rims FORD F650 2015 13.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2015, Model line: F650, Model: FORD F650 2015 13.GPages: 384, PDF Size: 4.95 MB

Page 19 of 384

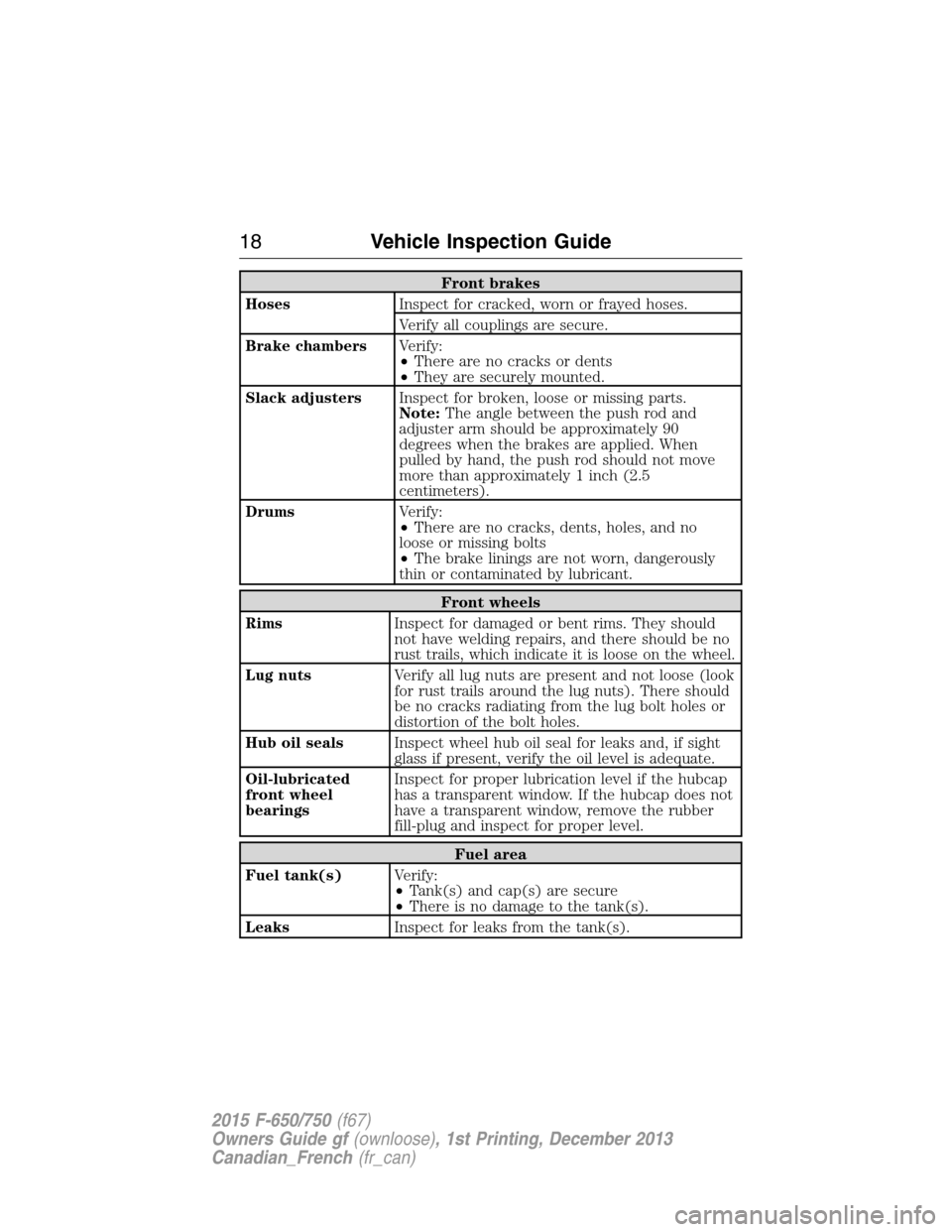

Front brakes

HosesInspect for cracked, worn or frayed hoses.

Verify all couplings are secure.

Brake chambersVerify:

•There are no cracks or dents

•They are securely mounted.

Slack adjustersInspect for broken, loose or missing parts.

Note:The angle between the push rod and

adjuster arm should be approximately 90

degrees when the brakes are applied. When

pulled by hand, the push rod should not move

more than approximately 1 inch (2.5

centimeters).

DrumsVerify:

•There are no cracks, dents, holes, and no

loose or missing bolts

•The brake linings are not worn, dangerously

thin or contaminated by lubricant.

Front wheels

RimsInspect for damaged or bent rims. They should

not have welding repairs, and there should be no

rust trails, which indicate it is loose on the wheel.

Lug nutsVerify all lug nuts are present and not loose (look

for rust trails around the lug nuts). There should

be no cracks radiating from the lug bolt holes or

distortion of the bolt holes.

Hub oil sealsInspect wheel hub oil seal for leaks and, if sight

glass if present, verify the oil level is adequate.

Oil-lubricated

front wheel

bearingsInspect for proper lubrication level if the hubcap

has a transparent window. If the hubcap does not

have a transparent window, remove the rubber

fill-plug and inspect for proper level.

Fuel area

Fuel tank(s)Verify:

•Tank(s) and cap(s) are secure

•There is no damage to the tank(s).

LeaksInspect for leaks from the tank(s).

18Vehicle Inspection Guide

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 22 of 384

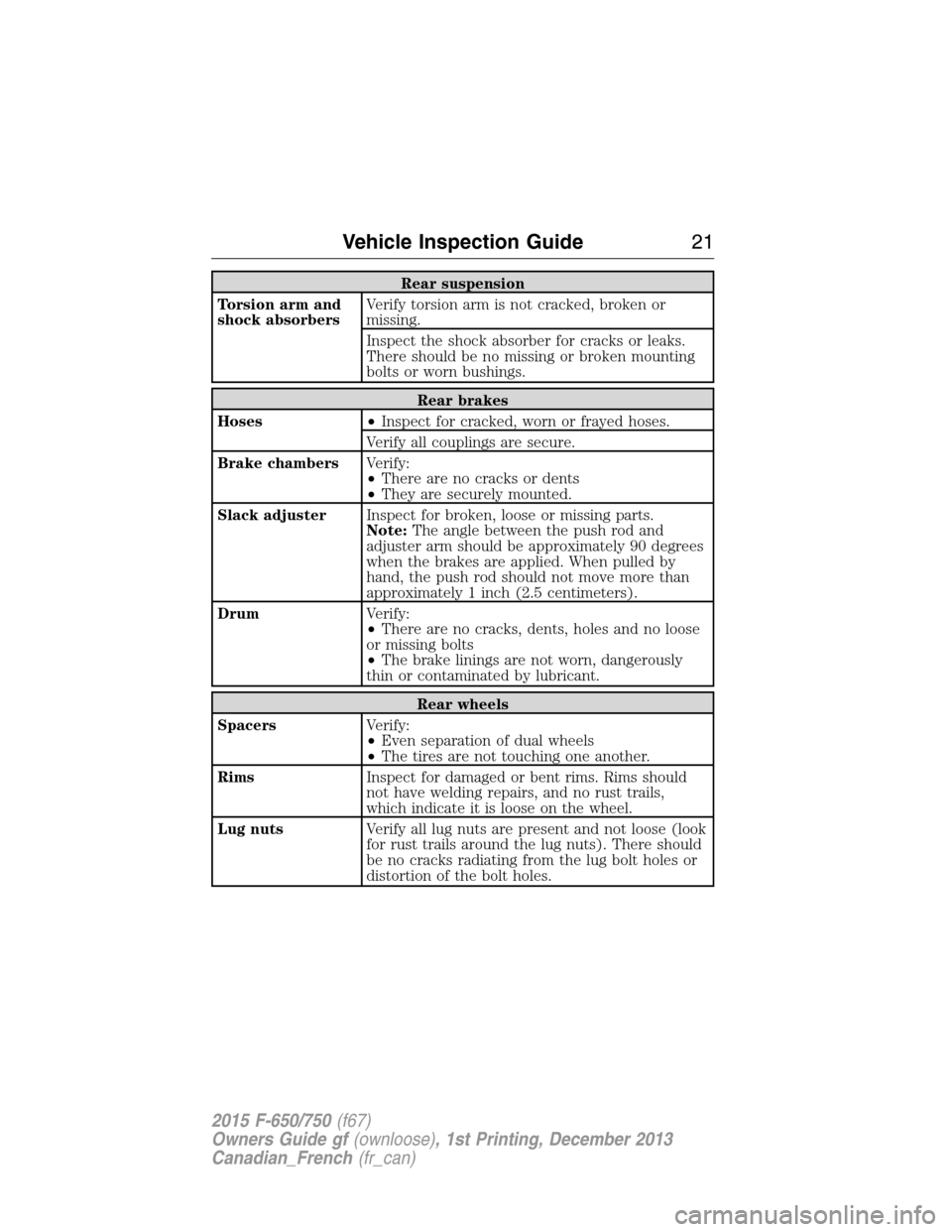

Rear suspension

Torsion arm and

shock absorbersVerify torsion arm is not cracked, broken or

missing.

Inspect the shock absorber for cracks or leaks.

There should be no missing or broken mounting

bolts or worn bushings.

Rear brakes

Hoses•Inspect for cracked, worn or frayed hoses.

Verify all couplings are secure.

Brake chambersVerify:

•There are no cracks or dents

•They are securely mounted.

Slack adjusterInspect for broken, loose or missing parts.

Note:The angle between the push rod and

adjuster arm should be approximately 90 degrees

when the brakes are applied. When pulled by

hand, the push rod should not move more than

approximately 1 inch (2.5 centimeters).

DrumVerify:

•There are no cracks, dents, holes and no loose

or missing bolts

•The brake linings are not worn, dangerously

thin or contaminated by lubricant.

Rear wheels

SpacersVerify:

•Even separation of dual wheels

•The tires are not touching one another.

RimsInspect for damaged or bent rims. Rims should

not have welding repairs, and no rust trails,

which indicate it is loose on the wheel.

Lug nutsVerify all lug nuts are present and not loose (look

for rust trails around the lug nuts). There should

be no cracks radiating from the lug bolt holes or

distortion of the bolt holes.

Vehicle Inspection Guide21

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 241 of 384

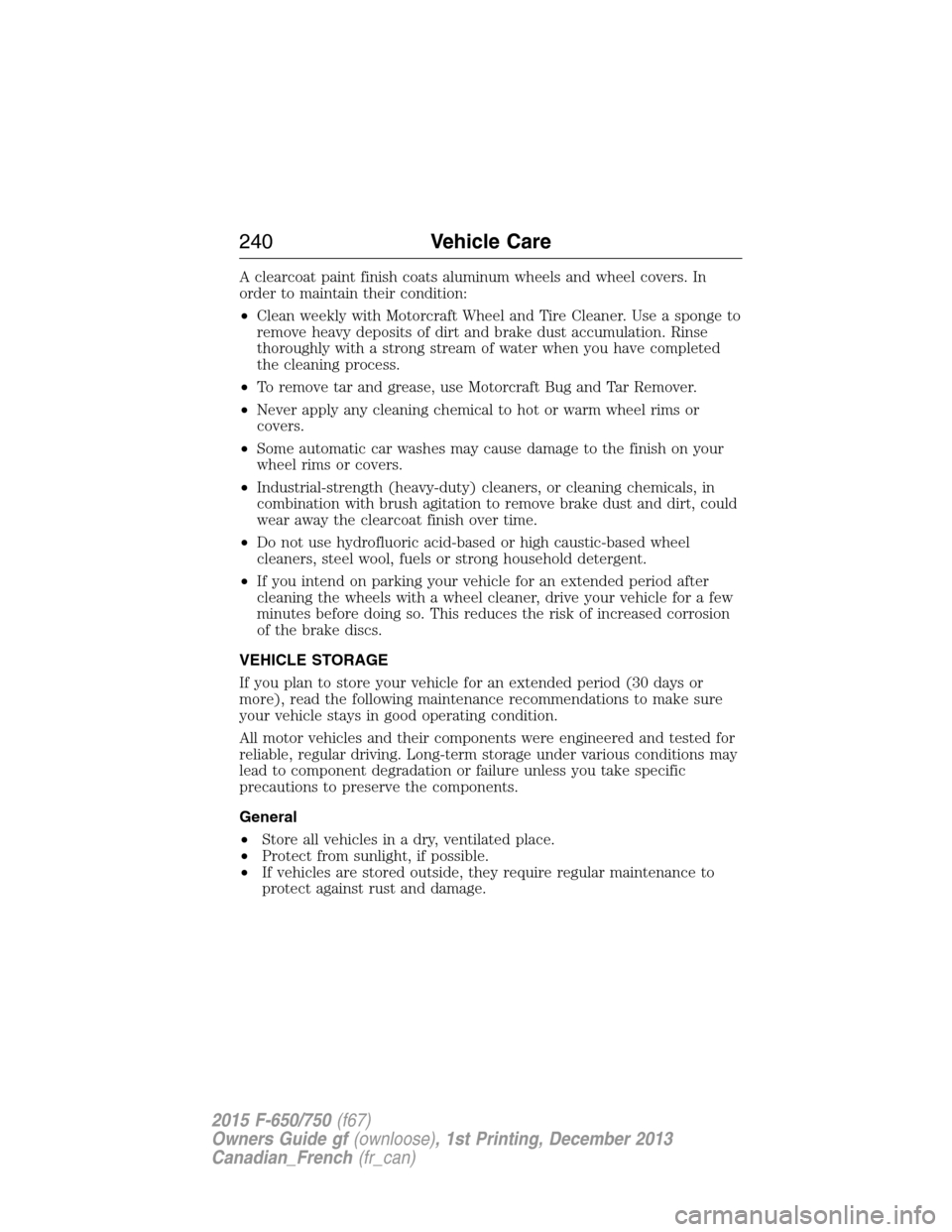

A clearcoat paint finish coats aluminum wheels and wheel covers. In

order to maintain their condition:

•Clean weekly with Motorcraft Wheel and Tire Cleaner. Use a sponge to

remove heavy deposits of dirt and brake dust accumulation. Rinse

thoroughly with a strong stream of water when you have completed

the cleaning process.

•To remove tar and grease, use Motorcraft Bug and Tar Remover.

•Never apply any cleaning chemical to hot or warm wheel rims or

covers.

•Some automatic car washes may cause damage to the finish on your

wheel rims or covers.

•Industrial-strength (heavy-duty) cleaners, or cleaning chemicals, in

combination with brush agitation to remove brake dust and dirt, could

wear away the clearcoat finish over time.

•Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

•If you intend on parking your vehicle for an extended period after

cleaning the wheels with a wheel cleaner, drive your vehicle for a few

minutes before doing so. This reduces the risk of increased corrosion

of the brake discs.

VEHICLE STORAGE

If you plan to store your vehicle for an extended period (30 days or

more), read the following maintenance recommendations to make sure

your vehicle stays in good operating condition.

All motor vehicles and their components were engineered and tested for

reliable, regular driving. Long-term storage under various conditions may

lead to component degradation or failure unless you take specific

precautions to preserve the components.

General

•Store all vehicles in a dry, ventilated place.

•Protect from sunlight, if possible.

•If vehicles are stored outside, they require regular maintenance to

protect against rust and damage.

240Vehicle Care

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 244 of 384

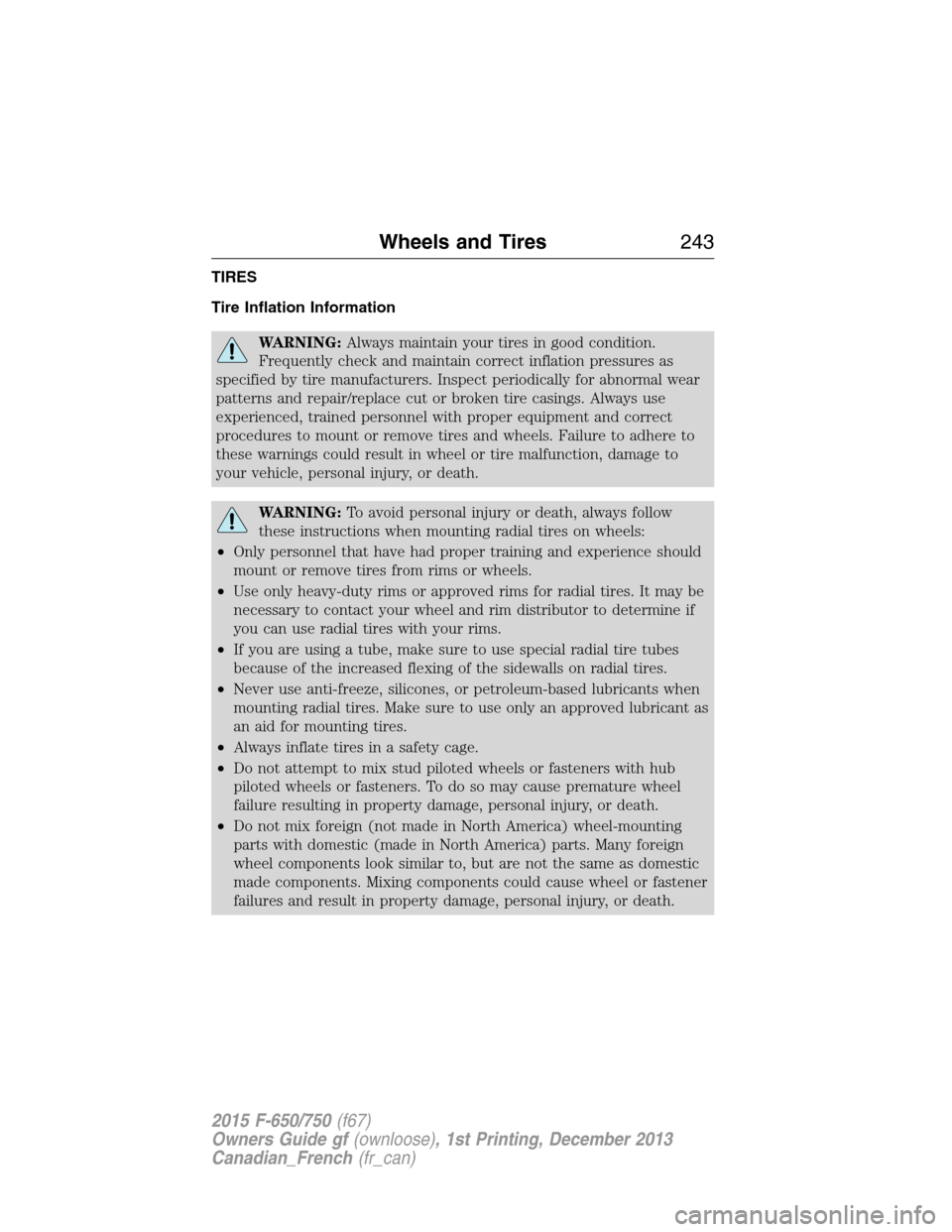

TIRES

Tire Inflation Information

WARNING:Always maintain your tires in good condition.

Frequently check and maintain correct inflation pressures as

specified by tire manufacturers. Inspect periodically for abnormal wear

patterns and repair/replace cut or broken tire casings. Always use

experienced, trained personnel with proper equipment and correct

procedures to mount or remove tires and wheels. Failure to adhere to

these warnings could result in wheel or tire malfunction, damage to

your vehicle, personal injury, or death.

WARNING:To avoid personal injury or death, always follow

these instructions when mounting radial tires on wheels:

•Only personnel that have had proper training and experience should

mount or remove tires from rims or wheels.

•Use only heavy-duty rims or approved rims for radial tires. It may be

necessary to contact your wheel and rim distributor to determine if

you can use radial tires with your rims.

•If you are using a tube, make sure to use special radial tire tubes

because of the increased flexing of the sidewalls on radial tires.

•Never use anti-freeze, silicones, or petroleum-based lubricants when

mounting radial tires. Make sure to use only an approved lubricant as

an aid for mounting tires.

•Always inflate tires in a safety cage.

•Do not attempt to mix stud piloted wheels or fasteners with hub

piloted wheels or fasteners. To do so may cause premature wheel

failure resulting in property damage, personal injury, or death.

•Do not mix foreign (not made in North America) wheel-mounting

parts with domestic (made in North America) parts. Many foreign

wheel components look similar to, but are not the same as domestic

made components. Mixing components could cause wheel or fastener

failures and result in property damage, personal injury, or death.

Wheels and Tires243

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 251 of 384

Oil-lubricated Front Wheel Bearings

During normal vehicle duty cycle, the lubricant and air inside the

hub/wheel cavity expands and, if not vented, causes pressure build-up

that could cause accelerated seal wear. You can use two venting methods

to prevent pressure build-up:

•A slit or small hole in the rubber check vent

•The window.

Over a period, if not routinely cleaned, a slight film of oil can collect dirt

around the rubber fill plug and face, which could appear to be a leak.

Routine cleaning helps make sure that you can easily observe the

lubricant level through the window as intended. In situations where the

window is clean on the outside but discolored on the inside, you can

check the lubricant level by inserting a finger through the rubber check

vent hole.

The specified lubricant level for a window-type hubcap is from the

minimum line to five–sixteenth inch (8 millimeters) above the minimum

line. If the lubricant level should suddenly drop dramatically below the

minimum level, see theWorkshop Manualfor diagnostic procedure.

Installation, Tightening and Alignment

Make sure the threads on the studs and nuts are clean to permit correct

torque when installing wheels. The mounting surfaces of rims, wheels,

spacer rings and clamps must be free of dirt, rust, lubricants or damage.

Use a wire brush to clean the mounting contact surfaces. Do not use

lubricant on threads.

After properly tightening the rim or wheel, check it for proper alignment.

Rotate the wheel with a piece of chalk attached to a steady, firm surface,

and placed to just barely clear the outside surface of the tire bead seat;

this procedure points out the high spot. A high spot does not necessarily

indicate unevenly tightened lug nuts, but may be the result of a bent

wheel.

Use the following installation procedure:

1. Slide inner rear or front tire and wheel in position over studs and push

it back as far as possible. Use care so you do not damage the threads on

the studs.

250Wheels and Tires

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)

Page 343 of 384

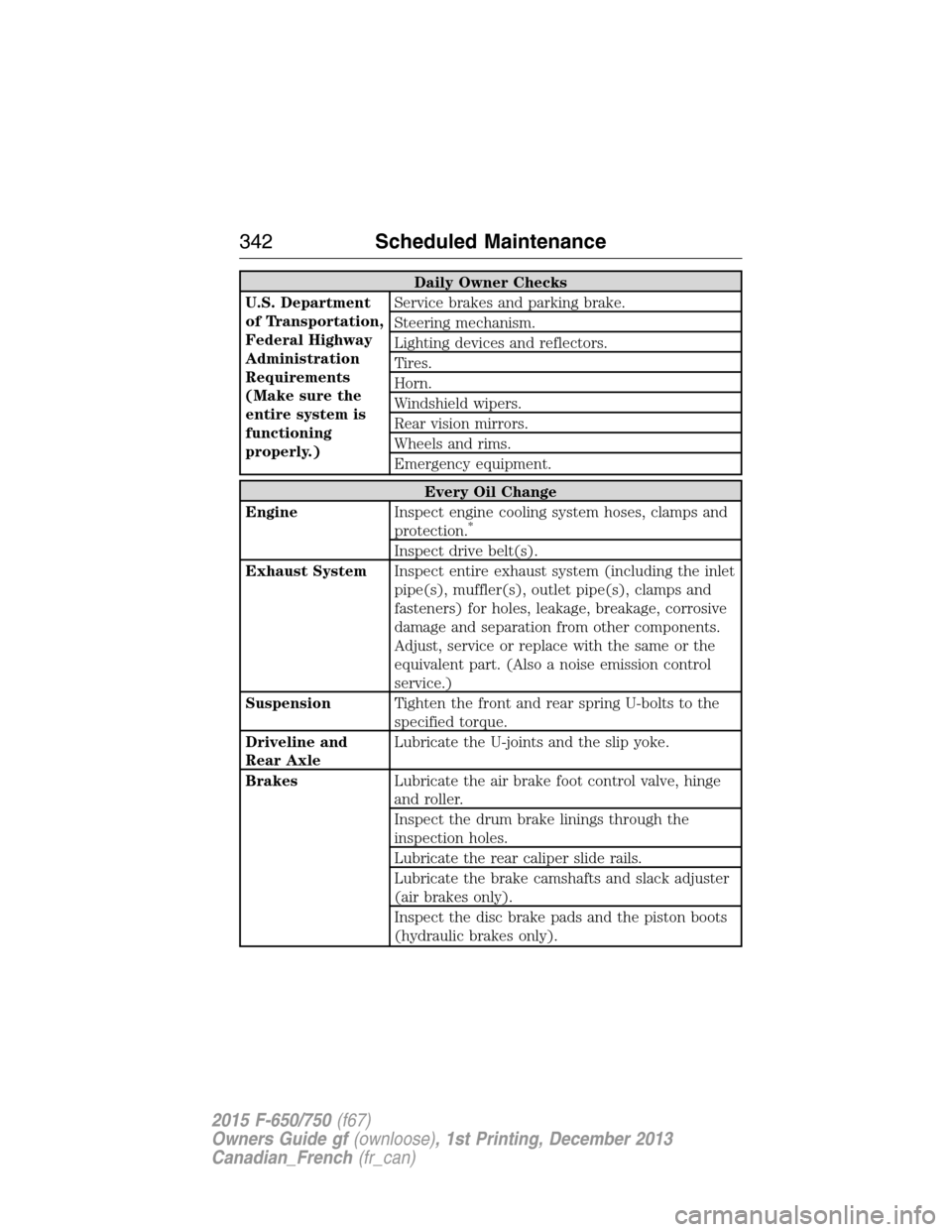

Daily Owner Checks

U.S. Department

of Transportation,

Federal Highway

Administration

Requirements

(Make sure the

entire system is

functioning

properly.)Service brakes and parking brake.

Steering mechanism.

Lighting devices and reflectors.

Tires.

Horn.

Windshield wipers.

Rear vision mirrors.

Wheels and rims.

Emergency equipment.

Every Oil Change

EngineInspect engine cooling system hoses, clamps and

protection.

*

Inspect drive belt(s).

Exhaust SystemInspect entire exhaust system (including the inlet

pipe(s), muffler(s), outlet pipe(s), clamps and

fasteners) for holes, leakage, breakage, corrosive

damage and separation from other components.

Adjust, service or replace with the same or the

equivalent part. (Also a noise emission control

service.)

SuspensionTighten the front and rear spring U-bolts to the

specified torque.

Driveline and

Rear AxleLubricate the U-joints and the slip yoke.

BrakesLubricate the air brake foot control valve, hinge

and roller.

Inspect the drum brake linings through the

inspection holes.

Lubricate the rear caliper slide rails.

Lubricate the brake camshafts and slack adjuster

(air brakes only).

Inspect the disc brake pads and the piston boots

(hydraulic brakes only).

342Scheduled Maintenance

2015 F-650/750(f67)

Owners Guide gf(ownloose), 1st Printing, December 2013

Canadian_French(fr_can)