ECU FORD F650 2004 11.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2004, Model line: F650, Model: FORD F650 2004 11.GPages: 264, PDF Size: 1.47 MB

Page 84 of 264

3. Buckle the seat belt. Push down

on the child seat and pull on the

shoulder portion of the belt to snug

the lap belt. Hold the lap and

shoulder belts next to the tongue

and unbuckle the belt.

4. Install a locking clip over both lap

and shoulder belt portions next to

the sliding tongue. Rebuckle the

belt. Obtain the locking clip kit (part

number FO3Z-5461248–A) at no

charge from an authorized Ford or

Lincoln-Mercury dealer.

5. Before placing the child in the seat, forcibly tilt the seat forward and

back to make sure the seat is securely held in place. To check this, grab

the seat at the belt path and attempt to move it side to side and forward

and back. There should be no more than one inch of movement for

proper installation.

6. If the child seat is not tight enough, unbuckle the seat belt, move the

tongue and locking clip to shorten the lap portion and push down hard

on the child seat while you rebuckle the belt.

7. Check to make sure the child seat is properly secured before each

use.

2004 F650/750(f67)

Supplement

USA English(fus)

Seating and safety restraints

84

Page 85 of 264

Attaching safety seats with tether straps

Most forward-facing child safety seats include a tether strap which goes

over the back of the seat and hooks to an anchoring point. Tether straps

are available as an accessory for many older safety seats. Contact the

manufacturer of your child safety seat for information about ordering a

tether strap.

Tether anchorage hardware

A tethered seat can be installed in the front seat. Put the tether strap

over the seatback and attach it to an anchor bracket.

An anchor bracket can be installed to the inside of the back panel of

your vehicle.

The anchor bracket must be installed using the instructions provided

with the tether anchorage hardware kit.

Tether anchorage hardware kits (part number 613D74) including

instructions, may be obtained at no charge from any Ford or

Lincoln/Mercury dealer.

If you have a Super Cab or Crew Cab, Ford recommends you attach

tether safety seats in the rear seating position (if possible) with the

tether strap attached to the tether anchorage bracket as shown in the

instructions provided with the tether anchor kit.

Tighten the anchor according to specifications. Otherwise, the

safety seat may not be properly secured and the child may be

injured in a sudden stop or collision.

2004 F650/750(f67)

Supplement

USA English(fus)

Seating and safety restraints

85

Page 103 of 264

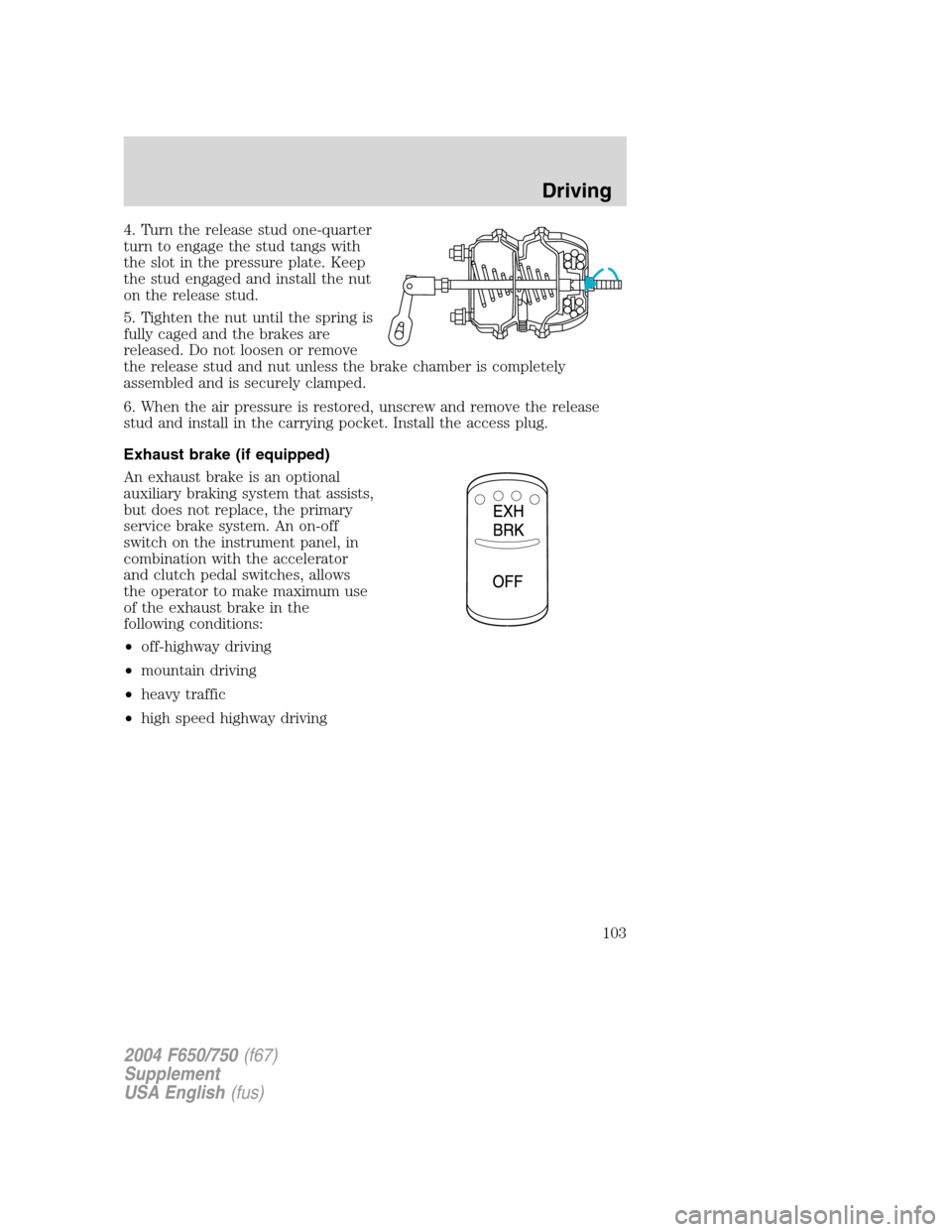

4. Turn the release stud one-quarter

turn to engage the stud tangs with

the slot in the pressure plate. Keep

the stud engaged and install the nut

on the release stud.

5. Tighten the nut until the spring is

fully caged and the brakes are

released. Do not loosen or remove

the release stud and nut unless the brake chamber is completely

assembled and is securely clamped.

6. When the air pressure is restored, unscrew and remove the release

stud and install in the carrying pocket. Install the access plug.

Exhaust brake (if equipped)

An exhaust brake is an optional

auxiliary braking system that assists,

but does not replace, the primary

service brake system. An on-off

switch on the instrument panel, in

combination with the accelerator

and clutch pedal switches, allows

the operator to make maximum use

of the exhaust brake in the

following conditions:

•off-highway driving

•mountain driving

•heavy traffic

•high speed highway driving

2004 F650/750(f67)

Supplement

USA English(fus)

Driving

103

Page 114 of 264

When operating a loaded vehicle, the driver must keep all

adjustable axles on the ground at all times, supporting their

share of the vehicle’s load. Failure to do so can overload other axles,

tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

FIFTH WHEEL OPERATION

Failure to follow the fifth wheel manufacturer’s instructions for

hooking and unhooking as well as sliding the fifth wheel could

result in an accident, personal injury or death.

When the tractor and trailer are parked unattended, the trailer

brake hand control should never be used to apply the brake,

since air may leak from the system, allowing vehicle movement,

resulting in possible property damage, personal injury or death.

Hook-up

1. Fifth wheel jaws must be fully opened.

2. Tilt the fifth wheel back to prevent body damage when the tractor is

backed under a trailer.

3. Block the trailer wheels and be sure the trailer spring brakes are

adjusted and applied. Never chase a trailer.

4. Make sure the brake hoses and light cords are clear of the fifth wheel.

5. Back the tractor squarely under the trailer, engaging the fifth wheel

jaws on the kingpin. Always back-up slowly, making sure the trailer is

neither too high nor too low. Avoid backing under the trailer from an

angle.

6. Connect the service and emergency brake hoses and trailer light

connector. Refer toTractor-trailer connectionin this chapter, adhering

to the warning and using the three-point stance while connecting and

disconnecting the trailer.

7. Inspect the jaws of the fifth wheel to be sure they have fully closed on

the trailer kingpin and the trailer plate is resting securely on the fifth

wheel.

8. Be sure the coupler release lever is in the locked position.

2004 F650/750(f67)

Supplement

USA English(fus)

Driving

114

Page 139 of 264

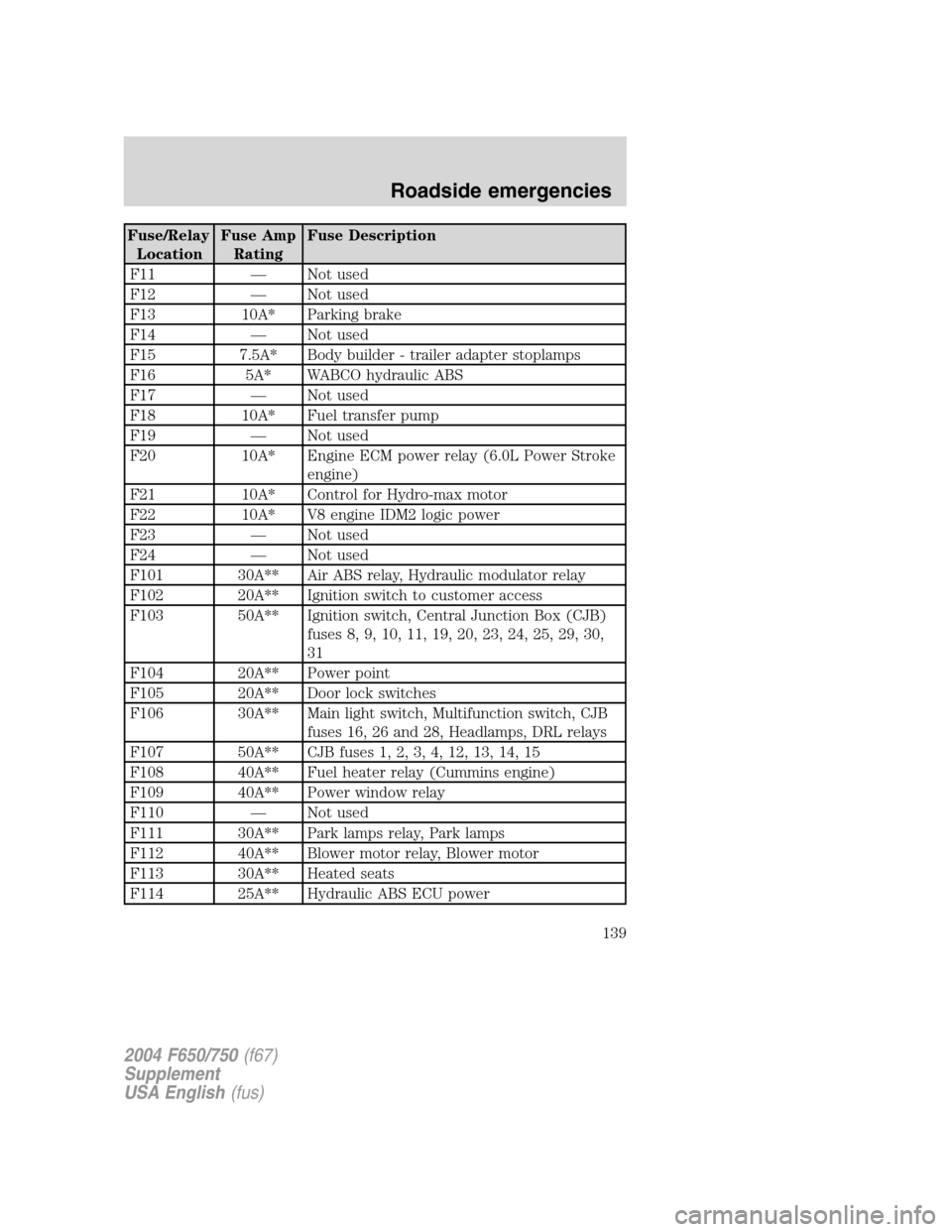

Fuse/Relay

LocationFuse Amp

RatingFuse Description

F11—Not used

F12—Not used

F13 10A* Parking brake

F14—Not used

F15 7.5A* Body builder - trailer adapter stoplamps

F16 5A* WABCO hydraulic ABS

F17—Not used

F18 10A* Fuel transfer pump

F19—Not used

F20 10A* Engine ECM power relay (6.0L Power Stroke

engine)

F21 10A* Control for Hydro-max motor

F22 10A* V8 engine IDM2 logic power

F23—Not used

F24—Not used

F101 30A** Air ABS relay, Hydraulic modulator relay

F102 20A** Ignition switch to customer access

F103 50A** Ignition switch, Central Junction Box (CJB)

fuses 8, 9, 10, 11, 19, 20, 23, 24, 25, 29, 30,

31

F104 20A** Power point

F105 20A** Door lock switches

F106 30A** Main light switch, Multifunction switch, CJB

fuses 16, 26 and 28, Headlamps, DRL relays

F107 50A** CJB fuses 1, 2, 3, 4, 12, 13, 14, 15

F108 40A** Fuel heater relay (Cummins engine)

F109 40A** Power window relay

F110—Not used

F111 30A** Park lamps relay, Park lamps

F112 40A** Blower motor relay, Blower motor

F113 30A** Heated seats

F114 25A** Hydraulic ABS ECU power

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

139

Page 146 of 264

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

WRECKER TOWING INSTRUCTIONS

Before moving the towed vehicle, check for adequate road clearance of

vehicle components. It is recommended the towed vehicle be unloaded

prior to being towed to reduce any abnormal load to the vehicle

components resulting from the towing procedures. Before towing, be

sure to fully release the parking brake. The spring-actuated type parking

brake can be reset by recharging the air system with at least 441 kPa (64

psi) of air. If the brake system will not retain air pressure, then the

spring brakes must be released manually. Refer toParking brakein the

Drivingchapter

Note:For towing, make sure the vehicle is securely connected to the

tow vehicle and the tow vehicle parking brakes are applied before

releasing the disabled vehicle’s spring brakes.

+–+–

+–+–

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

146

Page 147 of 264

To reduce the risk of personal injury or property damage when

manually releasing the spring brakes, be sure to block the wheels

so the vehicle cannot move once the brakes are released.

Towing the vehicle with the front wheels suspended

When it is necessary to tow a vehicle with the front wheels suspended,

extra precautions must be taken to avoid transmission or differential

damage. Proceed as follows:

•Remove the axle shafts from the axle assembly to prevent the wheels

from driving the differential and the transmission.

•The wheel hub ends must be covered to prevent loss of axle lubricant

and entrance of other contaminants. If the axle shafts are not

removed, removal of the propeller shafts is required.

Note:To avoid transmission damage, vehicles should not be towed even

a short distance without suspending rear wheels or removing the axle

shaft or propeller shaft.

Note:In the event the chassis is equipped with a tandem axle and the

vehicle is to be towed from the front, the forward rear axle may be

raised to clear the road surface and secured to the frame by chains or

U-bolts, allowing only the rear rear axle to contact the road surface. Axle

shafts must be removed from the rear rear axle assembly. The wheel hub

ends must be covered to prevent loss of axle lubricant and entrance of

contaminants. Use extreme care in securing the chains or U-bolts to

avoid possible damage to the brake lines, hoses or other components.

Towing vehicles equipped with a driver-controlled differential lock

Note:If the vehicle must be towed to a service facility with the drive

axle wheels on the ground, it is necessary to remove the axle shafts

before the vehicle is towed.

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

147

Page 153 of 264

1. Two or more repair attempts are made on the same nonconformity

likely to cause death or serious bodily injury OR

2. Four or more repair attempts are made on the same nonconformity (a

defect or condition that substantially impairs the use, value or safety of

the vehicle) OR

3. The vehicle is out of service for repair of nonconformities for a total of

more than 30 calendar days (not necessarily all at one time)

In the case of 1 or 2 above, the consumer must also notify the

manufacturer of the need for the repair of the nonconformity at the

following address:

Ford Motor Company

16800 Executive Plaza Drive

Mail Drop 3NE-B

Dearborn, MI 48126

REPORTING SAFETY DEFECTS (U.S. ONLY)

If you believe that your vehicle has

a defect which could cause a crash

or could cause injury or death, you

should immediately inform the National Highway Traffic Safety

Administration (NHTSA) in addition to notifying Ford Motor Company.

If NHTSA receives similar complaints, it may open an investigation, and

if it finds that a safety defect exists in a group of vehicles, it may order a

recall and remedy campaign. However, NHTSA cannot become involved

in individual problems between you, your dealer, or Ford Motor

Company.

To contact NHTSA, you may either call the Auto Safety Hotline toll-free

at 1–800–424–9393 (or 366–0123 in the Washington D.C. area) or write

to:

NHTSA

U.S. Department of Transportation

Washington, D.C. 20590

You can also obtain other information about motor vehicle safety from

the Hotline.

2004 F650/750(f67)

Supplement

USA English(fus)

Customer assistance

153

Page 160 of 264

Check to make sure that the axle mounting U-bolt nuts, attaching or

mounting bolts and nuts are securely tightened. Regularly check front

axle for damage, binding, worn parts and adequate lubrication.

At regular intervals, or during other scheduled maintenance, (tire

rotation/service, wheel bearing service, alignment, etc.) the kingpins

should be checked for excessive wear. Refer to the service manual for

proper procedures.

Toe-in setting - general inspection

Inspecting steer axle tires in the first 4,800–16,000 service km

(3,000–10,000 service miles) will generally show if tires are wearing

normally.

Rapid outside shoulder wear on both tires indicates too much toe-in.

Rapid inside shoulder wear on both tires indicates too much toe-out. In

P&D-type service, which includes school buses, left-to-right steer tire

tread life differentials up to 40% can be observed depending on routes

and other variables.

Follow the tire manufacturer’s recommended cold inflation pressure for

the tire size, load range (ply rating) and steer axle loading typical for

their operation (each steer axle tire will equal

1⁄2steer axle loading).

Special applications may warrant a setting based on past experience with

the type of tire operating loads and conditions. Radial tires are more

sensitive to toe-in setting than bias ply tires. While not insensitive to

vehicle alignment, fine tuning school bus alignment to line-haul truck

standards will not drastically improve tire tread life.

It is essential that correct toe-in and tire pressure be maintained for

optimum tire wear.

Rear axle - general inspection

Check to make sure that the axle mounting U-bolts, attaching or

mounting bolts and nuts are securely tightened. Refer toU-bolt nut

torque chartin this chapter. Regularly check the rear axle for damaged,

binding or worn parts.

NoSpin Detroit Locker positive locking differential

Vehicle equipped with this type differential have the operator’s manual

supplied with the vehicle. Refer to this manual for maintenance checks.

Brake system - general inspection

Your vehicle is equipped with non-asbestos brake linings. However,

exposure to excessive amounts of brake material (whether asbestos or

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

160

Page 180 of 264

To avoid damage to the power steering system,do notoperate the

vehicle with a low power steering fluid level.

Whenever the dipstick is installed, make sure it is properly seated and

tightened securely.

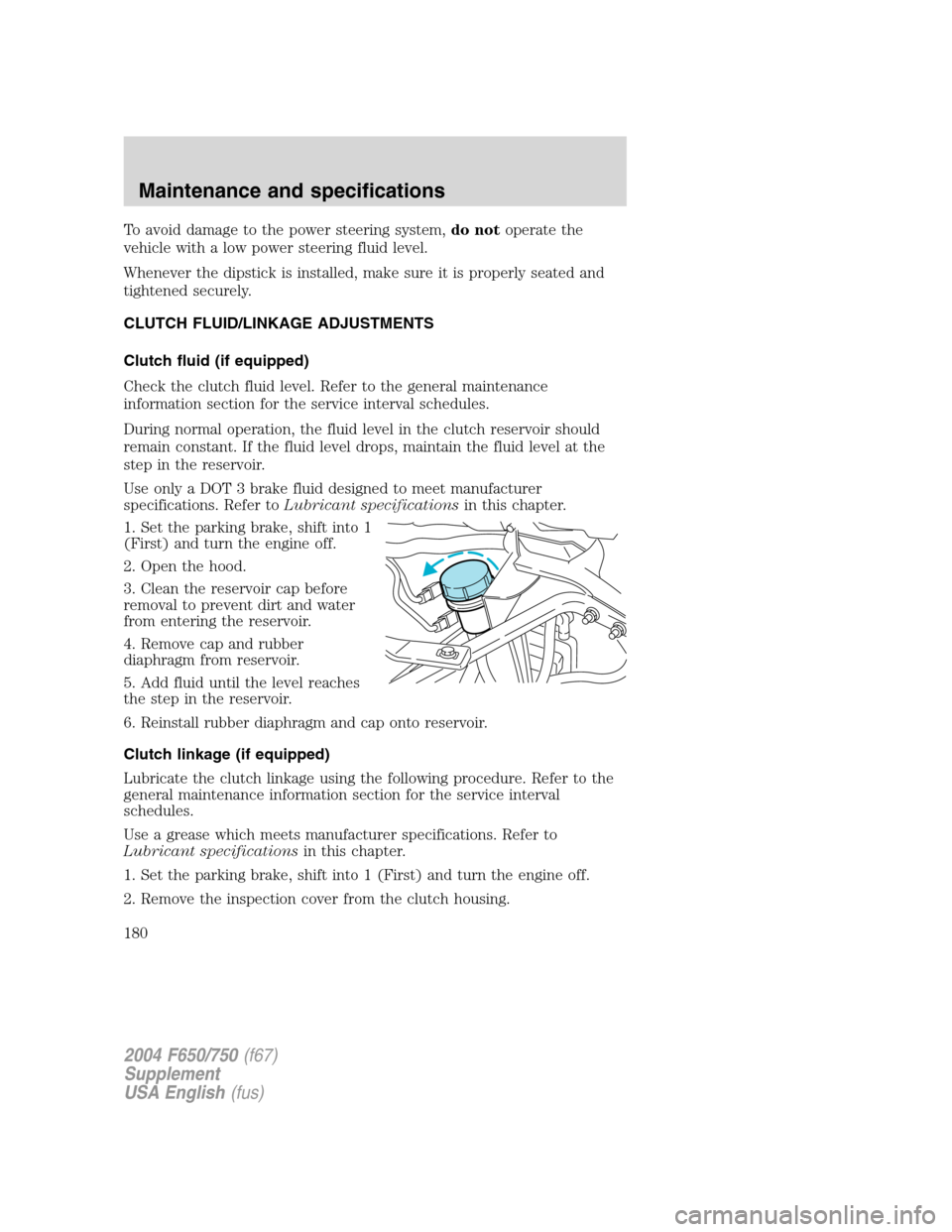

CLUTCH FLUID/LINKAGE ADJUSTMENTS

Clutch fluid (if equipped)

Check the clutch fluid level. Refer to the general maintenance

information section for the service interval schedules.

During normal operation, the fluid level in the clutch reservoir should

remain constant. If the fluid level drops, maintain the fluid level at the

step in the reservoir.

Use only a DOT 3 brake fluid designed to meet manufacturer

specifications. Refer toLubricant specificationsin this chapter.

1. Set the parking brake, shift into 1

(First) and turn the engine off.

2. Open the hood.

3. Clean the reservoir cap before

removal to prevent dirt and water

from entering the reservoir.

4. Remove cap and rubber

diaphragm from reservoir.

5. Add fluid until the level reaches

the step in the reservoir.

6. Reinstall rubber diaphragm and cap onto reservoir.

Clutch linkage (if equipped)

Lubricate the clutch linkage using the following procedure. Refer to the

general maintenance information section for the service interval

schedules.

Use a grease which meets manufacturer specifications. Refer to

Lubricant specificationsin this chapter.

1. Set the parking brake, shift into 1 (First) and turn the engine off.

2. Remove the inspection cover from the clutch housing.

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

180