check engine FORD F650 2017 13.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F650, Model: FORD F650 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 205 of 382

DRAINING THE FUEL FILTER

WATER TRAP - 6.7L DIESEL

Your vehicle is equipped with a diesel fuel

conditioner module located on the

frame-rail under the driver-side floorboard

near the transmission.

You should drain water from the

module assembly whenever the

warning light comes on and the

message center directs you to drain the

water separator. This will occur when

approximately 8.45 fl oz (250 ml) of water

accumulates in the module. If you allow

the water level to exceed this level, the

water may pass through to the engine and

may cause fuel injection equipment

damage.

Draining the Diesel Fuel

Conditioner Module (DFCM) WARNING

Your vehicle must be stopped with

the engine off when draining the

Diesel Fuel Conditioner Module. Fuel

may ignite if the separator is drained while

the engine is running or vehicle is moving. Note:

If you drain the diesel fuel conditioner

module while the system is running air will

enter into the fuel system. The engine will

not operate properly if air enters the system.

Note: With fuel tank levels above 3⁄4 tank

it may be necessary to loosen the bowl three

turns before opening the drain. This will

actuate an anti-siphon valve at the fuel and

water separator inlet and prevent the fuel

from siphoning out of the tank.

Note: A loose drain valve can allow air to

enter the fuel system and cause drivetrain

issues. The engine will not operate properly.

Be sure that you fully tighten the drain valve. 1. Stop your vehicle and shut off the

engine.

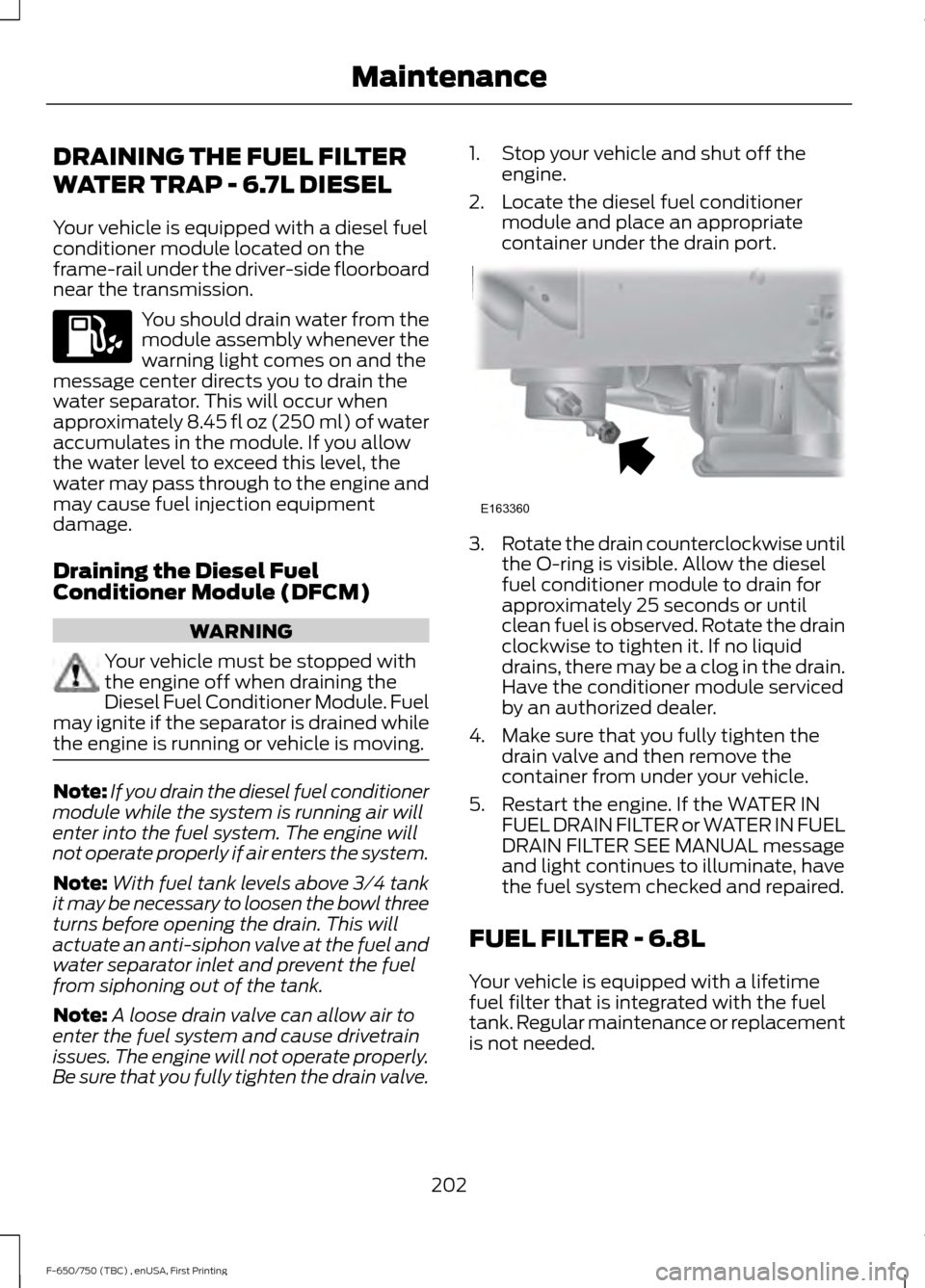

2. Locate the diesel fuel conditioner module and place an appropriate

container under the drain port. 3.

Rotate the drain counterclockwise until

the O-ring is visible. Allow the diesel

fuel conditioner module to drain for

approximately 25 seconds or until

clean fuel is observed. Rotate the drain

clockwise to tighten it. If no liquid

drains, there may be a clog in the drain.

Have the conditioner module serviced

by an authorized dealer.

4. Make sure that you fully tighten the drain valve and then remove the

container from under your vehicle.

5. Restart the engine. If the WATER IN FUEL DRAIN FILTER or WATER IN FUEL

DRAIN FILTER SEE MANUAL message

and light continues to illuminate, have

the fuel system checked and repaired.

FUEL FILTER - 6.8L

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

is not needed.

202

F-650/750 (TBC) , enUSA, First Printing Maintenance E163360

Page 214 of 382

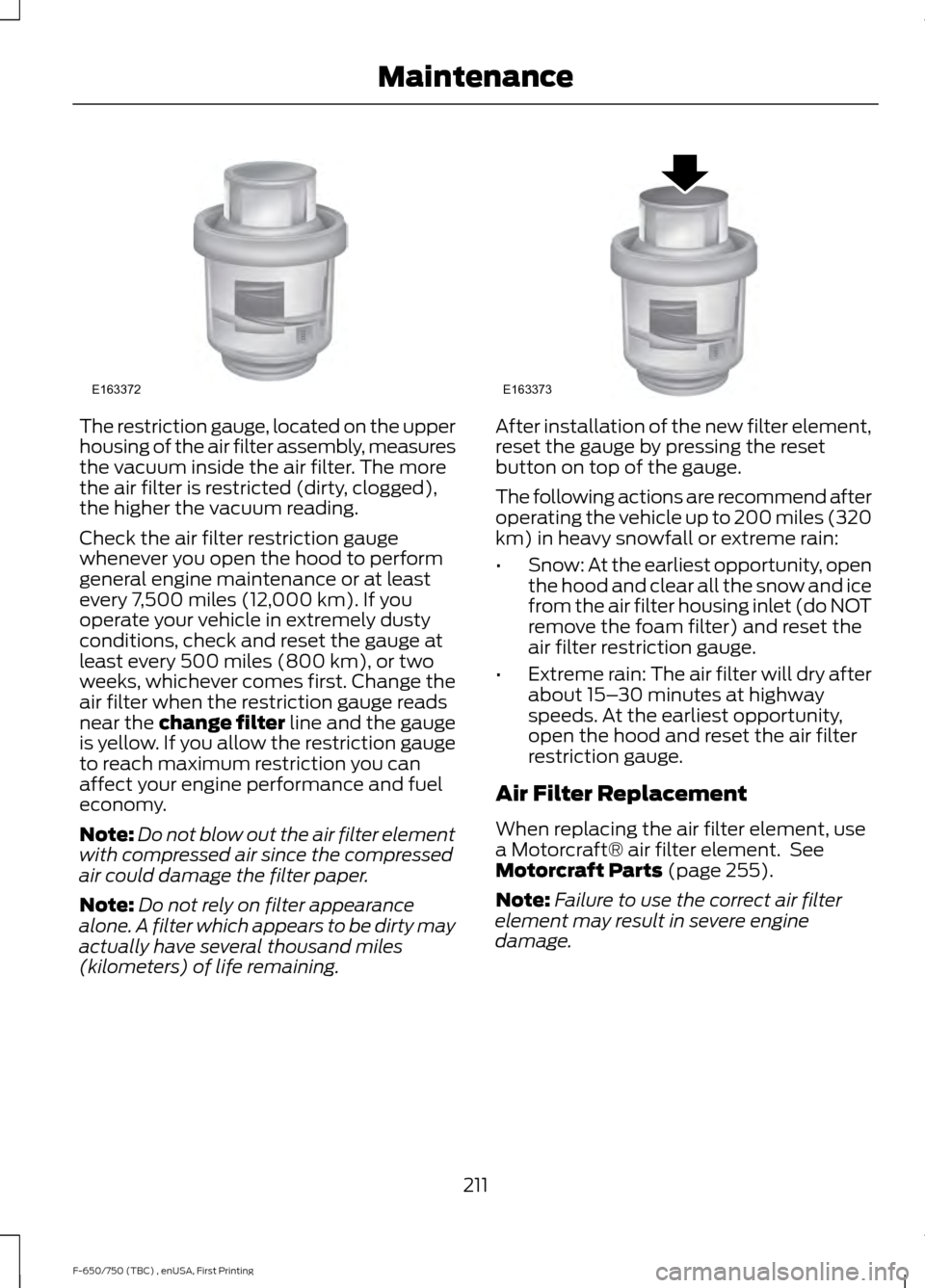

The restriction gauge, located on the upper

housing of the air filter assembly, measures

the vacuum inside the air filter. The more

the air filter is restricted (dirty, clogged),

the higher the vacuum reading.

Check the air filter restriction gauge

whenever you open the hood to perform

general engine maintenance or at least

every 7,500 miles (12,000 km). If you

operate your vehicle in extremely dusty

conditions, check and reset the gauge at

least every 500 miles (800 km), or two

weeks, whichever comes first. Change the

air filter when the restriction gauge reads

near the change filter line and the gauge

is yellow. If you allow the restriction gauge

to reach maximum restriction you can

affect your engine performance and fuel

economy.

Note:

Do not blow out the air filter element

with compressed air since the compressed

air could damage the filter paper.

Note: Do not rely on filter appearance

alone. A filter which appears to be dirty may

actually have several thousand miles

(kilometers) of life remaining. After installation of the new filter element,

reset the gauge by pressing the reset

button on top of the gauge.

The following actions are recommend after

operating the vehicle up to 200 miles (320

km) in heavy snowfall or extreme rain:

•

Snow: At the earliest opportunity, open

the hood and clear all the snow and ice

from the air filter housing inlet (do NOT

remove the foam filter) and reset the

air filter restriction gauge.

• Extreme rain: The air filter will dry after

about 15– 30 minutes at highway

speeds. At the earliest opportunity,

open the hood and reset the air filter

restriction gauge.

Air Filter Replacement

When replacing the air filter element, use

a Motorcraft® air filter element. See

Motorcraft Parts (page 255).

Note: Failure to use the correct air filter

element may result in severe engine

damage.

211

F-650/750 (TBC) , enUSA, First Printing MaintenanceE163372 E163373

Page 221 of 382

In areas where road salt is used,

disassemble the joints of each aluminum

component and inspect for salt build-up

and presence of chlorine that can cause

aluminum particles to flake off and enter

the engine combustion chambers. If

evidence of corrosion is found (usually at

the pipe connections), use a wire brush to

clean the inside of the pipes and inside the

rubber hoses.

If pitting is evident at the joint ends of the

intake pipes, use Motorcraft Silicone

Gasket and Sealant TA-30 to seal the

joints. Make sure no excess material, which

can pull into the engine, is on the inside of

the pipes. If the service condition of the

pipes, hoses or clamps is questionable,

replace the defective part(s).

Make sure to clean all dust and debris out

of the pipes and couplings with a clean,

damp rag before reassembly.

Chassis-mounted Charge Air

Cooler

Visually inspect the core assembly for

debris and clogging of external fins with

the engine off.

Before engine operation, remove any debris

blocking the core.

•

Turbocharger-to-charge air cooler.

• Charge air cooler-to-intake manifold

pipe.

• Mounting bracket.

• Chassis-mounted charge air cooler

core.

Inspect air intake piping:

• Check for accumulation of salt

deposits (where applicable). If present,

disassemble and clean the complete

air intake piping system. If pitting is

evident on the intake piping, use

Motorcraft Silicone Gasket and Sealant

TA-30 to seal joints against leakage.

• Check for loose hoses and clamps. •

Check for ruptured or collapsed hoses.

• Check air cleaner housing for cracks.

EXHAUST SYSTEM

INSPECTION

Note: If your vehicle is equipped with a

catalytic converter or muffler, do not blend

waste oil with diesel fuel. Operate only on

ultra-low sulfur (less than 15 parts per

million sulfur) diesel fuel with a cetane

value of 45 or higher.

If your diesel engine is equipped with a

catalytic converter, it is important to review

the maintenance schedule to make sure

proper functioning of the catalytic

converter. Also, take precautions not to

damage the catalytic converter when

servicing your engine or storing your

vehicle.

218

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 224 of 382

any air tanks equipped with automatic

moisture ejector valves, as required, to

maintain a dry air system. Contact an

authorized dealer if you are unsure of the

air reservoir locations or the draining

procedure.

Hydraulic Brakes

Establish a regular schedule for periodic

cleaning, lubrication and adjustment

inspection based on vehicle use. Exact

maintenance intervals are difficult to

predetermine due to vehicle applications

and operating conditions. If you are

uncertain of the proper schedule for your

vehicle, contact an authorized dealer.

Regular inspections should include:

•

Checking the brake lining (every service

interval). Establish inspection intervals

that provide for lining replacement

before damage to the disc occurs.

Excessive lining wear may expose the

backing plate to the disc causing

scoring of the disc faces. A qualified

technician should perform this inspection and keep to instructions

provided by the service manual.

Hydraulic brake systems are

power-assisted. There is a great

reduction in braking capabilities

without engine assist.

• Proper fluid level. The level should be

at the bottom edge of the ring on each

reservoir fill port. Do not fill the master

cylinder to the top of the reservoir. If

fluid level requires attention to

maintain a proper master cylinder level,

this is an indication of either severe

operation (pad wear) or fluid leakage.

A more frequent and thorough brake

inspection is required.

• Brake lines, hoses and fittings. Repair

or replace brake line tubes, hoses or

fittings as required. Inspect these

components every 4,000 mi

(6,000 km) for the following.

• Lines for kinks, dents, corrosion or

rupture.

• Hoses for abrasions, kinks, soft

spots or rupture, collapse, cracks,

twists or loose frame supports.

When replacing a hose, be sure

there is adequate clearance to the

hose to avoid an abrasion to the

new hose.

• All connections for leaks.

Driveline Parking Brake WARNING

Use wheel chocks and exercise

caution when inspecting under the

vehicle. A vehicle roll-away could

result in property damage, personal injury

or death. A qualified technician should adjust the

parking brake and keep to the instructions

in the service manual.

221

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 226 of 382

•

Maintaining proper steering gear and

power steering pump lubricant levels.

• Checking steering column joint bolts

and steering linkage, particularly for

body-to-chassis clearance.

Steering Column Joint Bolts

As a good maintenance practice, check

steering column joint bolt tightness every

60,000 mi (96,000 km) or annually,

whichever occurs first. Do not overtighten

the bolts.

Hydraulic System

Whenever draining and refilling the power

steering's hydraulic system for any reason,

bleed air from the system before returning

the vehicle to service. Failure to bleed the

hydraulic system properly can result in

degradation of power system performance.

Consult an authorized dealer who is aware

of the proper procedures for filling and

bleeding the system.

SUSPENSION SYSTEM

INSPECTION

Note: Do not adjust air suspension height

to any setting other than the specified

setting. Altering the height setting changes

the driveline angle and may result in

unwarrantable component damage, such

as transmission component damage.

Verify drive axle air suspension height and

height control valve performance at engine

oil change intervals.

Periodically check:

• Condition of spring leaves for evidence

of fatigue, bending or breakage.

• Condition of suspension mounting

brackets and bushings.

• Torque rod mounting fasteners for

tightness. •

For proper suspension alignment.

Maintain proper alignment at all times.

• U-bolts. After the chassis has been

operating under load for

1,000 mi

(1,600 km) or six months (whichever

comes first), the U-bolt nuts must be

re-torqued. Re-torque the U-bolt nuts

every

37,000 mi (60,000 km)

thereafter. Clean and lubricate the

U-bolt and nut threads and seats to

make sure a like new condition when

re-torqueing. See

Spring U-Bolt

Check (page 224).

FRAME AND TOW HOOK

INSPECTION

Your vehicle's chassis is manufactured

with frame rails of either HSLA steel or

heat-treated steel. Handle each in a

specific manner to make sure maximum

service life. Consult the service manual or

an authorized dealer before attempting

frame repair or modification.

It is important, particularly on vehicles that

use tow hooks frequently, to inspect the

front and rear tow hooks for damage or a

loose mounting.

REAR AXLE FLUID CHECK

Your rear axle may have an optional

synthetic lubricant that allows the use of

extended service intervals. A tag on the

filler plug identifies the use of the synthetic

lubricant.

Only use a lubricant that meets

manufacturer specifications. Only use a

lubricant that meets manufacturer

specifications. Use of a non-approved rear

axle lubricant may cause internal axle

component damage. See Capacities and

Specifications

(page 258).

223

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 227 of 382

Checking the Fluid Level

1. Park your vehicle on level ground.

2. Set the parking brake and shift into

position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle filler plug.

4. Remove the filler plug and inspect the lubricant level. It should be at the

bottom of the filler plug opening.

5. Add lubricant, if necessary, through the

filler plug opening.

6. Clean and install the filler plug securely.

Changing the Fluid

Note: Drain the rear axle while the lubricant

is warm.

1. Park your vehicle on level ground.

2. Set the parking brake and shift into position neutral (N) or park (P). Turn

the engine off.

3. Clean any dirt from around the axle filler and drain plugs.

4. Remove the filler and drain plugs. Drain

the lubricant into a suitable container.

Dispose of all used automotive fluids

in a responsible manner following your

local authorized standards.

5. Clean and install the drain plug securely.

6. Add lubricant through the filler plug opening.

7. Clean and install the filler plug securely.

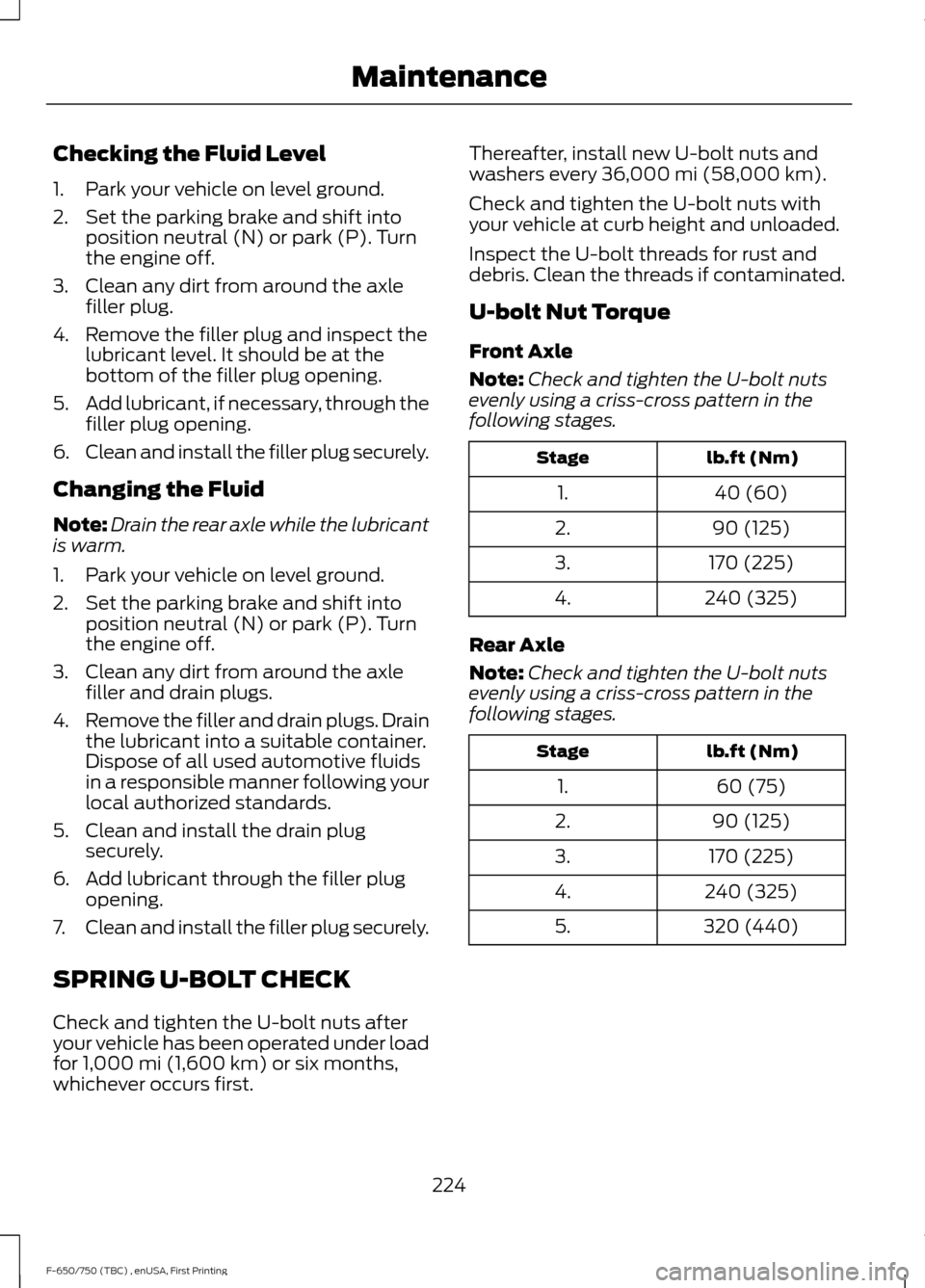

SPRING U-BOLT CHECK

Check and tighten the U-bolt nuts after

your vehicle has been operated under load

for 1,000 mi (1,600 km) or six months,

whichever occurs first. Thereafter, install new U-bolt nuts and

washers every

36,000 mi (58,000 km).

Check and tighten the U-bolt nuts with

your vehicle at curb height and unloaded.

Inspect the U-bolt threads for rust and

debris. Clean the threads if contaminated.

U-bolt Nut Torque

Front Axle

Note: Check and tighten the U-bolt nuts

evenly using a criss-cross pattern in the

following stages. lb.ft (Nm)

Stage

40 (60)

1.

90 (125)

2.

170 (225)

3.

240 (325)

4.

Rear Axle

Note: Check and tighten the U-bolt nuts

evenly using a criss-cross pattern in the

following stages. lb.ft (Nm)

Stage

60 (75)

1.

90 (125)

2.

170 (225)

3.

240 (325)

4.

320 (440)

5.

224

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 234 of 382

Engine

•

Change the engine oil and filter prior to

storage because used engine oil

contains contaminates which may

cause engine damage.

• Start the engine every 15 days for a

minimum of 15 minutes. Run at fast idle

with the climate controls set to defrost

until the engine reaches normal

operating temperature.

• With your foot on the brake, shift

through all the gears while the engine

is running.

• We recommend that you change the

engine oil before you use your vehicle

again.

Fuel system

• Fill the fuel tank with high-quality fuel

until the first automatic shutoff of the

fuel pump nozzle.

Cooling system

• Protect against freezing temperatures.

• When removing your vehicle from

storage, check coolant fluid level.

Confirm that there are no cooling

system leaks and that fluid is at the

recommended level.

Battery

• Check and recharge as necessary. Keep

connections clean.

• If storing your vehicle for more than 30

days without recharging the battery,

we recommend that you disconnect

the battery cables to maintain battery

charge for quick starting.

Note: It is necessary to reset memory

features if battery cables are disconnected. Brakes

•

Make sure the brakes and parking brake

release fully.

Tires

• Maintain recommended air pressure.

Miscellaneous

• Make sure all linkages, cables, levers

and pins under your vehicle are covered

with grease to prevent rust.

• Move vehicles at least 25 ft (7.5 m)

every 15 days to lubricate working parts

and prevent corrosion.

Removing Vehicle From Storage

When your vehicle is ready to come out of

storage, do the following:

• Wash your vehicle to remove any dirt

or grease film build-up on window

surfaces.

• Check windshield wipers for any

deterioration.

• Check under the hood for any foreign

material that may have collected

during storage such as mice or squirrel

nests.

• Check the exhaust for any foreign

material that may have collected

during storage.

• Check tire pressures and set tire

inflation per the Tire Label.

• Check brake pedal operation. Drive

your vehicle

15 ft (4.5 m) back and

forth to remove rust build-up.

• Check fluid levels (including coolant,

oil and gas) to make sure there are no

leaks, and fluids are at recommended

levels.

• If you remove the battery, clean the

battery cable ends and check for

damage.

231

F-650/750 (TBC) , enUSA, First Printing Vehicle Care

Page 259 of 382

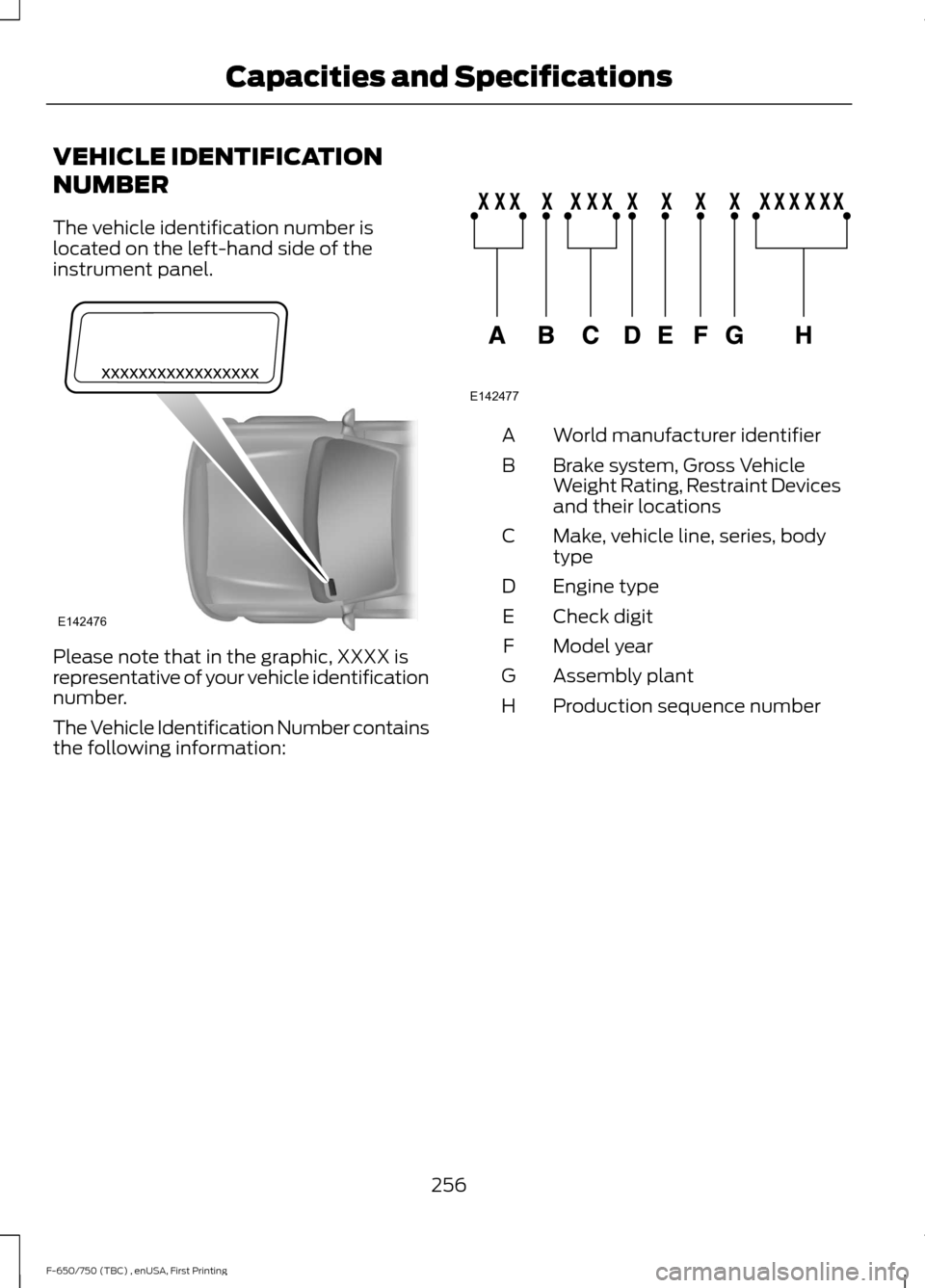

VEHICLE IDENTIFICATION

NUMBER

The vehicle identification number is

located on the left-hand side of the

instrument panel.

Please note that in the graphic, XXXX is

representative of your vehicle identification

number.

The Vehicle Identification Number contains

the following information: World manufacturer identifier

A

Brake system, Gross Vehicle

Weight Rating, Restraint Devices

and their locations

B

Make, vehicle line, series, body

type

C

Engine type

D

Check digit

E

Model year

F

Assembly plant

G

Production sequence number

H

256

F-650/750 (TBC) , enUSA, First Printing Capacities and SpecificationsE142476 E142477

Page 318 of 382

•

Brake pads and linings.

• Shock absorbers.

• Struts.

• Engine Belts.

• Engine coolant hoses, clamps and

o-rings.

• Diesel exhaust fluid replenishment.

Interest Free Finance Options

Just a 10% down payment will provide you

with an affordable, no interest, no fee

payment program allowing you all the

security and benefits Ford ESP has to offer

while paying over time. You are

pre-approved with no credit check or

hassles. To learn more, call our Ford

Protect Extended Service Plan specialists

at 800-367-3377.

Ford Protect Extended Service Plan

P.O. Box 321067

Detroit, MI 48232

EXTENDED SERVICE PLAN

(CANADA ONLY)

You can get more protection for your

vehicle by purchasing a Ford Extended

Service Plan. Ford Extended Service Plan

is the only service contract backed by Ford

Motor Company of Canada, Limited.

Depending on the plan you purchase, Ford

Extended Service Plan provides benefits

such as:

• Rental reimbursement.

• Coverage for certain maintenance and

wear items.

• Protection against repair costs after

your New Vehicle Limited Warranty

Coverage expires.

• Roadside Assistance benefits. There are several Ford Extended Service

Plans available in various time, distance

and deductible combinations. Each plan

is tailored to fit your own driving needs,

including reimbursement for towing and

rental. When you purchase Ford Extended

Service Plan, you receive added

peace-of-mind protection throughout

Canada, the United States and Mexico,

provided by a network of participating

authorized Ford Motor Company dealers.

Note:

Repairs performed outside of

Canada, the United States and Mexico are

not eligible for Ford Extended Service Plan

coverage.

This information is subject to change. For

more information, visit your local Ford of

Canada dealer or www.ford.ca to find the

Ford Extended Service Plan that is right for

you.

315

F-650/750 (TBC) , enUSA, First Printing Ford Protect

Page 323 of 382

There are three types of maintenance

intervals for general vehicle environments:

On-Highway, City and Severe Service. In

all applications, monitoring miles

(kilometers) and time and when the engine

is due for an oil change determine the

actual interval. When the engine oil change

is required before the truck lubrication

interval, perform the lubrication at the

same time in order to reduce your vehicle

’s

time out of service.

Air Brake Adjustment WARNING

Failure to maintain proper air brake

adjustment can result in reduction

or loss of braking ability.

A qualified service technician, keeping to

the instructions in the service manual,

should perform air brake inspection and

adjustment or repairs.

Cam Brakes - Automatic Slack

Adjusters

WARNING

Do not manually adjust the

automatic slack adjusters to correct

excessive push rod stroke as it may

result in reduced brake effectiveness and

a vehicle crash. Excessive push rod stroke

indicates that a problem exists with the

automatic adjuster, with the installation

of the adjuster, or with foundation brake

components that manual adjustment does

not remedy. Seek service from a qualified

facility for excessive push rod stroke. Inspect standard air brakes equipped with

automatic slack adjusters for proper brake

adjustment as listed in the maintenance

schedule charts.

However, inspect the brakes more

frequently when subjecting them to heavy

use or adverse operating conditions such

as:

•

Frequent brake applications while fully

loaded.

• Operation on hilly or mountainous

terrain.

• Frequent operation on dirt, gravel or

mud.

Some aftermarket brake linings also

require more frequent inspections.

Owner Checks and Services

Make sure you perform the following basic

maintenance checks and inspections every

month or at six-month intervals.

320

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance