ESP FORD F650 2008 11.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: F650, Model: FORD F650 2008 11.GPages: 273, PDF Size: 1.71 MB

Page 164 of 273

non-asbestos, fiberglass, mineral wool, aramid or carbon) may be a

potentially serious health hazard.

Note:Persons handling brake linings should follow all precautions listed

below:

1. Always wear a respirator approved by the National Institute of

Occupational Studies of Health (NIOSH) or Mine Safety and Appliance

(MSA) during all brake service procedures. Wear the respirator from

removal of the wheels through assembly.

2.Neveruse compressed air or dry brushing to clean brake parts or

assemblies.

3. Clean brake parts and assemblies in open air. During assembly,

carefully place all parts on the floor to avoid getting dust in the air. Use

an industrial vacuum cleaner with a HEPA filter system to clean dust

from the brake drums, backing plates and other brake parts. After using

the vacuum, remove any remaining dust with a rag soaked in water and

wrung until nearly dry.

4.Neveruse compressed air or dry sweeping to clean the work area.

Use an industrial vacuum cleaner with a HEPA filter system and rags

soaked in water until wrung until nearly dry. Dispose of used rags with

care to avoid getting dust in the air. Use an approved respirator when

emptying vacuum cleaners and handling used rags.

5.Worker clean-up:Wash your hands before eating, drinking or

smoking. Vacuum your work clothes after use and then launder them

separately, without shaking them, to prevent fiber dust getting into the

air.

Air brakes - inspection and adjustment

A regular schedule for periodic cleaning, lubrication and adjustment

inspection should be established based on the type of vehicle operation.

It is difficult to predetermine an exact maintenance interval (time or

mileage), since vehicles will be used in a wide variety of applications and

conditions. If you are uncertain of the proper schedule and procedures

for your vehicle, contact your dealer.

Periodic checking of push rod travel or brake adjustment is essential for

effective braking. Push rod travel should be checked every service

interval to determine if adjustment is correct. Brake chamber push rods

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

163

Page 174 of 273

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

Battery posts, terminals and related accessories contain lead and

lead compounds.Wash hands after handling.

Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized

standards for disposal. Call your

local authorized recycling center to

find out more about recycling

automotive batteries.

ENGINE COOLANT

Refer to your engine operator’s manual for engine coolant checking and

adding instructions as well as engine coolant specifications and

capacities.

Severe climates

If you drive in extremely cold climates (less than –34°F [–36°C]):

•It may be necessary to increase the coolant concentration

above 50%.

•NEVER increase the coolant concentration above 60%.

•Engine coolant concentrations above 60% will decrease the

overheat protection characteristics of the engine coolant and

may cause engine damage.

•If available, refer to the chart on the coolant container to

ensure the coolant concentration in your vehicle will provide

adequate freeze protection at the temperatures in which you

drive in the winter months.

L

E

A

D

RETURN

RECYCLE

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

173

Page 176 of 273

FUEL INFORMATION

Important safety precautions

Do not overfill the fuel tank. The pressure in an overfilled tank

may cause leakage and lead to fuel spray and fire.

The fuel system may be under pressure. If the fuel cap is venting

vapor or if you hear a hissing sound, wait until it stops before

completely removing the cap.

Automotive fuels can cause serious injury or death if misused or

mishandled.

Observe the following guidelines when handling fuel:

•Extinguish all smoking materials

and any open flames before

fueling your vehicle.

•Always turn off the vehicle before

fueling.

•Automotive fuels can be harmful

or fatal if swallowed. If fuel is swallowed, call a physician immediately,

even if no symptoms are immediately apparent. The toxic effects of

fuel may not be visible for hours.

•Avoid inhaling fuel vapors. Inhaling too much fuel vapor of any kind

can lead to eye and respiratory tract irritation. In severe cases,

excessive or prolonged breathing of fuel vapor can cause serious

illness and permanent injury.

•Avoid getting fuel liquid in your eyes. If fuel is splashed in the eyes,

remove contact lenses (if worn), flush with water for 15 minutes and

seek medical attention. Failure to seek proper medical attention could

lead to permanent injury.

•Fuels can also be harmful if absorbed through the skin. If fuel is

splashed on the skin and/or clothing, promptly remove contaminated

clothing and wash skin thoroughly with soap and water. Repeated or

prolonged skin contact with fuel liquid or vapor causes skin irritation.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

175

Page 191 of 273

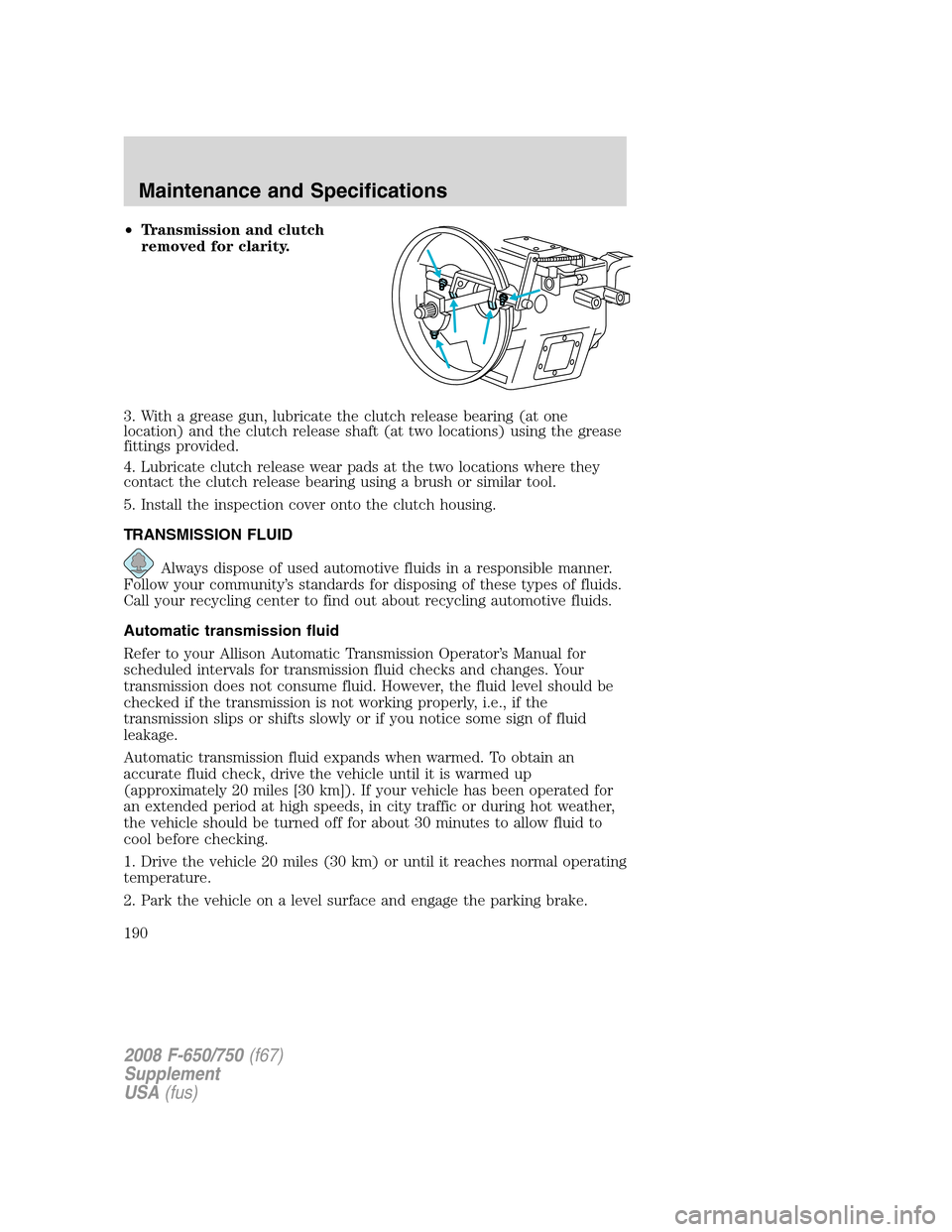

•Transmission and clutch

removed for clarity.

3. With a grease gun, lubricate the clutch release bearing (at one

location) and the clutch release shaft (at two locations) using the grease

fittings provided.

4. Lubricate clutch release wear pads at the two locations where they

contact the clutch release bearing using a brush or similar tool.

5. Install the inspection cover onto the clutch housing.

TRANSMISSION FLUID

Always dispose of used automotive fluids in a responsible manner.

Follow your community’s standards for disposing of these types of fluids.

Call your recycling center to find out about recycling automotive fluids.

Automatic transmission fluid

Refer to your Allison Automatic Transmission Operator’s Manual for

scheduled intervals for transmission fluid checks and changes. Your

transmission does not consume fluid. However, the fluid level should be

checked if the transmission is not working properly, i.e., if the

transmission slips or shifts slowly or if you notice some sign of fluid

leakage.

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is warmed up

(approximately 20 miles [30 km]). If your vehicle has been operated for

an extended period at high speeds, in city traffic or during hot weather,

the vehicle should be turned off for about 30 minutes to allow fluid to

cool before checking.

1. Drive the vehicle 20 miles (30 km) or until it reaches normal operating

temperature.

2. Park the vehicle on a level surface and engage the parking brake.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

190

Page 193 of 273

Drain and refill your transmission fluid using the following procedure:

1. Drain the transmission while the fluid is warm.

2. Park the vehicle on level ground.

3. Set the parking brake and shift into 1 (First) and turn the engine off.

4. Clean any dirt from around the filler and drain plugs.

5. Remove the filler and drain plugs and drain the fluid into a suitable

container. Dispose all used automotive fluids in a responsible manner

following your local authorized standards.

6. Clean and install the drain plug securely.

7. Add enough fluid through the filler plug opening so that the fluid level

is up to the bottom of the opening.

8. Clean and install the filler plug securely.

CHASSIS-MOUNTED CHARGE AIR COOLER

Inspect charge air cooler daily

With the engine off, visually inspect the charge air cooler core assembly

for debris and clogging of external fins. Prior to engine operation,

remove any debris blocking the core.

•Turbocharger-to-charge air cooler

•Charge air cooler-to-intake manifold pipe

•Mounting bracket

•Chassis-mounted charge air cooler core

Inspect air intake piping

•Check for accumulation of salt deposits (where applicable). If present,

disassemble and clean the complete air intake piping system. If the

intake piping is pitted, use Motorcraft Silicone Gasket and Sealant

TA-30 to seal joints against leakage.

•Check for loose hoses and clamps.

•Check for ruptured or collapsed hoses.

•Check air cleaner housing for cracks.

ELECTRICAL SYSTEM INSPECTIONS

Periodically inspect electrical connectors on the outside of the cab, on

the engine and frame for corrosion and tightness. Exposed terminals

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

192

Page 197 of 273

Your rear axle may be filled with an optional synthetic lubricant which

allows the use of extended service intervals. A tag on the filler plug will

identify the use of the synthetic lubricant.

Use only a lubricant that meets manufacturer specifications (refer to

Lubricant specificationsin this chapter).

Use of a non-approved rear axle lubricant may cause internal axle

component damage.

Checking the rear axle lubricant level

1. Park the vehicle on level ground.

2. Set the parking brake and shift into N (Neutral) (automatic

transmission) or 1 (First) (manual transmission) and turn the engine off.

3. Clean any dirt from around the rear axle filler plug.

4. Remove the filler plug and inspect the lubricant level.

5. The lubricant level should be up to the bottom of the filler plug

opening.

6. If necessary, add enough lubricant through the filler plug opening so

that the lubricant level is at the bottom of the opening.

7. Clean and install the filler plug securely.

Draining and refilling the rear axle lubricant

1. Drain the rear axle while the lubricant is warm.

2. Park the vehicle on level ground.

3. Set the parking brake and shift into N (Neutral) (automatic

transmission) or 1 (First) (manual transmission) and turn the engine off.

4. Clean any dirt from around the rear axle filler and drain plugs.

5. Remove the filler and drain plugs and drain the lubricant into a

suitable container. Dispose of all used automotive fluids in a responsible

manner following your local authorized standards.

6. Clean and install the drain plug securely.

7. Add enough lubricant through the filler plug opening so that the

lubricant level is up to the bottom of the opening.

8. Clean and install the filler plug securely.

WHEELS

General

Wheel bearings should be inspected, lubricated and adjusted at regular

intervals. This is especially important if operating in deep sand, mud, or

water. Refer toLubricant specificationsin this chapter.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

196

Page 209 of 273

Rotating tires from one wheel position to another is a way often used to

even out many types of irregular wear or to avoid it altogether. Some of

the more effective tire rotation programs are:

•Steer tires that have developed some type of irregular wear pattern

can be rotated to drive axles if rib tires are being used on all wheel

positions. Applying steer tires to a drive position will often clean them

and they can be moved back to the steer axles or run out to re-tread

stage on the rear axle.

•Another rotation possibility for fleets with rib tires in all wheel

positions is to break in the new steer tires in the drive axle positions,

then move them to steer axles. This will wear away tread rubber

relatively quickly in the early life of a tire when it is most likely to

develop an unusual wear pattern.

•Drive axle tires may be placed on the other end of the same axle so

that direction of rotation is reversed. This is often helpful if a heel and

toe or alternate lug wear pattern has developed.

Irregular wear can be minimized by:

•Using the right inflation pressure for the load being carried.

•Maintaining proper front wheel alignment -especially toe-in-to

specifications.

•Maintaining proper tire and wheel balance.

•Maintaining shock absorbers and suspension components.

Use of tire chains

Refer to chain manufacturer’s recommendation for correct tire chain

usage, installation and removal.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

208

Page 230 of 273

FACTORY AUTHORIZED SYSTEMS CHECKS

In the event that your vehicle experiences a component related concern,

please contact your Ford dealership. The Ford Motor Company Trained

Technicians who work at Ford dealerships are specifically trained to

understand your vehicle.

A proper repair begins with a thorough system check. A Factory

Authorized Systems Check can ONLY be found at a Ford dealership. In

some circumstances, the technician may need to request your

authorization to perform additional operations to determine the final

diagnosis. The technician’s goal is to ensure that your vehicle is fixed

right the first time, at the best value to you.

The following list represents several of the Factory Authorized Systems

Checks available at a participating Ford dealers:

•Air Conditioning

•Check Engine Light

•All Wheel Drive and 4x4

•Automatic Transmission

•Engine Cooling and Cabin Heating

•Steering and Suspension

•Charge/Start/Battery

•Wheel Alignment

•Anti-Lock Brake System

EMISSIONS CONTROL SYSTEM

To ensure the emissions control systems operate effectively, you should

have the services listed in the maintenance schedule performed at the

specified time and mileage/km intervals. You should avoid running out of

fuel or turning off the ignition while the vehicle is in motion, especially

at high speeds.

Because of high engine compartment and exhaust system

temperatures resulting from emissions equipment, do not park,

idle or operate your vehicle in dry grass or other dry ground cover

where the possibility of ground fire exists.

Do not make unauthorized modifications to the engine or vehicle.

Modifications causing increased amounts of unburned fuel to reach the

exhaust system can significantly increase the temperature of the engine

compartment and/or the exhaust system.

2008 F-650/750(f67)

Supplement

USA(fus)

Scheduled Maintenance Guide

229