warning FORD F650 2011 12.G Manual Online

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: F650, Model: FORD F650 2011 12.GPages: 290, PDF Size: 1.96 MB

Page 141 of 290

Operating the Spicer ES56-7B and ES066-7B 7-speed

transmissions

These 7-speed transmissions are

equipped with seven forward gears

and one reverse. Gears 2–7 are

synchronized. The shift pattern is

embossed on the gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

POWER TAKE-OFF (PTO) OPERATION (IF EQUIPPED)

Vehicles equipped with an Allison automatic transmission (except

Allison 3000 Series applications)

The PTO can be operated while the vehicle is standing or moving. To

engage the PTO, apply the brakes and shift to any gear other than N

(Neutral), then engage the PTO.

If engagement is prevented by the gear teeth not meshing properly,

release the brakes and allow the vehicle to creep slightly or shift the

selector to N (Neutral) and then back into gear. The PTO should never

be engaged by clashing the gear teeth as this may damage the PTO unit

and the transmission PTO drive gear teeth. This could result in further

damage to the transmission and PTO.

PTO operation with vehicle stationary

Stop the vehicle, idle the engine and set the parking brake. Make sure

the gear selector is in any forward drive range, then engage the PTO.

After the PTO is engaged, move the range selector to N (Neutral).

Increase the engine speed until the desired power take-off operation

speed is obtained. To disengage the PTO after operation with the vehicle

standing, release the throttle, allow the drive equipment to come to a

stop, and then disengage the PTO.

WARNING:When the PTO is operated with the vehicle

stationary, the transmission must be placed in N (Neutral) with

the parking brake set. If the transmission is not in N (Neutral) and is

equipped with a remote throttle control, an increase in engine speed

can overpower the parking brake and cause the vehicle to move,

possibly resulting in personal injury and/or property damage.

2 4 6

3 5 71 R

Driving

141

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 143 of 290

REAR AXLE INFORMATION

Axle operating temperature normally will not exceed 100°F (38°C). If

the operating temperature exceeds 230°F (110°C), the rate of axle

lubrication oxidation will increase and shorten the life of the lubricant

and seals, requiring axle lubrication changes to become more frequent to

preserve the axle. Extreme Pressure (EP) lubricants should not be run

consistently above 230°F (110°C).

Gross axle weight

Your truck has gross axle weight, gross vehicle weight and gross

combination weight ratings. Do not exceed these ratings.

WARNING:Exceeding these ratings by overloading can cause

component failure resulting in property damage, personal injury

or death.

Rear axles with locking or limited-slip differentials (if equipped)

If your vehicle is equipped with a locking or limited-slip differential, note

the following:

•Power will be transmitted to the opposite wheel should one of the

wheels begin to slip.

•Both wheels must be raised off the ground should it be necessary to

operate one wheel with the vehicle stationary.

WARNING:If both wheels are not raised off the ground, the

one wheel that is not raised may pull the vehicle off its support,

possibly resulting in personal injury

Driver-controlled differential lock

To prevent the vehicle from moving when servicing the wheels, tires or

brakes, turn the engine off and raise all drive wheels of the locker

differential axle. Axles equipped with NoSPIN Detroit Locker differentials

deliver power to both wheels even when only one wheel is on the

ground.

WARNING:Failure to raise all drive wheels with this type of

differential could cause the vehicle to move unexpectedly,

resulting in property damage, personal injury or death.

Driving

143

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 144 of 290

Care should be taken to avoid sudden accelerations when both drive

wheels are on a slippery surface.

WARNING:Sudden accelerations on slippery surfaces could

cause the wheels to spin, the vehicle to turn sideways on a

crowned road surface or in a turn, possibly resulting in loss of vehicle

control and personal injury.

Some drive axles have a driver-controlled differential lock. The

differential lock can lock or unlock the differential when the vehicle is

moving or stopped. When extra traction is required, the differential lock

will provide full power to both axles.

When the differential is locked, the vehicle’s turning radius will increase

(vehicle will “under-steer”)

The differential can be locked or unlocked when the vehicle is moving at

a constant speed of less than 25 mph (40 km/h) and while the wheels

are not slipping. The differential must not be locked when the vehicle is

traveling down steep grades and traction is minimal.

Note:Never use the differential lock at vehicle speeds above 25 mph

(40 km/h).

The differential lock and differential lock light will automatically

disengage at speeds above 25 mph (40 km/h). The differential lock will

remain off until either the vehicle is restarted or the differential lock

switch is turned off then back on.

Axle conversions

It is not recommended, or approved, for axle conversions to be

performed. However, it is understood that, on occasion, aftermarket

add-on axles are installed by others on the truck chassis which allow

operator control for weight transfer from other axles (i.e., air lift axles).

WARNING:When operating a loaded vehicle, the driver must

keep all adjustable axles on the ground at all times, supporting

their share of the vehicle’s load. Failure to do so can overload other

axles, tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

Driving

144

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 145 of 290

TWO-SPEED REAR AXLE (IF EQUIPPED)

A two-speed rear axle allows the

driver to select a LO range for

greater pulling power and a HI

range for greater road speed and

fuel economy. These ranges can also

be used to provide additional steps

between transmission shifts when

driving on steep grades and/or fuel

economy may be factors.

Note:Do not shift between ranges

when the speed control is on.

WARNING:Never shift a two-speed axle when descending a

steep grade as this may cause loss of vehicle control and result

in personal injury.

Axle shifting

Manual transmissions:

•To downshift,select the next lower gear, release and press the

accelerator pedal rapidly, or while holding the accelerator pedal down,

release and engage the clutch rapidly.Note:The clutch method is

recommended when driving at slower speeds.

•To upshift,keep the accelerator pedal down, select the next higher

gear, release the accelerator and pause until the axle upshifts.Note:

De-clutch for smoother axle upshifts when driving at slower speeds.

Automatic transmissions:

•Use LO range for when you drive

a fully loaded vehicle on a severe

grade or in congested traffic. To

activate LO range, press the

upper portion of the switch.

•Use HI range for all normal

driving conditions with a lightly

loaded or partially loaded vehicle.

To activate HI range, press the

lower portion of the switch.

2SPD

LOW

HIGH

2SPD

LOW

HIGH

Driving

145

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 147 of 290

High End

To use the two-speed axle as a high end ratio-extender, stay in the LO

range for normal upshifts and only shift the axle to HI on the freeway for

greater road speed.

Transmission (5-speed) 1st 2nd 3rd 4th 5th 6th

Two-speed axle Low for gradeability Axle high

MAXIMUM VEHICLE LOADING

Every vehicle manufactured by Ford Motor Company is supplied with

information on the Safety Compliance Certification Label, located on

either the B-pillar or the driver’s door edge, listing the maximum loading

for the vehicle (GVWR), and its axle systems (GAWR) at the tire to

ground interface.

Under no circumstances should your vehicle be loaded in excess of the

GVWR or GAWR. It is the operator’s responsibility to ensure that neither

the axle capacities, spring capacities, tire capacities nor the vehicle rated

GVWR is exceeded.

WARNING:Do not exceed the GVWR or the GAWR specified on

the Safety Compliance Certification Label.

Driving

147

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 148 of 290

WARNING:Do not use replacement tires with lower load

carrying capacities than the originals because they may lower

the vehicle’s GVWR and GAWR limitations. Replacement tires with a

higher limit than the originals do not increase the GVWR and GAWR

limitations.

WARNING:Exceeding any vehicle weight rating limitation could

result in serious damage to the vehicle and/or personal injury.

Unloaded or lightly loaded vehicles

The braking system has been designed to safely stop your vehicle when

fully loaded to its GVWR.

WARNING:When operating empty or lightly loaded, sudden or

hard braking may induce wheel lockup with loss of vehicle

control and the possibility of accident and serious injury, especially on

wet or slippery road surfaces.

TRAILER TOWING

Towing a trailer places an additional load on your vehicle’s engine,

transmission, axle, brakes, tires and suspension. Inspect these

components carefully prior to and after any towing operation.

Consult your local motor vehicle speed regulations for towing a trailer.

Your vehicle’s load capacity is designated by weight, not by volume, so

you cannot necessarily use all available space when loading a vehicle.

2nd unit bodies are not included in maximum trailer weight ratings. The

weight of the additional “body” must be subtracted from the maximum

trailer weight.

Note:Do not exceed the GVWR or the GAWR specified on the

certification label.

Note:Do not exceed the GCWR rating or transmission damage may

occur.

WARNING:Towing trailers beyond the maximum recommended

gross trailer weight exceeds the limit of the vehicle and could

result in engine damage, transmission damage, structural damage, loss

of vehicle control, vehicle rollover and personal injury.

Driving

148

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 150 of 290

WARNING:Do not connect a trailer’s hydraulic brake system

directly to your vehicle’s brake system. Your vehicle may not

have enough braking power and your chances of having a collision

greatly increase.

Trailer lamps

Trailer lamps are required on most towed vehicles. Your vehicle may be

equipped with one of two possible trailer wiring designs. Make sure all

running lights, brake lights, turn signals and hazard lights are working.

See your dealer or trailer rental agency for proper instructions and

equipment for hooking up trailer lamps.

Driving while you tow

When towing a trailer:

•Do not drive faster than 70 mph (113 km/h) during the first 500 miles

(800 km) of trailer towing and don’t make full-throttle starts.

•Turn off the speed control. The speed control may shut off

automatically when you are towing on long, steep grades.

•Use a lower gear to eliminate excessive shifting and assist in

transmission cooling.

•Allow more distance for stopping with a trailer attached; anticipate

stops and brake gradually.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to theScheduled Maintenance Guide

chapter for more information.

Trailer towing tips

•Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

•Allow more distance for stopping with a trailer attached.

•If you are driving down a long or steep hill, shift to a lower gear. Do

not apply the brakes continuously, as they may overheat and become

less effective.

•The trailer tongue weight should be 10–15% of the loaded trailer

weight.

Driving

150

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 151 of 290

•If you will be towing a trailer frequently in hot weather, hilly

conditions, at GCW, or any combination of these factors, consider

refilling your rear axle with synthetic gear lube if not already so

equipped. Refer toLubricant specificationsin theMaintenance and

Specificationschapter for the lubricant specification. Remember that

regardless of the rear axle lube used, do not tow a trailer for the first

500 miles (800 km) of a new vehicle, and that the first 500 miles

(800 km) of towing be done at no faster than 70 mph (112 km/h) with

no full throttle starts.

•After you have traveled 50 miles (80 km), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

•To aid in engine/transmission cooling and A/C efficiency during hot

weather while stopped in traffic, place the gearshift lever in P (Park)

(if available on your automatic transmission) or N (Neutral) (manual

transmissions and automatic transmissions without a P [Park]

position).

•Vehicles with trailers should not be parked on a grade. If you must

park on a grade, place wheel chocks under the trailer’s wheels.

FIFTH-WHEEL OPERATION

WARNING:Failure to follow the fifth-wheel manufacturer’s

instructions for hooking and unhooking as well as sliding the

fifth-wheel could result in an accident, personal injury or death.

WARNING:When the tractor and trailer are parked unattended,

the trailer brake hand control should never be used to apply the

brake, since air may leak from the system, allowing vehicle movement,

resulting in possible property damage, personal injury or death.

Before hook-up, make sure:

•The fifth-wheel jaws are fully opened.

•The fifth-wheel is fully tilted back to prevent body damage when the

tractor is backed under a trailer.

•The trailer wheels are blocked and the trailer spring brakes are

adjusted and applied. Never chase a trailer.

•The brake hoses and light cords are clear of the fifth-wheel.

Driving

151

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 152 of 290

Hook-up

1. Back the tractor squarely under the trailer, engaging the fifth-wheel

jaws on the kingpin. Always back-up slowly, making sure the trailer is

neither too high nor too low. Avoid backing under the trailer from an

angle.

2. Connect the service and emergency brake hoses and trailer light

connector. Refer toTractor-trailer connectionsin theAir suspension

section of this chapter, adhering to the warning and using the three-point

stance while connecting and disconnecting the trailer.

3. Inspect the jaws of the fifth-wheel to be sure they have fully closed on

the trailer kingpin and the trailer plate is resting securely on the

fifth-wheel.

4. Be sure the coupler release lever is in the locked position.

5. Charge the trailer brake system. Set the trailer brakes, either with the

hand valve or tractor protection valve. Pull against the trailer for an

additional check of proper hook-up. Do not pull hard enough to damage

or strain the equipment.

6. Set the tractor parking brakes and fully raise the trailer landing gear.

Refer toBrakesin this chapter for proper operation of the parking brake

and trailer brakes.

7. Check the operation of all trailer lights and correct any lights that may

be faulty.

Un-hook

1. Try to keep the tractor and trailer in a straight line.

2. Apply the parking brakes.

3. Lower the trailer landing gear, making sure it is on solid, level ground.

The weight of the trailer is to be on the landing gear.

4. Block the trailer wheels.

5. Disconnect the brake hoses and light cords. Be sure hoses and cords

are clear.

6. Pull coupler release lever to disengage the fifth-wheel jaws.

7. Release the tractor parking brakes.

8. Pull out from the trailer slowly, allowing the landing gear to take the

load gradually.

Driving

152

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 155 of 290

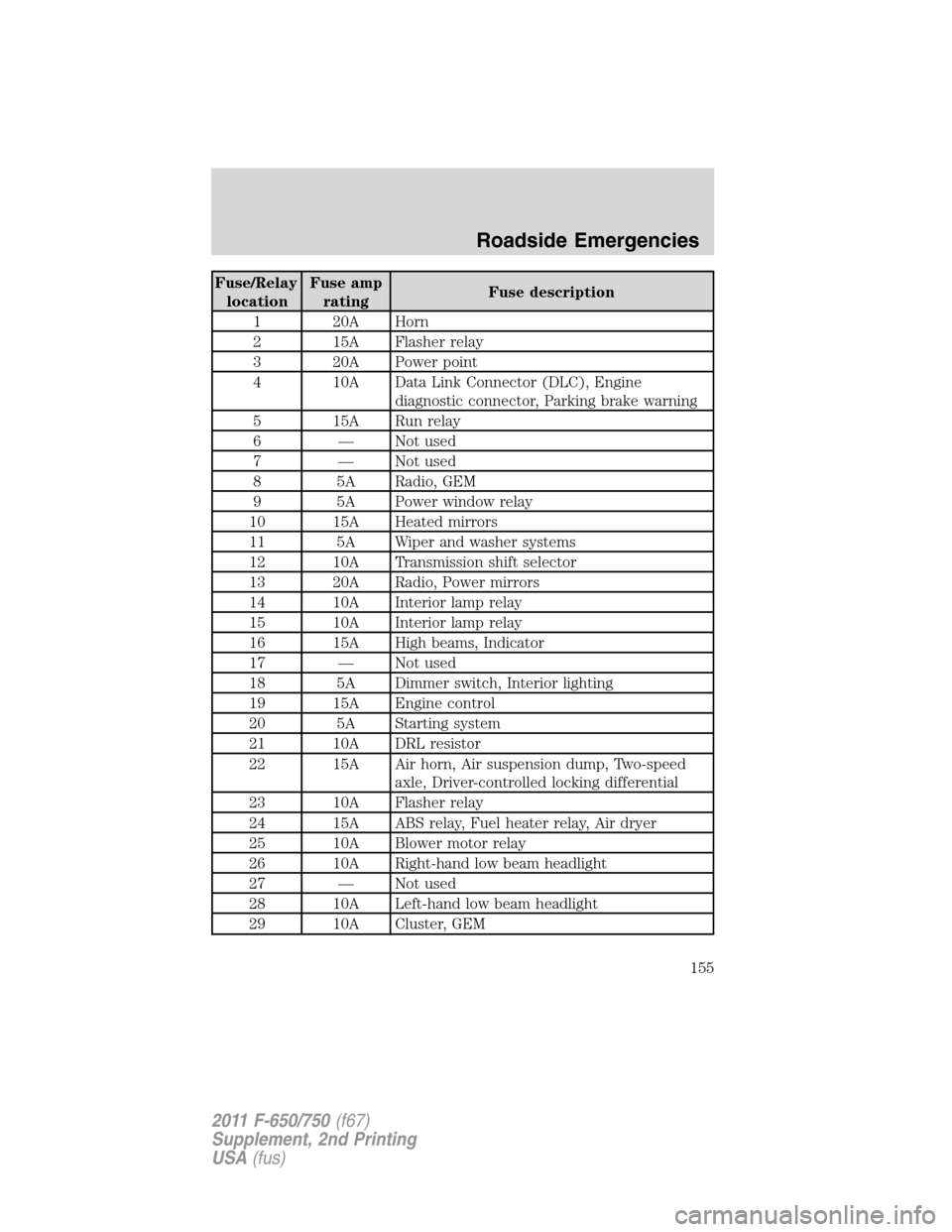

Fuse/Relay

locationFuse amp

ratingFuse description

1 20A Horn

2 15A Flasher relay

3 20A Power point

4 10A Data Link Connector (DLC), Engine

diagnostic connector, Parking brake warning

5 15A Run relay

6 — Not used

7 — Not used

8 5A Radio, GEM

9 5A Power window relay

10 15A Heated mirrors

11 5A Wiper and washer systems

12 10A Transmission shift selector

13 20A Radio, Power mirrors

14 10A Interior lamp relay

15 10A Interior lamp relay

16 15A High beams, Indicator

17 — Not used

18 5A Dimmer switch, Interior lighting

19 15A Engine control

20 5A Starting system

21 10A DRL resistor

22 15A Air horn, Air suspension dump, Two-speed

axle, Driver-controlled locking differential

23 10A Flasher relay

24 15A ABS relay, Fuel heater relay, Air dryer

25 10A Blower motor relay

26 10A Right-hand low beam headlight

27 — Not used

28 10A Left-hand low beam headlight

29 10A Cluster, GEM

Roadside Emergencies

155

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)