FORD F650 2003 10.G Owners Manual

Manufacturer: FORD, Model Year: 2003, Model line: F650, Model: FORD F650 2003 10.GPages: 248, PDF Size: 2.54 MB

Page 121 of 248

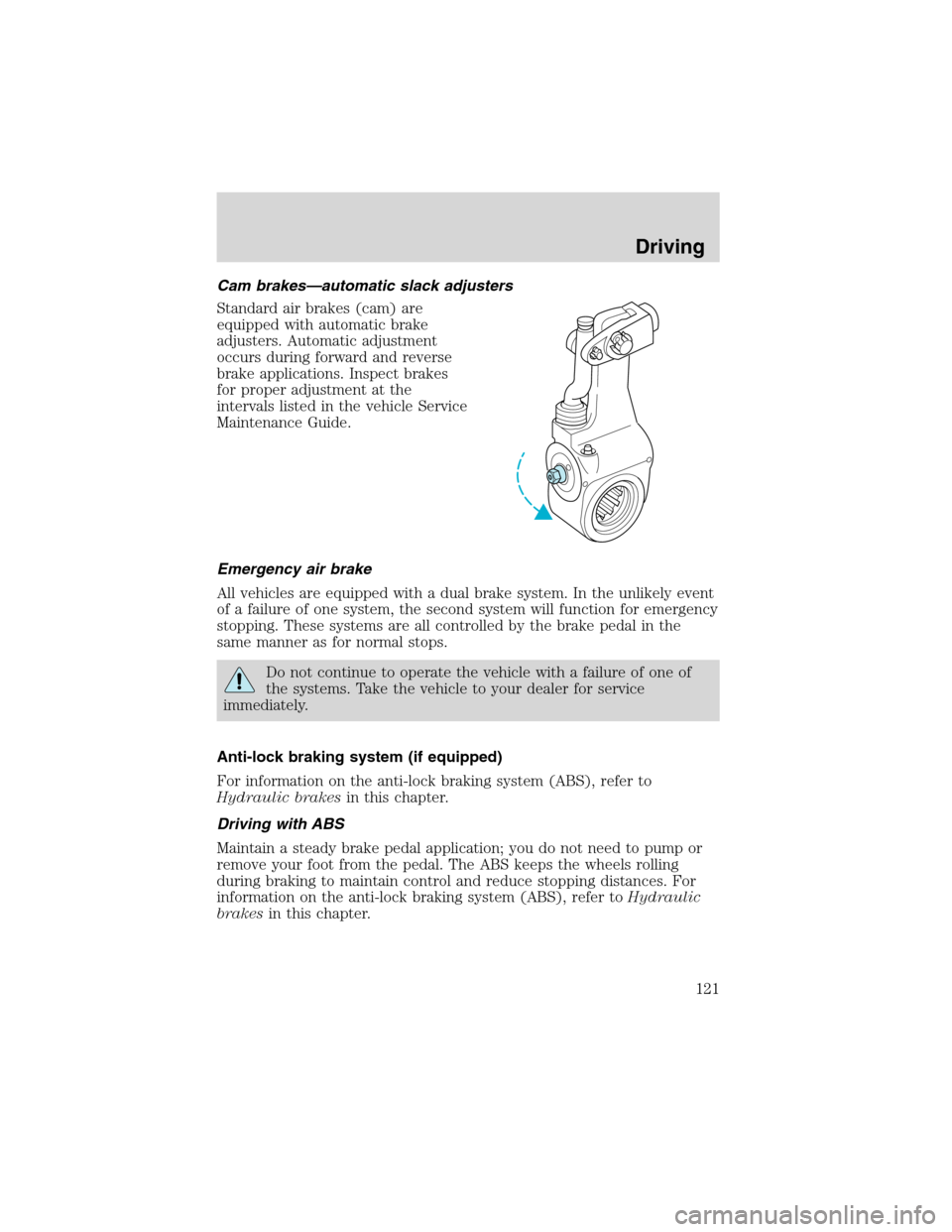

Cam brakes—automatic slack adjusters

Standard air brakes (cam) are

equipped with automatic brake

adjusters. Automatic adjustment

occurs during forward and reverse

brake applications. Inspect brakes

for proper adjustment at the

intervals listed in the vehicle Service

Maintenance Guide.

Emergency air brake

All vehicles are equipped with a dual brake system. In the unlikely event

of a failure of one system, the second system will function for emergency

stopping. These systems are all controlled by the brake pedal in the

same manner as for normal stops.

Do not continue to operate the vehicle with a failure of one of

the systems. Take the vehicle to your dealer for service

immediately.

Anti-lock braking system (if equipped)

For information on the anti-lock braking system (ABS), refer to

Hydraulic brakesin this chapter.

Driving with ABS

Maintain a steady brake pedal application; you do not need to pump or

remove your foot from the pedal. The ABS keeps the wheels rolling

during braking to maintain control and reduce stopping distances. For

information on the anti-lock braking system (ABS), refer toHydraulic

brakesin this chapter.

Driving

121

Page 122 of 248

Parking brake

Do not use the gearshift selector in place of the parking brake.

Always set the parking brake fully AND make sure the gearshift

selector is in R (Reverse) for vehicles equipped with manual

transmission or N (Neutral) for vehicles with automatic transmission.

Unexpected and possible sudden vehicle movement may occur if

these precautions are not taken.

If the service brakes should fail to operate while the vehicle is in motion,

you can make an emergency stop with the parking brake. The stopping

distance, however, will be much greater than normal. Repairs should be

made immediately to an inoperative air brake system circuit.

Parking brake control

Pull the yellow parking brake knob

out to apply the parking brake. Push

the knob in to release the parking

brake.

This control is used for

parking only. Do not leave

the vehicle unattended after

setting the parking brake without

placing the transmission in R

(Reverse) for manual transmission

or N (Neutral) for automatic

transmission. Use of wheel chocks

is also recommended in hilly or

off-road usage.

Releasing spring brake with air pressure

The air system in all vehicles with spring-actuated rear wheel parking

brakes is equipped with a tank valve located on the supply or service air

tank for connection to an outside air supply. The valve permits the

system to be recharged with air from an outside source, releasing the

spring-actuated parking brakes. The vehicle may then be towed in an

emergency.PARKING

BRAKE

PULL TO

RELEASE

APPLY

PUSH TO

Driving

122

Page 123 of 248

An outside air source can be used only if the protected system is in

operating condition. If air pressure cannot be restored in the protected

air system, the spring-actuated brakes must be released manually.

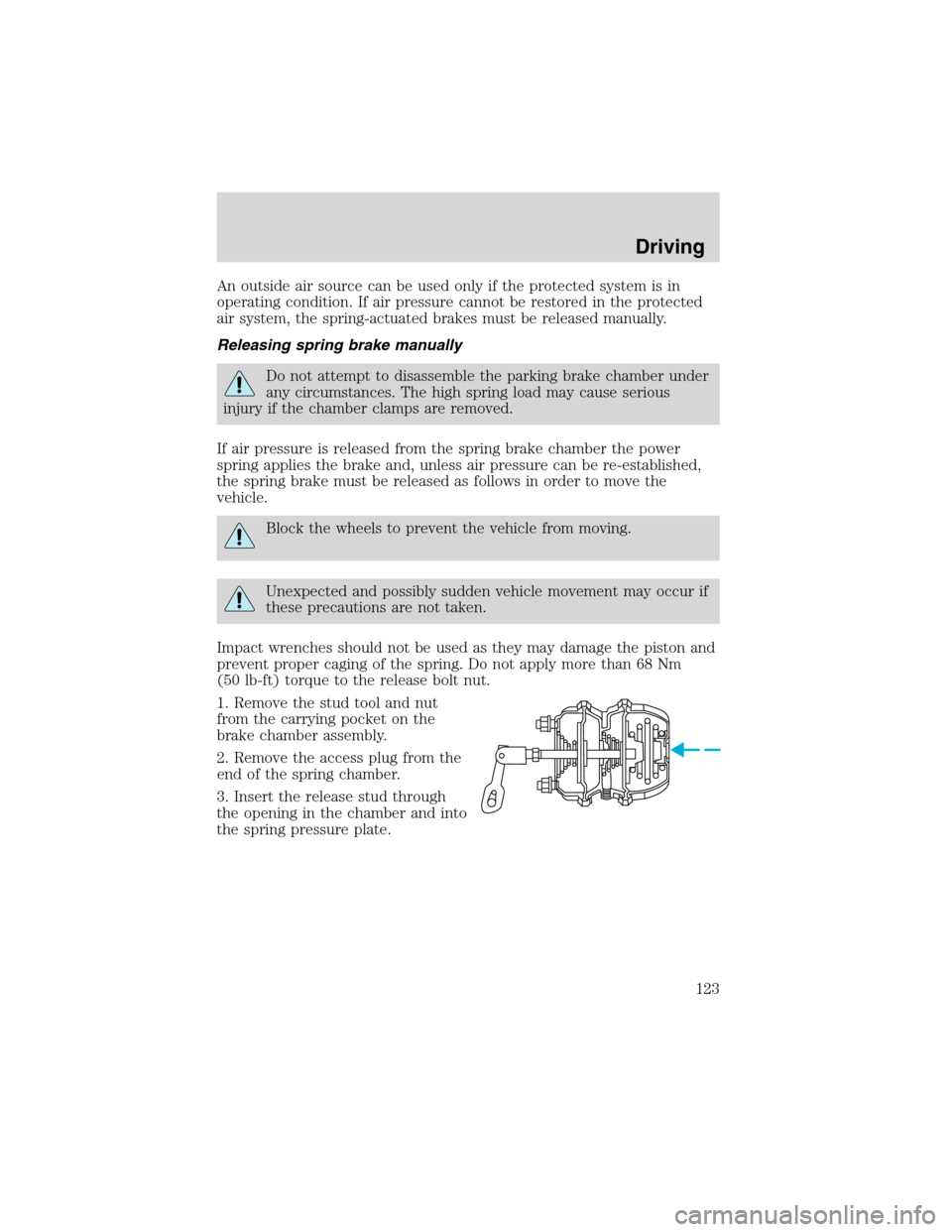

Releasing spring brake manually

Do not attempt to disassemble the parking brake chamber under

any circumstances. The high spring load may cause serious

injury if the chamber clamps are removed.

If air pressure is released from the spring brake chamber the power

spring applies the brake and, unless air pressure can be re-established,

the spring brake must be released as follows in order to move the

vehicle.

Block the wheels to prevent the vehicle from moving.

Unexpected and possibly sudden vehicle movement may occur if

these precautions are not taken.

Impact wrenches should not be used as they may damage the piston and

prevent proper caging of the spring. Do not apply more than 68 Nm

(50 lb-ft) torque to the release bolt nut.

1. Remove the stud tool and nut

from the carrying pocket on the

brake chamber assembly.

2. Remove the access plug from the

end of the spring chamber.

3. Insert the release stud through

the opening in the chamber and into

the spring pressure plate.

Driving

123

Page 124 of 248

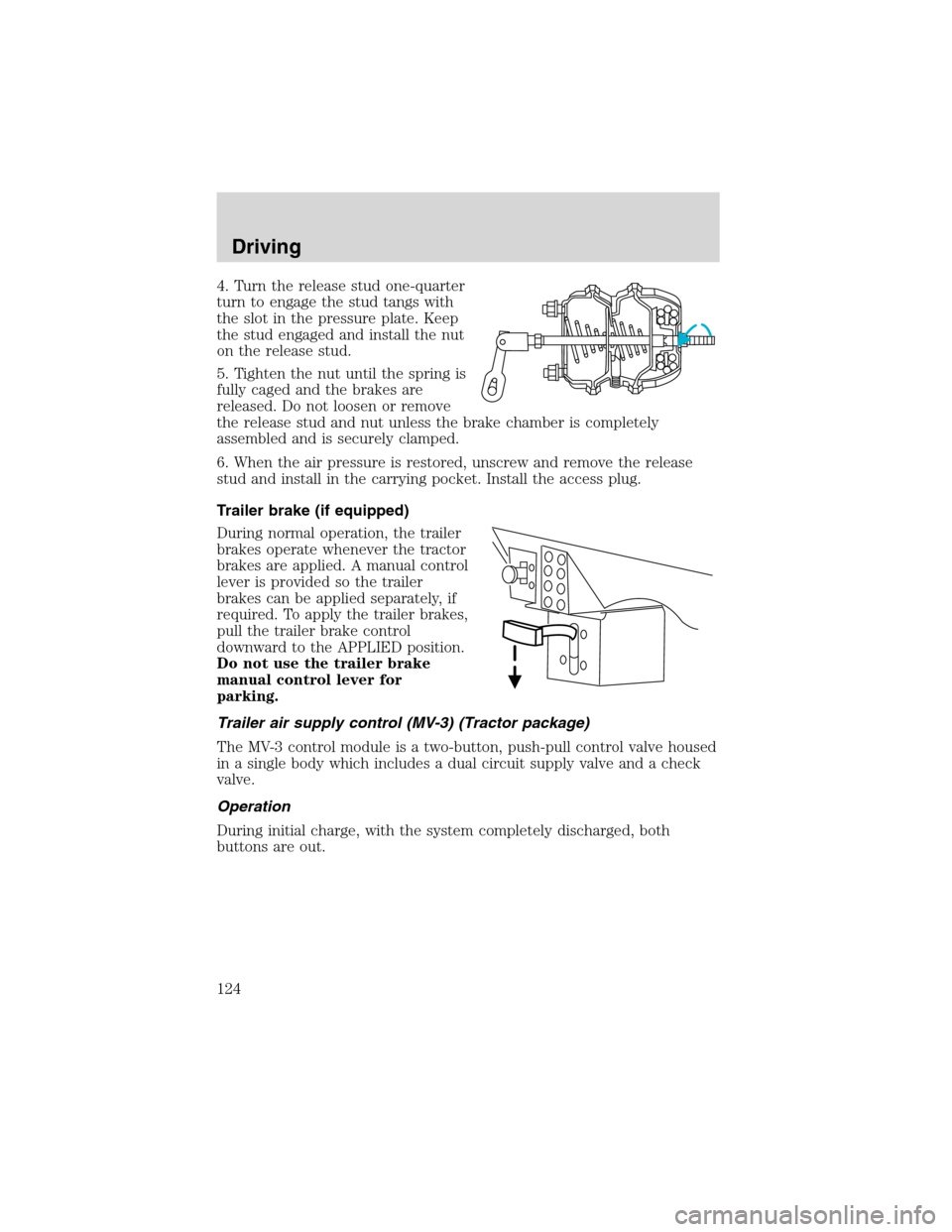

4. Turn the release stud one-quarter

turn to engage the stud tangs with

the slot in the pressure plate. Keep

the stud engaged and install the nut

on the release stud.

5. Tighten the nut until the spring is

fully caged and the brakes are

released. Do not loosen or remove

the release stud and nut unless the brake chamber is completely

assembled and is securely clamped.

6. When the air pressure is restored, unscrew and remove the release

stud and install in the carrying pocket. Install the access plug.

Trailer brake (if equipped)

During normal operation, the trailer

brakes operate whenever the tractor

brakes are applied. A manual control

lever is provided so the trailer

brakes can be applied separately, if

required. To apply the trailer brakes,

pull the trailer brake control

downward to the APPLIED position.

Do not use the trailer brake

manual control lever for

parking.

Trailer air supply control (MV-3) (Tractor package)

The MV-3 control module is a two-button, push-pull control valve housed

in a single body which includes a dual circuit supply valve and a check

valve.

Operation

During initial charge, with the system completely discharged, both

buttons are out.

Driving

124

Page 125 of 248

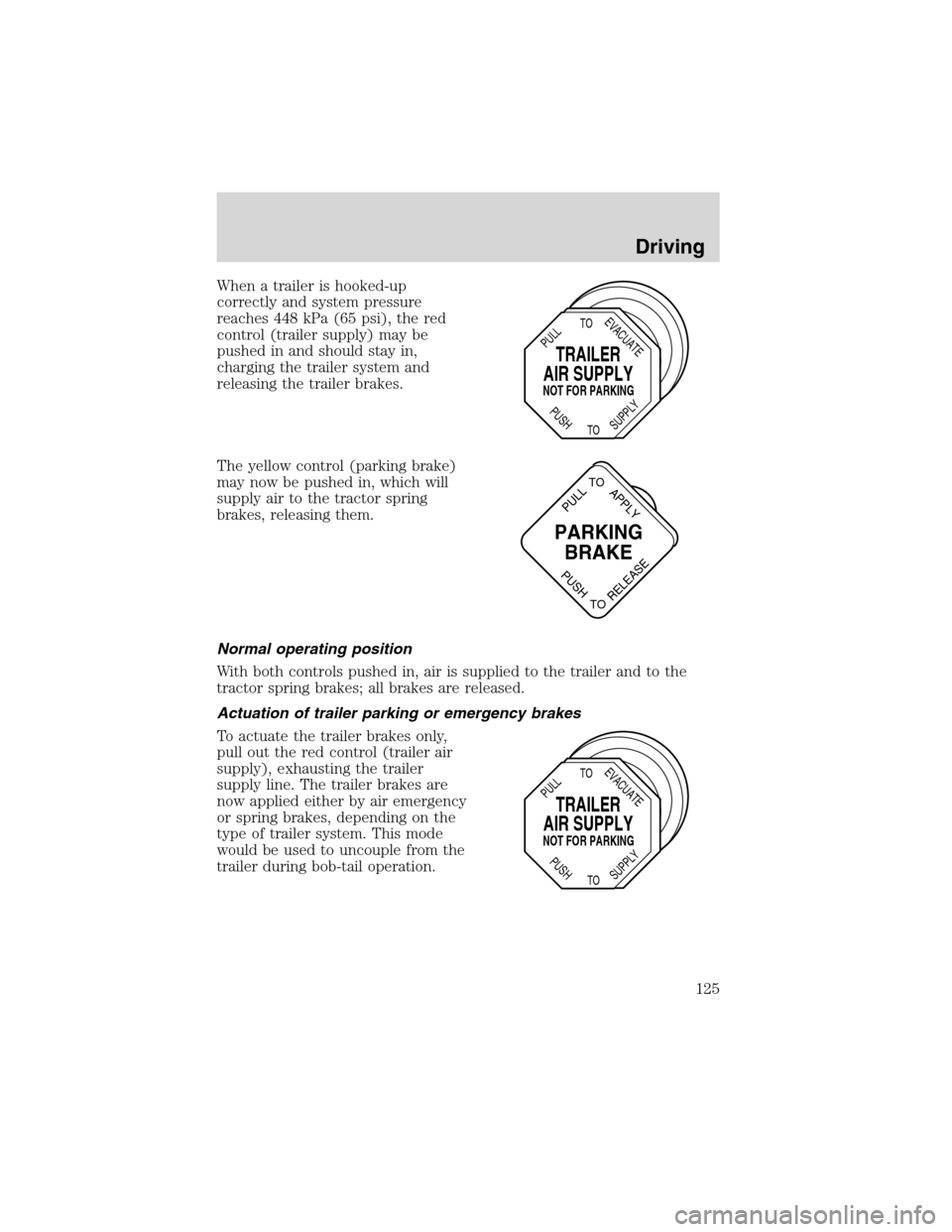

When a trailer is hooked-up

correctly and system pressure

reaches 448 kPa (65 psi), the red

control (trailer supply) may be

pushed in and should stay in,

charging the trailer system and

releasing the trailer brakes.

The yellow control (parking brake)

may now be pushed in, which will

supply air to the tractor spring

brakes, releasing them.

Normal operating position

With both controls pushed in, air is supplied to the trailer and to the

tractor spring brakes; all brakes are released.

Actuation of trailer parking or emergency brakes

To actuate the trailer brakes only,

pull out the red control (trailer air

supply), exhausting the trailer

supply line. The trailer brakes are

now applied either by air emergency

or spring brakes, depending on the

type of trailer system. This mode

would be used to uncouple from the

trailer during bob-tail operation.

TRAILER

AIR SUPPLY

NOT FOR PARKING

PULL

TO

TOEVACUATE

PUSH

SUPPLY

PARKING

BRAKE

PULL

TOAPPLY

PUSH

TORELEASE

TRAILER

AIR SUPPLY

NOT FOR PARKING

PULL

TO

TOEVACUATE

PUSH

SUPPLY

Driving

125

Page 126 of 248

System park

With both controls in for normal run modes, the parking brakes on both

tractor and trailer may be actuated by pulling the yellow control (parking

brake) out, which exhausts the air from the tractor spring brakes and

simultaneously causes the red control (trailer supply) to pop out,

applying the trailer brakes. This complies with federal regulations stating

one control must apply all the parking brakes on the vehicle.

Trailer charge

If both controls are out when parking the combination vehicle and it is

desired to recharge the trailer (leaving the tractor spring brakes

applied), the trailer air supply control may be pushed in, repressurizing

the trailer supply line. This mode could also be used to park a

combination vehicle with air actuated emergency brakes on the trailer to

provide demonstrated parking capability with tractor spring brakes only.

Automatic application

With both controls in (in the normal run configuration), if the supply

pressure to the push-pull valves is reduced to approximately 240 to 310

kPa (35-45 psi), the red control (trailer supply valve) must pop out,

applying the emergency or parking brakes on the trailer. If the red

control is held in manually and the pressure decreases to approximately

172 to 240 kPa (25-35 psi), a tripper piston within the MV-3 valve will

move upward. This will exhaust the trailer supply, causing the required

non-override feature. The yellow control (parking brake) will pop out at

approximately 138 to 207 kPa (20-30 psi).

Reservoir selection

The number one service reservoir will at all times be selected as the

primary supply source for the MV-3. This is accomplished automatically

by the function of the dual circuit supply valve contained in the body of

the MV-3. Only in the event of a pressure drop of more than 207 kPa (30

psi) below that of the number two service reservoir will the dual circuit

supply valve shuttle and establish the front service reservoir as the

supply.

Driving

126

Page 127 of 248

Exhaust brake (if equipped)

An exhaust brake is an optional

auxiliary braking system that assists

but does not replace the primary

service brake system. An on-off

switch on the instrument panel, in

combination with the accelerator

and clutch pedal switches, allows

the operator to make maximum use

of the exhaust brake in the

following conditions:

•off-highway driving

•mountain driving

•heavy traffic

•high speed highway driving

It is not available with automatic transmissions.

The exhaust brake is a butterfly

type valve mounted in the exhaust

pipe. When the operator’s foot is not

on the accelerator pedal and the

exhaust brake switch is in the ON

position, an air cylinder shuts the

butterfly valve, restricting the flow

of exhaust gases and retarding the

engine. This retarding action is

carried through the engine and drivetrain, slowing the vehicle and

reducing the need for frequent service brake applications.

Exhaust brakes are not intended for use as the primary braking system

during vehicle operation.

Driving

127

Page 128 of 248

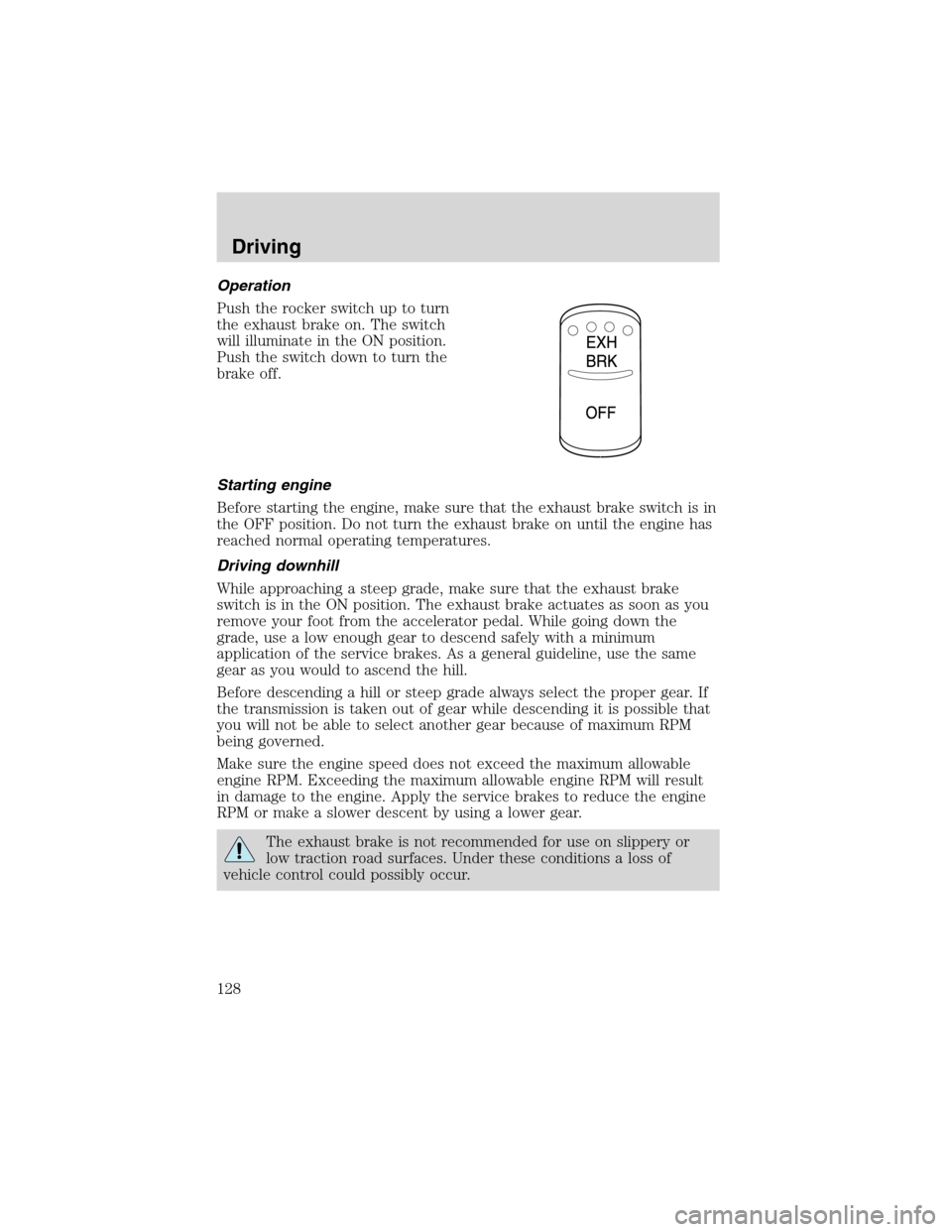

Operation

Push the rocker switch up to turn

the exhaust brake on. The switch

will illuminate in the ON position.

Push the switch down to turn the

brake off.

Starting engine

Before starting the engine, make sure that the exhaust brake switch is in

the OFF position. Do not turn the exhaust brake on until the engine has

reached normal operating temperatures.

Driving downhill

While approaching a steep grade, make sure that the exhaust brake

switch is in the ON position. The exhaust brake actuates as soon as you

remove your foot from the accelerator pedal. While going down the

grade, use a low enough gear to descend safely with a minimum

application of the service brakes. As a general guideline, use the same

gear as you would to ascend the hill.

Before descending a hill or steep grade always select the proper gear. If

the transmission is taken out of gear while descending it is possible that

you will not be able to select another gear because of maximum RPM

being governed.

Make sure the engine speed does not exceed the maximum allowable

engine RPM. Exceeding the maximum allowable engine RPM will result

in damage to the engine. Apply the service brakes to reduce the engine

RPM or make a slower descent by using a lower gear.

The exhaust brake is not recommended for use on slippery or

low traction road surfaces. Under these conditions a loss of

vehicle control could possibly occur.

Driving

128

Page 129 of 248

Exhaust brake operating characteristics

When you remove your feet from both the accelerator and clutch pedals

and the exhaust brake switch is in the ON position, the exhaust brake is

activated. The following conditions should exist if the brake is operating

properly:

•A slight change in the sound of the engine when the exhaust brake is

activated.

•Exhaust smoke appears normal.

•Engine temperature remains in the normal operating range.

•Road speed usually decreases when the exhaust brake is applied

during a descent, except when the vehicle is carrying a heavy load or

the grade is extremely steep. In these instances, you may need to

apply the service brakes occasionally.

•During a descent, the tachometer usually shows a drop in RPM

depending on the grade and the vehicle load.

•Do not expect a retarding effect similar to sudden hard application of

the service brakes. The exhaust brake retards the vehicle with a

smooth braking effect.

•Depending on the grade and vehicle load, you may or may not feel the

retarding force acting against your body when the brake is applied.

The brake’s retarding force is actually preventing the vehicle from

going much faster.

Make sure the exhaust brake is turned off before shutting off the engine.

Installing an exhaust or auxiliary brake should never allow the

engine to exceed maximum governed speeds under any

conditions.

Air brake reservoir draining

Failure to drain air brake reservoirs can result in a reduction or

loss of braking ability due to fluid accumulation in the reservoir

and/or possible freeze-up during cold weather.

Driving

129

Page 130 of 248

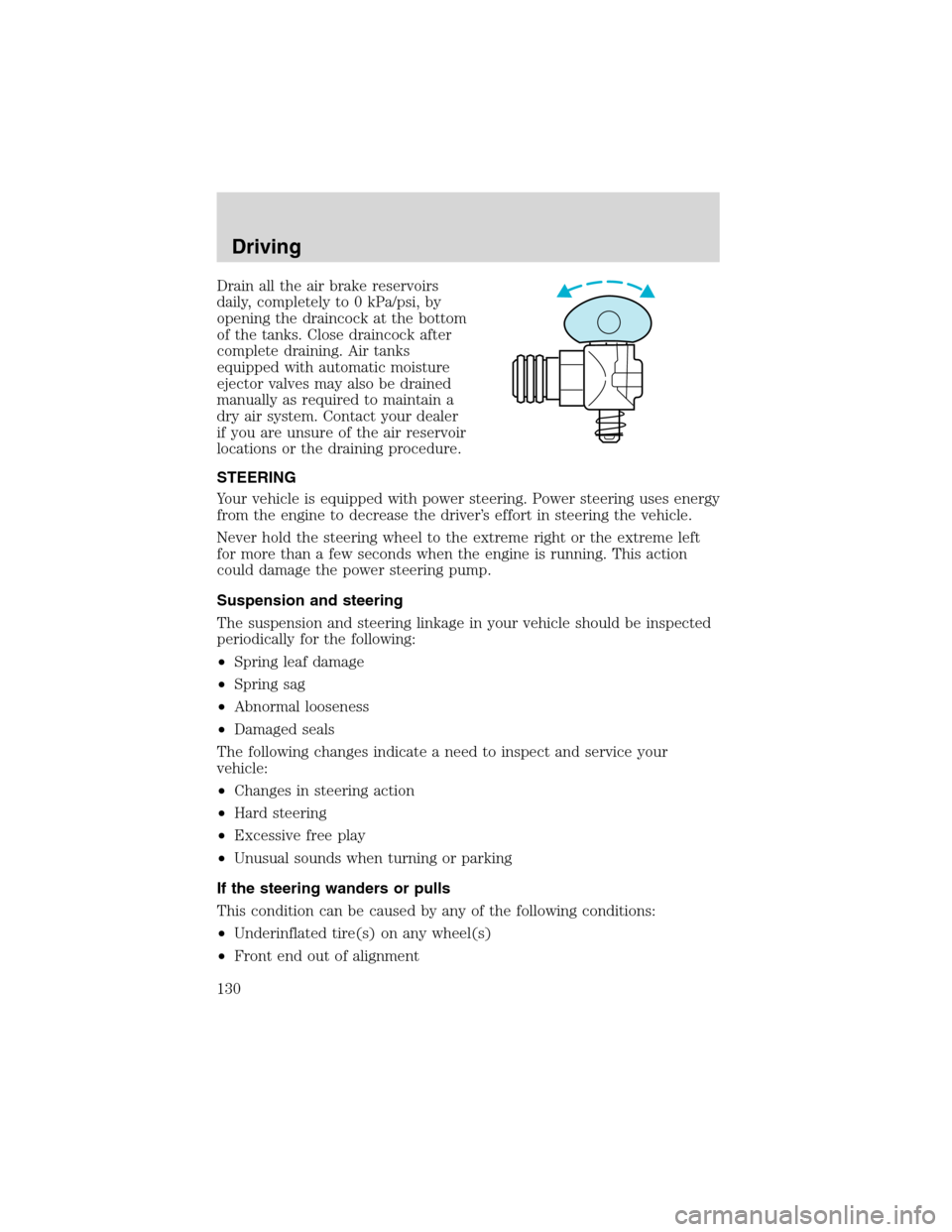

Drain all the air brake reservoirs

daily, completely to 0 kPa/psi, by

opening the draincock at the bottom

of the tanks. Close draincock after

complete draining. Air tanks

equipped with automatic moisture

ejector valves may also be drained

manually as required to maintain a

dry air system. Contact your dealer

if you are unsure of the air reservoir

locations or the draining procedure.

STEERING

Your vehicle is equipped with power steering. Power steering uses energy

from the engine to decrease the driver’s effort in steering the vehicle.

Never hold the steering wheel to the extreme right or the extreme left

for more than a few seconds when the engine is running. This action

could damage the power steering pump.

Suspension and steering

The suspension and steering linkage in your vehicle should be inspected

periodically for the following:

•Spring leaf damage

•Spring sag

•Abnormal looseness

•Damaged seals

The following changes indicate a need to inspect and service your

vehicle:

•Changes in steering action

•Hard steering

•Excessive free play

•Unusual sounds when turning or parking

If the steering wanders or pulls

This condition can be caused by any of the following conditions:

•Underinflated tire(s) on any wheel(s)

•Front end out of alignment

Driving

130