light FORD F650 2013 12.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2013, Model line: F650, Model: FORD F650 2013 12.GPages: 378, PDF Size: 3.82 MB

Page 172 of 378

AIR SUSPENSION (IF EQUIPPED)

Note:

The vehicle must not be operated without air in the suspension

springs. Operating the vehicle without air in the suspension springs damages

the suspension, degrades ride performance and may cause property damage.

The air suspension system automatically adjusts to different loads to

maintain a constant frame height, allows for ease of vehicle loading and

provides improved vehicle ride and increased driver comfort.

Air Suspension Dump Switch

Note:The suspension dumps air when the ignition is in the accessory or

on position, but fills only when the ignition is in the on position.

The system is controlled by a switch

located in the overhead switch

pack. It operates only when the

ignition is in the accessory or on

position and the air tanks have

sufficient pressure to fill the air

springs. When the ignition is turned

off, the suspension remains in

whatever state it was last set.

Pressing the lower portion of the switch exhausts air from the air

springs, lowering the frame for loading. Pressing the upper portion of the

switch fills the air springs so the vehicle remains at normal ride height.

System Indicator Light

The air suspension indicator light illuminates when the switch

has been activated to release air pressure in the rear air shocks.

Never drive the vehicle when the warning lamp is illuminated

and there is low (or no) air pressure in the shocks.

Connecting and Disconnecting a Trailer with Air Suspension and

Air Suspension Dump Switch

When connecting to a trailer:

•Press the lower portion of the switch to exhaust air from the air

suspension system.

•Press the upper portion of the switch, then raise the landing gear

after making the connection to the trailer.

When disconnecting the trailer:

•Lower the landing gear, then press the lower portion of the switch.

•Disconnect the brake hoses, trailer-side and rear light connectors,

then pull the release lever on the fifth-wheel.

CK

SUSP

Driving Aids171

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 175 of 378

Unloaded or Lightly Loaded Vehicles

WARNING:When operating empty or lightly loaded, sudden or

hard braking may induce wheel lockup with loss of vehicle

control and the possibility of accident and serious injury, especially on

wet or slippery road surfaces.

The braking system has been designed to safely stop your vehicle when

fully loaded to its GVWR.

174Load Carrying

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 176 of 378

TOWING A TRAILER

WARNING:Do not exceed the GVWR or the GAWR specified on

the certification label.

WARNING:Towing trailers beyond the maximum recommended

gross trailer weight exceeds the limit of the vehicle and could

result in engine damage, transmission damage, structural damage, loss

of vehicle control, vehicle rollover and personal injury.

Your vehicle’s load capacity is designated by weight, not by volume, so

you cannot necessarily use all available space when loading a vehicle.

Second-unit bodies are not included in maximum trailer weight ratings.

The weight of the additional body must be subtracted from the maximum

trailer weight.

Towing a trailer places an additional load on your vehicle’s engine,

transmission, axle, brakes, tires and suspension. Inspect these

components periodically during, and after, any towing operation.

Load Placement

To help minimize how trailer movement affects the vehicle when driving:

•Load the heaviest items closest to the trailer floor.

•Load the heaviest items so they are centered between the left and

right side trailer tires.

•Load the heaviest items above the trailer axles or just slightly forward

toward the trailer tongue. Do not allow the final trailer tongue weight

to go above or below 10–15% of the loaded trailer weight.

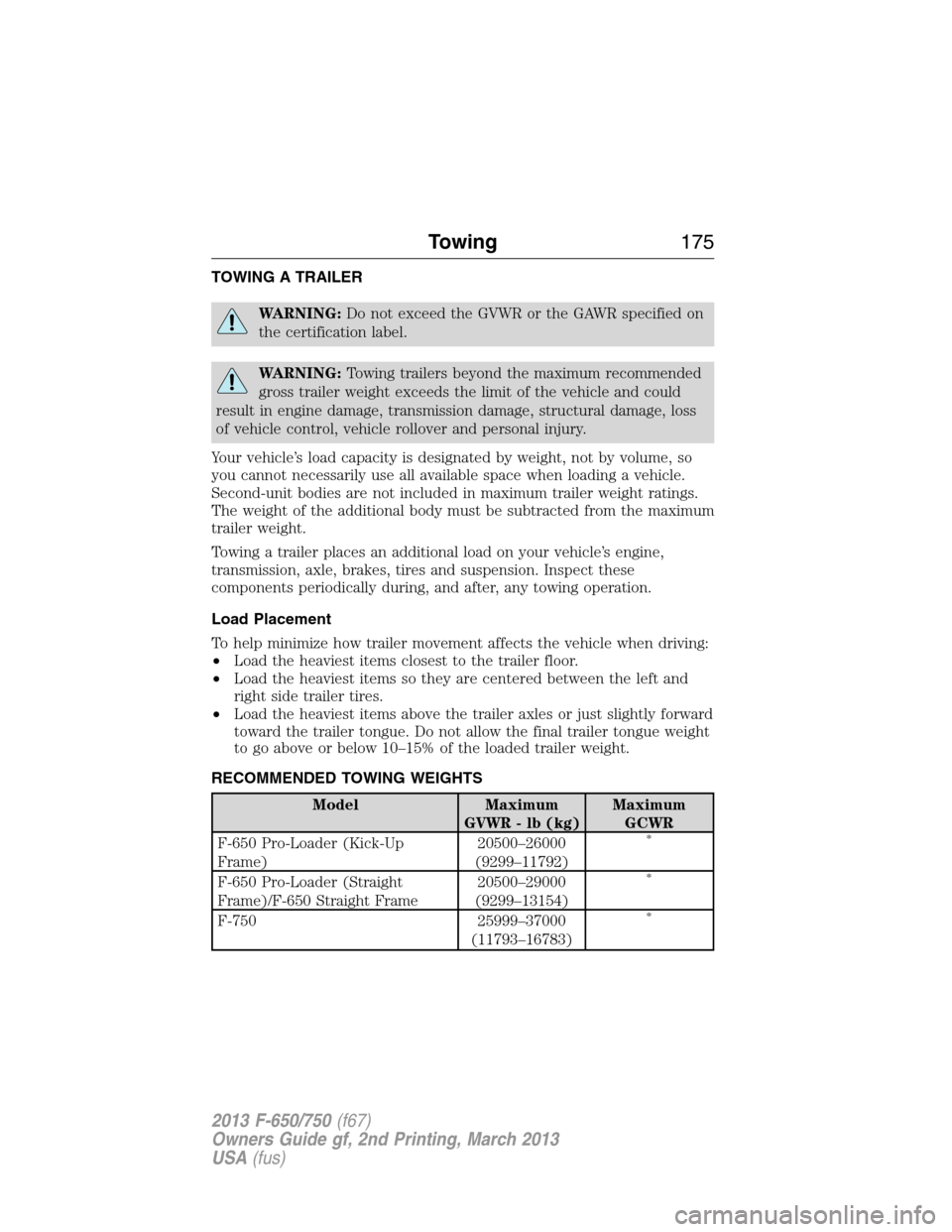

RECOMMENDED TOWING WEIGHTS

Model Maximum

GVWR - lb (kg)Maximum

GCWR

F-650 Pro-Loader (Kick-Up

Frame)20500–26000

(9299–11792)

*

F-650 Pro-Loader (Straight

Frame)/F-650 Straight Frame20500–29000

(9299–13154)*

F-750 25999–37000

(11793–16783)*

Towing175

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 178 of 378

Trailer Lamps

WARNING:Never connect any trailer lamp wiring to the

vehicle’s tail lamp wiring; this may damage the electrical system

resulting in a fire. Contact an authorized dealer as soon as possible for

assistance in proper trailer tow wiring installation. Additional electrical

equipment may be required.

Trailer lamps are required on most towed vehicles. Make sure all running

lights, brake lights, turn signals and hazard lights are working.

Before Towing a Trailer

Practice turning, stopping and backing up to get the feel of your

vehicle-trailer combination before starting on a trip. When turning, make

wider turns so the trailer wheels clear curbs and other obstacles.

When Towing a Trailer

•Check your hitch, electrical connections and trailer wheel lug nuts

thoroughly after you have traveled 50 miles (80 kilometers).

•Place the gearshift lever in positionP(if equipped) or neutral to aid

in engine and transmission cooling and A/C efficiency during hot

weather while stopped in traffic.

•Turn off the speed control. The speed control may turn off

automatically when you are towing on long, steep grades.

•Shift to a lower gear when driving down a long or steep hill. Do not

apply the brakes continuously, as they may overheat and become less

effective.

•Allow more distance for stopping with a trailer attached. Anticipate

stops and brake gradually.

FIFTH-WHEEL OPERATION

WARNING:Failure to follow the fifth-wheel manufacturer’s

instructions for hooking and unhooking as well as sliding the

fifth-wheel could result in an accident, personal injury or death.

WARNING:When the tractor and trailer are parked unattended,

the trailer brake hand control should never be used to apply the

brake, since air may leak from the system, allowing vehicle movement,

resulting in possible property damage, personal injury or death.

Towing177

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 179 of 378

Before hook-up, make sure:

•The fifth-wheel jaws are fully opened.

•The fifth-wheel is fully tilted back to prevent body damage when the

tractor is backed under a trailer.

•The trailer wheels are blocked and the trailer spring brakes are

adjusted and applied. Never chase a trailer.

•The brake hoses and light cords are clear of the fifth-wheel.

Hook-up

1. Back the tractor squarely under the trailer, engaging the fifth-wheel

jaws on the kingpin. Always back up slowly, making sure the trailer is

neither too high nor too low. Avoid backing under the trailer from an

angle.

2. Connect the service and emergency brake hoses and trailer light

connector.

3. Inspect the jaws of the fifth-wheel to be sure they have fully closed

on the trailer kingpin and the trailer plate is resting securely on the

fifth-wheel.

4. Make sure the coupler release lever is in the locked position.

5. Charge the trailer brake system. Set the trailer brakes, either with

the hand valve or tractor protection valve. Pull against the trailer for

an additional check of proper hook-up. Do not pull hard enough to

damage or strain the equipment.

6. Set the tractor parking brakes and fully raise the trailer landing gear.

See theBrakeschapter for proper operation of the parking brake

and trailer brakes.

7. Check the operation of all trailer lights and correct any lights that

may be faulty.

Un-hook

1. Try to keep the tractor and trailer in a straight line.

2. Apply the parking brakes.

3. Lower the trailer landing gear, making sure it is on solid, level

ground. The weight of the trailer is to be on the landing gear.

4. Block the trailer wheels.

5. Disconnect the brake hoses and light cords. Be sure hoses and cords

are clear.

6. Pull coupler release lever to disengage the fifth-wheel jaws.

7. Release the tractor parking brakes.

8. Pull out from the trailer slowly, allowing the landing gear to take the

load gradually.

178Towing

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 182 of 378

Removing Axle Shafts before Towing

1. Shift the main differential to the unlocked (disengaged) position; the

differential lock light turns off.

2. Remove the capscrews and washers or stud nuts and washers from

flanges of both axle shafts.

3. Loosen the tapered dowels in the flanges of both axle shafts by

holding a 1

1�2inch diameter brass drift or hammer against the axle

shaft center and hitting it with a five or six pound hammer.Note:Do

not use a chisel or wedge to loosen the axle shafts and dowels. Use

of a chisel or wedge can damage the hub, axle shafts and oil seals.

4. Remove the tapered dowels and both axle shafts from the axle

assembly.

5. Assemble a cover over openings of both wheel ends to prevent loss of

lubricant and keep dirt away from the wheel bearing cavities.

Note:One of the axle shafts has two sets of splines. One set to engage

with the differential side gear and one set to engage with the shift collar

for the differential lock. It may be necessary to rotate the shaft slightly

to align the gear spline teeth with the shift collar teeth in order to

remove the axle shaft.

Installing the Axle Shafts

1. Remove the covers from the wheel ends.

2. Shift the differential lock to the unlocked (disengaged) position.

3. Install the axle shafts.

•Place the gaskets on the wheel hub studs.

•Push the right-hand axle shaft and gasket into the wheel end and

housing until the shaft stops against the differential shift collar.

•Push down and in on the axle shaft flange and rotate the shaft

until the splines of the shaft and shift collar are engaged.

•Push the axle shaft further into the housing until the shaft stops

against the differential side gear.

•Push down on the axle shaft flange and rotate the shaft until the

splines of the shaft and side gear are engaged.

•Push the axle shaft completely into the housing until the axle

shaft flange and the gasket are flush against the wheel hub.

•Install the left-hand axle shaft and gasket into the wheel end.

4. If tapered dowels are required, install them at each stud and into the

flange of the axle shaft. Use a punch or drift and hammer, if needed.

5. Install the fasteners and tighten to correct torque value. See the

Workshop Manual.

Towing181

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 183 of 378

BREAKING-IN

You need to break in new tires for approximately 300 miles

(480 kilometers). During this time, your vehicle may exhibit some unique

driving characteristics. Avoid driving too fast during the first 1000 miles

(1600 kilometers). Vary your speed frequently and change up through

the gears early. Do not labor the engine.

ECONOMICAL DRIVING

Fuel economy is affected by several things such as how you drive, the

conditions you drive under and how you maintain your vehicle.

There are some things to keep in mind that may improve your fuel

economy:

•Accelerate and slow down in a smooth, moderate fashion.

•Drive at steady speeds without stopping.

•Anticipate stops; slowing down may eliminate the need to stop.

•Close the windows for high-speed driving.

•Drive at reasonable speeds (traveling at 55 mph [88 km/h] uses 15%

less fuel than traveling at 65 mph [105 km/h]).

•Keep the tires properly inflated and use only the recommended size.

•Use the recommended engine oil.

•Perform all regularly scheduled maintenance.

There are also some things you may not want to do because they may

reduce your fuel economy:

•Sudden or hard accelerations.

•Warm up your vehicle on cold mornings.

•Use the air conditioner or front defroster.

•Use the speed control in hilly terrain.

•Rest your foot on the brake pedal while driving.

•Carry unnecessary weight (approximately 1 mpg [0.4 km/L] is lost for

every 400 pounds [180 kilograms] of weight carried).

•Add particular accessories to your vehicle (e.g., bug deflectors,

rollbars and light bars, running boards, ski racks).

•Drive with the wheels out of alignment.

182Driving Hints

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 184 of 378

DRIVING THROUGH WATER

If driving through deep or standing water is unavoidable, proceed very

slowly especially if the depth is not known. Never drive through water

that is higher than the bottom of the hubs. Traction or brake capability

may be limited and your vehicle may stall. Water may also enter your

engine’s air intake and severely damage your engine, drive axles or the

transmission (through the breather ports).

Once through the water, always dry the brakes by moving your vehicle

slowly while applying light pressure on the brake pedal. Wet brakes do

not stop the vehicle as quickly as dry brakes.

Driving Hints183

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 198 of 378

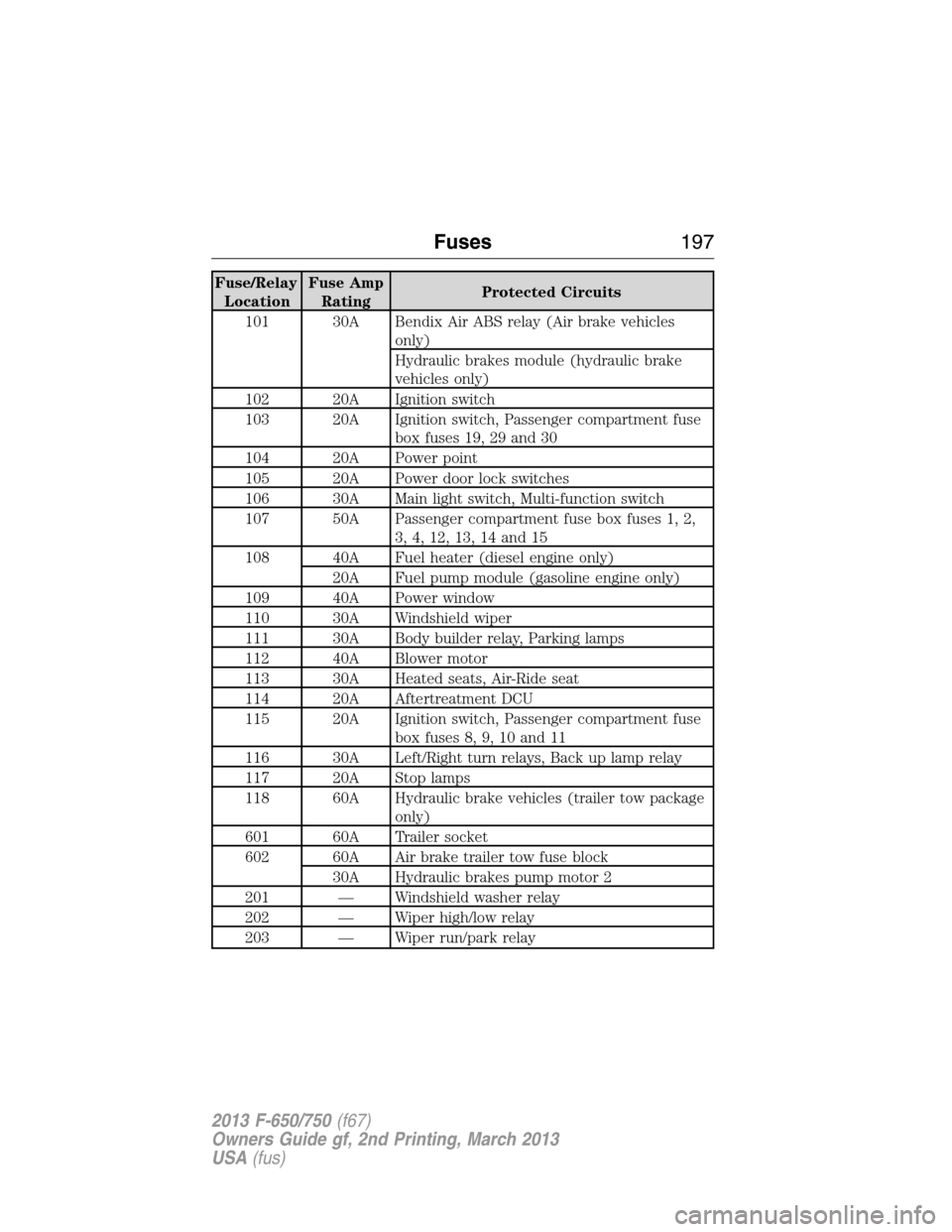

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

101 30A Bendix Air ABS relay (Air brake vehicles

only)

Hydraulic brakes module (hydraulic brake

vehicles only)

102 20A Ignition switch

103 20A Ignition switch, Passenger compartment fuse

box fuses 19, 29 and 30

104 20A Power point

105 20A Power door lock switches

106 30A Main light switch, Multi-function switch

107 50A Passenger compartment fuse box fuses 1, 2,

3, 4, 12, 13, 14 and 15

108 40A Fuel heater (diesel engine only)

20A Fuel pump module (gasoline engine only)

109 40A Power window

110 30A Windshield wiper

111 30A Body builder relay, Parking lamps

112 40A Blower motor

113 30A Heated seats, Air-Ride seat

114 20A Aftertreatment DCU

115 20A Ignition switch, Passenger compartment fuse

box fuses 8, 9, 10 and 11

116 30A Left/Right turn relays, Back up lamp relay

117 20A Stop lamps

118 60A Hydraulic brake vehicles (trailer tow package

only)

601 60A Trailer socket

602 60A Air brake trailer tow fuse block

30A Hydraulic brakes pump motor 2

201 — Windshield washer relay

202 — Wiper high/low relay

203 — Wiper run/park relay

Fuses197

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 201 of 378

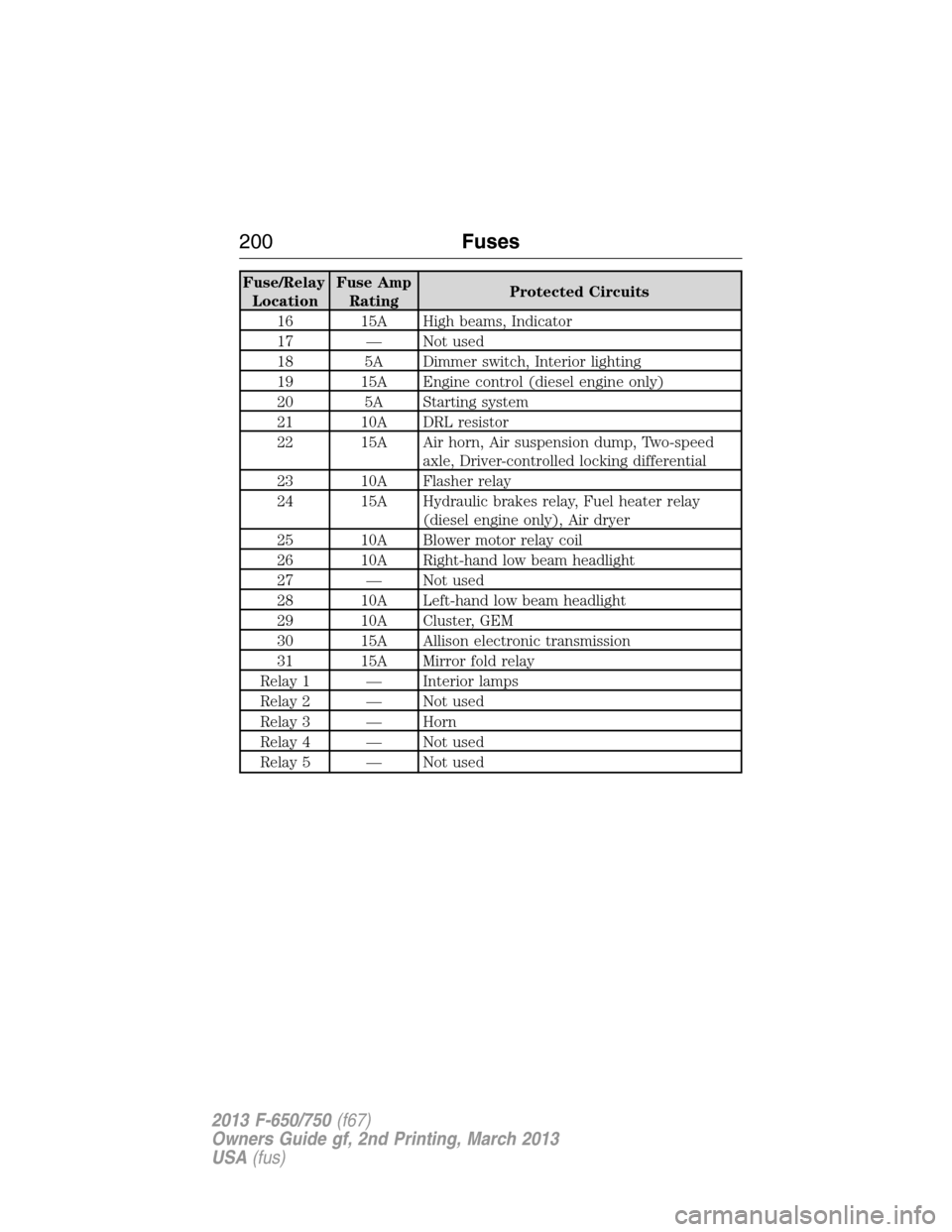

Fuse/Relay

LocationFuse Amp

RatingProtected Circuits

16 15A High beams, Indicator

17 — Not used

18 5A Dimmer switch, Interior lighting

19 15A Engine control (diesel engine only)

20 5A Starting system

21 10A DRL resistor

22 15A Air horn, Air suspension dump, Two-speed

axle, Driver-controlled locking differential

23 10A Flasher relay

24 15A Hydraulic brakes relay, Fuel heater relay

(diesel engine only), Air dryer

25 10A Blower motor relay coil

26 10A Right-hand low beam headlight

27 — Not used

28 10A Left-hand low beam headlight

29 10A Cluster, GEM

30 15A Allison electronic transmission

31 15A Mirror fold relay

Relay 1 — Interior lamps

Relay 2 — Not used

Relay 3 — Horn

Relay 4 — Not used

Relay 5 — Not used

200Fuses

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)