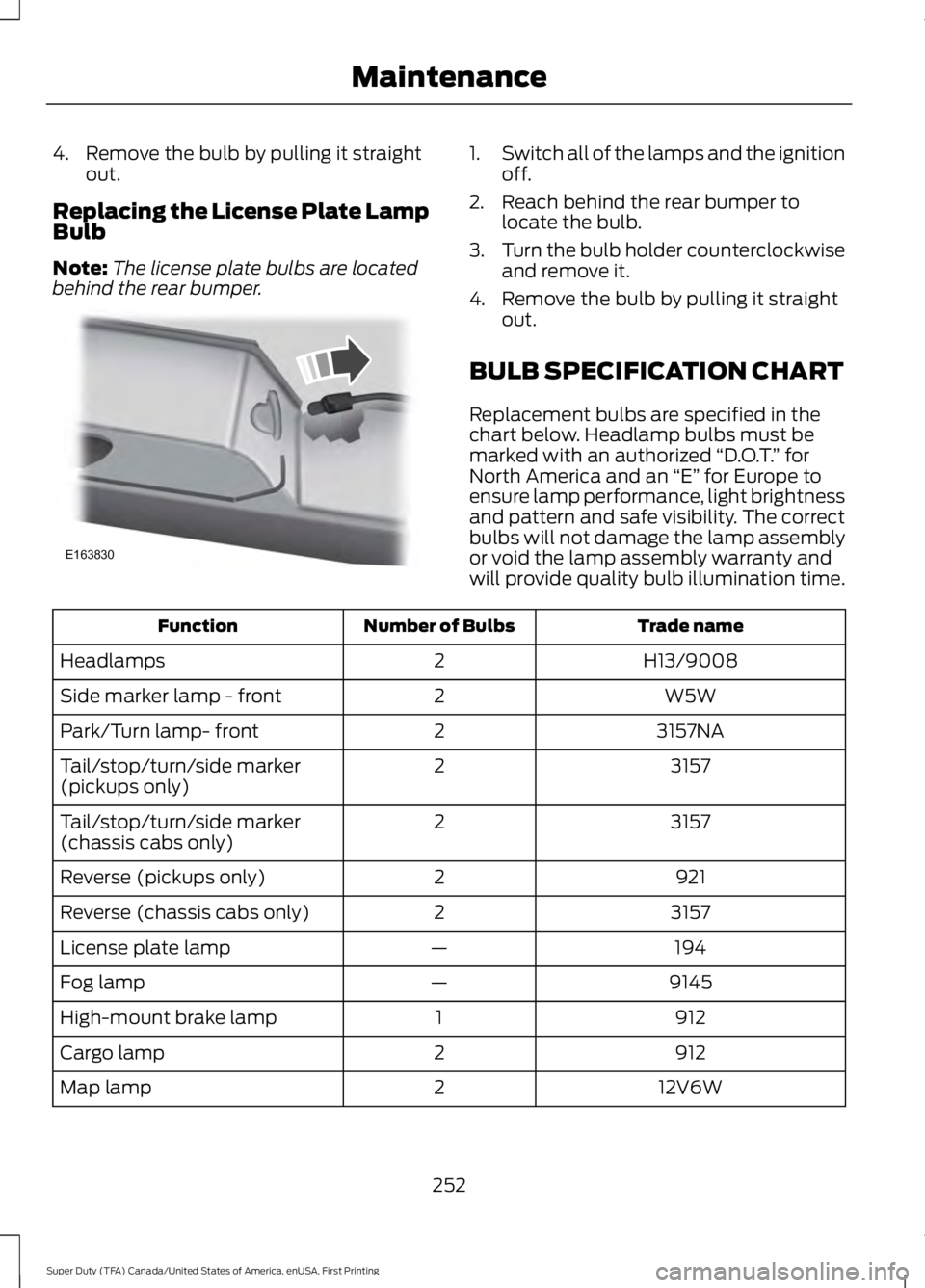

4. Remove the bulb by pulling it straightout.

Replacing the License Plate LampBulb

Note:The license plate bulbs are locatedbehind the rear bumper.

1.Switch all of the lamps and the ignitionoff.

2. Reach behind the rear bumper tolocate the bulb.

3.Turn the bulb holder counterclockwiseand remove it.

4. Remove the bulb by pulling it straightout.

BULB SPECIFICATION CHART

Replacement bulbs are specified in thechart below. Headlamp bulbs must bemarked with an authorized “D.O.T.” forNorth America and an “E” for Europe toensure lamp performance, light brightnessand pattern and safe visibility. The correctbulbs will not damage the lamp assemblyor void the lamp assembly warranty andwill provide quality bulb illumination time.

Trade nameNumber of BulbsFunction

H13/90082Headlamps

W5W2Side marker lamp - front

3157NA2Park/Turn lamp- front

31572Tail/stop/turn/side marker(pickups only)

31572Tail/stop/turn/side marker(chassis cabs only)

9212Reverse (pickups only)

31572Reverse (chassis cabs only)

194—License plate lamp

9145—Fog lamp

9121High-mount brake lamp

9122Cargo lamp

12V6W2Map lamp

252

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

MaintenanceE163830

Page 261 of 507

•Never wash or rinse any ignition coil,spark plug wire or spark plug well, orthe area in and around these locations.

•Cover the battery, power distributionbox, and air filter assembly to preventwater damage when cleaning theengine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmentalfallout can result in windshield and wiperblade contamination. Dirty windshield andwipers will result in poor windshield wiperoperation. Keep the windshield and wiperblades clean to maintain windshield wiperperformance.

To clean the windshield and wiper blades:

•Clean the windshield with anon-abrasive glass cleaner. Whencleaning the interior of the windshield,avoid getting any glass cleaner on theinstrument panel or door panels. Wipeany glass cleaner off these surfacesimmediately.

•For windshields contaminated withtree sap, chemicals, wax or bugs, cleanthe entire windshield using steel wool(no greater than 0000 grade) in acircular motion and rinse with water.

•Clean the wiper blades with isopropylrubbing alcohol or windshield washerconcentrate.

Note: Do not use razor blades or othersharp objects to clean or remove decalsfrom the inside of the heated rear window.The vehicle warranty does not coverdamage caused to the heated rear windowgrid lines.

CLEANING THE INTERIOR

WARNINGS

Do not use cleaning solvents, bleachor dye on the vehicle’s safety belts,as these actions may weaken thebelt webbing.

On vehicles equipped withseat-mounted airbags, do not usechemical solvents or strongdetergents. Such products couldcontaminate the side airbag system andaffect performance of the side airbag in acollision.

For fabric, carpets, cloth seats, safety beltsand seats equipped with side airbags:

•Remove dust and loose dirt with avacuum cleaner.

•Remove light stains and soil withMotorcraft Professional StrengthCarpet & Upholstery Cleaner.

•If grease or tar is present on thematerial, spot-clean the area first withMotorcraft Spot and Stain Remover. InCanada, use Motorcraft Multi-PurposeCleaner.

•If a ring forms on the fabric after spotcleaning, clean the entire areaimmediately (but do not oversaturate)or the ring will set.

•Do not use household cleaningproducts or glass cleaners, which canstain and discolor the fabric and affectthe flame retardant abilities of the seatmaterials.

258

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Vehicle Care

Page 292 of 507

•To reduce the chances of interferencefrom another vehicle, perform thesystem reset procedure at least threefeet (one meter) away from anotherFord Motor Company vehicleundergoing the system reset procedureat the same time.

•Do not wait more than two minutesbetween resetting each tire sensor orthe system will time-out and the entireprocedure will have to be repeated onall four wheels.

•A double horn will sound indicating theneed to repeat the procedure.

Performing the System Reset Procedure

Read the entire procedure beforeattempting.

1. Drive the vehicle above 20 mph (32km/h) for at least two minutes, thenpark in a safe location where you caneasily get to all four tires and haveaccess to an air pump.

2.Place the ignition in the off position andkeep the key in the ignition.

3. Cycle the ignition to the on positionwith the engine off.

4. Turn the hazard flashers on then offthree times. You must accomplish thiswithin 10 seconds. If the reset modehas been entered successfully, the hornwill sound once, the system indicatorwill flash and a message is shown inthe information display. If this does notoccur, please try again starting at Step2. If after repeated attempts to enterthe reset mode, the horn does notsound, the system indicator does notflash and no message is shown in theinformation display, seek service fromyour authorized dealer.

5. Train the tire pressure monitoringsystem sensors in the tires using thefollowing system reset sequencestarting with the left front tire in thefollowing clockwise order: Left front(driver's side front tire), Right front(passenger's side front tire), Right rear(passenger's side rear tire), Left rear(driver's side rear tire).

6. Remove the valve cap from the valvestem on the left front tire. Decrease theair pressure until the horn sounds.Note: The single horn chirp confirmsthat the sensor identification code hasbeen learned by the module for thisposition. If a double horn is heard, thereset procedure was unsuccessful, andyou must repeat it.

7. Remove the valve cap from the valvestem on the right front tire. Decreasethe air pressure until the horn sounds.

8. Remove the valve cap from the valvestem on the right rear tire. Decrease theair pressure until the horn sounds.

9. Remove the valve cap from the valvestem on the left rear tire. Decrease theair pressure until the horn sounds.Training is complete after the hornsounds for the last tire trained (driver'sside rear tire), the system indicatorstops flashing, and a message is shownin the information display.

10.Turn the ignition off. If two short hornbeeps are heard, the reset procedurewas unsuccessful and you mustrepeat it. If after repeating theprocedure and two short beeps areheard when the ignition is turned tooff, seek assistance from yourauthorized dealer.

289

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Wheels and Tires

Page 306 of 507

ENGINE SPECIFICATIONS

6.8L V10 Engine6.2L V8 EngineEngine

413378Cubic inches

Minimum 87 octaneMinimum 87 octaneRequired fuel

1-6-5-10-2-7-3-8-4-91-5-4-8-6-3-7-2Firing order

Coil on plugCoil on plugIgnition system

0.039-0.043 inch (1.00-1.10mm)0.041-0.047 inch (1.04-1.20mm)Spark plug gap

9.2:19.8:1Compression ratio

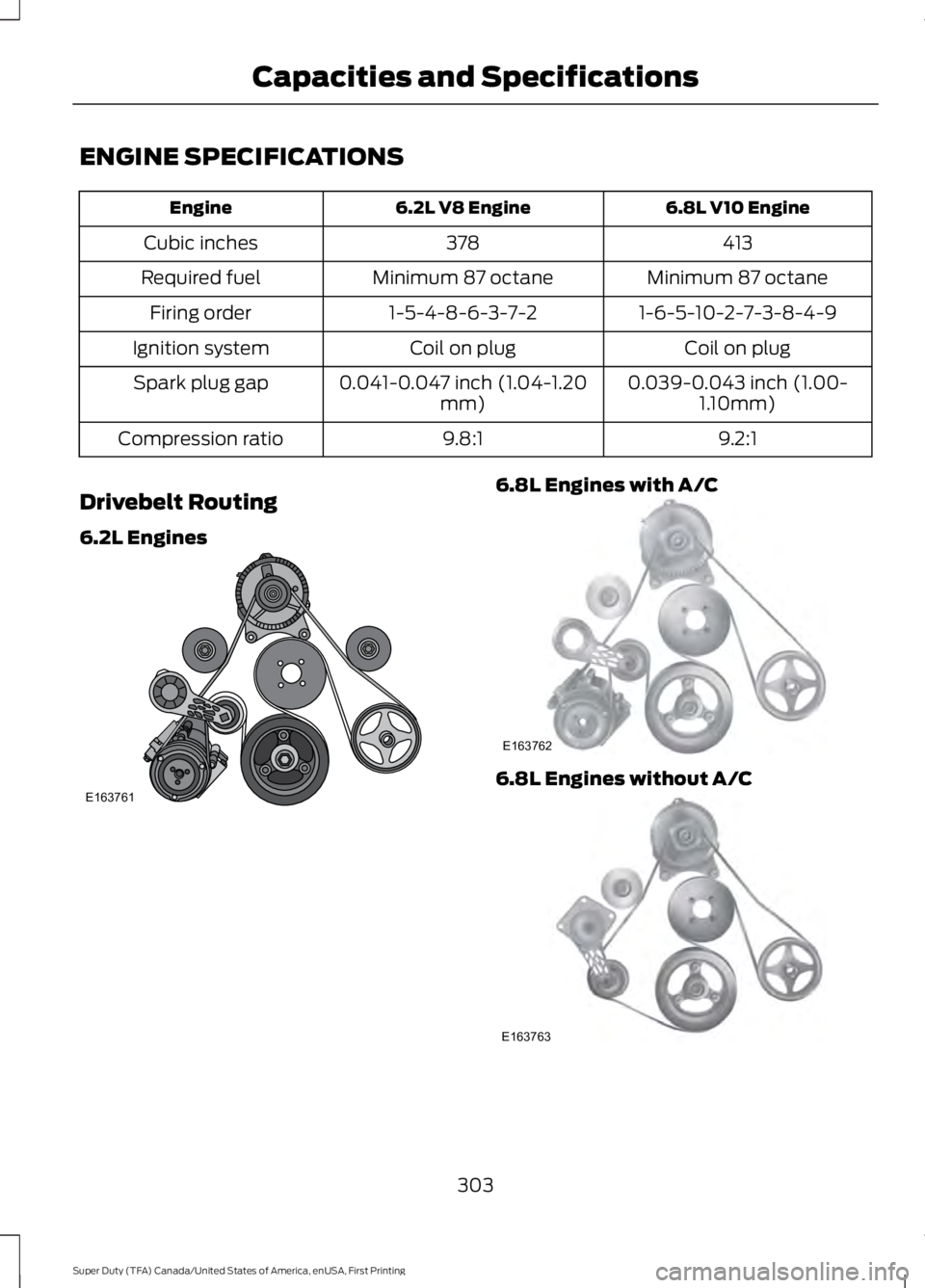

Drivebelt Routing

6.2L Engines

6.8L Engines with A/C

6.8L Engines without A/C

303

Super Duty (TFA) Canada/United States of America, enUSA, First Printing

Capacities and SpecificationsE163761 E163762 E163763