automatic transmission fluid FORD F650 2013 12.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2013, Model line: F650, Model: FORD F650 2013 12.GPages: 378, PDF Size: 3.82 MB

Page 5 of 378

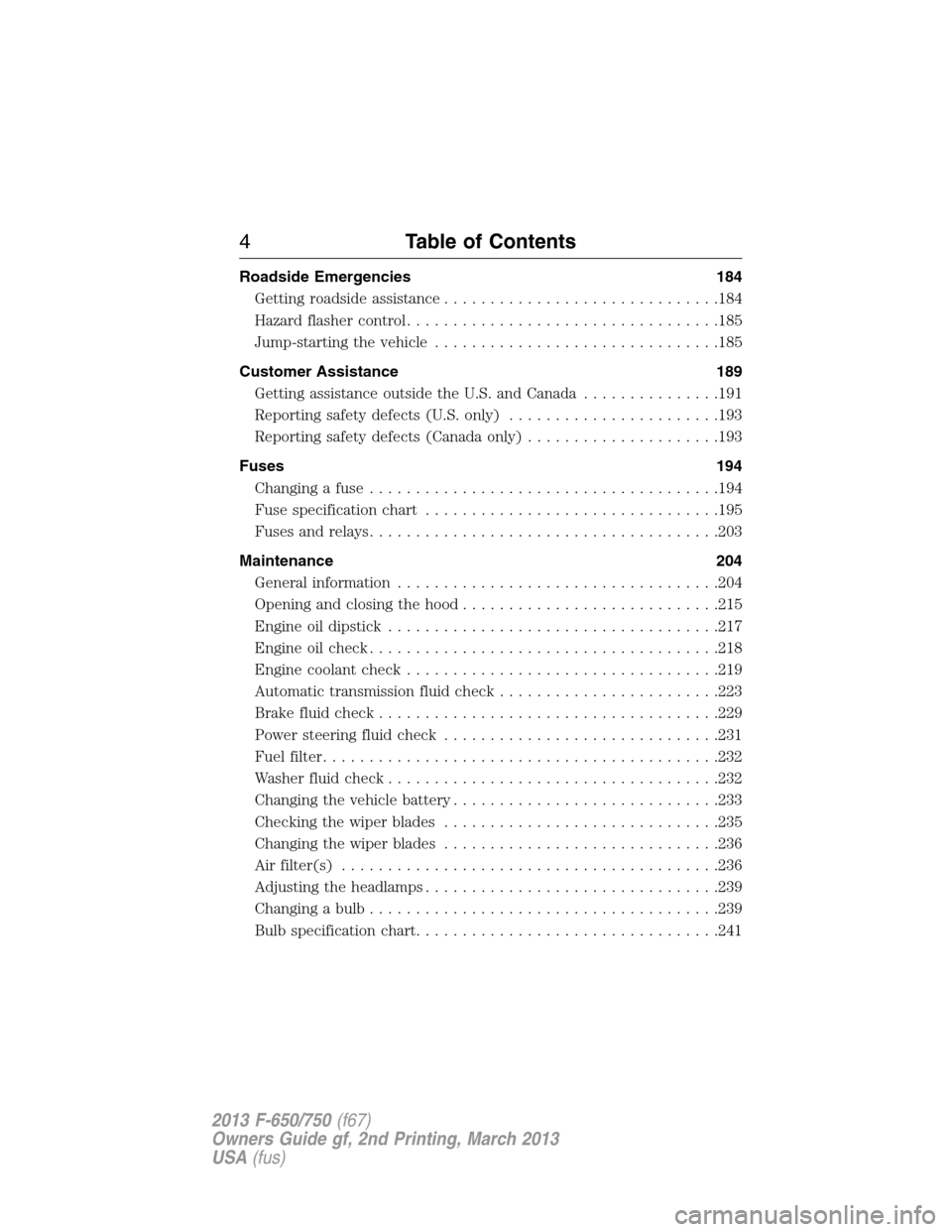

Roadside Emergencies 184

Getting roadside assistance..............................184

Hazard flasher control..................................185

Jump-starting the vehicle...............................185

Customer Assistance 189

Getting assistance outside the U.S. and Canada...............191

Reporting safety defects (U.S. only).......................193

Reporting safety defects (Canada only).....................193

Fuses 194

Changing a fuse......................................194

Fuse specification chart................................195

Fuses and relays......................................203

Maintenance 204

General information...................................204

Opening and closing the hood............................215

Engine oil dipstick....................................217

Engine oil check......................................218

Engine coolant check..................................219

Automatic transmission fluid check........................223

Brake fluid check.....................................229

Power steering fluid check..............................231

Fuel filter...........................................232

Washer fluid check....................................232

Changing the vehicle battery.............................233

Checking the wiper blades..............................235

Changing the wiper blades..............................236

Air filter(s).........................................236

Adjusting the headlamps................................239

Changing a bulb......................................239

Bulb specification chart.................................241

4Table of Contents

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 19 of 378

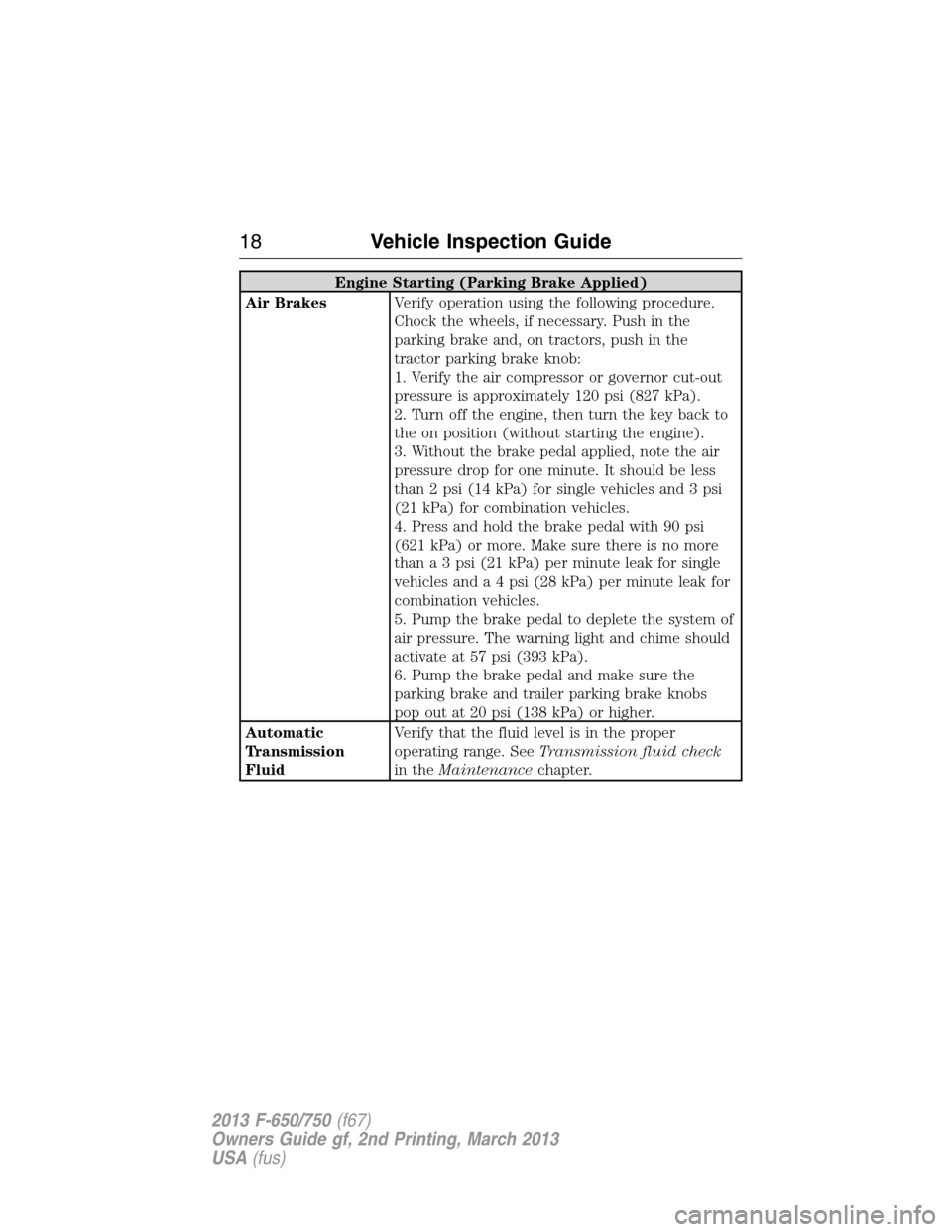

Engine Starting (Parking Brake Applied)

Air BrakesVerify operation using the following procedure.

Chock the wheels, if necessary. Push in the

parking brake and, on tractors, push in the

tractor parking brake knob:

1. Verify the air compressor or governor cut-out

pressure is approximately 120 psi (827 kPa).

2. Turn off the engine, then turn the key back to

the on position (without starting the engine).

3. Without the brake pedal applied, note the air

pressure drop for one minute. It should be less

than 2 psi (14 kPa) for single vehicles and 3 psi

(21 kPa) for combination vehicles.

4. Press and hold the brake pedal with 90 psi

(621 kPa) or more. Make sure there is no more

than a 3 psi (21 kPa) per minute leak for single

vehicles and a 4 psi (28 kPa) per minute leak for

combination vehicles.

5. Pump the brake pedal to deplete the system of

air pressure. The warning light and chime should

activate at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the

parking brake and trailer parking brake knobs

pop out at 20 psi (138 kPa) or higher.

Automatic

Transmission

FluidVerify that the fluid level is in the proper

operating range. SeeTransmission fluid check

in theMaintenancechapter.

18Vehicle Inspection Guide

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 26 of 378

Trailer

If you are pulling a trailer, an inspection of the trailer similar to that of

the tractor should be done. The inspection should follow trailer

manufacturer recommendations and should include at a minimum:

general condition, landing gear, doors, sides, lights, reflectors,

suspension, brakes, tires, wheels, cargo placement, stability and

tie-downs.

Transmission

WARNING:If the unit starts in gear and/or the neutral start

switch is not functioning correctly, the vehicle may inadvertently

move which could result in property damage, personal injury or death.

If your vehicle is equipped with an automatic transmission, regularly

inspect the transmission’s neutral start switch. The engine should only

start in positionNorP.

Inspect the transmission fluid level and shift linkage for proper

operation.

Vehicle Inspection Guide25

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 71 of 378

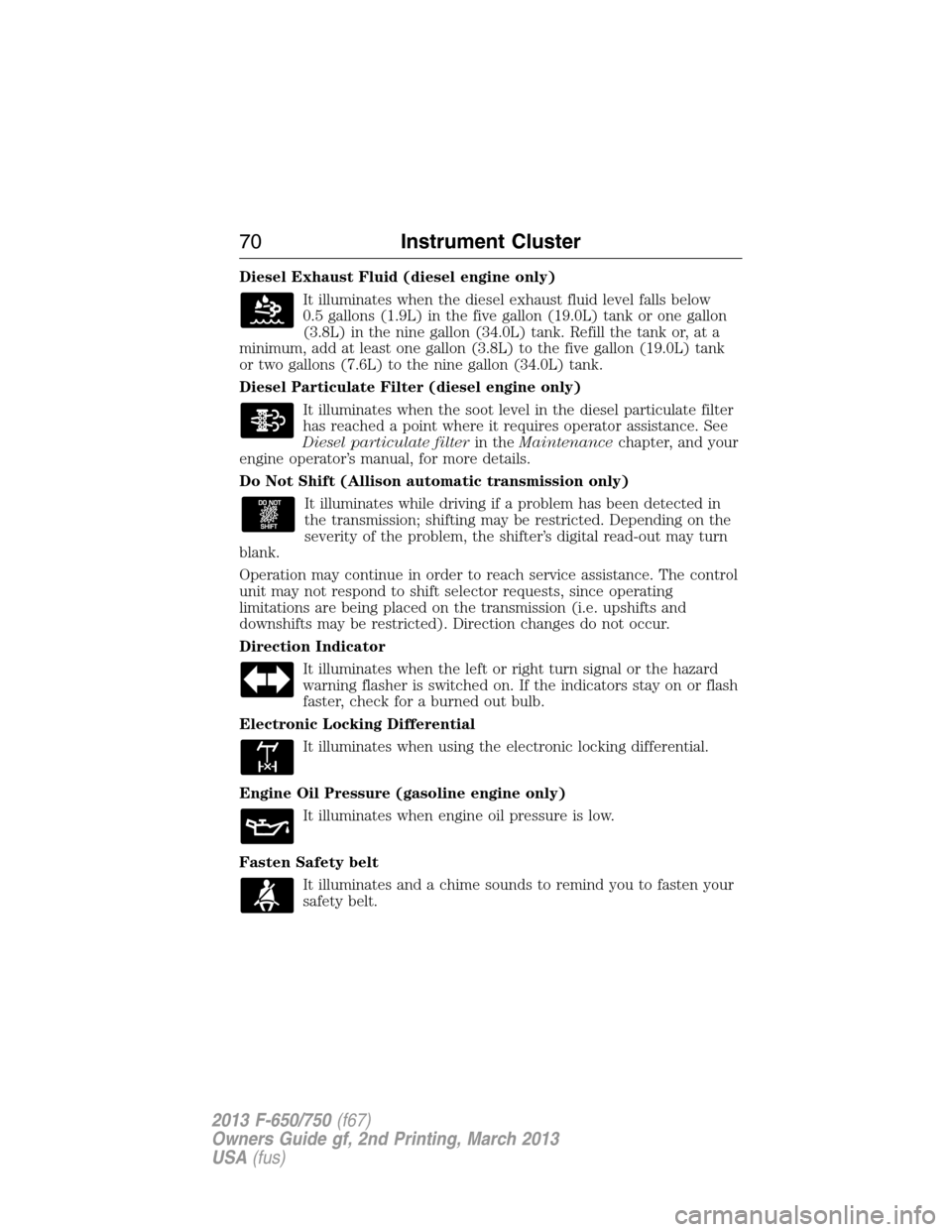

Diesel Exhaust Fluid (diesel engine only)

It illuminates when the diesel exhaust fluid level falls below

0.5 gallons (1.9L) in the five gallon (19.0L) tank or one gallon

(3.8L) in the nine gallon (34.0L) tank. Refill the tank or, at a

minimum, add at least one gallon (3.8L) to the five gallon (19.0L) tank

or two gallons (7.6L) to the nine gallon (34.0L) tank.

Diesel Particulate Filter (diesel engine only)

It illuminates when the soot level in the diesel particulate filter

has reached a point where it requires operator assistance. See

Diesel particulate filterin theMaintenancechapter, and your

engine operator’s manual, for more details.

Do Not Shift (Allison automatic transmission only)

It illuminates while driving if a problem has been detected in

the transmission; shifting may be restricted. Depending on the

severity of the problem, the shifter’s digital read-out may turn

blank.

Operation may continue in order to reach service assistance. The control

unit may not respond to shift selector requests, since operating

limitations are being placed on the transmission (i.e. upshifts and

downshifts may be restricted). Direction changes do not occur.

Direction Indicator

It illuminates when the left or right turn signal or the hazard

warning flasher is switched on. If the indicators stay on or flash

faster, check for a burned out bulb.

Electronic Locking Differential

It illuminates when using the electronic locking differential.

Engine Oil Pressure (gasoline engine only)

It illuminates when engine oil pressure is low.

Fasten Safety belt

It illuminates and a chime sounds to remind you to fasten your

safety belt.

70Instrument Cluster

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 142 of 378

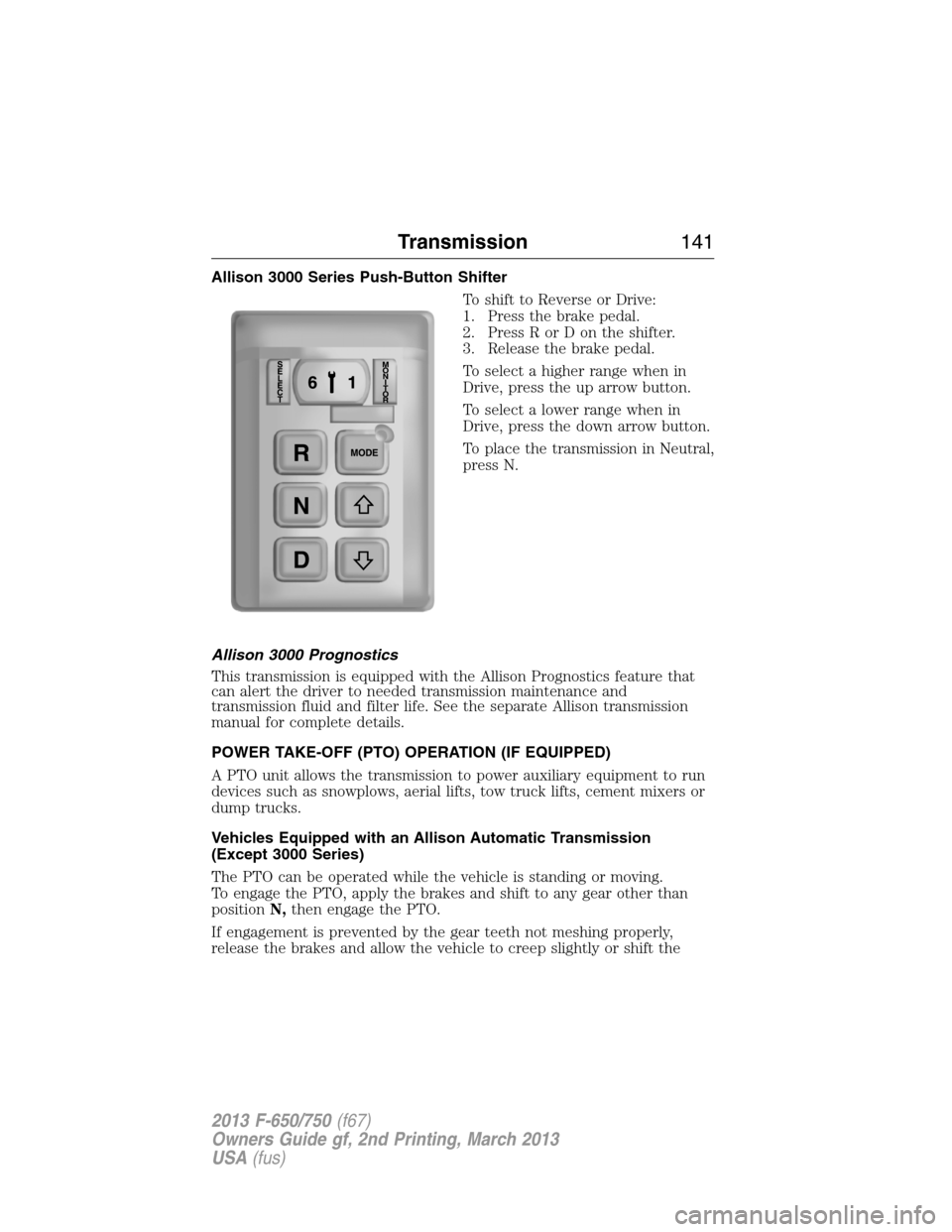

Allison 3000 Series Push-Button Shifter

To shift to Reverse or Drive:

1. Press the brake pedal.

2. Press R or D on the shifter.

3. Release the brake pedal.

To select a higher range when in

Drive, press the up arrow button.

To select a lower range when in

Drive, press the down arrow button.

To place the transmission in Neutral,

press N.

Allison 3000 Prognostics

This transmission is equipped with the Allison Prognostics feature that

can alert the driver to needed transmission maintenance and

transmission fluid and filter life. See the separate Allison transmission

manual for complete details.

POWER TAKE-OFF (PTO) OPERATION (IF EQUIPPED)

A PTO unit allows the transmission to power auxiliary equipment to run

devices such as snowplows, aerial lifts, tow truck lifts, cement mixers or

dump trucks.

Vehicles Equipped with an Allison Automatic Transmission

(Except 3000 Series)

The PTO can be operated while the vehicle is standing or moving.

To engage the PTO, apply the brakes and shift to any gear other than

positionN,then engage the PTO.

If engagement is prevented by the gear teeth not meshing properly,

release the brakes and allow the vehicle to creep slightly or shift the

Transmission141

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 145 of 378

The differential can be locked or unlocked when the vehicle is moving at

a constant speed of under 25 mph (40 km/h) and while the wheels are

not slipping. The differential must not be locked when the vehicle is

traveling down steep grades and traction is minimal.

The differential lock and differential lock light automatically disengage at

speeds above 25 mph (40 km/h). The differential lock remains off until

either the vehicle is restarted or the differential lock switch is turned off

then back on.

Turn the engine off and raise all drive wheels of the locker differential

axle in order to prevent the vehicle from moving when servicing the

wheels, tires or brakes. Axles equipped with a NoSPIN Detroit Locker

differential deliver power to both wheels even when only one wheel is on

the ground.

WARNING:Failure to raise all drive wheels with this type of

differential could cause the vehicle to move unexpectedly,

resulting in property damage, personal injury or death.

Care should be taken to avoid sudden accelerations when both drive

wheels are on a slippery surface.

WARNING:Sudden accelerations on slippery surfaces could

cause the wheels to spin, the vehicle to turn sideways on a

crowned road surface or in a turn, possibly resulting in loss of vehicle

control and personal injury.

Fluid Temperature

Axle operating temperatures normally do not exceed 100°F (38°C).

If the operating temperature exceeds 230°F (110°C), the rate of axle

lubrication oxidation increases and shortens the life of the lubricant and

seals, requiring axle lubrication changes to become more frequent to

preserve the axle. Extreme Pressure (EP) lubricants should not be run

consistently above 230°F (110°C).

Axle Conversions

WARNING:When operating a loaded vehicle, the driver must

keep all adjustable axles on the ground at all times, supporting

their share of the vehicle’s load. Failure to do so can overload other

axles, tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

144Transmission

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 224 of 378

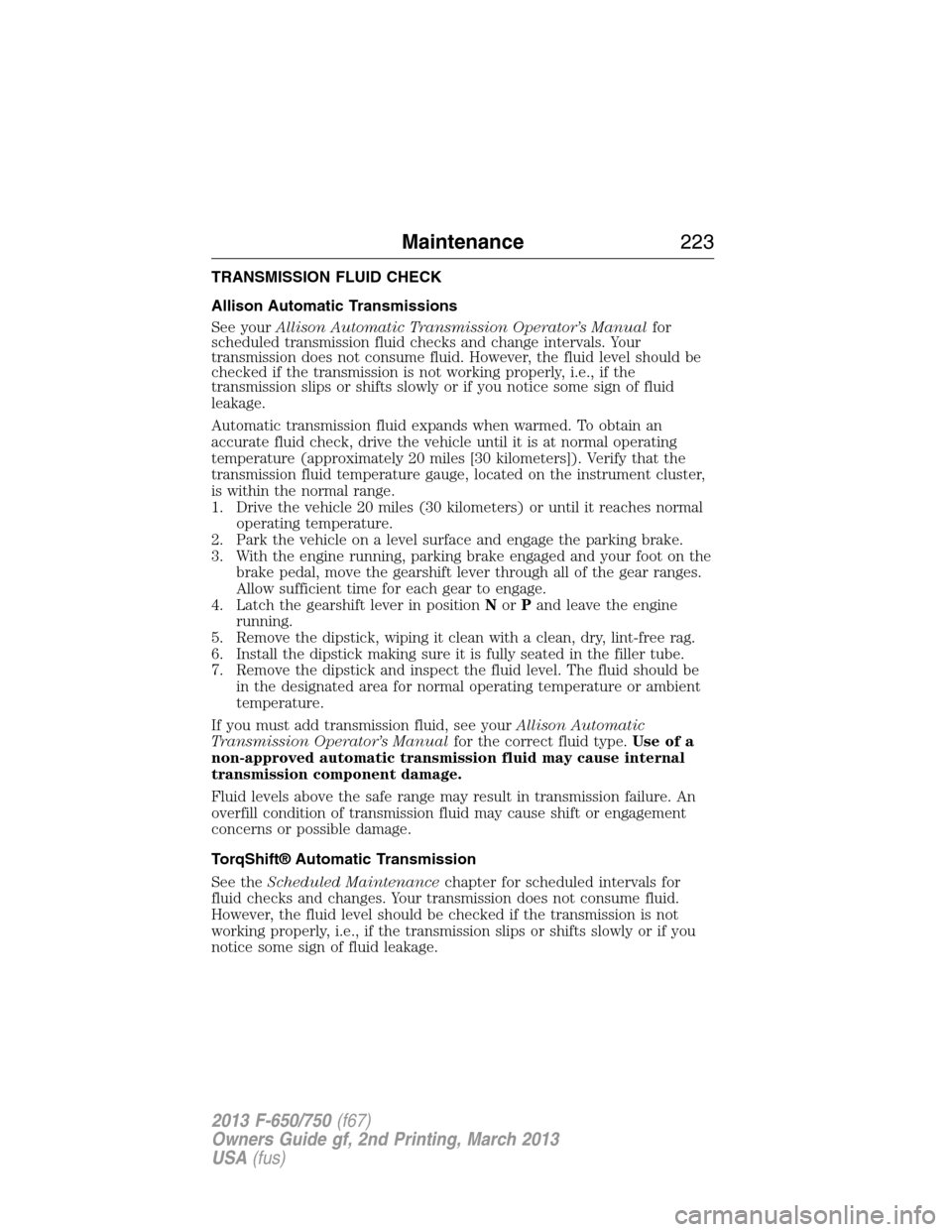

TRANSMISSION FLUID CHECK

Allison Automatic Transmissions

See yourAllison Automatic Transmission Operator’s Manualfor

scheduled transmission fluid checks and change intervals. Your

transmission does not consume fluid. However, the fluid level should be

checked if the transmission is not working properly, i.e., if the

transmission slips or shifts slowly or if you notice some sign of fluid

leakage.

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 kilometers]). Verify that the

transmission fluid temperature gauge, located on the instrument cluster,

is within the normal range.

1. Drive the vehicle 20 miles (30 kilometers) or until it reaches normal

operating temperature.

2. Park the vehicle on a level surface and engage the parking brake.

3. With the engine running, parking brake engaged and your foot on the

brake pedal, move the gearshift lever through all of the gear ranges.

Allow sufficient time for each gear to engage.

4. Latch the gearshift lever in positionNorPand leave the engine

running.

5. Remove the dipstick, wiping it clean with a clean, dry, lint-free rag.

6. Install the dipstick making sure it is fully seated in the filler tube.

7. Remove the dipstick and inspect the fluid level. The fluid should be

in the designated area for normal operating temperature or ambient

temperature.

If you must add transmission fluid, see yourAllison Automatic

Transmission Operator’s Manualfor the correct fluid type.Use of a

non-approved automatic transmission fluid may cause internal

transmission component damage.

Fluid levels above the safe range may result in transmission failure. An

overfill condition of transmission fluid may cause shift or engagement

concerns or possible damage.

TorqShift® Automatic Transmission

See theScheduled Maintenancechapter for scheduled intervals for

fluid checks and changes. Your transmission does not consume fluid.

However, the fluid level should be checked if the transmission is not

working properly, i.e., if the transmission slips or shifts slowly or if you

notice some sign of fluid leakage.

Maintenance223

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 225 of 378

![FORD F650 2013 12.G Owners Manual Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 kilometers]). Verify that FORD F650 2013 12.G Owners Manual Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 kilometers]). Verify that](/img/11/5079/w960_5079-224.png)

Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is at normal operating

temperature (approximately 20 miles [30 kilometers]). Verify that the

transmission fluid temperature gauge, located on the instrument cluster,

is within the normal range.

1. Drive the vehicle 20 miles (30 kilometers) or until it reaches normal

operating temperature.

2. Park the vehicle on a level surface and engage the parking brake.

3. With the engine running, parking brake engaged and your foot on the

brake pedal, move the gearshift lever through all of the gear ranges.

Allow sufficient time for each gear to engage.

4. Latch the gearshift lever in positionPand leave the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry, lint-free rag.

6. Install the dipstick making sure it is fully seated in the filler tube.

7. Remove the dipstick and inspect the fluid level. The fluid should be

in the designated area for normal operating temperature or ambient

temperature.

Low Fluid Level

Do not drive the vehicle if there is

no indication of fluid on the dipstick

and the ambient temperature is

above 50°F (10°C).

Correct Fluid Level

The fluid should be checked at

normal operating temperature

196°F-216°F (91°C-102°C) on a

level surface. The normal operating

temperature can be reached after approximately 20 miles (30 kilometers)

of driving.

224Maintenance

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 226 of 378

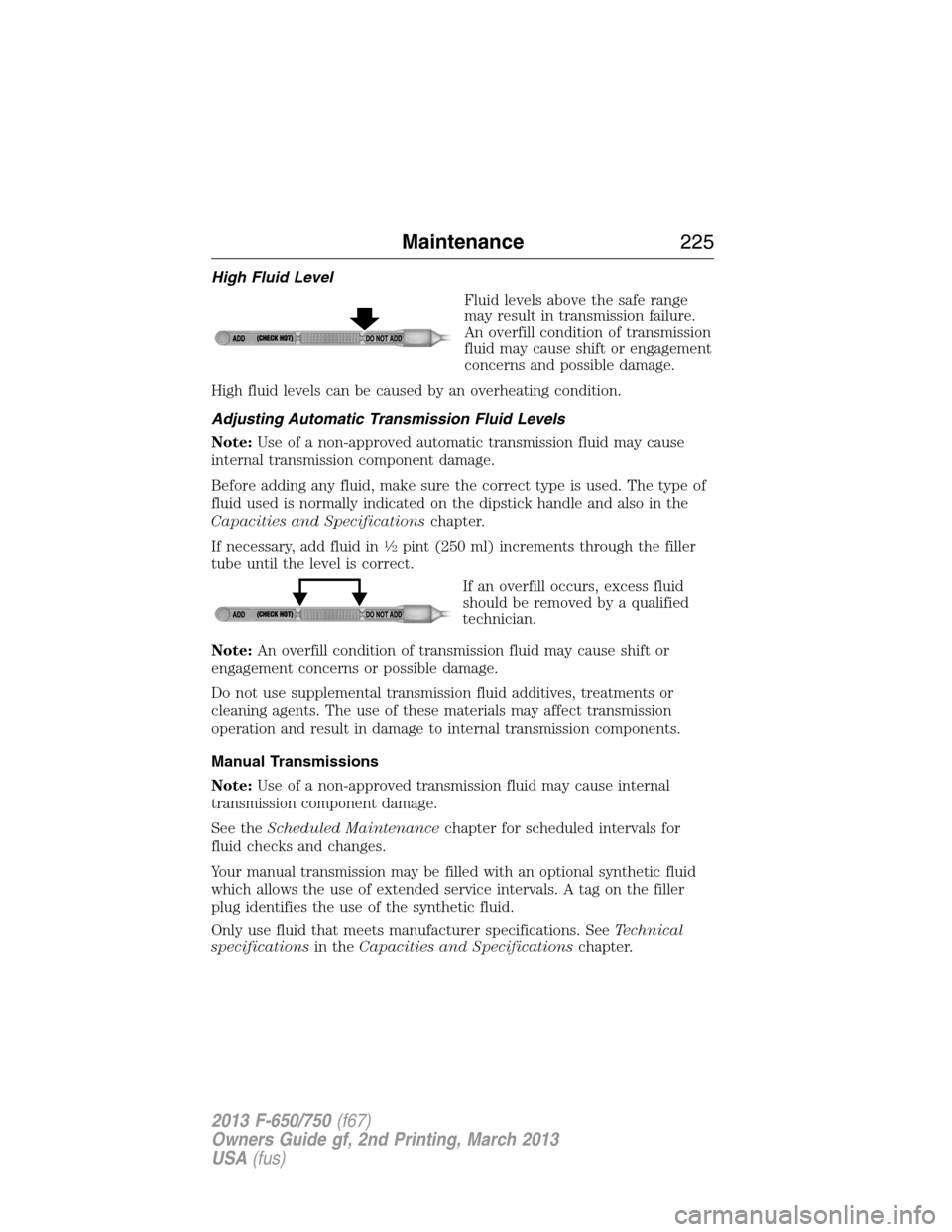

High Fluid Level

Fluid levels above the safe range

may result in transmission failure.

An overfill condition of transmission

fluid may cause shift or engagement

concerns and possible damage.

High fluid levels can be caused by an overheating condition.

Adjusting Automatic Transmission Fluid Levels

Note:Use of a non-approved automatic transmission fluid may cause

internal transmission component damage.

Before adding any fluid, make sure the correct type is used. The type of

fluid used is normally indicated on the dipstick handle and also in the

Capacities and Specificationschapter.

If necessary, add fluid in

1�2pint (250 ml) increments through the filler

tube until the level is correct.

If an overfill occurs, excess fluid

should be removed by a qualified

technician.

Note:An overfill condition of transmission fluid may cause shift or

engagement concerns or possible damage.

Do not use supplemental transmission fluid additives, treatments or

cleaning agents. The use of these materials may affect transmission

operation and result in damage to internal transmission components.

Manual Transmissions

Note:Use of a non-approved transmission fluid may cause internal

transmission component damage.

See theScheduled Maintenancechapter for scheduled intervals for

fluid checks and changes.

Your manual transmission may be filled with an optional synthetic fluid

which allows the use of extended service intervals. A tag on the filler

plug identifies the use of the synthetic fluid.

Only use fluid that meets manufacturer specifications. SeeTechnical

specificationsin theCapacities and Specificationschapter.

Maintenance225

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)

Page 228 of 378

Checking the Fluid Level

See theScheduled Maintenancechapter for rear axle lubricant level

check intervals.

1. Park the vehicle on level ground.

2. Set the parking brake and shift into positionNorP(automatic

transmission), or first gear (manual transmission). Turn the engine

off.

3. Clean any dirt from around the rear axle filler plug.

4. Remove the filler plug and inspect the lubricant level. It should be at

the bottom of the filler plug opening.

5. Add lubricant, if necessary, through the filler plug opening.

6. Clean and install the filler plug securely.

Changing the Fluid

See theScheduled Maintenancechapter for rear axle lubricant change

intervals.

1. Drain the rear axle while the lubricant is warm.

2. Park the vehicle on level ground.

3. Set the parking brake and shift into positionNorP(automatic

transmission), or first gear (manual transmission). Turn the engine

off.

4. Clean any dirt from around the rear axle filler and drain plugs.

5. Remove the filler and drain plugs. Drain the lubricant into a suitable

container. Dispose of all used automotive fluids in a responsible

manner following your local authorized standards.

6. Clean and install the drain plug securely.

7. Add lubricant through the filler plug opening.

8. Clean and install the filler plug securely.

Maintenance227

2013 F-650/750(f67)

Owners Guide gf, 2nd Printing, March 2013

USA(fus)