engine FORD F650 2010 12.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2010, Model line: F650, Model: FORD F650 2010 12.GPages: 274, PDF Size: 1.51 MB

Page 128 of 274

pressure on the gearshift lever will help the synchronizer perform its job

more quickly. If the gearshift lever is forced into position, this action

defeats the purpose of the synchronizer by causing gear clash.

Shifting with a non-synchronized transmission

Refer toClutch brakeandDouble clutch proceduresin theClutch

section of this chapter.

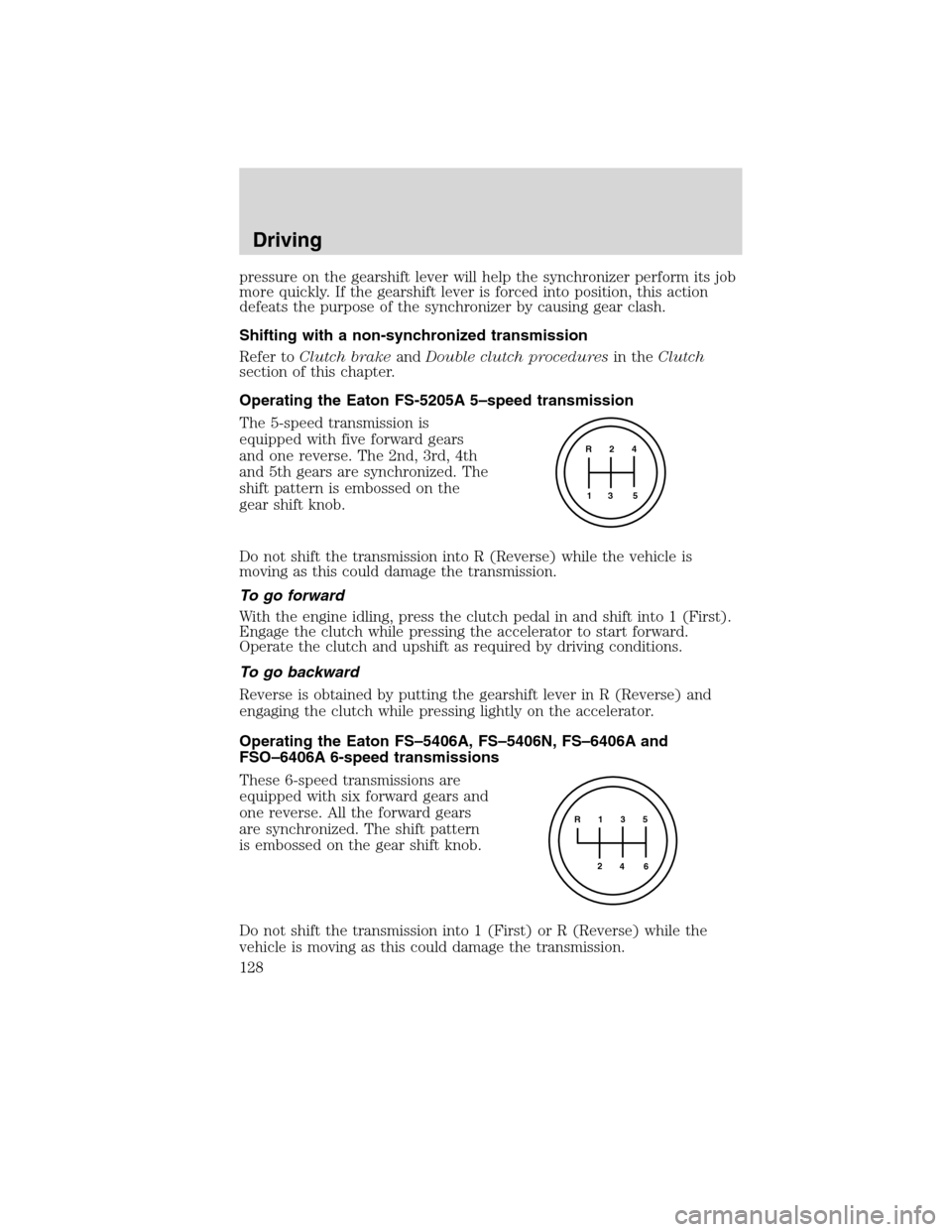

Operating the Eaton FS-5205A 5–speed transmission

The 5-speed transmission is

equipped with five forward gears

and one reverse. The 2nd, 3rd, 4th

and 5th gears are synchronized. The

shift pattern is embossed on the

gear shift knob.

Do not shift the transmission into R (Reverse) while the vehicle is

moving as this could damage the transmission.

To go forward

With the engine idling, press the clutch pedal in and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

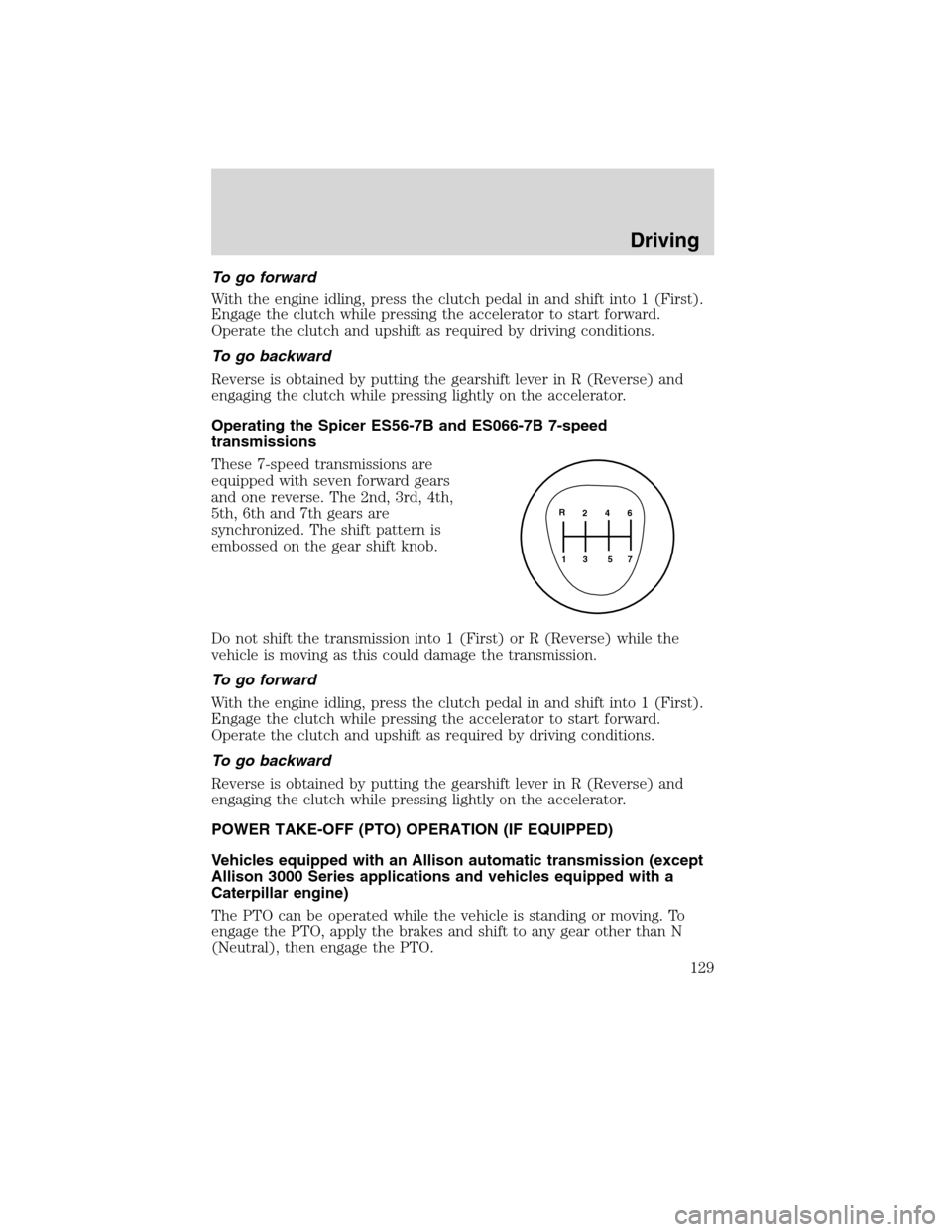

Operating the Eaton FS–5406A, FS–5406N, FS–6406A and

FSO–6406A 6-speed transmissions

These 6-speed transmissions are

equipped with six forward gears and

one reverse. All the forward gears

are synchronized. The shift pattern

is embossed on the gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

R 2 4

3 5 1

R 1 3 5

4

6 2

Driving

128

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 129 of 274

To go forward

With the engine idling, press the clutch pedal in and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

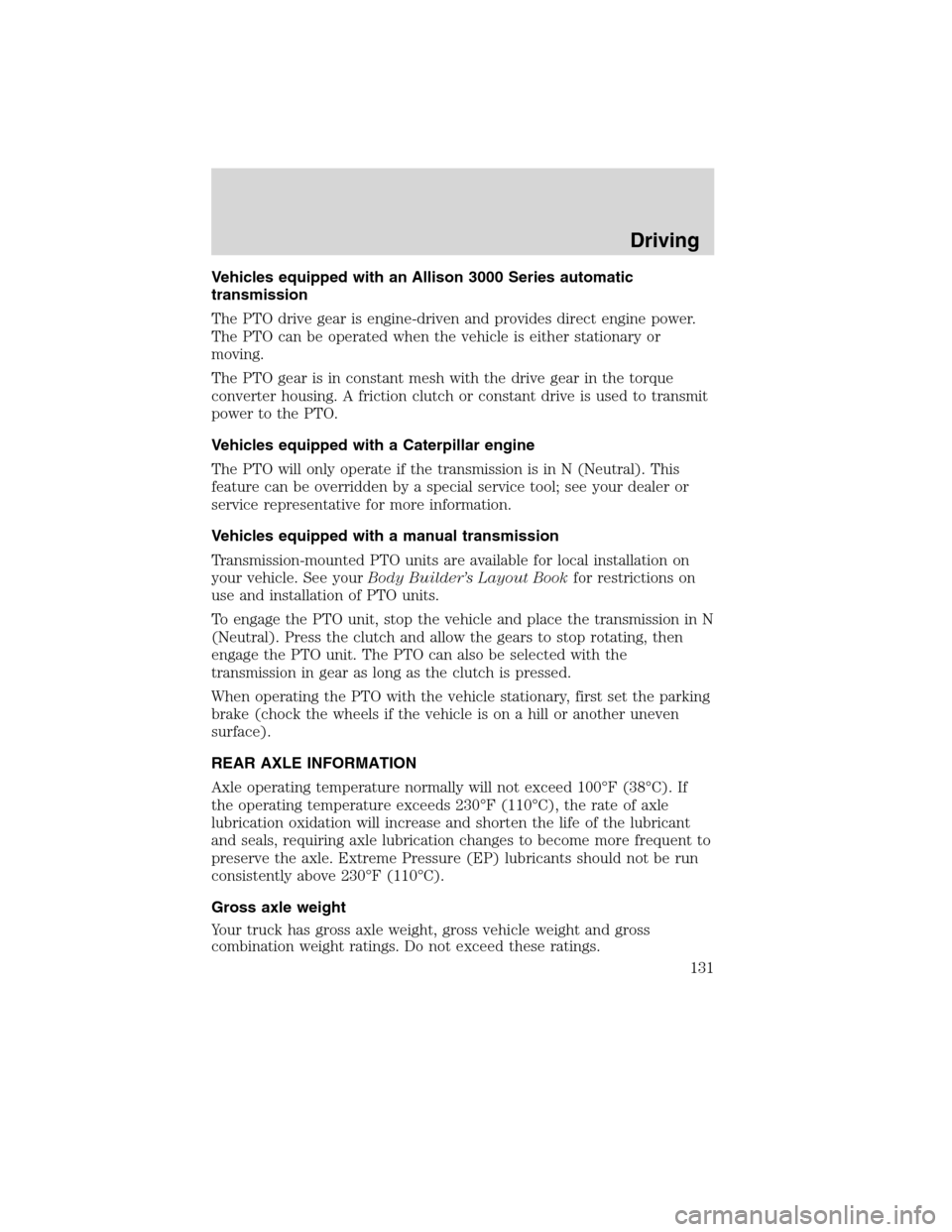

Operating the Spicer ES56-7B and ES066-7B 7-speed

transmissions

These 7-speed transmissions are

equipped with seven forward gears

and one reverse. The 2nd, 3rd, 4th,

5th, 6th and 7th gears are

synchronized. The shift pattern is

embossed on the gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

To go forward

With the engine idling, press the clutch pedal in and shift into 1 (First).

Engage the clutch while pressing the accelerator to start forward.

Operate the clutch and upshift as required by driving conditions.

To go backward

Reverse is obtained by putting the gearshift lever in R (Reverse) and

engaging the clutch while pressing lightly on the accelerator.

POWER TAKE-OFF (PTO) OPERATION (IF EQUIPPED)

Vehicles equipped with an Allison automatic transmission (except

Allison 3000 Series applications and vehicles equipped with a

Caterpillar engine)

The PTO can be operated while the vehicle is standing or moving. To

engage the PTO, apply the brakes and shift to any gear other than N

(Neutral), then engage the PTO.

2 4 6

3 5 71 R

Driving

129

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 130 of 274

If engagement is prevented by the gear teeth not meshing properly,

release the brakes and allow the vehicle to creep slightly or shift the

selector to N (Neutral) and then back into gear. The PTO should never

be engaged by clashing the gear teeth as this may damage the PTO unit

and the transmission PTO drive gear teeth. This could result in further

damage to the transmission and PTO.

PTO operation with vehicle stationary

Stop the vehicle, idle the engine and set the parking brake. Make sure

the gear selector is in any forward drive range, then engage the PTO.

After the PTO is engaged, move the range selector to N (Neutral).

Increase the engine speed until the desired power take-off operation

speed is obtained. To disengage the PTO after operation with the vehicle

standing, release the throttle, allow the drive equipment to come to a

stop, and then disengage the PTO.

WARNING:When the PTO is operated with the vehicle

stationary, the transmission must be placed in N (Neutral) with

the parking brake set. If the transmission is not in N (Neutral) and is

equipped with a remote throttle control, an increase in engine speed

can overpower the parking brake and cause the vehicle to move,

possibly resulting in personal injury and/or property damage.

PTO operation while vehicle is moving

After the PTO is engaged for driven vehicle operation, shift to the

desired range and drive the vehicle. The speed of the PTO, during this

period of operation, will always maintain direct relation to vehicle speed.

PTO speed will decrease in relation to vehicle (transmission output)

speed as shifts to a higher gear occur. When operating the PTO while the

vehicle is moving, the PTO may be disengaged whenever it is no longer

required. When there is no load on the PTO gear, it can be pulled out of

engagement.

Vehicles equipped with an Eaton UltraShift transmission

Refer to the operationTransmission Power Take Offsection of the

UltraShift Driver Instructions Manual.

Driving

130

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 131 of 274

Vehicles equipped with an Allison 3000 Series automatic

transmission

The PTO drive gear is engine-driven and provides direct engine power.

The PTO can be operated when the vehicle is either stationary or

moving.

The PTO gear is in constant mesh with the drive gear in the torque

converter housing. A friction clutch or constant drive is used to transmit

power to the PTO.

Vehicles equipped with a Caterpillar engine

The PTO will only operate if the transmission is in N (Neutral). This

feature can be overridden by a special service tool; see your dealer or

service representative for more information.

Vehicles equipped with a manual transmission

Transmission-mounted PTO units are available for local installation on

your vehicle. See yourBody Builder’s Layout Bookfor restrictions on

use and installation of PTO units.

To engage the PTO unit, stop the vehicle and place the transmission in N

(Neutral). Press the clutch and allow the gears to stop rotating, then

engage the PTO unit. The PTO can also be selected with the

transmission in gear as long as the clutch is pressed.

When operating the PTO with the vehicle stationary, first set the parking

brake (chock the wheels if the vehicle is on a hill or another uneven

surface).

REAR AXLE INFORMATION

Axle operating temperature normally will not exceed 100°F (38°C). If

the operating temperature exceeds 230°F (110°C), the rate of axle

lubrication oxidation will increase and shorten the life of the lubricant

and seals, requiring axle lubrication changes to become more frequent to

preserve the axle. Extreme Pressure (EP) lubricants should not be run

consistently above 230°F (110°C).

Gross axle weight

Your truck has gross axle weight, gross vehicle weight and gross

combination weight ratings. Do not exceed these ratings.

Driving

131

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 132 of 274

WARNING:Exceeding these ratings by overloading can cause

component failure resulting in property damage, personal injury

or death.

Rear axles with locking or limited-slip differentials (if equipped)

If your vehicle is equipped with a locking or limited-slip differential, note

the following:

•Power will be transmitted to the opposite wheel should one of the

wheels begin to slip.

•Both wheels must be raised off the ground should it be necessary to

operate one wheel with the vehicle stationary.

WARNING:If both wheels are not raised off the ground, the

one wheel that is not raised may pull the vehicle off its support,

possibly resulting in personal injury

Driver-controlled differential lock

To prevent the vehicle from moving when servicing the wheels, tires or

brakes, turn the engine off and raise all drive wheels of the locker

differential axle. Axles equipped with NoSPIN Detroit Locker differentials

deliver power to both wheels even when only one wheel is on the

ground.

WARNING:Failure to raise all drive wheels with this type of

differential could cause the vehicle to move unexpectedly,

resulting in property damage, personal injury or death.

Care should be taken to avoid sudden accelerations when both drive

wheels are on a slippery surface.

WARNING:Sudden accelerations on slippery surfaces could

cause the wheels to spin, the vehicle to turn sideways on a

crowned road surface or in a turn, possibly resulting in loss of vehicle

control and personal injury.

Some Dana/Spicer drive axles have a driver-controlled differential lock.

The differential lock can lock or unlock the differential when the vehicle

is moving or stopped. When extra traction is required, the differential

lock will provide full power to both axles.

Driving

132

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 137 of 274

Unloaded or lightly loaded vehicles

The braking system has been designed to safely stop your vehicle when

fully loaded to its GVWR.

WARNING:When operating empty or lightly loaded, sudden or

hard braking may induce wheel lockup with loss of vehicle

control and the possibility of accident and serious injury, especially on

wet or slippery road surfaces.

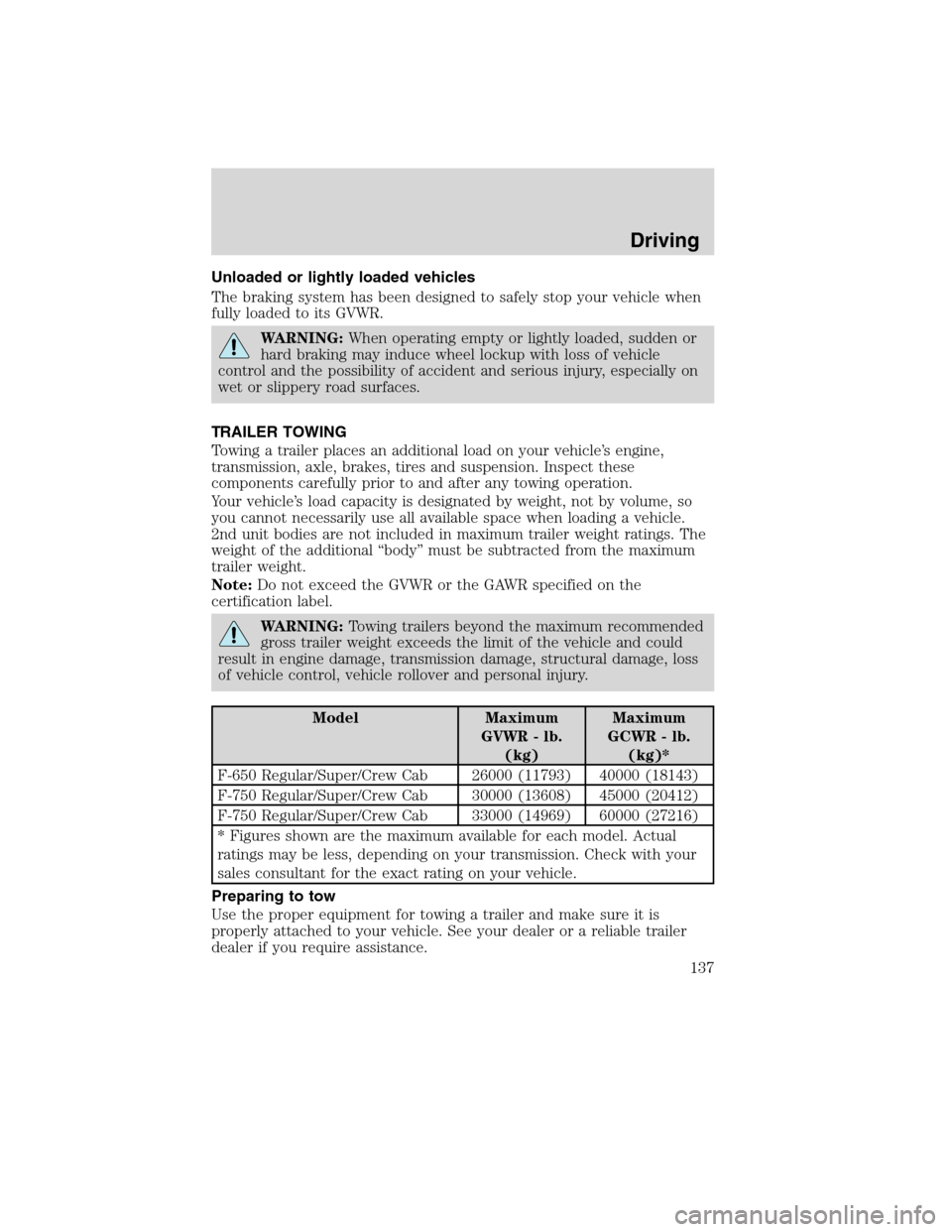

TRAILER TOWING

Towing a trailer places an additional load on your vehicle’s engine,

transmission, axle, brakes, tires and suspension. Inspect these

components carefully prior to and after any towing operation.

Your vehicle’s load capacity is designated by weight, not by volume, so

you cannot necessarily use all available space when loading a vehicle.

2nd unit bodies are not included in maximum trailer weight ratings. The

weight of the additional “body” must be subtracted from the maximum

trailer weight.

Note:Do not exceed the GVWR or the GAWR specified on the

certification label.

WARNING:Towing trailers beyond the maximum recommended

gross trailer weight exceeds the limit of the vehicle and could

result in engine damage, transmission damage, structural damage, loss

of vehicle control, vehicle rollover and personal injury.

Model Maximum

GVWR - lb.

(kg)Maximum

GCWR - lb.

(kg)*

F-650 Regular/Super/Crew Cab 26000 (11793) 40000 (18143)

F-750 Regular/Super/Crew Cab 30000 (13608) 45000 (20412)

F-750 Regular/Super/Crew Cab 33000 (14969) 60000 (27216)

* Figures shown are the maximum available for each model. Actual

ratings may be less, depending on your transmission. Check with your

sales consultant for the exact rating on your vehicle.

Preparing to tow

Use the proper equipment for towing a trailer and make sure it is

properly attached to your vehicle. See your dealer or a reliable trailer

dealer if you require assistance.

Driving

137

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 139 of 274

•To eliminate excessive transmission shifting, use a lower gear. This will

also assist in transmission cooling.

•Anticipate stops and brake gradually.

•Do not exceed the GCWR rating or transmission damage may occur.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to yourScheduled Maintenance Guide

for more information.

Trailer towing tips

•Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

•Allow more distance for stopping with a trailer attached.

•If you are driving down a long or steep hill, shift to a lower gear. Do

not apply the brakes continuously, as they may overheat and become

less effective.

•The trailer tongue weight should be 10–15% of the loaded trailer

weight.

•If you will be towing a trailer frequently in hot weather, hilly

conditions, at GCW, or any combination of these factors, consider

refilling your rear axle with synthetic gear lube if not already so

equipped. Refer toLubricant specificationsin theMaintenance and

Specificationschapter for the lubricant specification. Remember that

regardless of the rear axle lube used, do not tow a trailer for the first

500 miles (800 km) of a new vehicle, and that the first 500 miles

(800 km) of towing be done at no faster than 70 mph (112 km/h) with

no full throttle starts.

•After you have traveled 50 miles (80 km), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

•To aid in engine/transmission cooling and A/C efficiency during hot

weather while stopped in traffic, place the gearshift lever in P (Park)

(if available on your automatic transmission) or N (Neutral) (manual

transmissions and automatic transmissions withoutaP[Park]

position).

•Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer’s wheels.

Driving

139

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 144 of 274

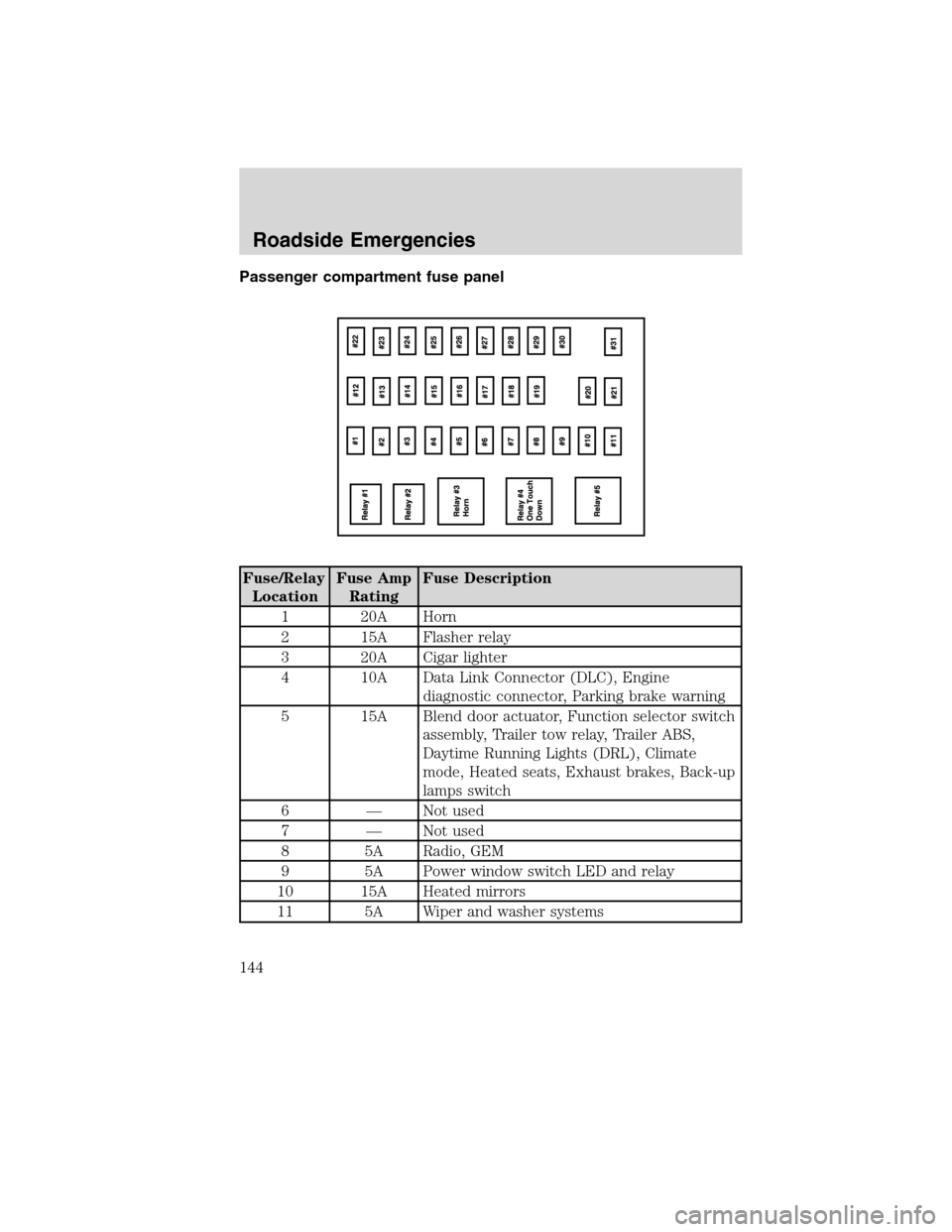

Passenger compartment fuse panel

Fuse/Relay

LocationFuse Amp

RatingFuse Description

1 20A Horn

2 15A Flasher relay

3 20A Cigar lighter

4 10A Data Link Connector (DLC), Engine

diagnostic connector, Parking brake warning

5 15A Blend door actuator, Function selector switch

assembly, Trailer tow relay, Trailer ABS,

Daytime Running Lights (DRL), Climate

mode, Heated seats, Exhaust brakes, Back-up

lamps switch

6 — Not used

7 — Not used

8 5A Radio, GEM

9 5A Power window switch LED and relay

10 15A Heated mirrors

11 5A Wiper and washer systems

Roadside Emergencies

144

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 145 of 274

Fuse/Relay

LocationFuse Amp

RatingFuse Description

12 10A Brake pedal position switch, Transmission

shift selector, Stoplamp switch, Cruise

switches

13 20A Cluster, Radio

14 10A Interior lamp relay

15 10A Interior lamp relay, Vanity mirror lamps,

Generic Electronic Module (GEM)

16 15A High beams, Indicator

17 — Not used

18 5A Headlamp switch interior lighting

19 15A Engine control

20 5A Starting system

21 10A DRL resistor

22 15A Air horn, Air suspension dump, Two-speed

axle, Driver-controlled locking differential

23 10A Flasher relay

24 15A Vacuum pump motor, ABS relay, Fuel heater

relay, Air dryer

25 10A Function selector switch assembly

26 10A Right hand low beam headlamp

27 — Not used

28 10A Left hand low beam headlamp

29 10A Cluster, GEM

30 15A Allison electronic transmission

31 — Not used

Relay 1 — Interior lamps

Relay 2 — Not used

Relay 3 — Horn

Relay 4 — One-touch down window

Relay 5 — Not used

Roadside Emergencies

145

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)

Page 146 of 274

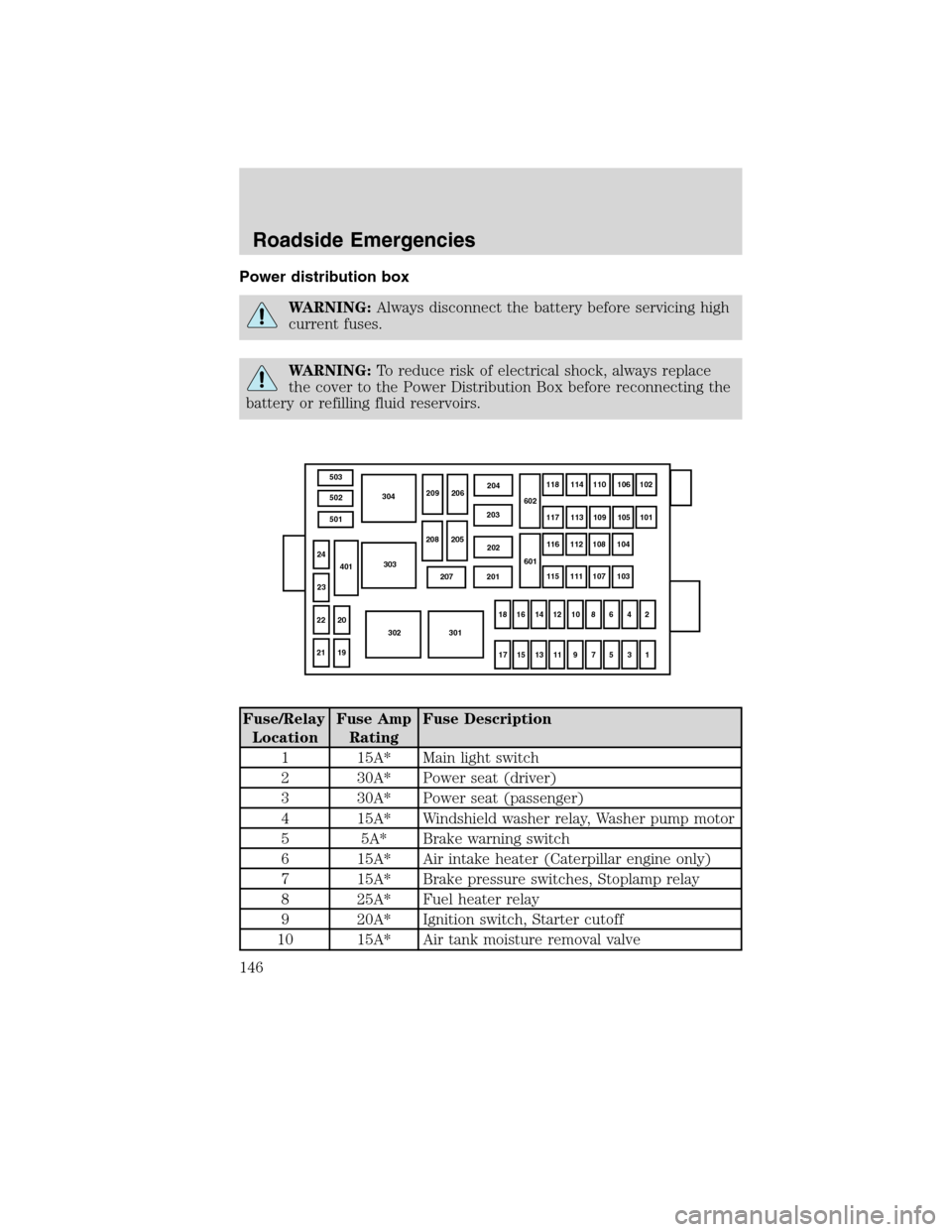

Power distribution box

WARNING:Always disconnect the battery before servicing high

current fuses.

WARNING:To reduce risk of electrical shock, always replace

the cover to the Power Distribution Box before reconnecting the

battery or refilling fluid reservoirs.

Fuse/Relay

LocationFuse Amp

RatingFuse Description

1 15A* Main light switch

2 30A* Power seat (driver)

3 30A* Power seat (passenger)

4 15A* Windshield washer relay, Washer pump motor

5 5A* Brake warning switch

6 15A* Air intake heater (Caterpillar engine only)

7 15A* Brake pressure switches, Stoplamp relay

8 25A* Fuel heater relay

9 20A* Ignition switch, Starter cutoff

10 15A* Air tank moisture removal valve

503

502

501304

303

302 301

2119 22 2024

23401

207 201202 203204

209 206

208 205602

601118114

110106

102

117 113 109105

101

116 112 108104

115 111 107103

18 16

14 12 10 864

2

17 15

13 11 9 753

1

Roadside Emergencies

146

2010 F-650/750(f67)

Supplement(supplement), 1st Printing

USA(fus)