automatic transmission FORD F650 2008 11.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2008, Model line: F650, Model: FORD F650 2008 11.GPages: 273, PDF Size: 1.71 MB

Page 127 of 273

These ranges can also be used to provide additional steps between

transmission shifts when driving on steep grades and/or fuel economy

may be factors.

Note:Do not shift between ranges when the speed control is on.

Never shift a two-speed axle when descending a steep grade as

this may cause loss of vehicle control and result in personal injury.

Axle shifting

Manual transmissions:

•To downshift,select the next lower gear, release and depress the

accelerator pedal rapidly, or while holding the accelerator pedal down,

release and engage the clutch rapidly.Note:The clutch method is

recommended when driving at slower speeds.

•To upshift,keep the accelerator pedal down, select the next higher

gear, release the accelerator and pause until the axle upshifts.Note:

De-clutch for smoother axle upshifts when driving at slower speeds.

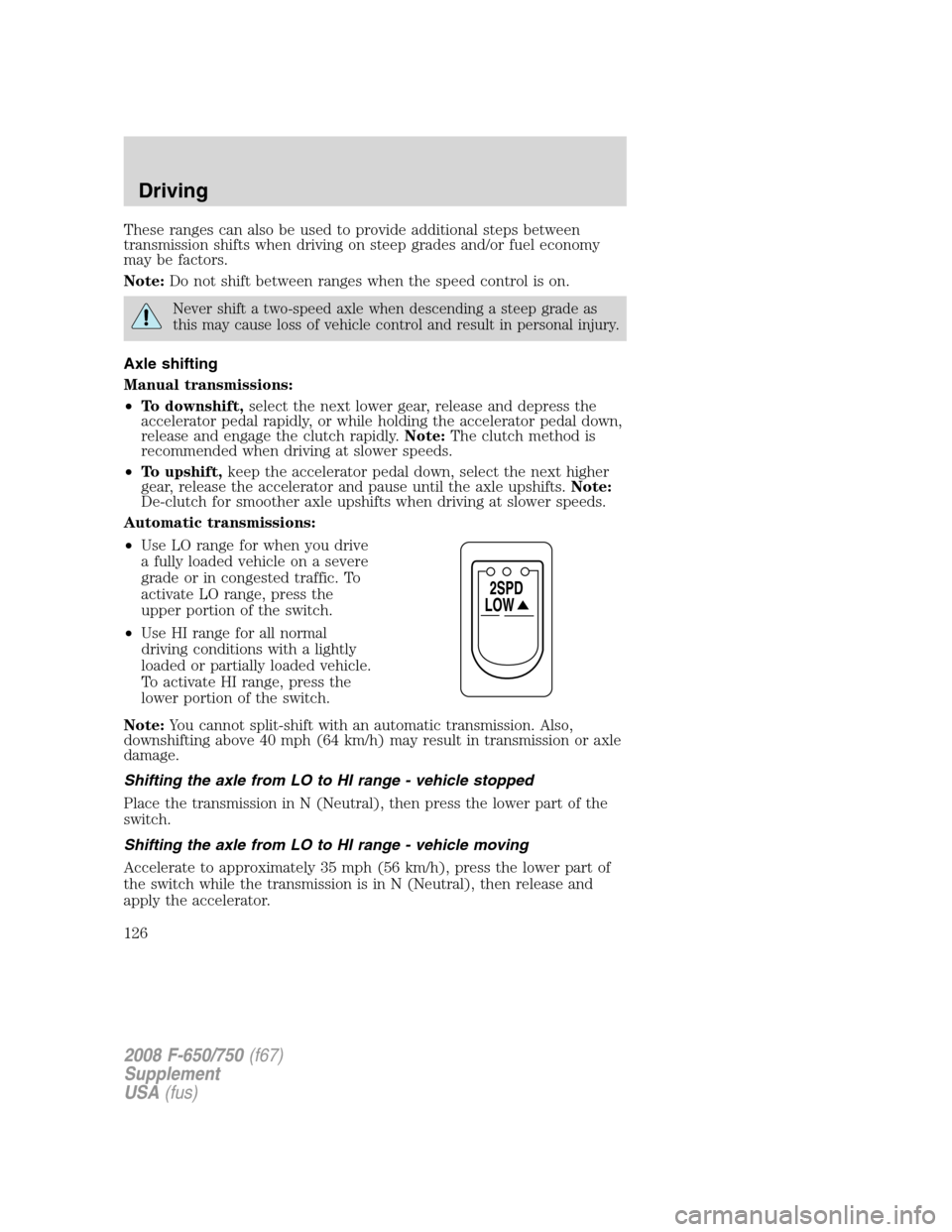

Automatic transmissions:

•Use LO range for when you drive

a fully loaded vehicle on a severe

grade or in congested traffic. To

activate LO range, press the

upper portion of the switch.

•Use HI range for all normal

driving conditions with a lightly

loaded or partially loaded vehicle.

To activate HI range, press the

lower portion of the switch.

Note:You cannot split-shift with an automatic transmission. Also,

downshifting above 40 mph (64 km/h) may result in transmission or axle

damage.

Shifting the axle from LO to HI range - vehicle stopped

Place the transmission in N (Neutral), then press the lower part of the

switch.

Shifting the axle from LO to HI range - vehicle moving

Accelerate to approximately 35 mph (56 km/h), press the lower part of

the switch while the transmission is in N (Neutral), then release and

apply the accelerator.

LOW

2SPD

2008 F-650/750(f67)

Supplement

USA(fus)

Driving

126

Page 131 of 273

Safety chains

Always connect the trailer’s safety chains to the frame or hook retainers

of the vehicle hitch. To connect the trailer’s safety chains, cross the

chains under the trailer tongue and allow slack for turning corners.

If you use a rental trailer, follow the instructions that the rental agency

gives to you.

Do not attach safety chains to the bumper.

Trailer brakes

Electric brakes and manual, automatic or surge-type trailer brakes are

safe if installed properly and adjusted to the manufacturer’s

specifications. The trailer brakes must meet local and Federal

regulations.

Do not connect a trailer’s hydraulic brake system directly to your

vehicle’s brake system. Your vehicle may not have enough

braking power and your chances of having a collision greatly increase.

Trailer lamps

Trailer lamps are required on most towed vehicles. Your vehicle may be

equipped with one of two possible trailer wiring designs. Make sure all

running lights, brake lights, turn signals and hazard lights are working.

See your dealer or trailer rental agency for proper instructions and

equipment for hooking up trailer lamps.

Driving while you tow

When towing a trailer:

•Keep your speed no faster than 70 mph (112 km/h) during the first

500 miles (800 km) of towing a trailer, and don’t make full throttle

starts.

•Turn off the speed control. The speed control may shut off

automatically when you are towing on long, steep grades.

•Consult your local motor vehicle speed regulations for towing a trailer.

•To eliminate excessive transmission shifting, use a lower gear. This will

also assist in transmission cooling.

•Anticipate stops and brake gradually.

•Do not exceed the GCWR rating or transmission damage may occur.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to yourScheduled Maintenance Guide

for more information.

2008 F-650/750(f67)

Supplement

USA(fus)

Driving

130

Page 132 of 273

Trailer towing tips

•Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

•Allow more distance for stopping with a trailer attached.

•If you are driving down a long or steep hill, shift to a lower gear. Do

not apply the brakes continuously, as they may overheat and become

less effective.

•The trailer tongue weight should be 10–15% of the loaded trailer

weight.

•If you will be towing a trailer frequently in hot weather, hilly

conditions, at GCW, or any combination of these factors, consider

refilling your rear axle with synthetic gear lube if not already so

equipped. Refer toLubricant specificationsin theMaintenance and

Specificationschapter for the lubricant specification. Remember that

regardless of the rear axle lube used, do not tow a trailer for the first

500 miles (800 km) of a new vehicle, and that the first 500 miles

(800 km) of towing be done at no faster than 70 mph (112 km/h) with

no full throttle starts.

•After you have traveled 50 miles (80 km), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

•To aid in engine/transmission cooling and A/C efficiency during hot

weather while stopped in traffic, place the gearshift lever in P (Park)

(if available on your automatic transmission) or N (Neutral) (manual

transmissions and automatic transmissions withoutaP[Park]

position).

•Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer’s wheels.

FIFTH WHEEL OPERATION

Failure to follow the fifth wheel manufacturer’s instructions for

hooking and unhooking as well as sliding the fifth wheel could

result in an accident, personal injury or death.

When the tractor and trailer are parked unattended, the trailer

brake hand control should never be used to apply the brake,

since air may leak from the system, allowing vehicle movement,

resulting in possible property damage, personal injury or death.

2008 F-650/750(f67)

Supplement

USA(fus)

Driving

131

Page 143 of 273

for the engine control module. Refer toAutomatic transmission

operationin theDrivingchapter andBatteryin theMaintenance and

Specificationschapter for more information.

JUMP STARTING

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your automatic transmission

vehicle. Automatic transmissions do not have push-start

capability. Attempting to push-start a vehicle with an automatic

transmission may cause transmission damage.

Before connecting a fast-charger, booster battery or installing a new

battery, make sure the ground polarities of the fast-charger, booster

battery or alternator (when installing a battery) are matched to the

ground polarity of the vehicle battery. Improper usage of the

fast-charger, hook-up of booster battery or installation of a new battery

can cause damage to the electrical system or to the alternator. Do not

attempt to polarize the alternator.

Preparing your vehicle

1.Use only a 12–volt supply to start your vehicle.Do not attach the

jumper cables to the glow plug relay as this could severely damage the

glow plugs, injector driver module and PCM.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

2008 F-650/750(f67)

Supplement

USA(fus)

Roadside Emergencies

142

Page 170 of 273

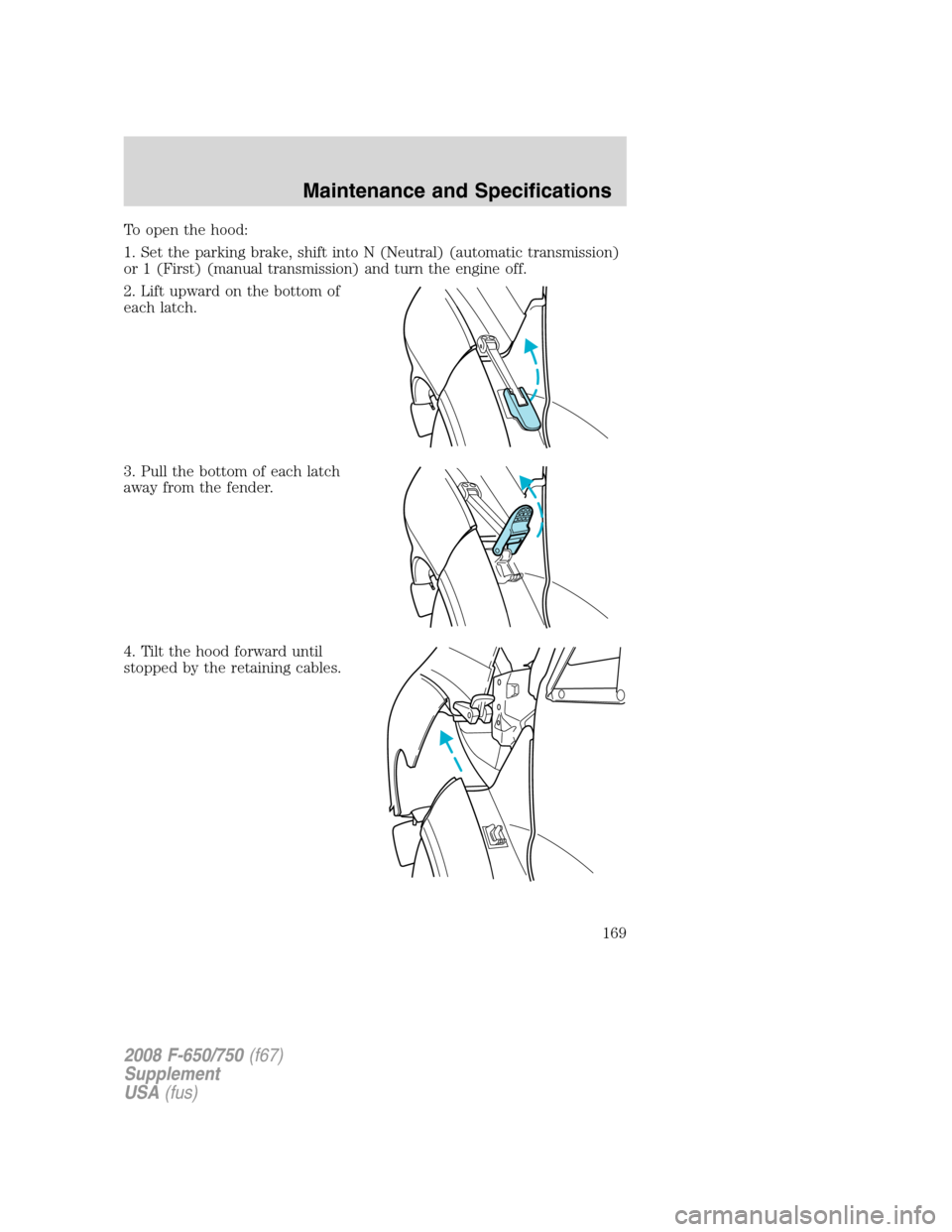

To open the hood:

1. Set the parking brake, shift into N (Neutral) (automatic transmission)

or 1 (First) (manual transmission) and turn the engine off.

2. Lift upward on the bottom of

each latch.

3. Pull the bottom of each latch

away from the fender.

4. Tilt the hood forward until

stopped by the retaining cables.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

169

Page 182 of 273

Conditions

•Carrying unnecessary weight may reduce fuel economy.

•Fuel economy may decrease with lower temperatures during the first

8–10 miles (12–16 km) of driving.

•Flat terrain driving improves fuel economy over hilly roads.

•Transmissions give their best fuel economy when operated in the top

cruise gear and with steady pressure on the accelerator.

•Close windows for highway driving.

DIESEL PARTICULATE FILTER (DPF)

Your vehicle is equipped with a diesel particulate filter (DPF), as part of

the after-treatment exhaust system, to trap soot and other large particles

produced by the engine combustion process. The soot that accumulates

in the filter must be periodically reduced to ash to prevent excessive

exhaust restriction. The soot reduction process, also known as “filter

regeneration,” is generally performed automatically by your engine and

after-treatment system.

The normal operating temperature of the exhaust system is very

high. Never work around, or attempt to repair, any part of the

exhaust system until it has cooled. Use special care when working

around the diesel particulate filter. The DPF heats up to a high

temperature after only a short period of engine operation, and can

remain hot even after the engine is turned off. Failure to follow these

instructions may result in personal injury.

Diesel particulate filter regeneration (Caterpillar engine only)

DPF regeneration requires no operator interaction and may occur at any

time. A small increase in engine sound-level during filter regeneration is

normal and should be no reason for concern.

A separate fuel injector/nozzle, which requires periodic cleaning, is used

in the regeneration process. Refer to Caterpillar’sOperation and

Maintenance Manualfor details regarding cleaning requirements.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

181

Page 184 of 273

Instrument cluster lamp(s) will

illuminate and/or flash when

operator assistance is required. In

addition, engine performance will

become increasingly limited above

Level 1.

At Levels 1 and 2, two courses of action may be taken by the operator to

facilitate filter regeneration:

1. The vehicle may be driven on the highway at highway speeds,

2. The operator may perform a parked regeneration by following the

steps inParked regeneration procedure (Cummins engine only).

At Level 3, performing a parked regeneration is the only available course

of action (short of professional servicing) available to the operator for

regenerating the filter. At Level 4, professional servicing is the only way

to regenerate the filter.

Parked regeneration procedure (Cummins engine only)

When performing the parked regeneration procedure, make

certain the vehicle is safely off roadway, and the exhaust system

is away from people, or any flammable materials, vapors, or structures.

Engine speed may increase during parked regeneration.

Note:Parked regeneration is only available when the DPF lamp on the

instrument cluster is illuminated (solid or flashing).

1. Bring the vehicle to a complete stop on level ground and safely off the

road with the exhaust system away from people, flammable materials,

vapors or structures.

2. If your vehicle is equipped with an automatic transmission and a

steering column shift lever, place transmission in P (Park). Otherwise,

place the transmission in N (Neutral).

3. Remove feet from the accelerator pedal and clutch pedal (if

equipped).

4. Set the parking brake.

5.Within 5 seconds of setting the parking brake,remove foot from

the service brake pedal.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

183

Page 187 of 273

•Check for proper operation of radiator shutters, if equipped. The

shutters should be open during normal operating temperatures.

Engine and Driveline System

•Transmission Enclosure:inspect for cracks, holes, and tears. Clean

any deposits such as oil, dirt, and stones.

•Engine valve covers and block covers are made to damp out engine

mechanical noise and, if needed, should be replaced with

recommended parts. Check for mechanical isolations.

Exhaust System

•Inspect the exhaust system for leaks at various joint connections and

tighten the clamps.

•Do a visual inspection for cracks or holes in the muffler and tail pipe.

•Always use the recommended parts when items need to be replaced.

•The tail pipe elbow or offset tail pipe orientation must not be changed

from the standard position as originally received.

•To avoid abnormal changes in vehicle sound levels, it is necessary for

the owner to perform inspections and necessary maintenance at the

intervals shown in theScheduled Maintenance Guidechapter.

POWER STEERING FLUID

Check the power steering fluid level using the following procedure. If

adding fluid is necessary, refer toLubricant Specificationsin this

chapter for the proper fluid type. Refer to theScheduled Maintenance

Guidechapter for the recommended service intervals.

1. Set the parking brake, shift into N (Neutral) (automatic transmission)

or 1 (First) (manual transmission) and turn the engine off.

2. Open the hood.

3. Clean the top of the power steering fluid reservoir.

4. Remove the dipstick from the reservoir and wipe the dipstick clean.

5. Reinstall the dipstick. Remove it again and check the fluid level.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

186

Page 191 of 273

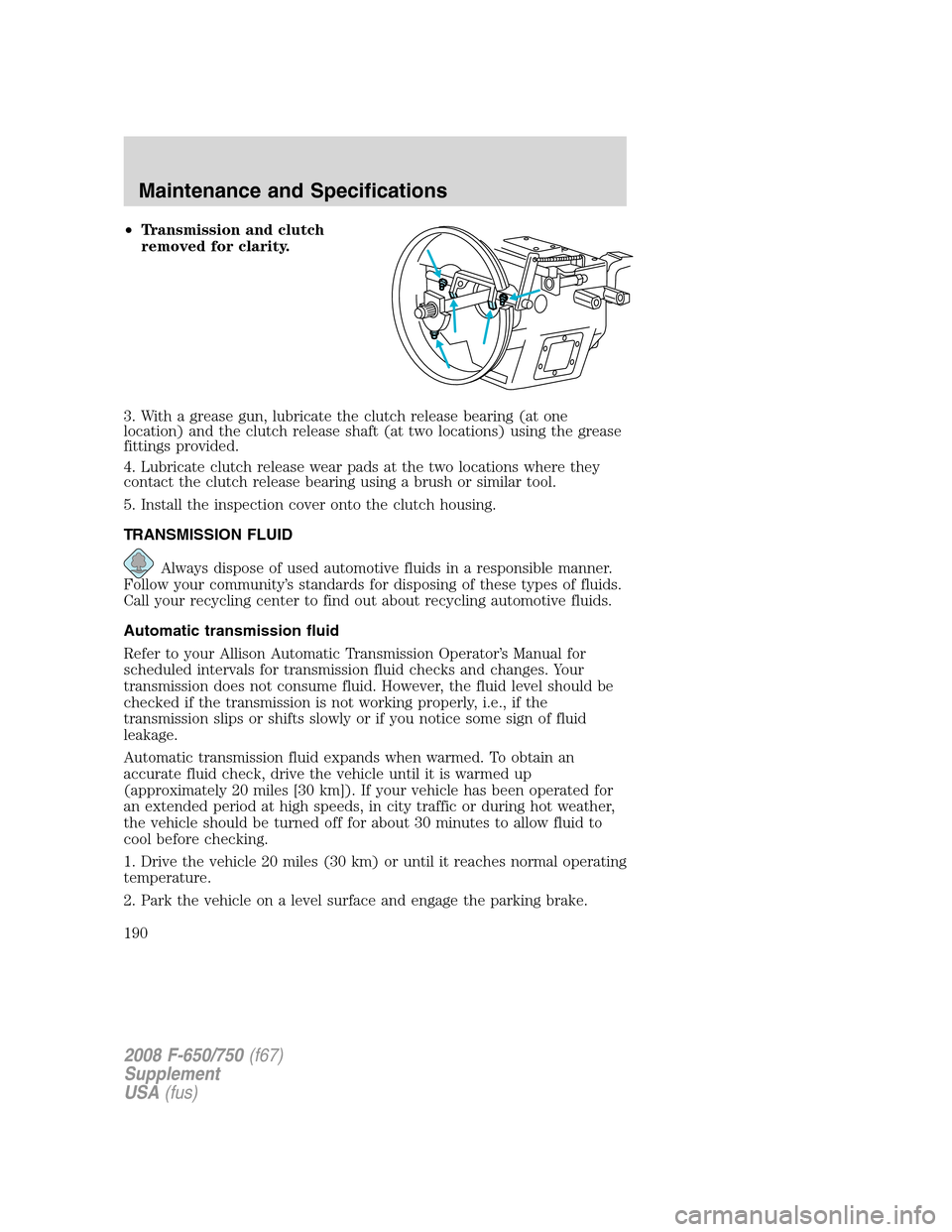

•Transmission and clutch

removed for clarity.

3. With a grease gun, lubricate the clutch release bearing (at one

location) and the clutch release shaft (at two locations) using the grease

fittings provided.

4. Lubricate clutch release wear pads at the two locations where they

contact the clutch release bearing using a brush or similar tool.

5. Install the inspection cover onto the clutch housing.

TRANSMISSION FLUID

Always dispose of used automotive fluids in a responsible manner.

Follow your community’s standards for disposing of these types of fluids.

Call your recycling center to find out about recycling automotive fluids.

Automatic transmission fluid

Refer to your Allison Automatic Transmission Operator’s Manual for

scheduled intervals for transmission fluid checks and changes. Your

transmission does not consume fluid. However, the fluid level should be

checked if the transmission is not working properly, i.e., if the

transmission slips or shifts slowly or if you notice some sign of fluid

leakage.

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is warmed up

(approximately 20 miles [30 km]). If your vehicle has been operated for

an extended period at high speeds, in city traffic or during hot weather,

the vehicle should be turned off for about 30 minutes to allow fluid to

cool before checking.

1. Drive the vehicle 20 miles (30 km) or until it reaches normal operating

temperature.

2. Park the vehicle on a level surface and engage the parking brake.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

190

Page 192 of 273

3. With the parking brake engaged and your foot on the brake pedal,

start the engine and move the gearshift lever through all of the gear

ranges. Allow sufficient time for each gear to engage.

4. Place the gearshift lever in N (Neutral) or P (Park) and leave the

engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lint free rag.

6. Install the dipstick making sure it is fully seated in the filler tube.

7. Remove the dipstick and inspect the fluid level.

If you must add transmission fluid, make sure the correct type of fluid is

being used. The type of fluid used is indicated in your Allison Automatic

Transmission Operator’s Manual.

Fluid levels above the safe range may result in transmission failure; an

overfill condition of transmission fluid may cause shift and/or

engagement concerns and/or possible damage.

Use of a non-approved automatic transmission fluid may cause

internal transmission component damage.

Manual transmission fluid

Refer to theScheduled Maintenance Guidechapter for transmission

fluid level checks and fluid change intervals.

Your manual transmission may be filled with an optional synthetic fluid

which allows the use of extended service intervals. A tag on the filler

plug will identify the use of the synthetic fluid.

Use only fluid that meets manufacturer specifications (refer to

Lubricant specificationsin this chapter.

Use of a non-approved transmission fluid may cause internal

transmission component damage.

Check your transmission fluid level using the following procedure:

1. Park the vehicle on level ground.

2. Set the parking brake and shift into 1 (First) and turn the engine off.

3. Clean any dirt from around the filler plug.

4. Remove the filler plug and inspect the fluid level.

5. The fluid level should be up to the bottom of the filler plug opening.

6. If necessary, add enough fluid through the filler plug opening so that

the fluid level is at the bottom of the opening.

7. Clean and install the filler plug securely.

2008 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

191