ECU FORD F650 2017 13.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F650, Model: FORD F650 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 41 of 382

GENERAL INFORMATION ON

RADIO FREQUENCIES

This device complies with Part 15 of the

FCC Rules and with Industry Canada

license-exempt RSS standard(s).

Operation is subject to the following two

conditions: (1) This device may not cause

harmful interference, and (2) This device

must accept any interference received,

including interference that may cause

undesired operation.

Note:

Changes or modifications not

expressively approved by the party

responsible for compliance could void the

user's authority to operate the equipment.

The term IC before the radio certification

number only signifies that Industry Canada

technical specifications were met.

The typical operating range for your

transmitter is approximately 33 feet (10

meters). Vehicles with the remote start

feature will have a greater range. One of

the following could cause a decrease in

operating range:

• weather conditions

• nearby radio towers

• structures around the vehicle

• other vehicles parked next to your

vehicle

The radio frequency used by your remote

control can also be used by other short

distance radio transmissions, for example

amateur radios, medical equipment,

wireless headphones, remote controls and

alarm systems. If the frequencies are

jammed, you will not be able to use your

remote control. You can lock and unlock

the doors with the key.

Note: Make sure to lock your vehicle before

leaving it unattended.

Note: If you are in range, the remote control

will operate if you press any button

unintentionally. Note:

The remote control contains sensitive

electrical components. Exposure to moisture

or impact may cause permanent damage.

REMOTE CONTROL

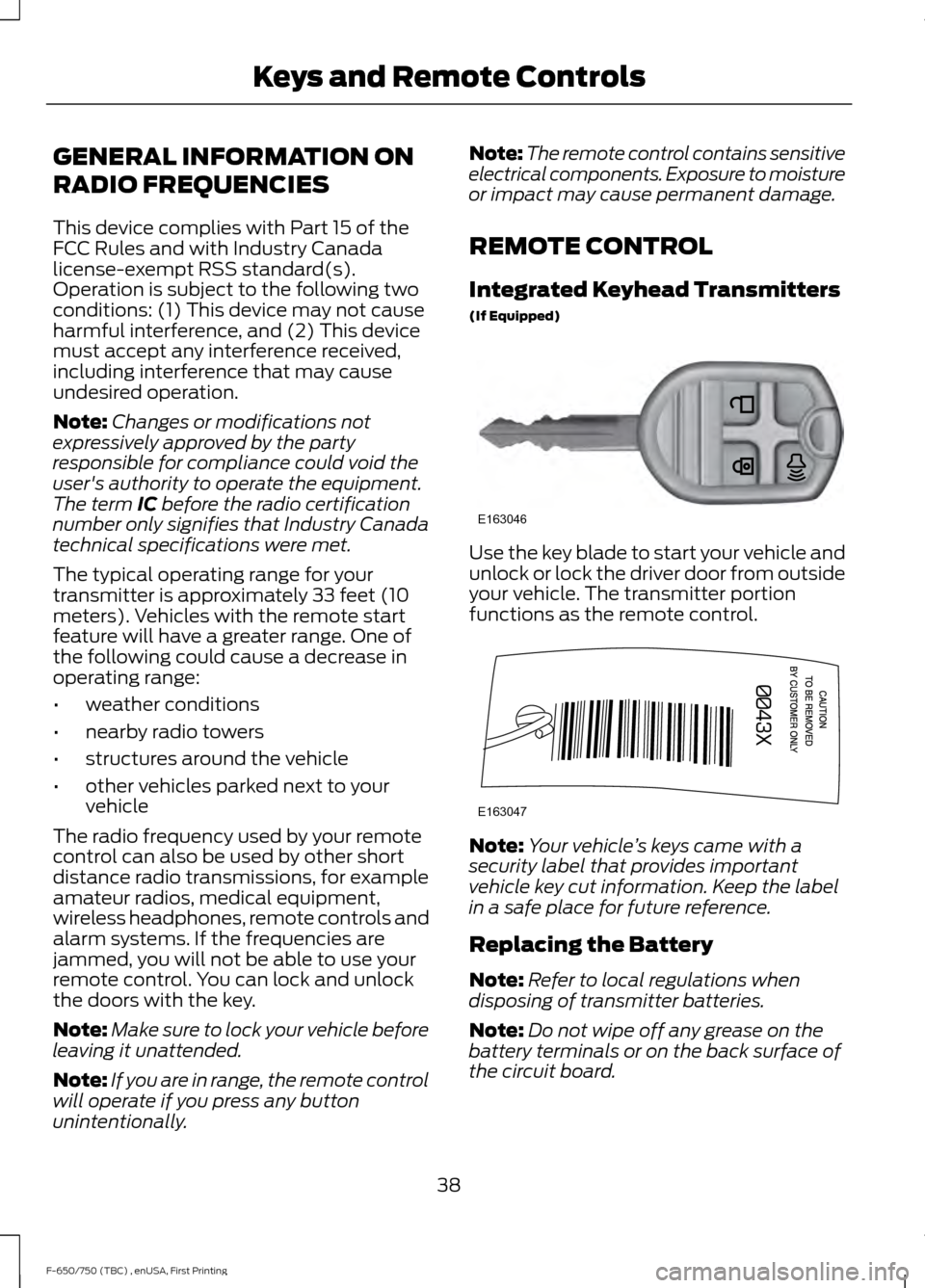

Integrated Keyhead Transmitters

(If Equipped) Use the key blade to start your vehicle and

unlock or lock the driver door from outside

your vehicle. The transmitter portion

functions as the remote control.

Note:

Your vehicle ’s keys came with a

security label that provides important

vehicle key cut information. Keep the label

in a safe place for future reference.

Replacing the Battery

Note: Refer to local regulations when

disposing of transmitter batteries.

Note: Do not wipe off any grease on the

battery terminals or on the back surface of

the circuit board.

38

F-650/750 (TBC) , enUSA, First Printing Keys and Remote ControlsE163046 E163047

Page 45 of 382

PASSIVE ANTI-THEFT

SYSTEM (If Equipped)

Note: The system is not compatible with

non-Ford aftermarket remote start systems.

Use of these systems may result in engine

starting problems and a loss of security

protection.

Note: Metallic objects, electronic devices

or a second coded key on the same key

chain may result in vehicle starting

problems, especially if they are too close to

the key when starting your vehicle. Prevent

these objects from touching the coded key

when starting your vehicle. Switch the

ignition off, move all objects on the key

chain away from the coded key and restart

your vehicle if a problem occurs.

Note: Do not leave a duplicate coded key

in your vehicle. Always take your keys and

lock all doors when leaving your vehicle.

SecuriLock®

The system helps prevent the engine from

starting unless you use a coded key

programmed to your vehicle. Using the

wrong key may prevent your vehicle from

starting. A message may appear in the

information display.

If you are unable to start your vehicle with

a coded key, it is not operating correctly.

A message may appear in the information

display.

Automatic Arming

The system arms when you switch the

ignition off.

Automatic Disarming

The system disarms when you switch the

ignition on with a coded key. Replacement Keys

Note:

Your vehicle may have two integrated

keyhead transmitters.

The integrated keyhead transmitter

functions as a programmed ignition key

that operates all the locks and starts your

vehicle, as well as a remote control.

If your programmed transmitters or

standard SecuriLock coded keys are lost

or stolen and you do not have an extra

coded key, you will need to have your

vehicle towed to an authorized dealer. You

need to erase the key codes from your

vehicle and program new coded keys.

Store an extra programmed key away from

your vehicle in a safe place. Contact an

authorized dealer to purchase additional

spare or replacement keys.

Programming a Spare Key

Note: You can program a maximum of six

keys to your vehicle.

You can program your own integrated

keyhead transmitter or standard

SecuriLock coded keys to your vehicle.

This procedure programs both the vehicle

immobilizer keycode and the remote

control to your vehicle.

Only use integrated keyhead transmitters

or standard SecuriLock keys.

You must have two previously

programmed coded keys and the new

unprogrammed key readily accessible.

Contact an authorized dealer to have the

spare key programmed if two previously

programmed keys are not available.

Read and understand the entire procedure

before you begin.

1. Insert the first previously programmed

coded key into the ignition.

2. Switch the ignition from off to on. Keep

the ignition on for at least 3 seconds,

but no more than 10 seconds.

42

F-650/750 (TBC) , enUSA, First Printing Security

Page 46 of 382

3.

Switch the ignition off and remove the

first coded key from the ignition.

4. After at least 3 seconds but within 10 seconds of switching the ignition off,

insert the second previously coded key

into the ignition.

5. Switch the ignition from off to on. Keep

the ignition on for at least 3 seconds,

but no more than 10 seconds.

6. Switch the ignition off and remove the

second previously programmed coded

key from the ignition.

7. After at least 3 seconds but within 10 seconds of switching the ignition off

and removing the previously

programmed coded key, insert the new

unprogrammed key into the ignition.

8. Switch the ignition from off to on. Keep

the ignition on for at least six seconds.

9. Remove the newly programmed coded

key from the ignition.

The doors lock then unlock to confirm that

programming was successful. If you have

successfully programmed the new

integrated keyhead transmitter, it will start

your vehicle and operate the remote entry

system.

If programming was unsuccessful, wait 20

seconds and repeat Steps 1 through 8. If

you are still unsuccessful, take your vehicle

to an authorized dealer.

43

F-650/750 (TBC) , enUSA, First Printing Security

Page 115 of 382

AUTOMATIC TRANSMISSION

WARNING

Always set the parking brake fully

and make sure you shift the gearshift

lever to park (P). Switch the ignition

off and remove the key whenever you leave

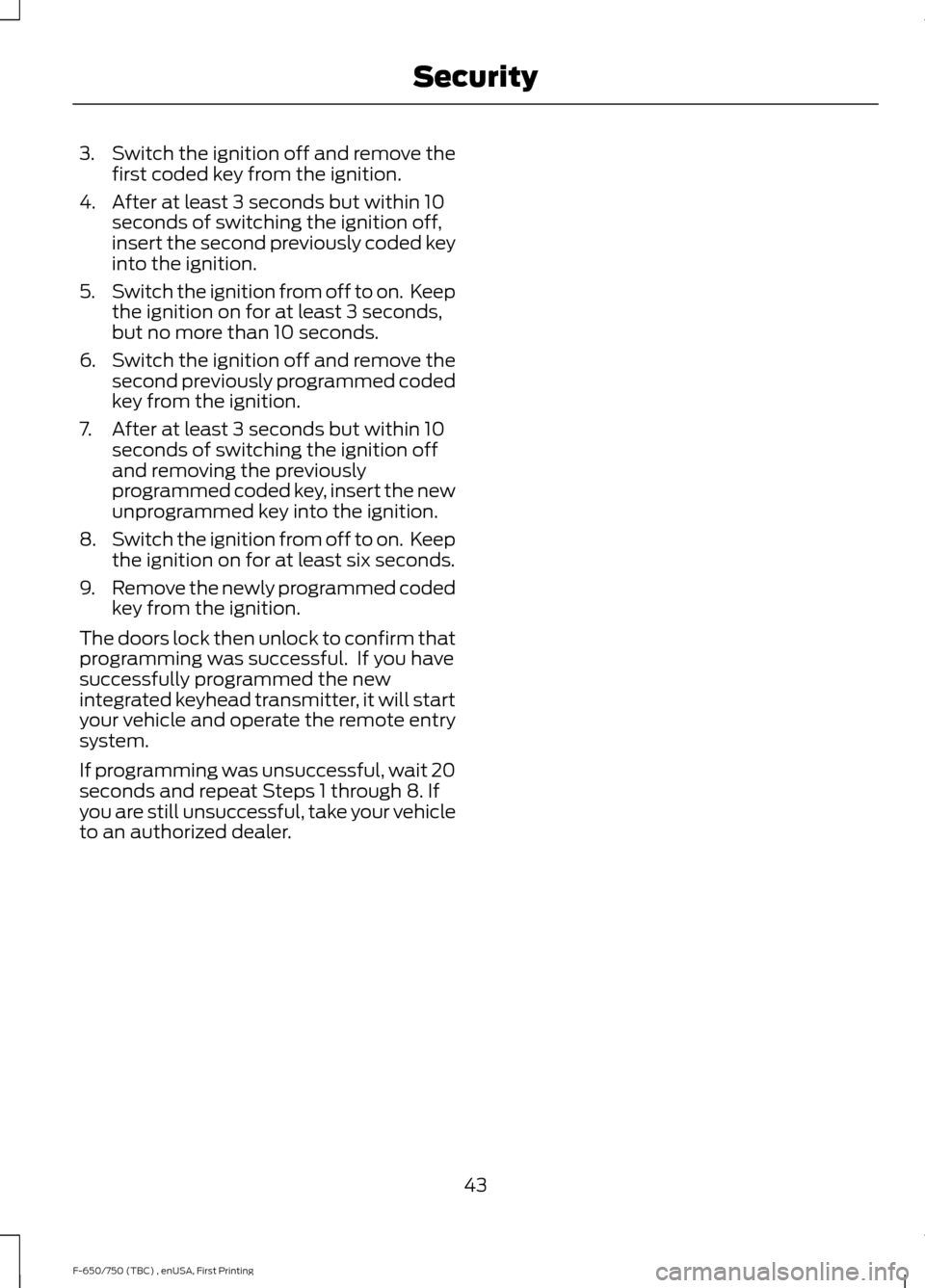

your vehicle. Understanding the Shift Positions

of a 6–

Speed Automatic

Transmission (If Equipped) Putting your vehicle in or out of gear:

1. Fully press down the brake pedal.

2. Move the gearshift lever into the

desired gear.

3. Come to a complete stop.

4. Move the gearshift lever and securely latch it in park (P) or neutral (N).

Park (P) (If Equipped)

If your transmission has a park position,

this position locks the transmission and

prevents the rear wheels from turning.

Reverse (R)

With the gearshift lever in reverse (R), your

vehicle moves backward. Always come to

a complete stop before shifting into and

out of reverse (R). Neutral (N)

With the gearshift lever in neutral (N), you

can start your vehicle and it is free to roll.

Hold the brake pedal down while in this

position.

Drive (D)

Drive (D) is the normal driving position for

the best fuel economy. The overdrive

function allows automatic upshifts and

downshifts through gears one through six.

M (Manual)

With the gearshift lever in manual (M), the

driver can change gears up or down as

desired. By moving the gearshift lever from

drive position drive (D) to manual (M) you

now have control of selecting the gear you

desire using buttons on the shift lever. See

Understanding your SelectShift

Automatic

™ transmission later in this

section.

To return to normal drive (D) position,

move the shift lever back from manual (M)

to drive (D).

The transmission operates in gears one

through six.

Second (2)

Transmission operates in second (2) gear

only. Use second (2) gear to start-up on

slippery roads.

First (1)

• Transmission operates in first (1) gear

only.

• Provides maximum engine braking.

• Allows upshifts by moving gearshift

lever.

• Does not downshift into first (1) gear

at high speeds; allows for first (1) gear

when vehicle reaches slower speeds.

112

F-650/750 (TBC) , enUSA, First Printing TransmissionE163183

Page 118 of 382

Brake-Shift Interlock (If Equipped)

WARNINGS

Do not drive your vehicle until you

verify that the brake lamps are

working.

When doing this procedure, you need

to take the transmission out of park

(P) which means your vehicle can

roll freely. To avoid unwanted vehicle

movement, always fully set the parking

brake prior to doing this procedure. Use

wheels chocks if appropriate. If the parking brake is fully released,

but the brake warning lamp remains

illuminated, the brakes may not be

working properly. Have your vehicle

checked as soon as possible. Your vehicle is equipped with a brake-shift

interlock feature that prevents the

gearshift lever from moving from park (P)

when the ignition is in the 3 (on) position

and the brake pedal is not pressed.

If you cannot move the gearshift lever out

of park (P) position with the ignition in the

4 (on) position and the brake pedal

pressed, a malfunction may have occurred.

It is possible that a fuse has blown or your

vehicle

’s brake lamps are not operating

properly. See

Fuse Specification Chart

(page 161).

If the fuse is not blown and the brake

lamps are working properly, the following

procedure allows you to move the gearshift

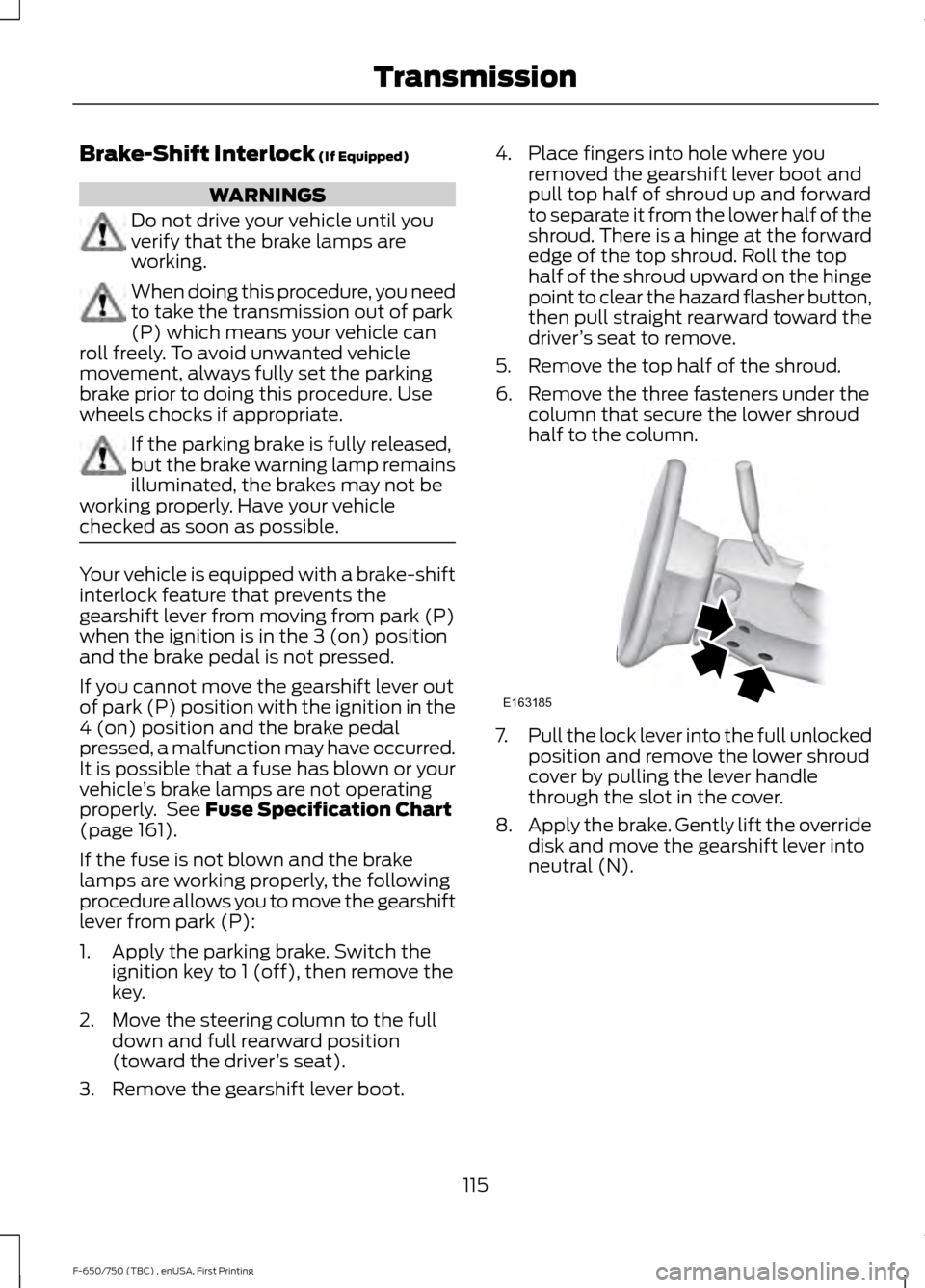

lever from park (P):

1. Apply the parking brake. Switch the ignition key to 1 (off), then remove the

key.

2. Move the steering column to the full down and full rearward position

(toward the driver ’s seat).

3. Remove the gearshift lever boot. 4. Place fingers into hole where you

removed the gearshift lever boot and

pull top half of shroud up and forward

to separate it from the lower half of the

shroud. There is a hinge at the forward

edge of the top shroud. Roll the top

half of the shroud upward on the hinge

point to clear the hazard flasher button,

then pull straight rearward toward the

driver ’s seat to remove.

5. Remove the top half of the shroud.

6. Remove the three fasteners under the column that secure the lower shroud

half to the column. 7.

Pull the lock lever into the full unlocked

position and remove the lower shroud

cover by pulling the lever handle

through the slot in the cover.

8. Apply the brake. Gently lift the override

disk and move the gearshift lever into

neutral (N).

115

F-650/750 (TBC) , enUSA, First Printing TransmissionE163185

Page 125 of 382

Parking Brake Light Illumination Due

to Low Air Pressure

If the air pressure becomes too low at any

time during vehicle operation, the parking

brake may apply and the parking brake

light turns on.

If the parking brake applies due to low air

pressure, immediate service is required to

the parking brake system.

Releasing Spring Brake with Air

Pressure

The air system in all vehicles with

spring-actuated rear wheel parking brakes

has a valve on the governor for connection

to an outside air supply. The valve lets you

recharge the system with air from an

outside source, releasing the

spring-actuated parking brakes. Your

vehicle is now ready to tow in an

emergency.

You can only use an outside air source if

the protected system is in operating

condition. If you cannot restore air pressure

in the protected air system, you must

release the spring-actuated brakes

manually.

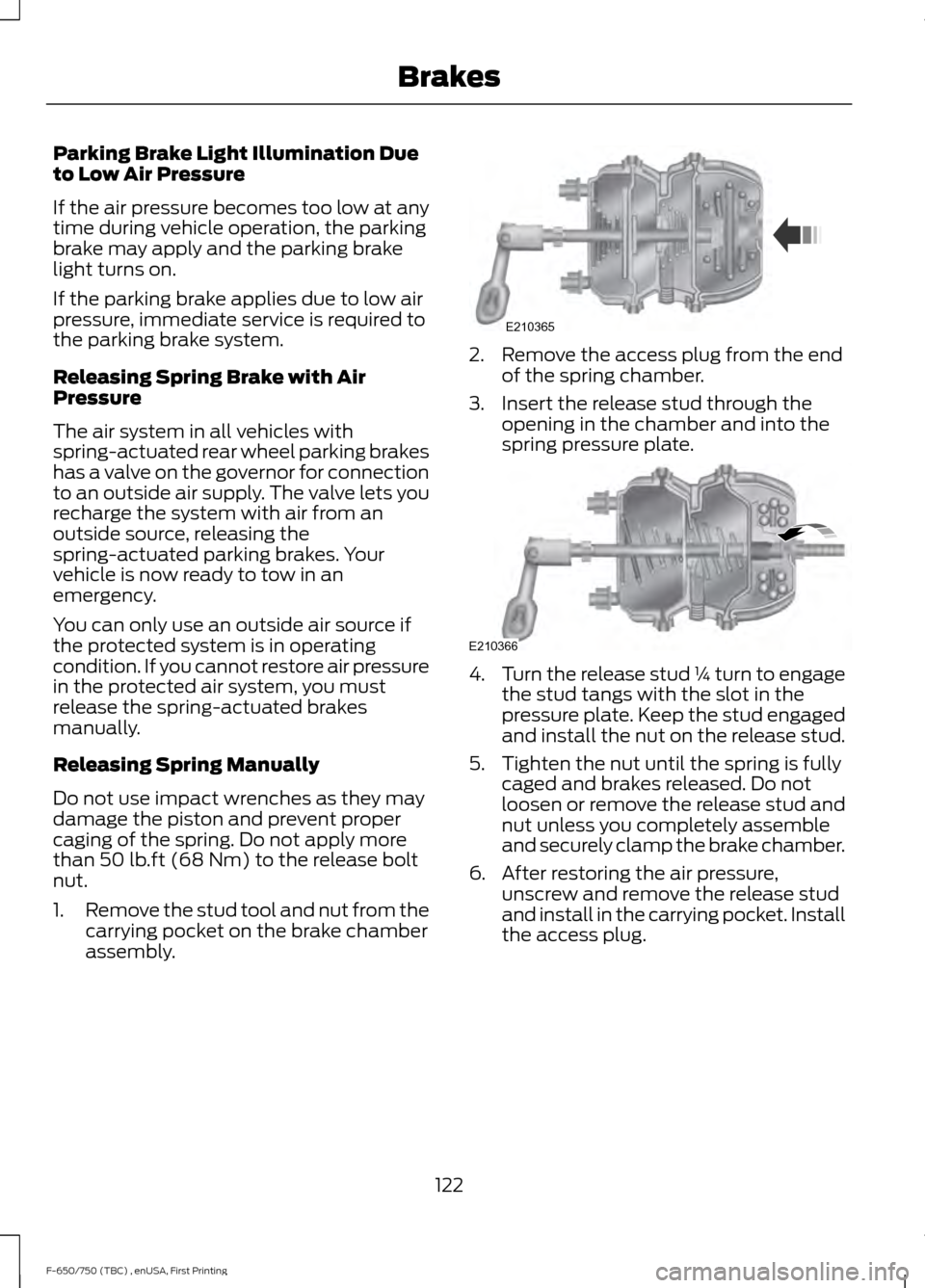

Releasing Spring Manually

Do not use impact wrenches as they may

damage the piston and prevent proper

caging of the spring. Do not apply more

than 50 lb.ft (68 Nm) to the release bolt

nut.

1. Remove the stud tool and nut from the

carrying pocket on the brake chamber

assembly. 2. Remove the access plug from the end

of the spring chamber.

3. Insert the release stud through the opening in the chamber and into the

spring pressure plate. 4.

Turn the release stud ¼ turn to engage

the stud tangs with the slot in the

pressure plate. Keep the stud engaged

and install the nut on the release stud.

5. Tighten the nut until the spring is fully caged and brakes released. Do not

loosen or remove the release stud and

nut unless you completely assemble

and securely clamp the brake chamber.

6. After restoring the air pressure, unscrew and remove the release stud

and install in the carrying pocket. Install

the access plug.

122

F-650/750 (TBC) , enUSA, First Printing BrakesE210365 E210366

Page 144 of 382

•

Shift to a lower gear when driving down

a long or steep hill. Do not apply the

brakes continuously, as they may

overheat and become less effective.

• If your transmission is equipped with

the Tow/Haul feature, use this feature

when towing. This provides engine

braking and helps eliminate excessive

transmission shifting for optimum fuel

economy and transmission cooling.

• Allow more distance for stopping with

a trailer attached. Anticipate stops and

brake gradually.

FIFTH WHEEL OPERATION WARNINGS

Failure to follow the fifth wheel

manufacturer

’s instructions for

hooking and unhooking as well as

sliding the fifth wheel could result in an

accident, personal injury or death. When the tractor and trailer are

parked unattended, the trailer brake

hand control should never be used

to apply the brake, since air may leak from

the system, allowing vehicle movement,

resulting in possible property damage,

personal injury or death. Before hook-up, make sure:

•

The fifth wheel jaws are fully open.

• The fifth wheel is fully tilted back to

prevent body damage when the tractor

is backed under a trailer.

• You block the trailer wheels and adjust

and apply the trailer spring brakes.

Never chase a trailer.

• The brake hoses and light cords are

clear of the fifth wheel. Hook-up

1. Back the tractor squarely under the

trailer, engaging the fifth-wheel jaws

on the kingpin. Always back up slowly;

make sure the trailer is neither too high

nor too low. Avoid backing under the

trailer from an angle.

2. Connect the service and emergency brake hoses and trailer light connector.

3. Inspect the jaws of the fifth wheel to be sure they have fully closed on the

trailer kingpin and the trailer plate is

resting securely on the fifth wheel.

4. Make sure the coupler release lever is in the locked position.

5. Charge the trailer brake system. Set the trailer brakes, with either the hand

valve or tractor protection valve. Pull

against the trailer for an extra check of

proper hook-up. Do not pull hard

enough to damage or strain the

equipment.

6. Set the tractor parking brakes and fully

raise the trailer landing gear.

7. Check the operation of all trailer lights

and correct any lights that may be

faulty.

Un-hook

1. Try to keep the tractor and trailer in a straight line.

2. Apply the parking brakes.

3. Lower the trailer landing gear, making sure it is on solid, level ground. The

weight of the trailer is to be on the

landing gear.

4. Block the trailer wheels.

5. Disconnect the brake hoses and light cords. Be sure hoses and cords are

clear.

6. Pull coupler release lever to disengage

the fifth wheel jaws.

141

F-650/750 (TBC) , enUSA, First Printing Towing

Page 159 of 382

•

Vehicle Identification Number.

• Your telephone number (home and

business).

• The name of the authorized dealer and

city where located.

• The vehicle ’s current odometer reading.

In some states, you must directly notify

Ford in writing before pursuing remedies

under your state ’s warranty laws. Ford is

also allowed a final repair attempt in some

states.

In the United States, a warranty dispute

must be submitted to the BBB AUTO LINE

before taking action under the

Magnuson-Moss Warranty Act, or to the

extent allowed by state law, before

pursuing replacement or repurchase

remedies provided by certain state laws.

This dispute handling procedure is not

required prior to enforcing state created

rights or other rights which are independent

of the Magnuson-Moss Warranty Act or

state replacement or repurchase laws.

IN CALIFORNIA (U.S. ONLY)

California Civil Code Section 1793.2(d)

requires that, if a manufacturer or its

representative is unable to repair a motor

vehicle to conform to the vehicle ’s

applicable express warranty after a

reasonable number of attempts, the

manufacturer shall be required to either

replace the vehicle with one substantially

identical or repurchase the vehicle and

reimburse the buyer in an amount equal to

the actual price paid or payable by the

consumer (less a reasonable allowance

for consumer use). The consumer has the

right to choose whether to receive a refund

or replacement vehicle. California Civil Code Section 1793.22(b)

presumes that the manufacturer has had

a reasonable number of attempts to

conform the vehicle to its applicable

express warranties if, within the first 18

months of ownership of a new vehicle or

the first 18000 miles (29 000 km),

whichever occurs first:

1.

Two or more repair attempts are made

on the same non-conformity likely to

cause death or serious bodily injury OR

2. Four or more repair attempts are made

on the same nonconformity (a defect

or condition that substantially impairs

the use, value or safety of the vehicle)

OR

3. The vehicle is out of service for repair of nonconformities for a total of more

than 30 calendar days (not necessarily

all at one time).

In the case of 1 or 2 above, the consumer

must also notify the manufacturer of the

need for the repair of the nonconformity

at the following address:

Ford Motor Company

16800 Executive Plaza Drive

Mail Drop 3NE-B

Dearborn, MI 48126

You are required to submit your warranty

dispute to BBB AUTO LINE before asserting

in court any rights or remedies conferred

by California Civil Code Section 1793.22(b).

You are also required to use BBB AUTO

LINE before exercising rights or seeking

remedies created by the Federal

Magnuson-Moss Warranty Act, 15 U.S.C.

sec. 2301 et seq. If you choose to seek

redress by pursuing rights and remedies

not created by California Civil Code Section

1793.22(b) or the Magnuson-Moss

Warranty Act, resort to BBB AUTO LINE is

not required by those statutes.

156

F-650/750 (TBC) , enUSA, First Printing Customer Assistance

Page 163 of 382

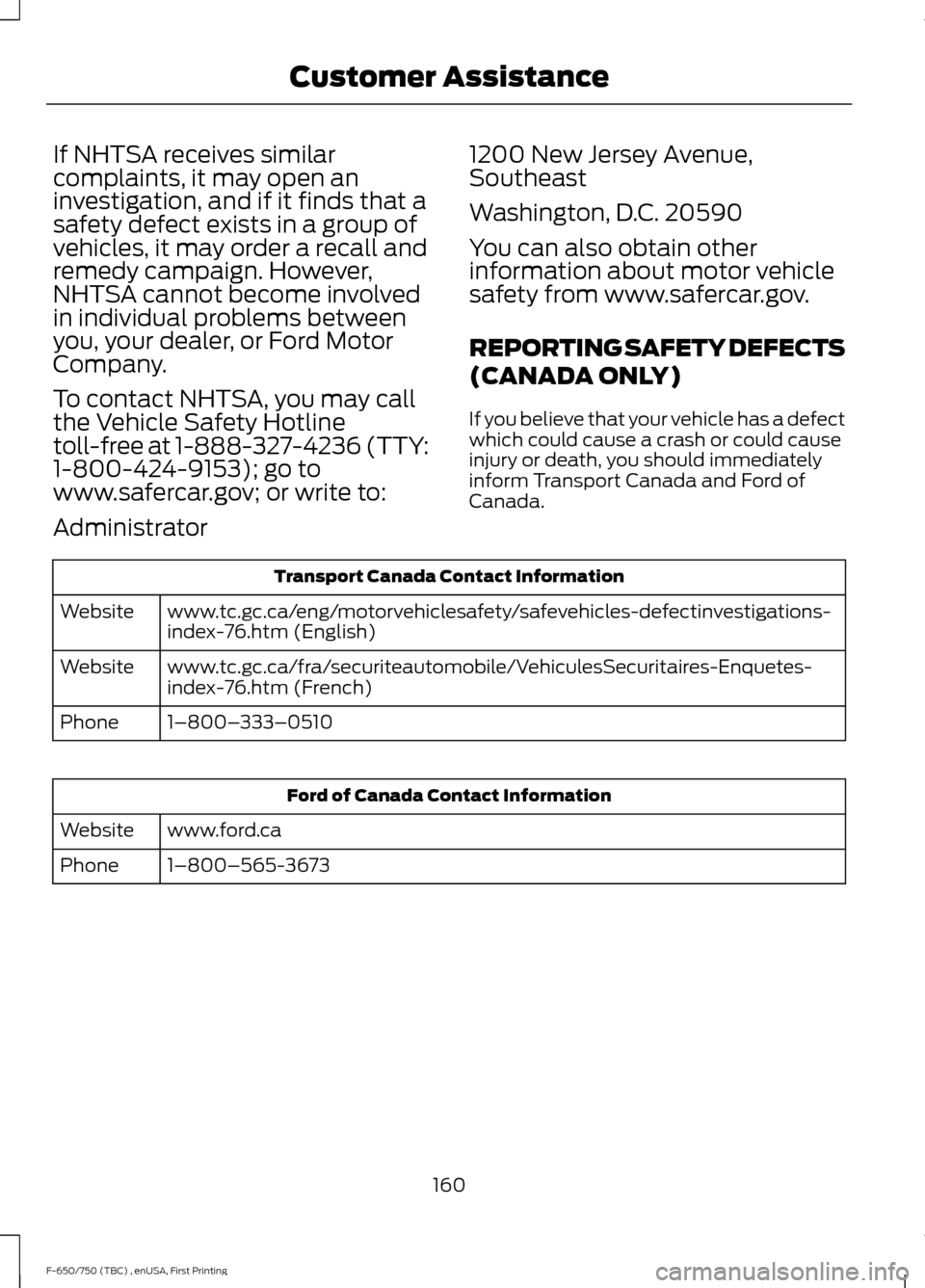

If NHTSA receives similar

complaints, it may open an

investigation, and if it finds that a

safety defect exists in a group of

vehicles, it may order a recall and

remedy campaign. However,

NHTSA cannot become involved

in individual problems between

you, your dealer, or Ford Motor

Company.

To contact NHTSA, you may call

the Vehicle Safety Hotline

toll-free at 1-888-327-4236 (TTY:

1-800-424-9153); go to

www.safercar.gov; or write to:

Administrator

1200 New Jersey Avenue,

Southeast

Washington, D.C. 20590

You can also obtain other

information about motor vehicle

safety from www.safercar.gov.

REPORTING SAFETY DEFECTS

(CANADA ONLY)

If you believe that your vehicle has a defect

which could cause a crash or could cause

injury or death, you should immediately

inform Transport Canada and Ford of

Canada.Transport Canada Contact Information

www.tc.gc.ca/eng/motorvehiclesafety/safevehicles-defectinvestigations-

index-76.htm (English)

Website

www.tc.gc.ca/fra/securiteautomobile/VehiculesSecuritaires-Enquetes-

index-76.htm (French)

Website

1–800–333–0510

Phone Ford of Canada Contact Information

www.ford.ca

Website

1–800–565-3673

Phone

160

F-650/750 (TBC) , enUSA, First Printing Customer Assistance

Page 178 of 382

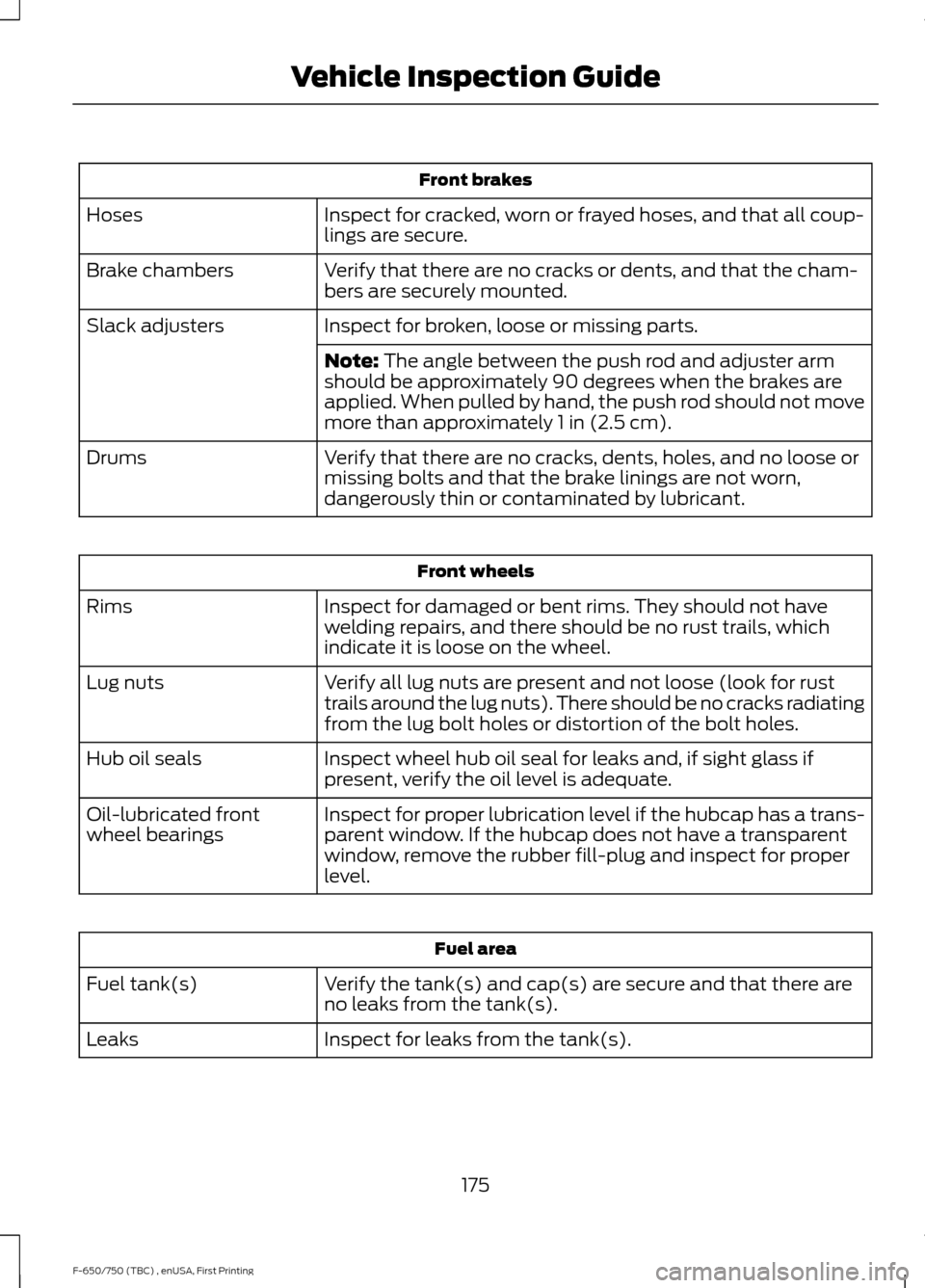

Front brakes

Inspect for cracked, worn or frayed hoses, and that all coup-

lings are secure.

Hoses

Verify that there are no cracks or dents, and that the cham-

bers are securely mounted.

Brake chambers

Inspect for broken, loose or missing parts.

Slack adjusters

Note: The angle between the push rod and adjuster arm

should be approximately 90 degrees when the brakes are

applied. When pulled by hand, the push rod should not move

more than approximately

1 in (2.5 cm).

Verify that there are no cracks, dents, holes, and no loose or

missing bolts and that the brake linings are not worn,

dangerously thin or contaminated by lubricant.

Drums Front wheels

Inspect for damaged or bent rims. They should not have

welding repairs, and there should be no rust trails, which

indicate it is loose on the wheel.

Rims

Verify all lug nuts are present and not loose (look for rust

trails around the lug nuts). There should be no cracks radiating

from the lug bolt holes or distortion of the bolt holes.

Lug nuts

Inspect wheel hub oil seal for leaks and, if sight glass if

present, verify the oil level is adequate.

Hub oil seals

Inspect for proper lubrication level if the hubcap has a trans-

parent window. If the hubcap does not have a transparent

window, remove the rubber fill-plug and inspect for proper

level.

Oil-lubricated front

wheel bearings Fuel area

Verify the tank(s) and cap(s) are secure and that there are

no leaks from the tank(s).

Fuel tank(s)

Inspect for leaks from the tank(s).

Leaks

175

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide