light FORD F650 2013 12.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2013, Model line: F650, Model: FORD F650 2013 12.GPages: 378, PDF Size: 3.82 MB

Page 145 of 378

The differential can be locked or unlocked when the vehicle is moving at

a constant speed of under 25 mph (40 km/h) and while the wheels are

not slipping. The differential must not be locked when the vehicle is

traveling down steep grades and traction is minimal.

The differential lock and differential lock light automatically disengage at

speeds above 25 mph (40 km/h). The differential lock remains off until

either the vehicle is restarted or the differential lock switch is turned off

then back on.

Turn the engine off and raise all drive wheels of the locker differential

axle in order to prevent the vehicle from moving when servicing the

wheels, tires or brakes. Axles equipped with a NoSPIN Detroit Locker

differential deliver power to both wheels even when only one wheel is on

the ground.

WARNING:Failure to raise all drive wheels with this type of

differential could cause the vehicle to move unexpectedly,

resulting in property damage, personal injury or death.

Care should be taken to avoid sudden accelerations when both drive

wheels are on a slippery surface.

WARNING:Sudden accelerations on slippery surfaces could

cause the wheels to spin, the vehicle to turn sideways on a

crowned road surface or in a turn, possibly resulting in loss of vehicle

control and personal injury.

Fluid Temperature

Axle operating temperatures normally do not exceed 100°F (38°C).

If the operating temperature exceeds 230°F (110°C), the rate of axle

lubrication oxidation increases and shortens the life of the lubricant and

seals, requiring axle lubrication changes to become more frequent to

preserve the axle. Extreme Pressure (EP) lubricants should not be run

consistently above 230°F (110°C).

Axle Conversions

WARNING:When operating a loaded vehicle, the driver must

keep all adjustable axles on the ground at all times, supporting

their share of the vehicle’s load. Failure to do so can overload other

axles, tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

144Transmission

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 146 of 378

It is not recommended, or approved, for axle conversions to be

performed. However, it is understood that, on occasion, aftermarket

add-on axles are installed by others on the truck chassis which allow

operator control for weight transfer from other axles (i.e., air lift axles).

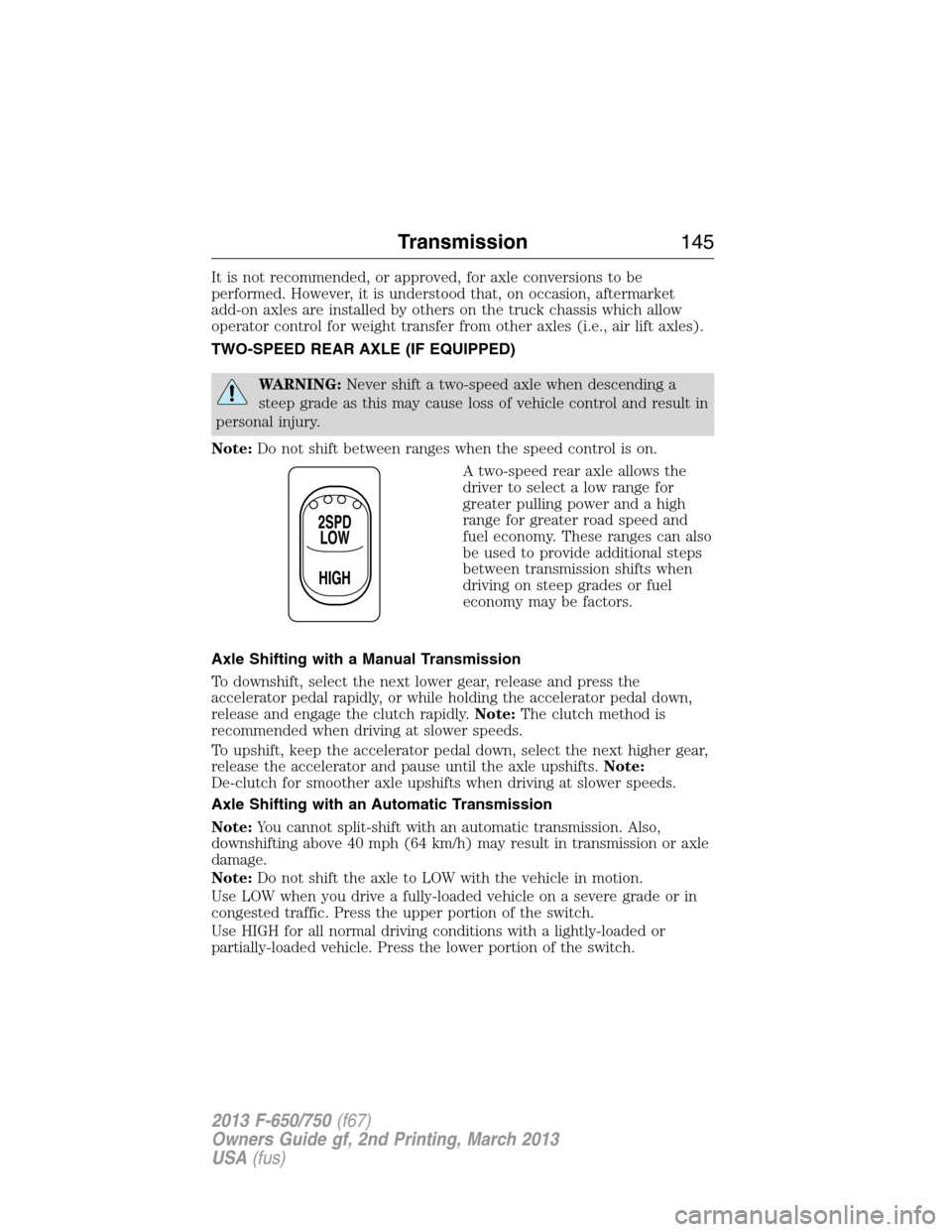

TWO-SPEED REAR AXLE (IF EQUIPPED)

WARNING:Never shift a two-speed axle when descending a

steep grade as this may cause loss of vehicle control and result in

personal injury.

Note:Do not shift between ranges when the speed control is on.

A two-speed rear axle allows the

driver to select a low range for

greater pulling power and a high

range for greater road speed and

fuel economy. These ranges can also

be used to provide additional steps

between transmission shifts when

driving on steep grades or fuel

economy may be factors.

Axle Shifting with a Manual Transmission

To downshift, select the next lower gear, release and press the

accelerator pedal rapidly, or while holding the accelerator pedal down,

release and engage the clutch rapidly.Note:The clutch method is

recommended when driving at slower speeds.

To upshift, keep the accelerator pedal down, select the next higher gear,

release the accelerator and pause until the axle upshifts.Note:

De-clutch for smoother axle upshifts when driving at slower speeds.

Axle Shifting with an Automatic Transmission

Note:You cannot split-shift with an automatic transmission. Also,

downshifting above 40 mph (64 km/h) may result in transmission or axle

damage.

Note:Do not shift the axle to LOW with the vehicle in motion.

Use LOW when you drive a fully-loaded vehicle on a severe grade or in

congested traffic. Press the upper portion of the switch.

Use HIGH for all normal driving conditions with a lightly-loaded or

partially-loaded vehicle. Press the lower portion of the switch.

2SPD

LOW

HIGH

Transmission145

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 148 of 378

GENERAL INFORMATION

All standard equipment brakes are designed to be self-adjusting.

Automatic adjustment, when required, occurs whenever the brakes are

applied and released during forward or reverse operation.

Note:Occasional brake noise is normal. If a metal-to-metal, continuous

grinding or continuous squeal sound is present, the brake linings may be

worn out and should be inspected by an authorized dealer. If the vehicle

has continuous vibration or shudder in the steering wheel while braking,

the vehicle should be inspected by an authorized dealer.

Know the required stopping distances for all driving conditions that may

be encountered. For longer brake lining life, take full advantage of engine

braking power when coming to a stop.

WARNING:Do not drive with your foot resting on the brake

pedal. This results in abnormally high brake temperatures,

excessive lining wear and increased stopping distances.

Before descending a long or steep hill, shift to a lower gear and avoid

continuous application of the brakes. Normally, choose the same gear to

descend the hill that you use to ascend the hill.

WARNING:Continuous application of the brakes causes the

brakes to overheat, resulting in a temporary loss of braking.

See theInstrument Clusterchapter for information on the

brake system warning light.

Wet brakes result in reduced braking efficiency. Gently press the brake

pedal a few times when driving from a car wash or standing water to dry

the brakes.

If Brakes Do Not Grip Well

•If you have been driving through deep water, gently apply the brakes

several times while the vehicle is moving slowly.

•Let the brakes cool if you have been using them excessively, as in

mountain driving or after several fast, high-speed stops.

•Check brake adjustment.

•Check brake linings for excessive wear.

•Check system air pressure on vehicles equipped with air brakes.

Brakes147

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 149 of 378

Anti-lock Brake System (ABS)

This system helps you maintain steering control during emergency stops

by keeping the brakes from locking.

The ABS lamp momentarily illuminates when the ignition is

turned on. If the light does not illuminate during start-up,

remains on or flashes, the ABS may be disabled and may need

to be serviced.

If the ABS is disabled, normal braking is still effective. If the

brake warning lamp illuminates, have your brake system

serviced immediately.

If a PLC trailer is connected when the ignition is switched on,

the trailer ABS light also illuminates. If the light fails to

illuminate, remains on after the vehicle is started or continues

to flash, have the system serviced immediately.

FULL POWER BRAKE SYSTEM

WARNING:If the red BRAKE warning lamp in the instrument

cluster remains illuminated after engine start up, this indicates a

system failure in the Full Power Brake System. Stop the vehicle safely

as soon as possible and seek service immediately.

This system incorporates standard braking, an anti-lock braking system

(ABS) and optional Power Park Brake into one fully-integrated hydraulic

brake system. With the Full Power Brake System, braking energy is

stored, similar to an air brake system, resulting in faster response times

and shorter stopping distances. This is accomplished using motor and

pump assemblies that pressurize the system by pumping brake fluid into

accumulators. This is similar to the air compressor of an air brake system

pressurizing the air tanks. The system includes a master cylinder that

provides the normal pedal feel and transfers the pedal force, via brake

fluid, to the main components of the system.

Note:The motor and pumps run momentarily with the ignition switch in

the on or run position, or in the off position with the brake pedal

pressed.

Note:During normal driving, the pump and motors may be heard

replenishing the accumulators. This is a normal function of the system.

148Brakes

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 150 of 378

AIR BRAKES

After starting the engine, give the air compressor time to build up the air

pressure to 60 psi (414 kPa) before moving the vehicle.

WARNING:Do not drive or continue to drive if the low air

pressure buzzer is sounding or the brake warning light is lit.

These warnings indicate that air pressure is not to normal operating

level. Continued use of the vehicle could result in loss of braking ability.

WARNING:Avoid repeated light application of the brake pedal.

This depletes air pressure faster and could result in loss of

braking capability.

Periodically check the air pressure

gauge while driving. Pressure should

range between approximately

100–125 psi (690–862 kPa). The air

compressor governor cut-in and

cut-out pressure settings are set at

the factory and are not adjustable.

When air pressure is insufficient (below 60 psi [414 kPa]), a

warning light illuminates and a buzzer sounds when the ignition

is in the on position.

This condition may be caused by excessive brake applications depleting

the system air pressure. If this condition occurs, stop driving the vehicle

until the compressor has fully recharged the air system.

WARNING:Do not move the vehicle when the air pressure is

insufficient because the brake system may be inoperative.

Select a gear ratio to help slow your vehicle before descending grades.

Supplement with brakes as required to safely slow the vehicle and avoid

overspeeding the engine.

Brakes149

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 154 of 378

Exhaust Brake Operating Characteristics

When you remove your feet from both the accelerator and clutch pedals

and the exhaust brake switch is in the on position, the exhaust brake is

activated. The following conditions exist if the brake is operating properly:

•A slight change in engine sound when the exhaust brake is activated.

•A smooth braking effect. Do not expect a retarding effect similar to

sudden, hard application of the service brakes.

•The retarding force possibly felt acting against your body when the

brake is applied (depending on the grade and vehicle load). This force

is actually preventing the vehicle from going much faster.

•Engine temperature remaining in the normal operating range.

•The tachometer showing a drop in engine RPM (depending on grade

and vehicle load) during a descent.

•A decrease in road speed when the exhaust brake is applied during a

descent, except when the vehicle is carrying a heavy load or the grade

is extremely steep. In these instances, you may need to apply the

service brakes occasionally.

TRAILER BRAKES

Trailer Brake Hand Control (If Equipped)

WARNING:The hand control should never be used to apply

the brakes when the tractor and trailer are parked unattended.

Air may leak from the system and the vehicle could possibly move,

resulting in possible property damage, personal injury or death.

The hand control is located on the

right-hand side of the instrument

panel. It is used to apply the

trailer service brakes which are

independent of the truck or tractor

service brakes.

It operates a valve that provides gradual control of air pressure applied.

When the valve is only partially applied, the trailer brakes can be

overridden by pressing fully on the brake pedal.

To apply the trailer brakes using the hand control, move the lever

downward. The further the lever is pushed down, the greater the air

pressure is applied to the brakes. The lever remains in place until

manually moved.

To release the trailer brakes, move the lever up completely.

Brakes153

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 160 of 378

The Power Park Brake is controlled by the park brake dash-mounted,

yellow knob-type switch. The switch has three positions: apply (out),

neutral (central), and release (in). The switch is spring-loaded to return

to the neutral (central) position after being pushed or pulled.

There is no visual indication at the knob that the park brake is

applied or released; check the instrument cluster. If the light is

illuminated, the parking brake is applied.

Applying the Parking Brake

Pull the yellow, dash-mounted parking brake knob. The parking brake

light illuminates indicating that the parking brake has been successfully

set.

Note:If the light blinks and a warning chime sounds when the control

knob is pulled, the parking brake is not functioning properly. Seek

immediate service from your dealer. SeeParking brake warning

systemin this section.

Releasing the Parking Brake

WARNING:Hold the brake pedal down while moving the

gearshift lever from position to position. If the brake pedal is not

held down, the vehicle may move unexpectedly resulting in property

damage, personal injury or death.

Note:Read and understand the following steps and perform them

whenever you prepare to drive the vehicle.

Note:The parking brake does not disengage unless sufficient system air

pressure is available.

If your vehicle is equipped with a dash-mounted push button (Allison

3000 Series) or steering column-mounted (Allison 2200 and 2500) gear

selector:

1. Press and hold the service brake pedal while the engine is running.

2. Select the appropriate drive gear.

3. Push and hold the yellow, dash-mounted parking brake knob until the

parking brake light turns off, then release.

If your vehicle is equipped with a manual transmission:

1. Press and hold the service brake pedal while the engine is running.

2. Press and hold the clutch pedal.

3. Select the appropriate drive gear.

4. Push and hold the yellow, dash-mounted parking brake knob until the

parking brake light turns off, then release.

P

Brakes159

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 161 of 378

Parking Brake Light Illumination Due to Low Air Pressure

If at any time during vehicle operation air pressure becomes too low, the

parking brake may apply and the parking brake light turns on.

If the parking brake is applied due to low air pressure, immediate service

is required to the parking brake system.

Parking Brake Warning System

If the parking brake light blinks and a chime sounds when pulling the

yellow control knob out, this indicates the parking brake is not

functioning properly. Seek service for the parking brake immediately.

With the ignition key not in the run position:

•A chime sounds if the parking brake remains released (or in an

unknown state). The chime stops in approximately eight minutes or

until the parking brake is applied. Seek service for the parking brake

immediately.

Diesel engines:Parking brake light operation (the light only works

when the ignition key is in the run position):

•On:Parking brake applied.

•Off:Parking brake released and no faults or malfunctions.

•Blink and chime:Parking brake released (or in an unknown state)

and faults or malfunctions exist.

Releasing Spring Manually

WARNING:Do not attempt to disassemble the parking brake

chamber under any circumstances. The high spring load may

cause serious injury.

WARNING:Block the wheels to help prevent the vehicle from

moving.

WARNING:Unexpected and possibly sudden vehicle movement

may occur if these precautions are not taken.

If hydraulic pressure is released from the spring brake chamber the

power spring applies the brake and, unless hydraulic pressure can be

re-established, the spring brake must be released as follows in order to

move the vehicle.

160Brakes

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 163 of 378

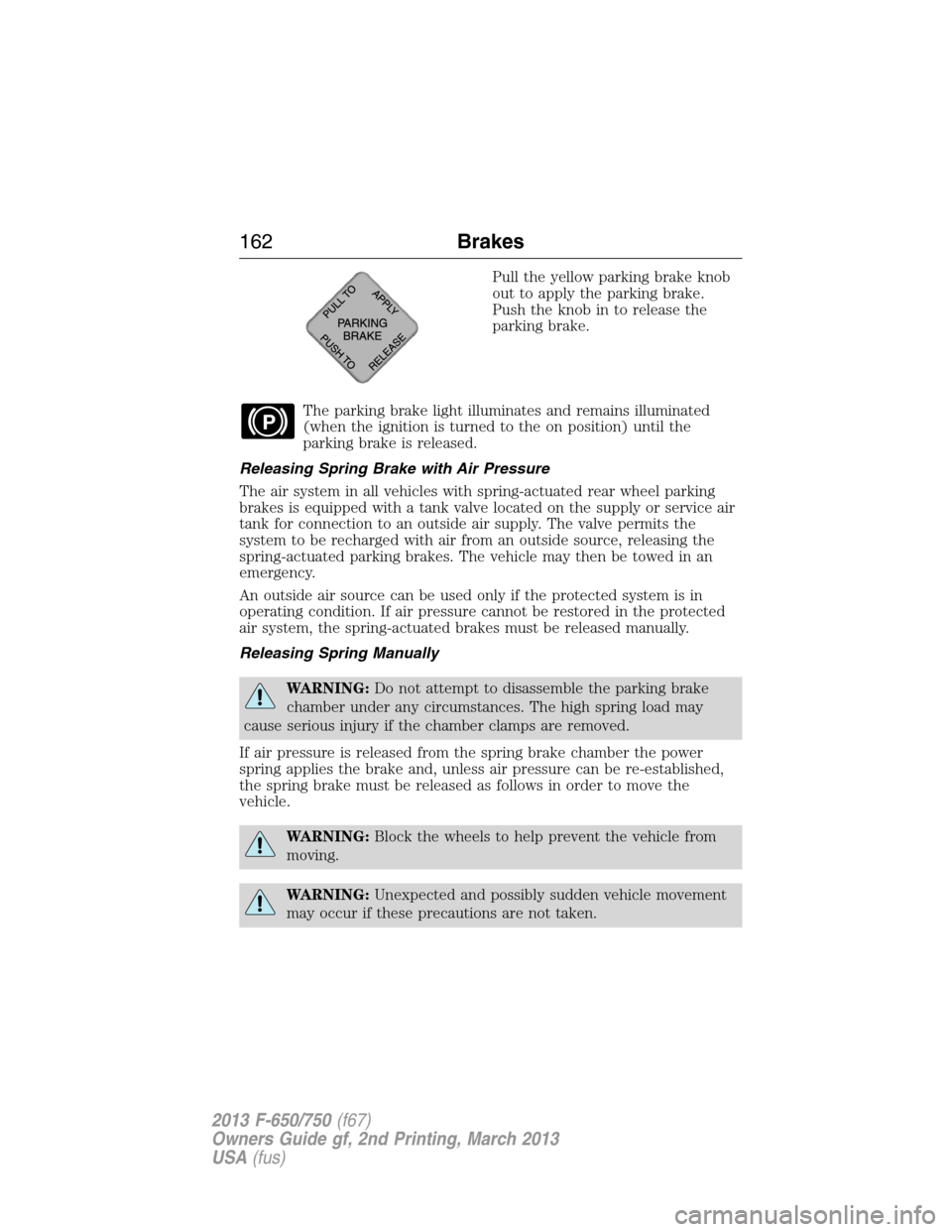

Pull the yellow parking brake knob

out to apply the parking brake.

Push the knob in to release the

parking brake.

The parking brake light illuminates and remains illuminated

(when the ignition is turned to the on position) until the

parking brake is released.

Releasing Spring Brake with Air Pressure

The air system in all vehicles with spring-actuated rear wheel parking

brakes is equipped with a tank valve located on the supply or service air

tank for connection to an outside air supply. The valve permits the

system to be recharged with air from an outside source, releasing the

spring-actuated parking brakes. The vehicle may then be towed in an

emergency.

An outside air source can be used only if the protected system is in

operating condition. If air pressure cannot be restored in the protected

air system, the spring-actuated brakes must be released manually.

Releasing Spring Manually

WARNING:Do not attempt to disassemble the parking brake

chamber under any circumstances. The high spring load may

cause serious injury if the chamber clamps are removed.

If air pressure is released from the spring brake chamber the power

spring applies the brake and, unless air pressure can be re-established,

the spring brake must be released as follows in order to move the

vehicle.

WARNING:Block the wheels to help prevent the vehicle from

moving.

WARNING:Unexpected and possibly sudden vehicle movement

may occur if these precautions are not taken.

P

162Brakes

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 166 of 378

System Indicator Light

Note:If the traction control light does not flash during a traction control

event or stays illuminated, the system is not functioning properly. Take

your vehicle to your dealer for service.

During traction control operation, the traction control light

flashes rapidly and the engine does not rev-up when you press

further on the accelerator. This is normal and is no reason for

concern.

In Off Road or Mud/Snow mode, the traction control light illuminates and

flashes slowly. If a traction event occurs, in either mode, the light flashes

rapidly.

Traction Control165

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)