ECU FORD F650 2017 13.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F650, Model: FORD F650 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 179 of 382

Diesel Exhaust Fluid (DEF) area

Verify the tanks and caps are secure and that there are no

leaks from the tanks.

DEF tanks

Inspect for leaks from the tanks.

Leaks Underbody

Verify that the driveshaft is not bent or cracked and that all

driveshaft couplings are secure.

Driveshaft

Verify that the visible outside parts are securely mounted and

that there are no cracks, holes or severe dents.

Exhaust system

Inspect for cracks or bends in longitudinal frame members.

Verify there are no loose, cracked, bent, broken or missing

crossmembers or crossmember fasteners.

Frame Rear of vehicle

Verify there are no cuts, cracks, chafing or wear on the air

hoses and electrical line insulation. Listen for audible air leaks.

Air hoses and electrical

lines

Verify air and electrical lines are not tangled, crimped or

pinched or being dragged against any truck parts. None of

the air or electrical line should be spliced or taped.

Inspect for corrosion on pins and in electrical sockets to verify

continuity and reduced heat build-up potential.

Verify the deck plate is clean, bolted securely to the frame

and is clear of loose objects.

Deck plate

Verify that both brake lights illuminate when the pedal is

applied, each signal flashes and that the four-way flashers

work properly.

Turns signals, brake

lights and flashers

Verify all exterior lights illuminate and are clean.

Lights and reflectors

Verify reflectors are clean, unbroken and of proper color (red

on rear, amber elsewhere).

Verify running lights are clean and unbroken.

Note: Inspect rear running lights separately from signal,

flasher and brake lights.

176

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide

Page 181 of 382

Rear brakes

Inspect for cracked, worn or frayed hoses, and that all coup-

lings are secure.

Hoses

Verify that there are no cracks or dents, and that the cham-

bers are securely mounted.

Brake chambers

Inspect for broken, loose or missing parts.

Slack adjusters

Note: The angle between the push rod and adjuster arm

should be approximately 90 degrees when the brakes are

applied. When pulled by hand, the push rod should not move

more than approximately

1 in (2.5 cm).

Verify that there are no cracks, dents, holes, and no loose or

missing bolts and that the brake linings are not worn,

dangerously thin or contaminated by lubricant.

Drums Rear wheels

Check for even separation of dual wheels, and that the tires

are not touching each other.

Spacers

Inspect for damaged or bent rims. They should not have

welding repairs, and there should be no rust trails, which

indicate it is loose on the wheel.

Rims

Verify all lug nuts are present and not loose (look for rust

trails around the lug nuts). There should be no cracks radiating

from the lug bolt holes or distortion of the bolt holes.

Lug nuts

Trailer

If you are pulling a trailer, perform an

inspection of the trailer similar to that of

the tractor. The inspection should follow

trailer manufacturer recommendations

and should include at a minimum: general

condition, landing gear, doors, sides, lights,

reflectors, suspension, brakes, tires,

wheels, cargo placement, stability and

tie-downs. Transmission WARNING

If the unit starts in gear and/or the

neutral start switch is not functioning

correctly, the vehicle may

inadvertently move which could result in

property damage, personal injury or death. Regularly inspect the transmission's

neutral start switch. The engine should

only start in neutral (N) or park (P) (if

equipped with a park position).

178

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide

Page 213 of 382

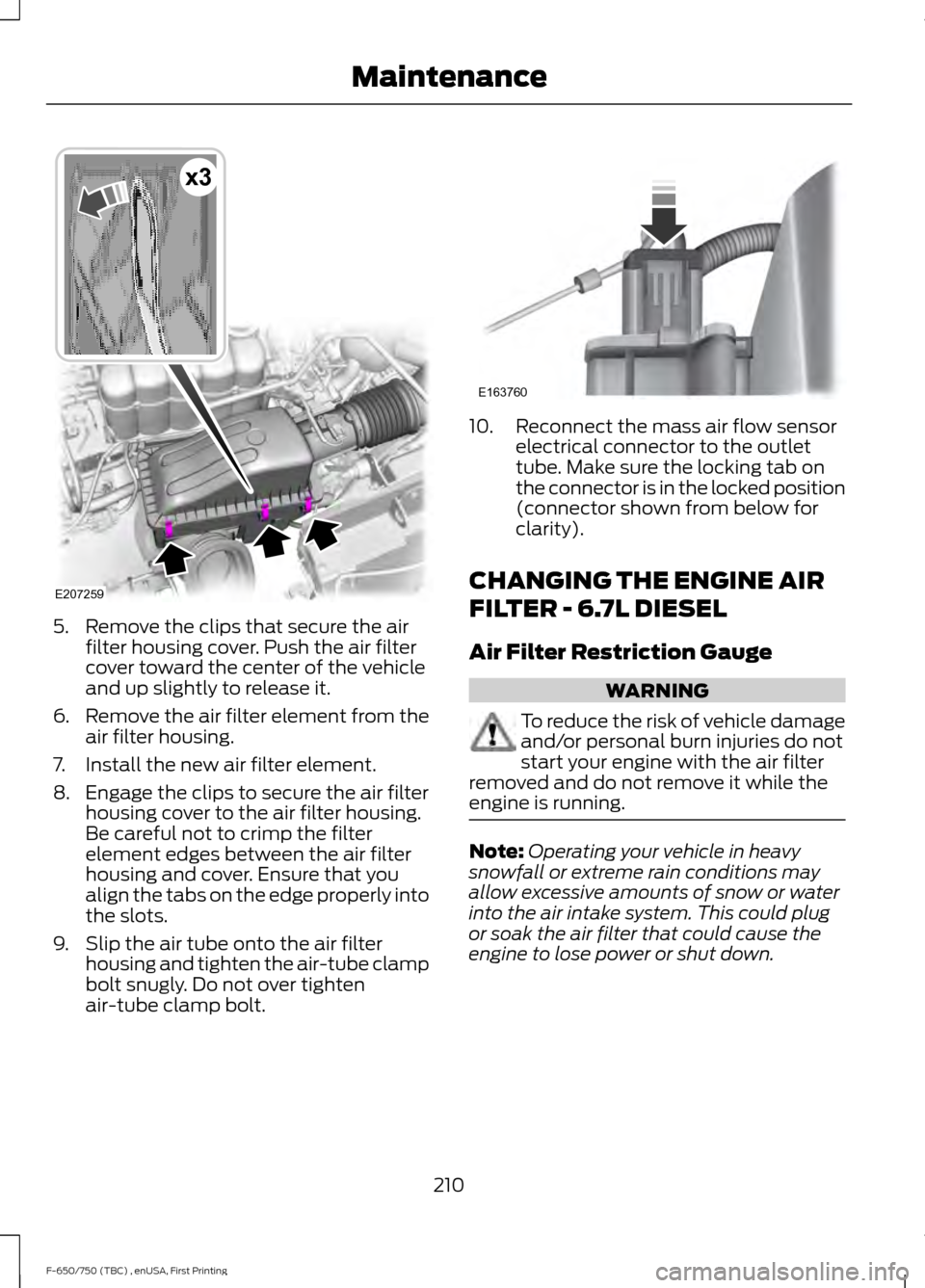

5. Remove the clips that secure the air

filter housing cover. Push the air filter

cover toward the center of the vehicle

and up slightly to release it.

6. Remove the air filter element from the

air filter housing.

7. Install the new air filter element.

8. Engage the clips to secure the air filter housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

9. Slip the air tube onto the air filter housing and tighten the air-tube clamp

bolt snugly. Do not over tighten

air-tube clamp bolt. 10. Reconnect the mass air flow sensor

electrical connector to the outlet

tube. Make sure the locking tab on

the connector is in the locked position

(connector shown from below for

clarity).

CHANGING THE ENGINE AIR

FILTER - 6.7L DIESEL

Air Filter Restriction Gauge WARNING

To reduce the risk of vehicle damage

and/or personal burn injuries do not

start your engine with the air filter

removed and do not remove it while the

engine is running. Note:

Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter that could cause the

engine to lose power or shut down.

210

F-650/750 (TBC) , enUSA, First Printing MaintenanceE207259

x3 E163760

Page 216 of 382

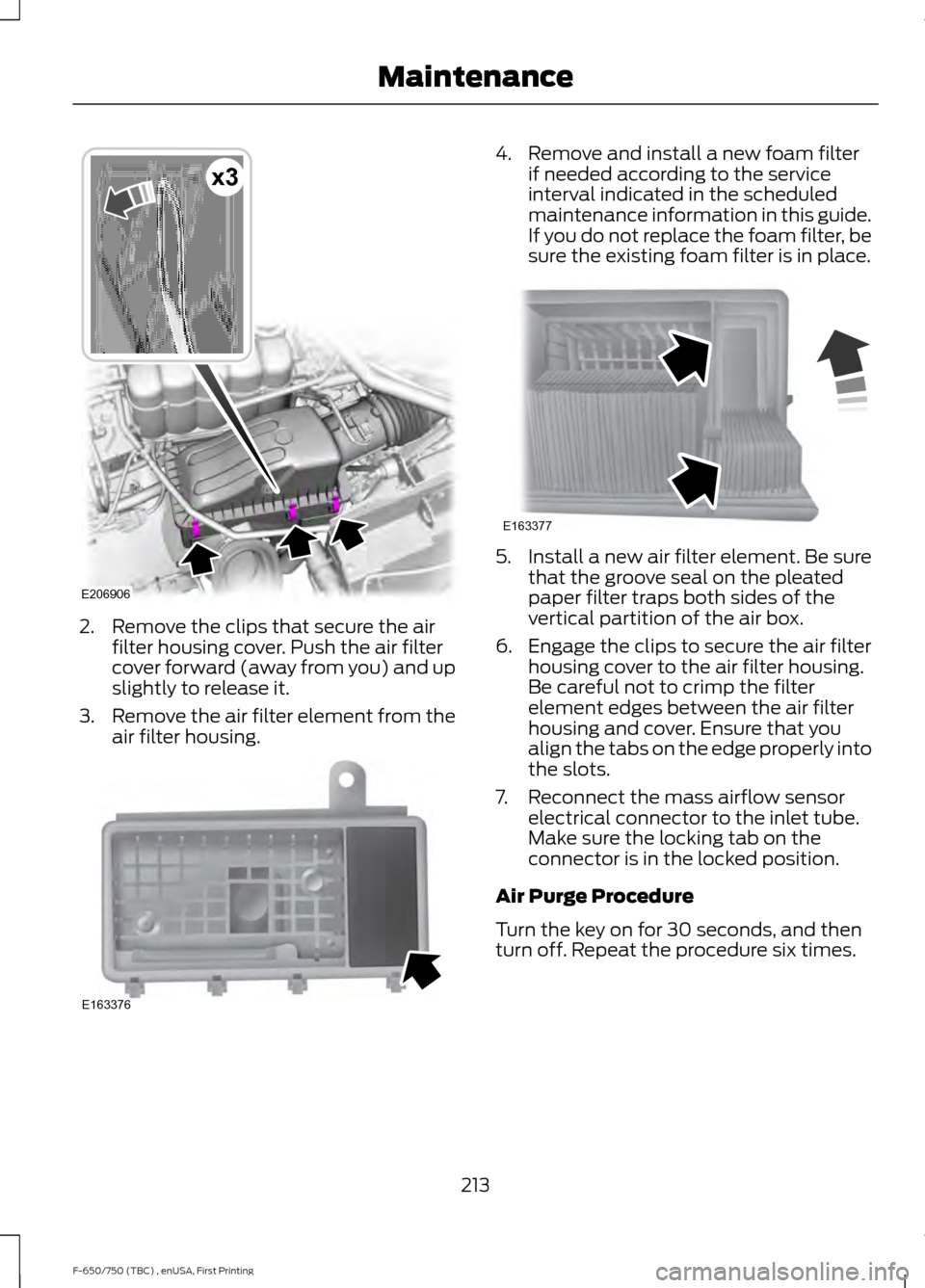

2. Remove the clips that secure the air

filter housing cover. Push the air filter

cover forward (away from you) and up

slightly to release it.

3. Remove the air filter element from the

air filter housing. 4. Remove and install a new foam filter

if needed according to the service

interval indicated in the scheduled

maintenance information in this guide.

If you do not replace the foam filter, be

sure the existing foam filter is in place. 5. Install a new air filter element. Be sure

that the groove seal on the pleated

paper filter traps both sides of the

vertical partition of the air box.

6. Engage the clips to secure the air filter housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

7. Reconnect the mass airflow sensor electrical connector to the inlet tube.

Make sure the locking tab on the

connector is in the locked position.

Air Purge Procedure

Turn the key on for 30 seconds, and then

turn off. Repeat the procedure six times.

213

F-650/750 (TBC) , enUSA, First Printing MaintenanceE206906

x3 E163376 E163377

Page 218 of 382

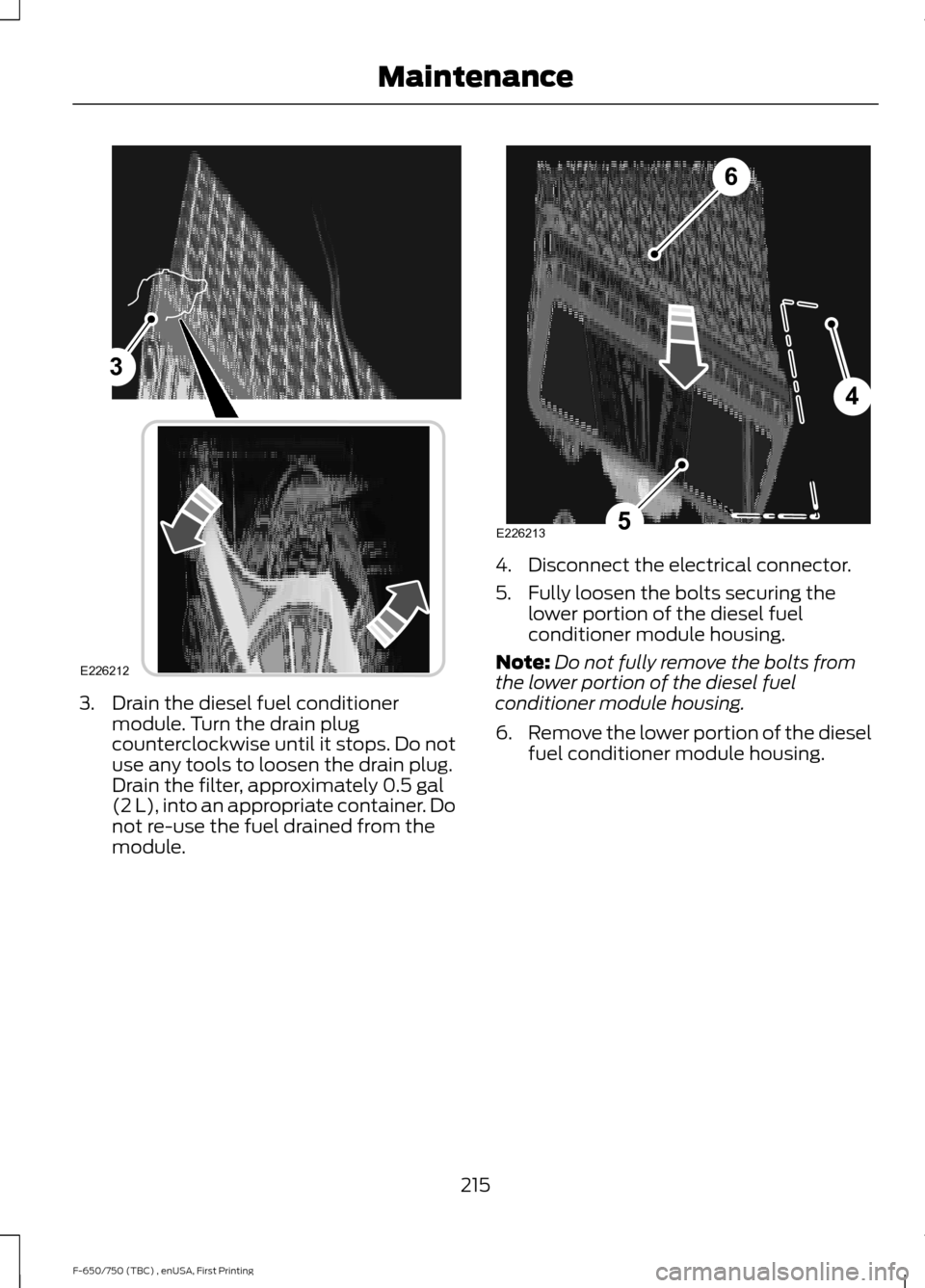

3. Drain the diesel fuel conditioner

module. Turn the drain plug

counterclockwise until it stops. Do not

use any tools to loosen the drain plug.

Drain the filter, approximately 0.5 gal

(2 L), into an appropriate container. Do

not re-use the fuel drained from the

module. 4. Disconnect the electrical connector.

5. Fully loosen the bolts securing the

lower portion of the diesel fuel

conditioner module housing.

Note: Do not fully remove the bolts from

the lower portion of the diesel fuel

conditioner module housing.

6. Remove the lower portion of the diesel

fuel conditioner module housing.

215

F-650/750 (TBC) , enUSA, First Printing Maintenance3

E226212 4

5

6

E226213

Page 219 of 382

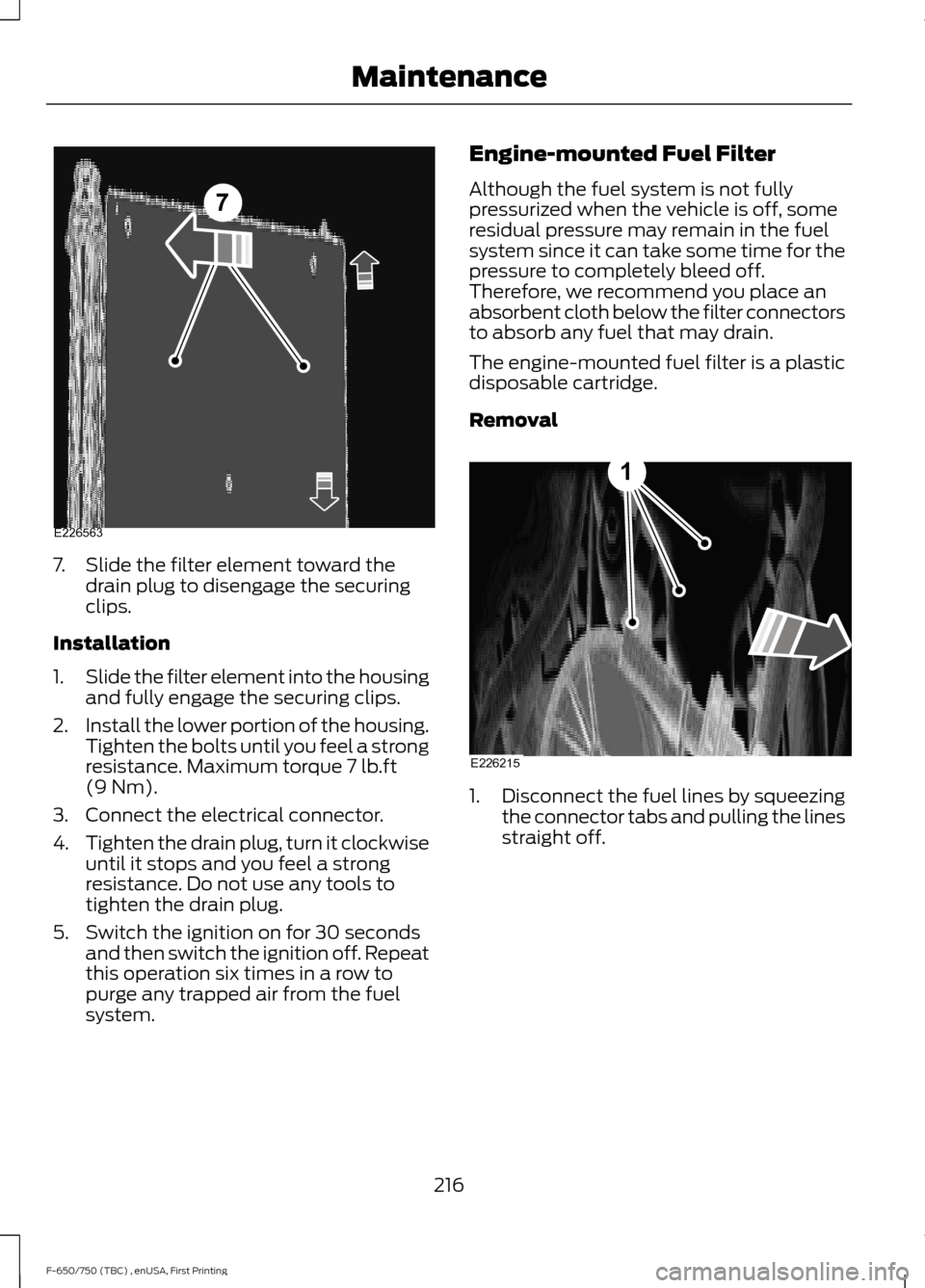

7. Slide the filter element toward the

drain plug to disengage the securing

clips.

Installation

1. Slide the filter element into the housing

and fully engage the securing clips.

2. Install the lower portion of the housing.

Tighten the bolts until you feel a strong

resistance. Maximum torque 7 lb.ft

(9 Nm).

3. Connect the electrical connector.

4. Tighten the drain plug, turn it clockwise

until it stops and you feel a strong

resistance. Do not use any tools to

tighten the drain plug.

5. Switch the ignition on for 30 seconds and then switch the ignition off. Repeat

this operation six times in a row to

purge any trapped air from the fuel

system. Engine-mounted Fuel Filter

Although the fuel system is not fully

pressurized when the vehicle is off, some

residual pressure may remain in the fuel

system since it can take some time for the

pressure to completely bleed off.

Therefore, we recommend you place an

absorbent cloth below the filter connectors

to absorb any fuel that may drain.

The engine-mounted fuel filter is a plastic

disposable cartridge.

Removal

1.

Disconnect the fuel lines by squeezing

the connector tabs and pulling the lines

straight off.

216

F-650/750 (TBC) , enUSA, First Printing Maintenance7

E226563 E226215

1

Page 227 of 382

Checking the Fluid Level

1. Park your vehicle on level ground.

2. Set the parking brake and shift into

position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle filler plug.

4. Remove the filler plug and inspect the lubricant level. It should be at the

bottom of the filler plug opening.

5. Add lubricant, if necessary, through the

filler plug opening.

6. Clean and install the filler plug securely.

Changing the Fluid

Note: Drain the rear axle while the lubricant

is warm.

1. Park your vehicle on level ground.

2. Set the parking brake and shift into position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle filler and drain plugs.

4. Remove the filler and drain plugs. Drain

the lubricant into a suitable container.

Dispose of all used automotive fluids

in a responsible manner following your

local authorized standards.

5. Clean and install the drain plug securely.

6. Add lubricant through the filler plug opening.

7. Clean and install the filler plug securely.

SPRING U-BOLT CHECK

Check and tighten the U-bolt nuts after

your vehicle has been operated under load

for 1,000 mi (1,600 km) or six months,

whichever occurs first. Thereafter, install new U-bolt nuts and

washers every

36,000 mi (58,000 km).

Check and tighten the U-bolt nuts with

your vehicle at curb height and unloaded.

Inspect the U-bolt threads for rust and

debris. Clean the threads if contaminated.

U-bolt Nut Torque

Front Axle

Note: Check and tighten the U-bolt nuts

evenly using a criss-cross pattern in the

following stages. lb.ft (Nm)

Stage

40 (60)

1.

90 (125)

2.

170 (225)

3.

240 (325)

4.

Rear Axle

Note: Check and tighten the U-bolt nuts

evenly using a criss-cross pattern in the

following stages. lb.ft (Nm)

Stage

60 (75)

1.

90 (125)

2.

170 (225)

3.

240 (325)

4.

320 (440)

5.

224

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 251 of 382

The tires on your vehicle have all-weather

treads to provide traction in rain and snow.

However, in some climates, you may need

to use snow tires and cables. If you need

to use cables, it is recommended that steel

wheels (of the same size and

specifications) be used, as cables may chip

aluminum wheels.

Note:

The suspension insulation and

bumpers help prevent vehicle damage. Do

not remove these components from your

vehicle when using snow tires and chains.

Follow these guidelines when using snow

tires and chains:

• If possible, avoid fully loading your

vehicle.

• Use only SAE Class S chains.

• Install chains securely, verifying that

the chains do not touch any wiring,

brake lines or fuel lines.

• Drive cautiously. If you hear the chains

rub or bang against your vehicle, stop

and retighten the chains. If this does

not work, remove the chains to prevent

damage to your vehicle.

• Remove the tire chains when they are

no longer needed. Do not use tire

chains on dry roads.

If you have any questions regarding snow

chains or cables, please contact your

authorized dealer.

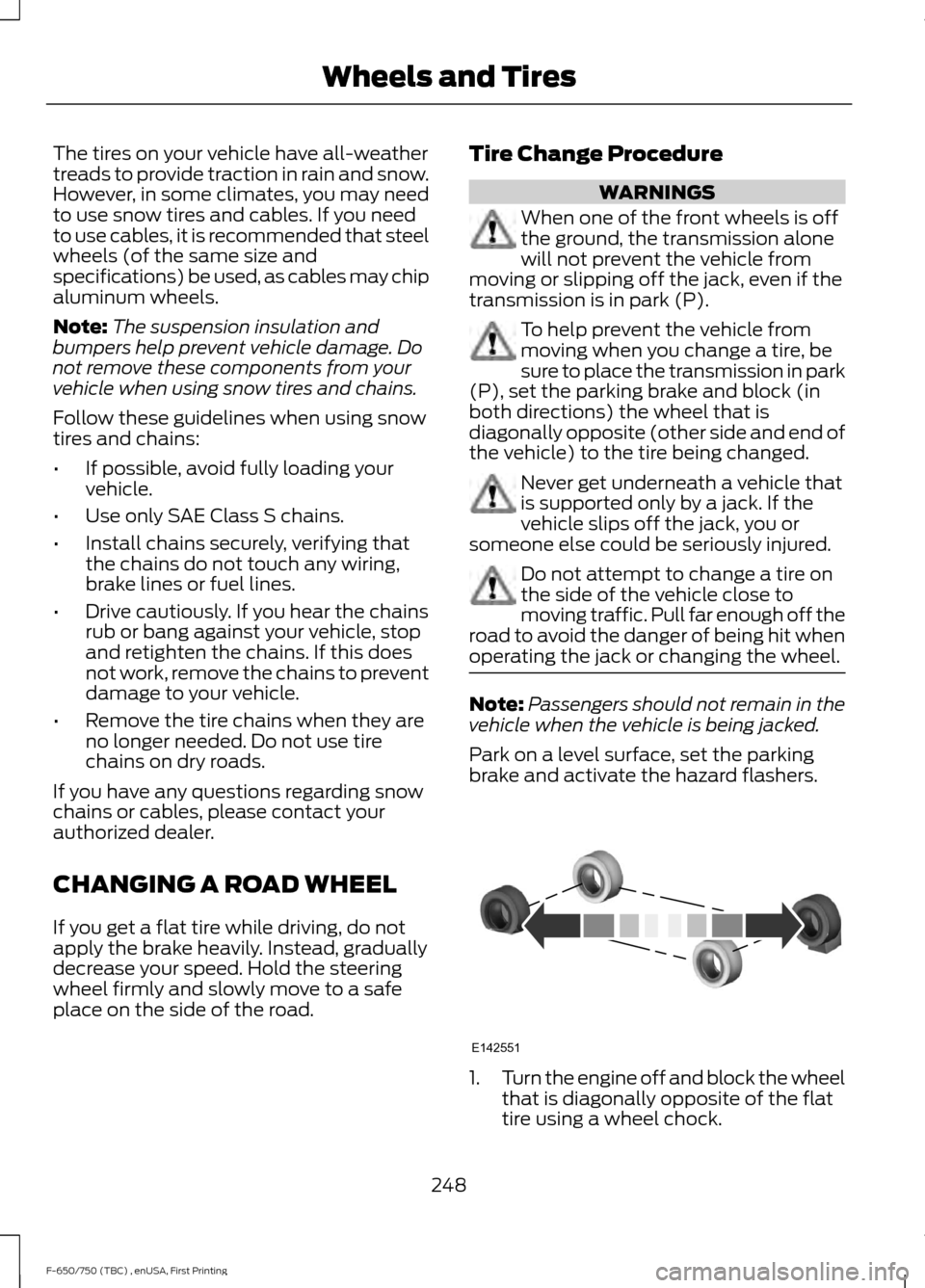

CHANGING A ROAD WHEEL

If you get a flat tire while driving, do not

apply the brake heavily. Instead, gradually

decrease your speed. Hold the steering

wheel firmly and slowly move to a safe

place on the side of the road. Tire Change Procedure WARNINGS

When one of the front wheels is off

the ground, the transmission alone

will not prevent the vehicle from

moving or slipping off the jack, even if the

transmission is in park (P). To help prevent the vehicle from

moving when you change a tire, be

sure to place the transmission in park

(P), set the parking brake and block (in

both directions) the wheel that is

diagonally opposite (other side and end of

the vehicle) to the tire being changed. Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured. Do not attempt to change a tire on

the side of the vehicle close to

moving traffic. Pull far enough off the

road to avoid the danger of being hit when

operating the jack or changing the wheel. Note:

Passengers should not remain in the

vehicle when the vehicle is being jacked.

Park on a level surface, set the parking

brake and activate the hazard flashers. 1.

Turn the engine off and block the wheel

that is diagonally opposite of the flat

tire using a wheel chock.

248

F-650/750 (TBC) , enUSA, First Printing Wheels and TiresE142551

Page 253 of 382

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign materials

present on the mounting surfaces of the wheel or the surface of the wheel hub,

brake drum or brake disc that contacts the wheel. Make sure that any fasteners

that attach the rotor to the hub are secured so they do not interfere with the mounting

surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off

while the vehicle is in motion, resulting in loss of control. lb.ft (Nm)

Bolt size

450–500 lb.ft (610–678 Nm)

M22 x 1.5

* Torque specifications are for nut and bolt threads free of dirt and rust. Use only Ford

recommended replacement fasteners.

On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque

at 100 miles (160 kilometers) after any wheel disturbance (such as tire rotation, changing

a flat tire, wheel removal).

On vehicles equipped with dual rear wheels, retighten the lug nuts to the specified torque

at 100 miles (160 kilometers) and again at 500 miles (800 kilometers) of new vehicle

operation and after any wheel disturbance (such as tire rotation, changing a flat tire,

wheel removal).

It is important to follow the proper wheel mounting and lug nut torque procedures. On all two-piece flat wheel nuts,

apply one drop of motor oil

between the flat washer and the

nut. Do not apply motor oil to the

wheel nut threads or the wheel

stud threads.

250

F-650/750 (TBC) , enUSA, First Printing Wheels and TiresE161443

Page 282 of 382

AUDIO INPUT JACK

WARNINGS

Driving while distracted can result in

loss of vehicle control, crash and

injury. We strongly recommend that

you use extreme caution when using any

device that may take your focus off the

road. Your primary responsibility is the safe

operation of your vehicle. We recommend

against the use of any hand-held device

while driving and encourage the use of

voice-operated systems when possible.

Make sure you are aware of all applicable

local laws that may affect the use of

electronic devices while driving. For safety reasons, do not connect

or adjust the settings on your

portable music player while your

vehicle is moving. Store the portable music player in a

secure location, such as the center

console or the glove box, when your

vehicle is moving. Hard objects may

become projectiles in a collision or sudden

stop, which may increase the risk of serious

injury. The audio extension cable must be

long enough to allow the portable music

player to be safely stored while your

vehicle is moving. The auxiliary input jack allows you to

connect and play music from your portable

music player through your vehicle speakers.

You can use any portable music player

designed for use with headphones. Your

audio extension cable must have male

1/8th-inch (3.5 millimeter) connectors at

each end.

1. Make sure your vehicle, radio and

portable music player are turned off

and the transmission is in position P.

2. Plug the extension cable from the portable music player into the AIJ.

3. Turn on the radio. Select either a tuned

FM station or a CD.

4. Adjust the volume as desired.

5. Turn on your portable music player and

adjust its volume to half its maximum

level.

6. Press

AUX until LINE or LINE IN

appears in the display. You should hear

music from your device even if it is low.

7. Adjust the volume on your portable music player until it reaches the volume

level of the FM station or CD. Do this

by switching back and forth between

the AUX and FM or CD controls.

USB PORT

(If Equipped) 279

F-650/750 (TBC) , enUSA, First Printing Audio SystemE163160 E163161