wheel FORD F650 2005 11.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2005, Model line: F650, Model: FORD F650 2005 11.GPages: 272, PDF Size: 1.5 MB

Page 1 of 272

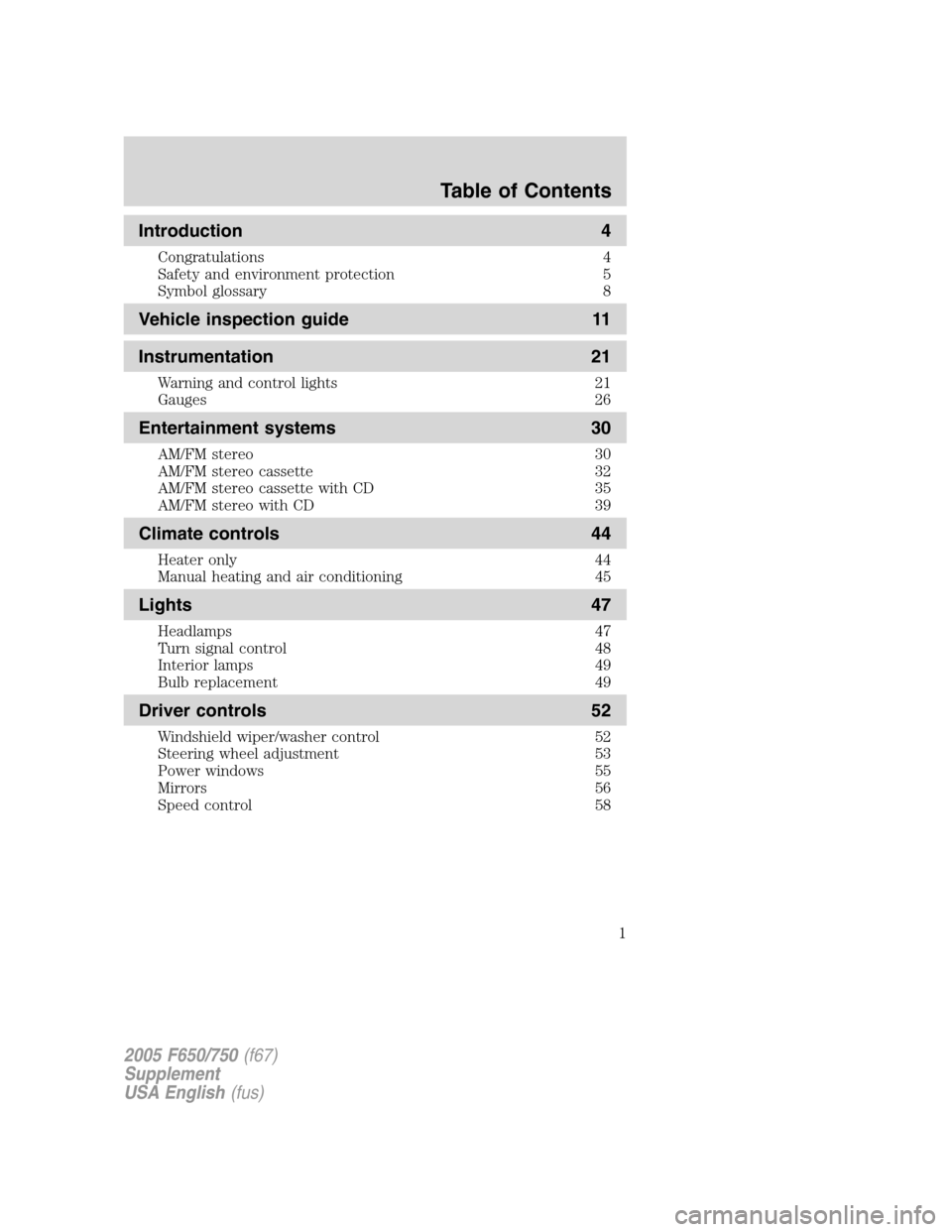

Introduction 4

Congratulations 4

Safety and environment protection 5

Symbol glossary 8

Vehicle inspection guide 11

Instrumentation 21

Warning and control lights 21

Gauges 26

Entertainment systems 30

AM/FM stereo 30

AM/FM stereo cassette 32

AM/FM stereo cassette with CD 35

AM/FM stereo with CD 39

Climate controls 44

Heater only 44

Manual heating and air conditioning 45

Lights 47

Headlamps 47

Turn signal control 48

Interior lamps 49

Bulb replacement 49

Driver controls 52

Windshield wiper/washer control 52

Steering wheel adjustment 53

Power windows 55

Mirrors 56

Speed control 58

Table of Contents

1

2005 F650/750(f67)

Supplement

USA English(fus)

Table of Contents

Page 7 of 272

Event Data Recording

Other modules in your vehicle—event data recorders—are capable of

collecting and storing data during a crash or near crash event. The

recorded information may assist in the investigation of such an event.

The modules may record information about both the vehicle and the

occupants, potentially including information such as:

•how various systems in your vehicle were operating;

•whether or not the driver and passenger seatbelts were buckled;

•how far (if at all) the driver was depressing the accelerator and/or the

brake pedal;

•how fast the vehicle was traveling; and

•where the driver was positioning the steering wheel.

To access this information, special equipment must be directly connected

to the recording modules. Ford Motor Company and Ford of Canada do

not access event data recorder information without obtaining consent,

unless pursuant to court order or where required by law enforcement,

other government authorities or other third parties acting with lawful

authority. Other parties may seek to access the information

independently of Ford Motor Company and Ford of Canada.

Introduction

7

Page 12 of 272

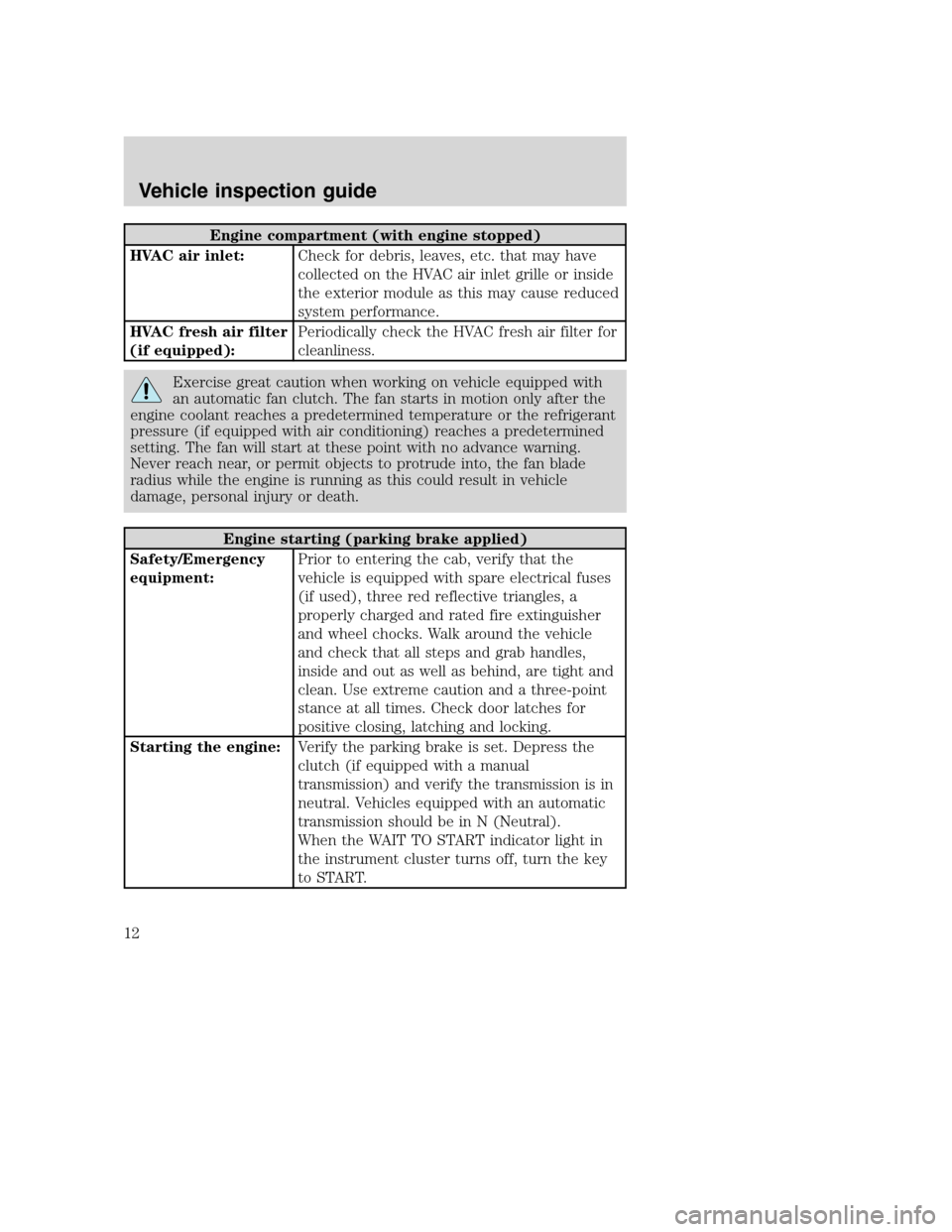

Engine compartment (with engine stopped)

HVAC air inlet:Check for debris, leaves, etc. that may have

collected on the HVAC air inlet grille or inside

the exterior module as this may cause reduced

system performance.

HVAC fresh air filter

(if equipped):Periodically check the HVAC fresh air filter for

cleanliness.

Exercise great caution when working on vehicle equipped with

an automatic fan clutch. The fan starts in motion only after the

engine coolant reaches a predetermined temperature or the refrigerant

pressure (if equipped with air conditioning) reaches a predetermined

setting. The fan will start at these point with no advance warning.

Never reach near, or permit objects to protrude into, the fan blade

radius while the engine is running as this could result in vehicle

damage, personal injury or death.

Engine starting (parking brake applied)

Safety/Emergency

equipment:Prior to entering the cab, verify that the

vehicle is equipped with spare electrical fuses

(if used), three red reflective triangles, a

properly charged and rated fire extinguisher

and wheel chocks. Walk around the vehicle

and check that all steps and grab handles,

inside and out as well as behind, are tight and

clean. Use extreme caution and a three-point

stance at all times. Check door latches for

positive closing, latching and locking.

Starting the engine:Verify the parking brake is set. Depress the

clutch (if equipped with a manual

transmission) and verify the transmission is in

neutral. Vehicles equipped with an automatic

transmission should be in N (Neutral).

When the WAIT TO START indicator light in

the instrument cluster turns off, turn the key

to START.

Vehicle inspection guide

12

Page 13 of 272

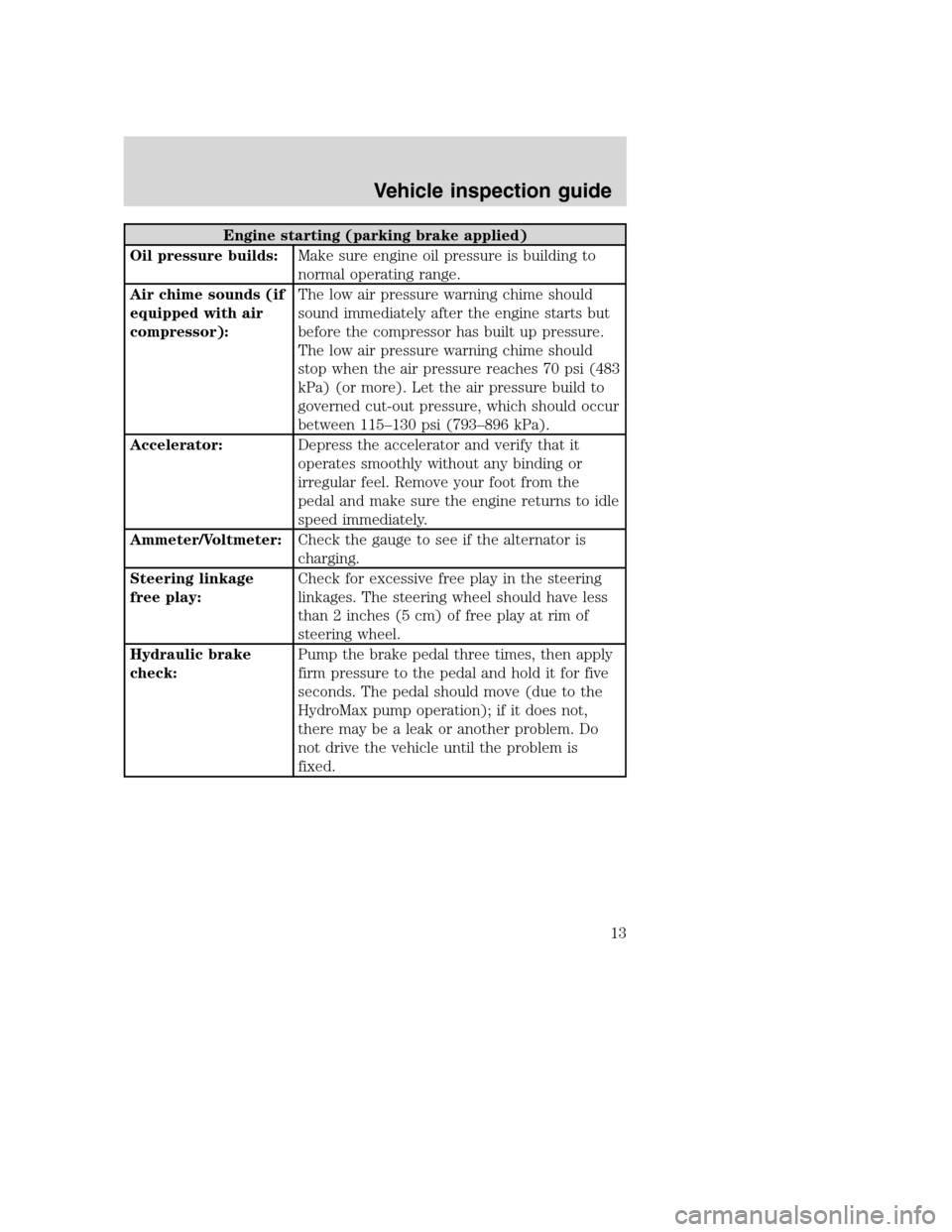

Engine starting (parking brake applied)

Oil pressure builds:Make sure engine oil pressure is building to

normal operating range.

Air chime sounds (if

equipped with air

compressor):The low air pressure warning chime should

sound immediately after the engine starts but

before the compressor has built up pressure.

The low air pressure warning chime should

stop when the air pressure reaches 70 psi (483

kPa) (or more). Let the air pressure build to

governed cut-out pressure, which should occur

between 115–130 psi (793–896 kPa).

Accelerator:Depress the accelerator and verify that it

operates smoothly without any binding or

irregular feel. Remove your foot from the

pedal and make sure the engine returns to idle

speed immediately.

Ammeter/Voltmeter:Check the gauge to see if the alternator is

charging.

Steering linkage

free play:Check for excessive free play in the steering

linkages. The steering wheel should have less

than 2 inches (5 cm) of free play at rim of

steering wheel.

Hydraulic brake

check:Pump the brake pedal three times, then apply

firm pressure to the pedal and hold it for five

seconds. The pedal should move (due to the

HydroMax pump operation); if it does not,

there may be a leak or another problem. Do

not drive the vehicle until the problem is

fixed.

Vehicle inspection guide

13

Page 14 of 272

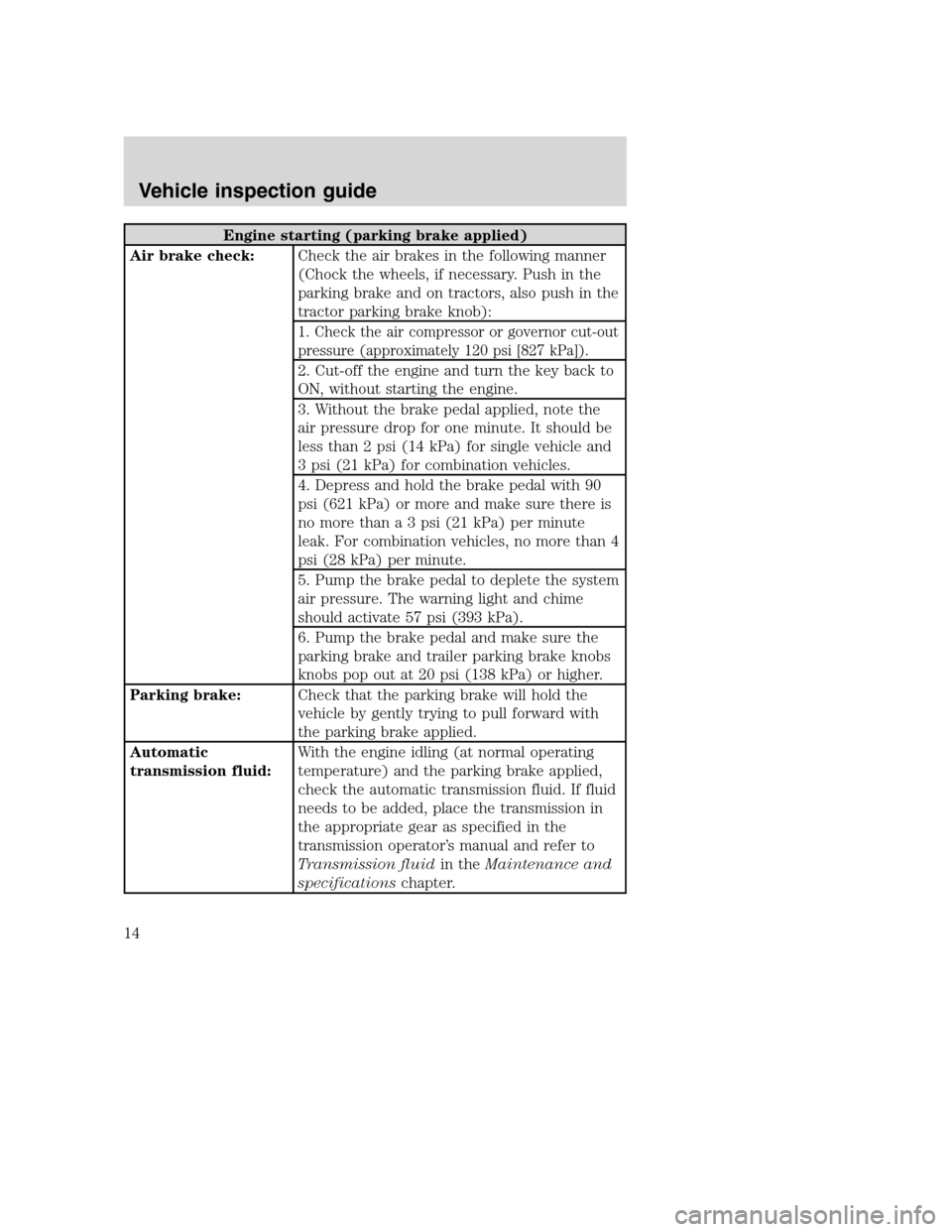

Engine starting (parking brake applied)

Air brake check:Check the air brakes in the following manner

(Chock the wheels, if necessary. Push in the

parking brake and on tractors, also push in the

tractor parking brake knob):

1. Check the air compressor or governor cut-out

pressure (approximately 120 psi [827 kPa]).

2. Cut-off the engine and turn the key back to

ON, without starting the engine.

3. Without the brake pedal applied, note the

air pressure drop for one minute. It should be

less than 2 psi (14 kPa) for single vehicle and

3 psi (21 kPa) for combination vehicles.

4. Depress and hold the brake pedal with 90

psi (621 kPa) or more and make sure there is

no more than a 3 psi (21 kPa) per minute

leak. For combination vehicles, no more than 4

psi (28 kPa) per minute.

5. Pump the brake pedal to deplete the system

air pressure. The warning light and chime

should activate 57 psi (393 kPa).

6. Pump the brake pedal and make sure the

parking brake and trailer parking brake knobs

knobs pop out at 20 psi (138 kPa) or higher.

Parking brake:Check that the parking brake will hold the

vehicle by gently trying to pull forward with

the parking brake applied.

Automatic

transmission fluid:With the engine idling (at normal operating

temperature) and the parking brake applied,

check the automatic transmission fluid. If fluid

needs to be added, place the transmission in

the appropriate gear as specified in the

transmission operator’s manual and refer to

Transmission fluidin theMaintenance and

specificationschapter.

Vehicle inspection guide

14

Page 16 of 272

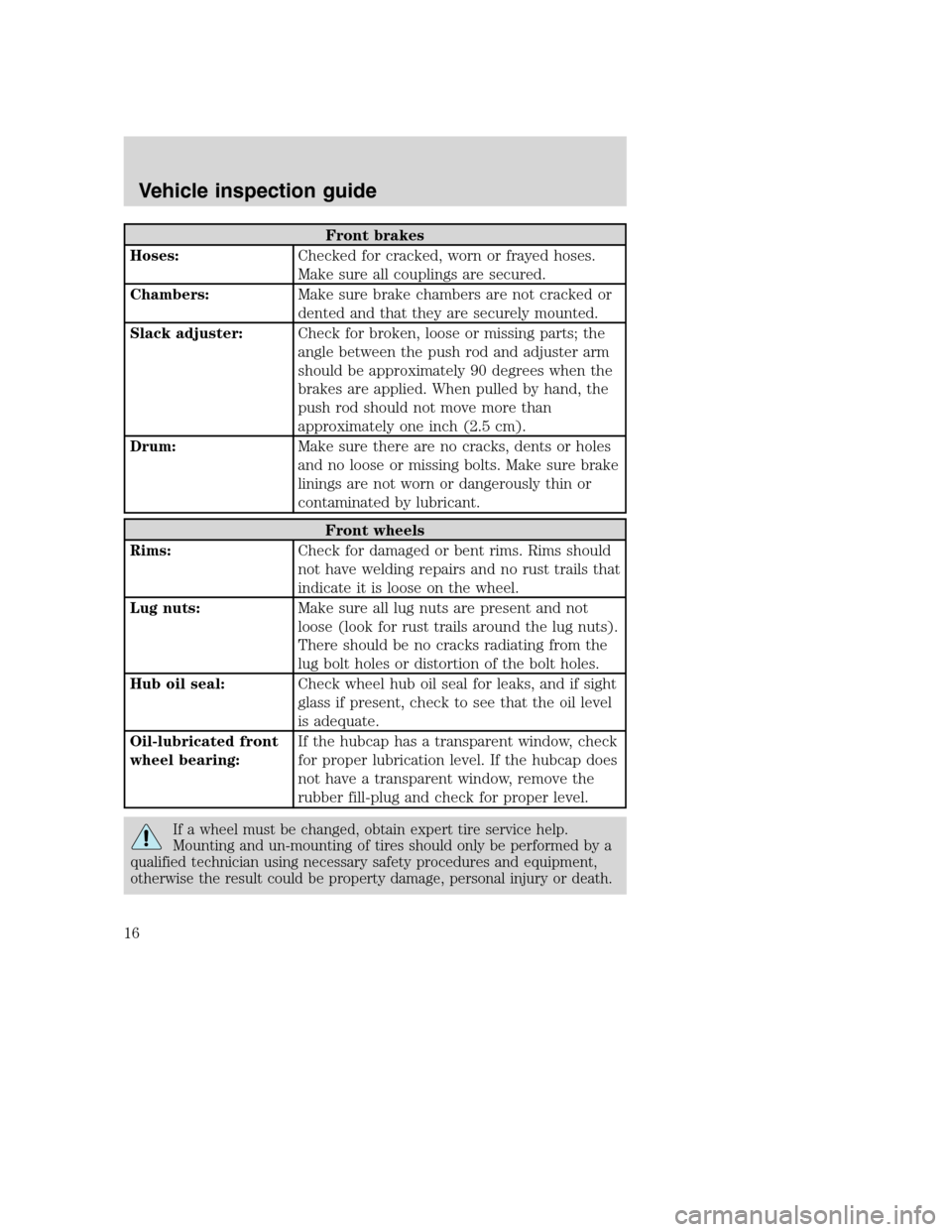

Front brakes

Hoses:Checked for cracked, worn or frayed hoses.

Make sure all couplings are secured.

Chambers:Make sure brake chambers are not cracked or

dented and that they are securely mounted.

Slack adjuster:Check for broken, loose or missing parts; the

angle between the push rod and adjuster arm

should be approximately 90 degrees when the

brakes are applied. When pulled by hand, the

push rod should not move more than

approximately one inch (2.5 cm).

Drum:Make sure there are no cracks, dents or holes

and no loose or missing bolts. Make sure brake

linings are not worn or dangerously thin or

contaminated by lubricant.

Front wheels

Rims:Check for damaged or bent rims. Rims should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nuts:Make sure all lug nuts are present and not

loose (look for rust trails around the lug nuts).

There should be no cracks radiating from the

lug bolt holes or distortion of the bolt holes.

Hub oil seal:Check wheel hub oil seal for leaks, and if sight

glass if present, check to see that the oil level

is adequate.

Oil-lubricated front

wheel bearing:If the hubcap has a transparent window, check

for proper lubrication level. If the hubcap does

not have a transparent window, remove the

rubber fill-plug and check for proper level.

If a wheel must be changed, obtain expert tire service help.

Mounting and un-mounting of tires should only be performed by a

qualified technician using necessary safety procedures and equipment,

otherwise the result could be property damage, personal injury or death.

Vehicle inspection guide

16

Page 18 of 272

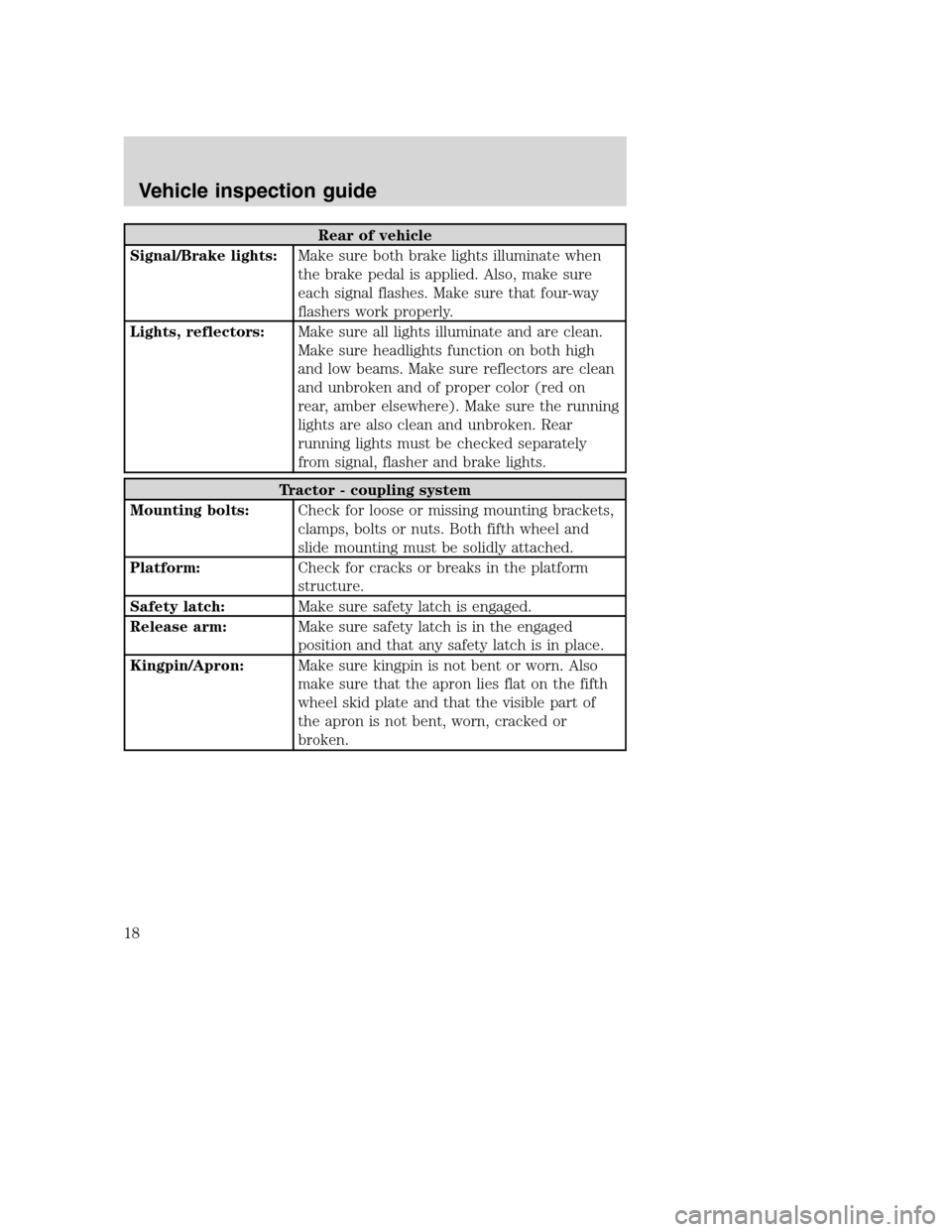

Rear of vehicle

Signal/Brake lights:Make sure both brake lights illuminate when

the brake pedal is applied. Also, make sure

each signal flashes. Make sure that four-way

flashers work properly.

Lights, reflectors:Make sure all lights illuminate and are clean.

Make sure headlights function on both high

and low beams. Make sure reflectors are clean

and unbroken and of proper color (red on

rear, amber elsewhere). Make sure the running

lights are also clean and unbroken. Rear

running lights must be checked separately

from signal, flasher and brake lights.

Tractor - coupling system

Mounting bolts:Check for loose or missing mounting brackets,

clamps, bolts or nuts. Both fifth wheel and

slide mounting must be solidly attached.

Platform:Check for cracks or breaks in the platform

structure.

Safety latch:Make sure safety latch is engaged.

Release arm:Make sure safety latch is in the engaged

position and that any safety latch is in place.

Kingpin/Apron:Make sure kingpin is not bent or worn. Also

make sure that the apron lies flat on the fifth

wheel skid plate and that the visible part of

the apron is not bent, worn, cracked or

broken.

Vehicle inspection guide

18

Page 20 of 272

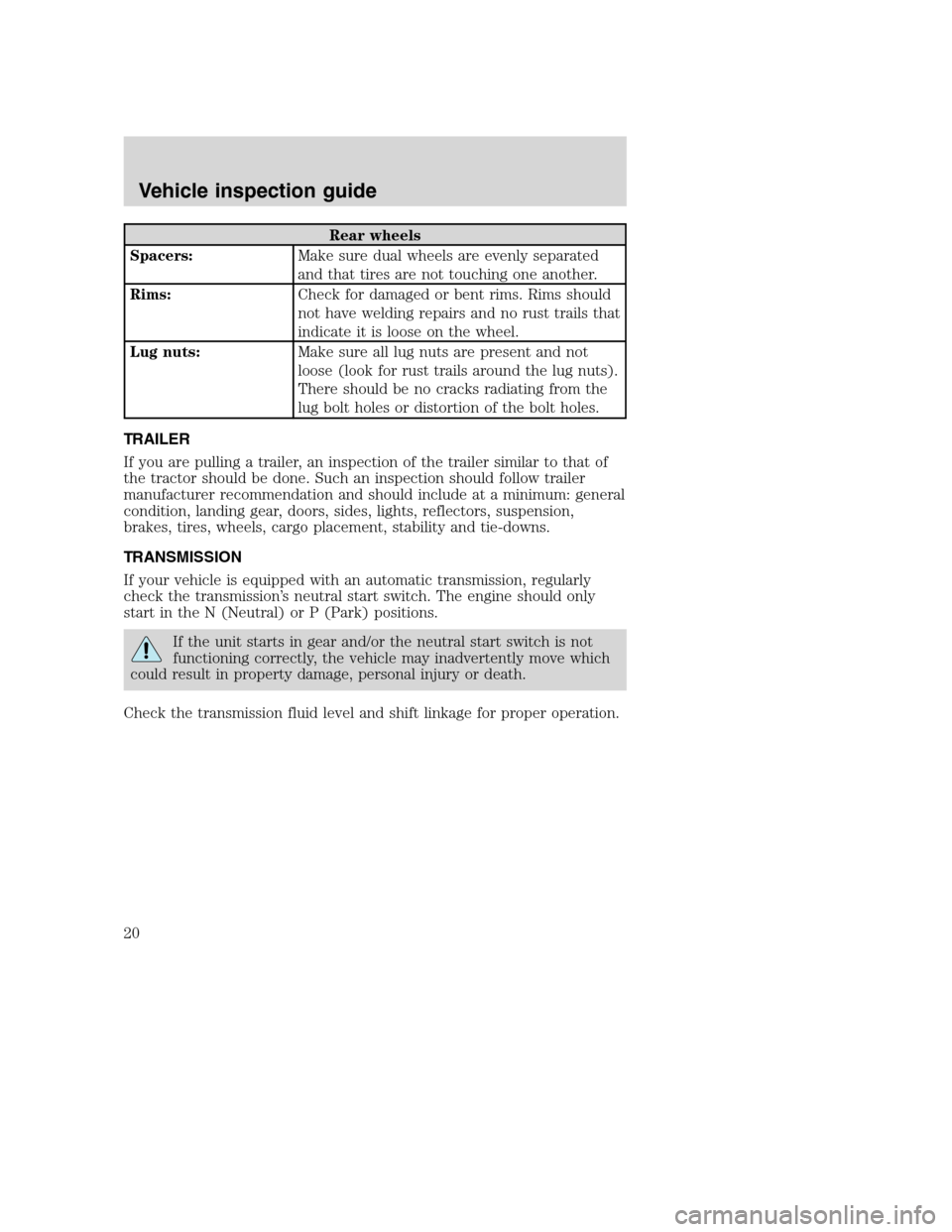

Rear wheels

Spacers:Make sure dual wheels are evenly separated

and that tires are not touching one another.

Rims:Check for damaged or bent rims. Rims should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nuts:Make sure all lug nuts are present and not

loose (look for rust trails around the lug nuts).

There should be no cracks radiating from the

lug bolt holes or distortion of the bolt holes.

TRAILER

If you are pulling a trailer, an inspection of the trailer similar to that of

the tractor should be done. Such an inspection should follow trailer

manufacturer recommendation and should include at a minimum: general

condition, landing gear, doors, sides, lights, reflectors, suspension,

brakes, tires, wheels, cargo placement, stability and tie-downs.

TRANSMISSION

If your vehicle is equipped with an automatic transmission, regularly

check the transmission’s neutral start switch. The engine should only

start in the N (Neutral) or P (Park) positions.

If the unit starts in gear and/or the neutral start switch is not

functioning correctly, the vehicle may inadvertently move which

could result in property damage, personal injury or death.

Check the transmission fluid level and shift linkage for proper operation.

Vehicle inspection guide

20

Page 22 of 272

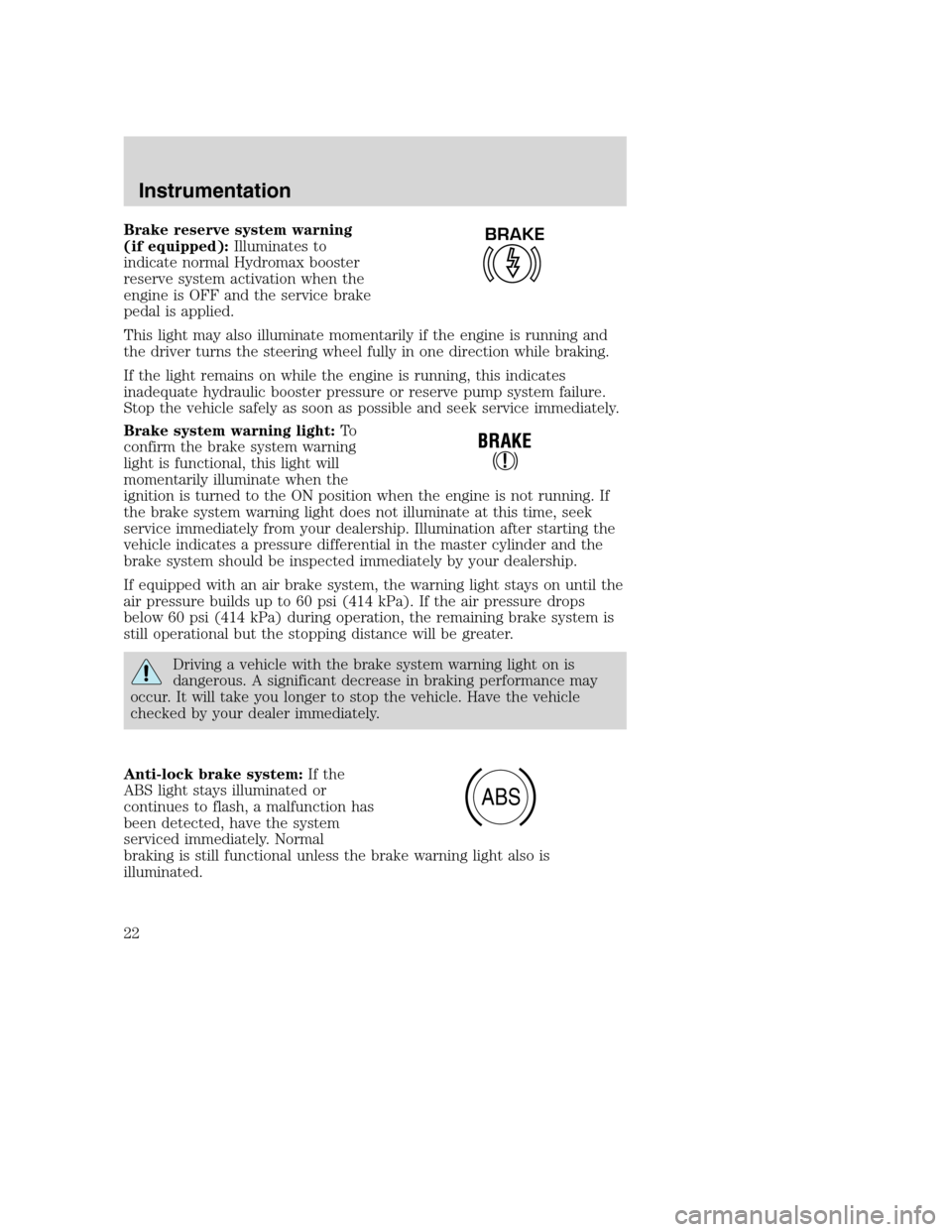

Brake reserve system warning

(if equipped):Illuminates to

indicate normal Hydromax booster

reserve system activation when the

engine is OFF and the service brake

pedal is applied.

This light may also illuminate momentarily if the engine is running and

the driver turns the steering wheel fully in one direction while braking.

If the light remains on while the engine is running, this indicates

inadequate hydraulic booster pressure or reserve pump system failure.

Stop the vehicle safely as soon as possible and seek service immediately.

Brake system warning light:To

confirm the brake system warning

light is functional, this light will

momentarily illuminate when the

ignition is turned to the ON position when the engine is not running. If

the brake system warning light does not illuminate at this time, seek

service immediately from your dealership. Illumination after starting the

vehicle indicates a pressure differential in the master cylinder and the

brake system should be inspected immediately by your dealership.

If equipped with an air brake system, the warning light stays on until the

air pressure builds up to 60 psi (414 kPa). If the air pressure drops

below 60 psi (414 kPa) during operation, the remaining brake system is

still operational but the stopping distance will be greater.

Driving a vehicle with the brake system warning light on is

dangerous. A significant decrease in braking performance may

occur. It will take you longer to stop the vehicle. Have the vehicle

checked by your dealer immediately.

Anti-lock brake system:If the

ABS light stays illuminated or

continues to flash, a malfunction has

been detected, have the system

serviced immediately. Normal

braking is still functional unless the brake warning light also is

illuminated.

BRAKE

ABS

Instrumentation

22

Page 53 of 272

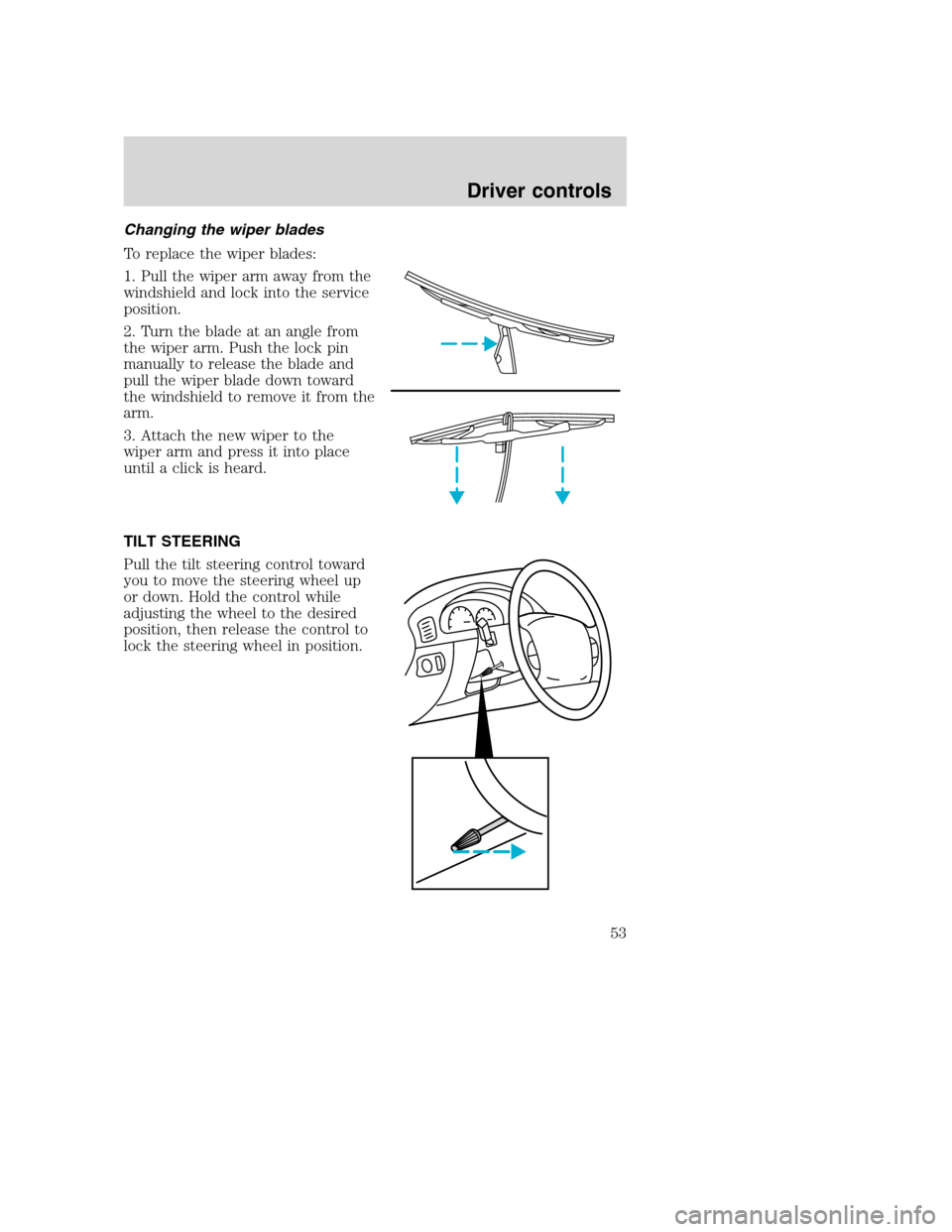

Changing the wiper blades

To replace the wiper blades:

1. Pull the wiper arm away from the

windshield and lock into the service

position.

2. Turn the blade at an angle from

the wiper arm. Push the lock pin

manually to release the blade and

pull the wiper blade down toward

the windshield to remove it from the

arm.

3. Attach the new wiper to the

wiper arm and press it into place

until a click is heard.

TILT STEERING

Pull the tilt steering control toward

you to move the steering wheel up

or down. Hold the control while

adjusting the wheel to the desired

position, then release the control to

lock the steering wheel in position.

Driver controls

53