sensor FORD F650 2017 13.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F650, Model: FORD F650 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 85 of 382

Note:

Depending on your vehicle, the power

point cover may open to the right or upward.

When the indicator light on the power point

is:

• On: The power point is working, the

ignition is on and a device is plugged

in.

• Off: The power point is off, the ignition

is off or no device is plugged in.

• Flashing: The power point is in fault

mode.

The power outlet temporarily turns off

power when in fault mode if the device

exceeds the 150 watt limit. Unplug your

device and switch the ignition off. Switch

the ignition back on, but do not plug your

device back in. Let the system cool off and

switch the ignition off to reset the fault

mode. Switch the ignition back on and

make sure the indicator light remains on.

Do not use the power point for certain

electric devices, including:

• Cathode-ray, tube-type televisions.

• Motor loads, such as vacuum cleaners,

electric saws and other electric power

tools or compressor-driven

refrigerators.

• Measuring devices, which process

precise data, such as medical

equipment or measuring equipment.

• Other appliances requiring an

extremely stable power supply such as

microcomputer-controlled electric

blankets or touch-sensor lamps.

82

F-650/750 (TBC) , enUSA, First Printing Auxiliary Power Points

Page 89 of 382

•

Open the windows at least 1 in (3 cm).

• Set your climate control to outside air.

STARTING A DIESEL ENGINE WARNING

Operation of a diesel engine near

flammable vapors in the air may

cause the engine speed to increase

uncontrollably and over speed. If this

situation occurs, mechanical damage, fire,

explosion, personal injury or death could

result. Turning off the ignition key does not

slow or stop the engine due to

uncontrollable fueling of the engine

through flammable vapors being drawn

into the engine air inlet. Operation of

components, for example starter,

alternator, electric motors and static

electricity could also ignite flammable

vapors. Do not operate your vehicle in the

possible presence of flammable vapors

unless both a complete hazard analysis is

carried out and necessary additional safety

processes and/or equipment, for example

vapor testing, air intake shutoff devices

and ventilation are utilized. You are

responsible for using those processes

and/or equipment to make sure that the

diesel engine and all other components on

your vehicle can be operated safely under

the specific conditions and hazards that

may be encountered. Read all starting instructions carefully

before you start your vehicle.

Diesel Engine Fast Start Glow Plug

System

The diesel engine glow system consists of:

•

Eight glow plugs (one per cylinder)

• Glow Plug Control Module

• Engine Coolant Temperature sensor •

Barometric pressure sensor

• Environmental temperature sensor

The powertrain and glow plug control

modules electronically control the glow

plug system. After you switch the ignition

on the glow plug control module

immediately energizes the glow plugs. The

glow plug control module using the engine

coolant temperature, barometric pressure

sensor and environmental temperature

sensor will determine how long the glow

plugs stay energized. The required time for

the glow plugs to be energized decreases

as the coolant temperature, barometric

pressure and environmental temperature

increase.

Before starting the engine, check the

following:

• Make sure all occupants have fastened

their safety belts.

• Make sure the headlamps and

electrical accessories are off.

• Make sure the parking brake is on.

• Make sure the transmission is in park

(P) or neutral (N).

• Turn the ignition key to the on position.

Note: Do not press the accelerator during

starting.

Cold Weather Starting WARNINGS

Do not use starting fluid, for example

ether, in the air intake system (see

air filter decal). Such fluid could

cause immediate explosive damage to the

engine and possible personal injury. Do not add gasoline, gasohol, alcohol

or Kerosene to diesel fuel. This

practice creates a serious fire hazard

and causes engine performance problems. 86

F-650/750 (TBC) , enUSA, First Printing Starting and Stopping the Engine

Page 102 of 382

•

Avoid spilling diesel exhaust fluid on

painted surfaces, carpeting or plastic

components. Immediately wipe away

any diesel exhaust fluid that has spilled

with a damp cloth and water. If it has

already crystallized, use warm water

and a sponge.

• Store diesel exhaust fluid out of direct

sunlight and in temperatures between

23°F (-5°C) and 68°F (20°C).

• Diesel exhaust fluid freezes below 12°F

(-11°C)

.

• Do not store the diesel exhaust fluid

bottle in your vehicle. If it leaks it could

cause damage to interior components

or release an ammonia odor inside your

vehicle.

• Diesel exhaust fluid is non-flammable,

non-toxic, colorless and water-soluble

liquid.

• The system has a diesel exhaust fluid

quality sensor. Dilution of diesel

exhaust fluid or use of any other liquid

in the SCR system leads to a diesel

exhaust fluid system fault, eventually

leading to the vehicle only operating in

idle-only mode.

• Do not dilute diesel exhaust fluid with

water or any other liquid.

• An ammonia odor may be smelled

when the cap is removed or during

refill. Refill diesel exhaust fluid in a well

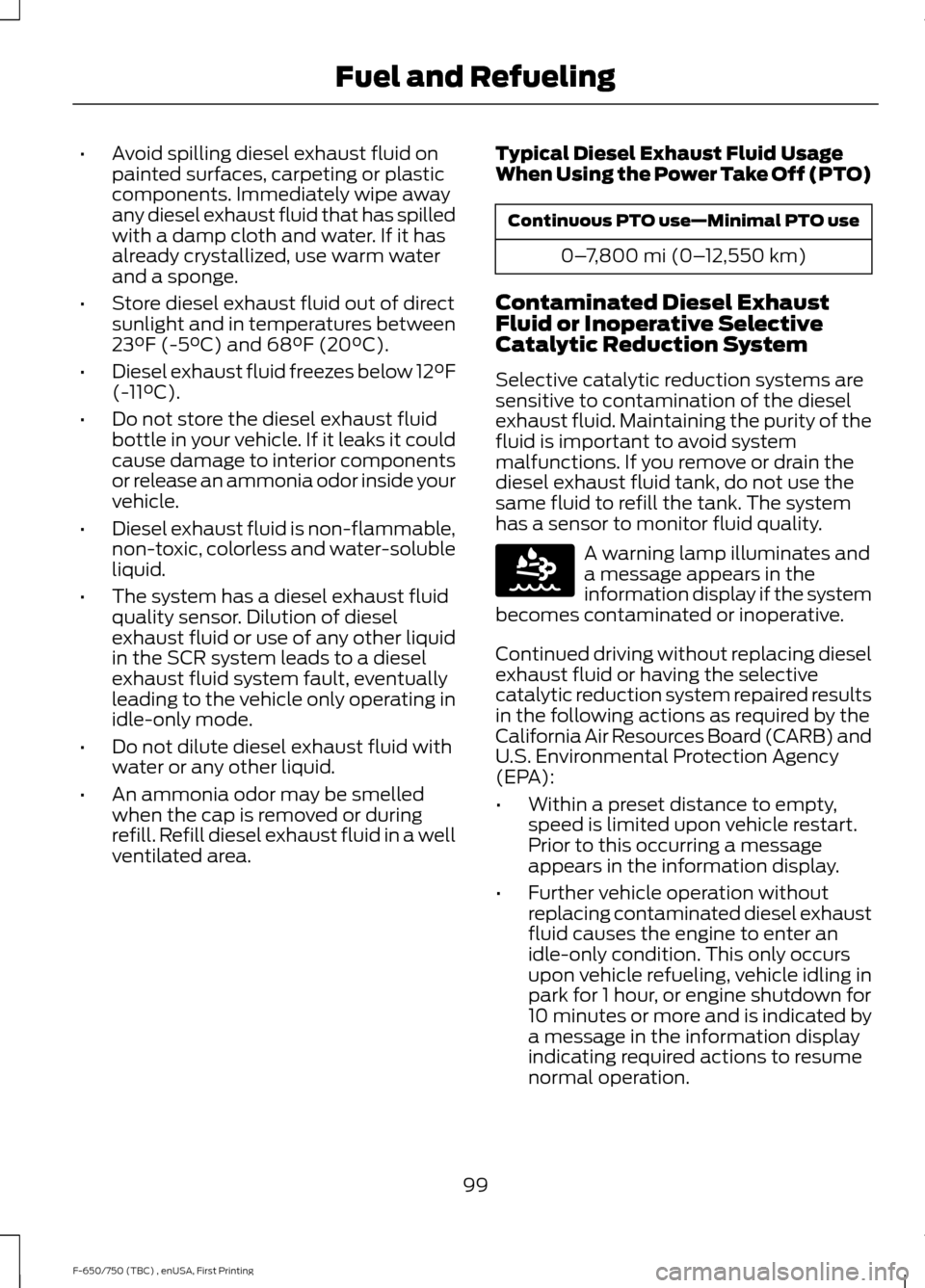

ventilated area. Typical Diesel Exhaust Fluid Usage

When Using the Power Take Off (PTO) Continuous PTO use—Minimal PTO use

0–7,800 mi (0– 12,550 km)

Contaminated Diesel Exhaust

Fluid or Inoperative Selective

Catalytic Reduction System

Selective catalytic reduction systems are

sensitive to contamination of the diesel

exhaust fluid. Maintaining the purity of the

fluid is important to avoid system

malfunctions. If you remove or drain the

diesel exhaust fluid tank, do not use the

same fluid to refill the tank. The system

has a sensor to monitor fluid quality. A warning lamp illuminates and

a message appears in the

information display if the system

becomes contaminated or inoperative.

Continued driving without replacing diesel

exhaust fluid or having the selective

catalytic reduction system repaired results

in the following actions as required by the

California Air Resources Board (CARB) and

U.S. Environmental Protection Agency

(EPA):

• Within a preset distance to empty,

speed is limited upon vehicle restart.

Prior to this occurring a message

appears in the information display.

• Further vehicle operation without

replacing contaminated diesel exhaust

fluid causes the engine to enter an

idle-only condition. This only occurs

upon vehicle refueling, vehicle idling in

park for 1 hour, or engine shutdown for

10 minutes or more and is indicated by

a message in the information display

indicating required actions to resume

normal operation.

99

F-650/750 (TBC) , enUSA, First Printing Fuel and RefuelingE163176

Page 113 of 382

In the United States, federal law and

certain state laws prohibit removing or

rendering the emission control system

inoperative. Similar federal or provincial

laws may apply in Canada. We do not

recommend any vehicle modification

without determining applicable law.

Tampering with emissions

control system, including related

sensors or the diesel exhaust

fluid injection system can result in reduced

engine power and the service engine soon

warning lamp illuminating in the

information display.

Tampering with a Noise Control

System

Federal law prohibits the following acts or

the causing thereof:

• The removal or rendering inoperative

by any person other than for purposes

of maintenance, repair or replacement

of any device or element of design

incorporated into any new vehicle for

the purpose of noise control prior to its

sale or delivery to the ultimate

purchaser or while it is in use.

• The use of the vehicle after such device

or element of design has been removed

or rendered inoperative by any person.

Among those acts, which the United States

Environmental Protection Agency may

presume to constitute tampering are the

acts listed below:

• Removal of hood blanket, fender apron

absorbers, fender apron barriers,

underbody noise shields or acoustically

absorptive material.

• Tampering or rendering inoperative the

engine speed governor, to allow engine

speed to exceed manufacturer ’s

specifications. The complexity of the diesel engine makes

it so the owner is discouraged from

attempting to perform maintenance other

than the services described in this Owner's

Manual.

If you experience difficulty starting the

engine, rough idling, excessive exhaust

smoke, a decrease in engine performance

or excess fuel consumption, perform the

following checks:

•

A plugged or disconnected air inlet

system or engine air filter element.

• Water in the fuel filter and water

separator.

• A clogged fuel filter.

• Contaminated fuel.

• Air in the fuel system, due to loose

connections.

• An open or pinched sensor hose.

• Check engine oil level.

• Wrong fuel or oil viscosity for the

climatic conditions.

If these checks do not help you correct the

engine performance problem you are

experiencing, have your vehicle checked

as soon as possible.

Noise Emissions Warranty, Prohibited

Tampering Acts and Maintenance

On January 1, 1978, Federal regulation

became effective governing the noise

emission on vehicles weighing over

10,000 lb (4,536 kg) Gross Vehicle Weight

Rating. The preceding statements

concerning prohibited tampering acts and

maintenance, and the noise warranty

found in the Warranty Guide, are

applicable to complete chassis cabs over

10,000 lb (4,536 kg) Gross Vehicle Weight

Rating.

110

F-650/750 (TBC) , enUSA, First Printing Fuel and Refueling

Page 212 of 382

CHANGING THE ENGINE AIR

FILTER - 6.8L

WARNING

To reduce the risk of vehicle damage

and personal burn injuries, do not

start your engine with the air cleaner

removed and do not remove it while the

engine is running. Note:

Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter that could cause the

engine to lose power or shut down.

When replacing the air filter element, use

a Motorcraft® air filter element. See

Motorcraft Parts (page 254).

Note: Failure to use the correct air filter

element may result in severe engine

damage. Resulting component damage

may not be covered by the vehicle Warranty.

Change the air filter element at the correct

interval. See

Scheduled Maintenance

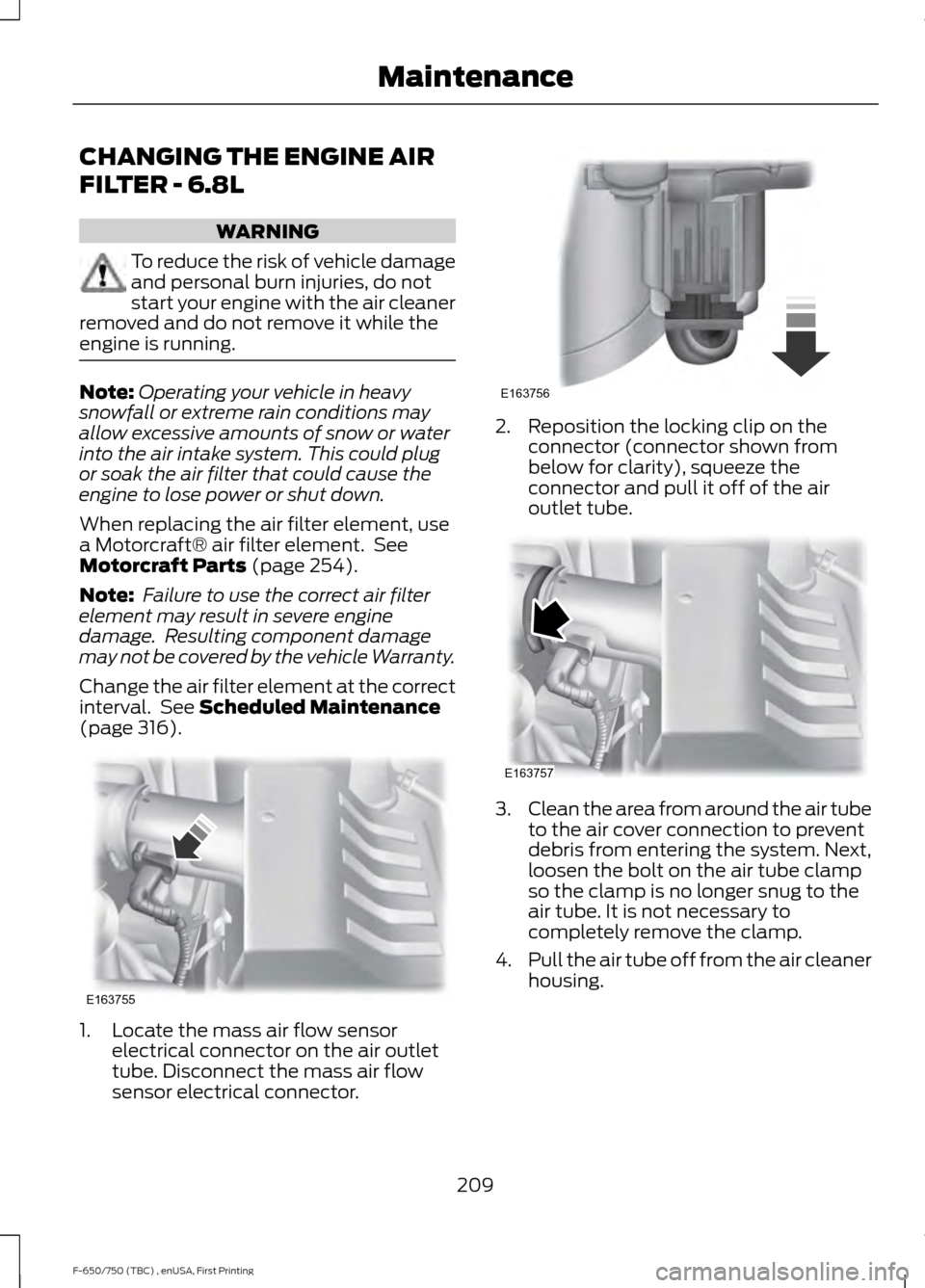

(page 316). 1. Locate the mass air flow sensor

electrical connector on the air outlet

tube. Disconnect the mass air flow

sensor electrical connector. 2. Reposition the locking clip on the

connector (connector shown from

below for clarity), squeeze the

connector and pull it off of the air

outlet tube. 3.

Clean the area from around the air tube

to the air cover connection to prevent

debris from entering the system. Next,

loosen the bolt on the air tube clamp

so the clamp is no longer snug to the

air tube. It is not necessary to

completely remove the clamp.

4. Pull the air tube off from the air cleaner

housing.

209

F-650/750 (TBC) , enUSA, First Printing MaintenanceE163755 E163756 E163757

Page 213 of 382

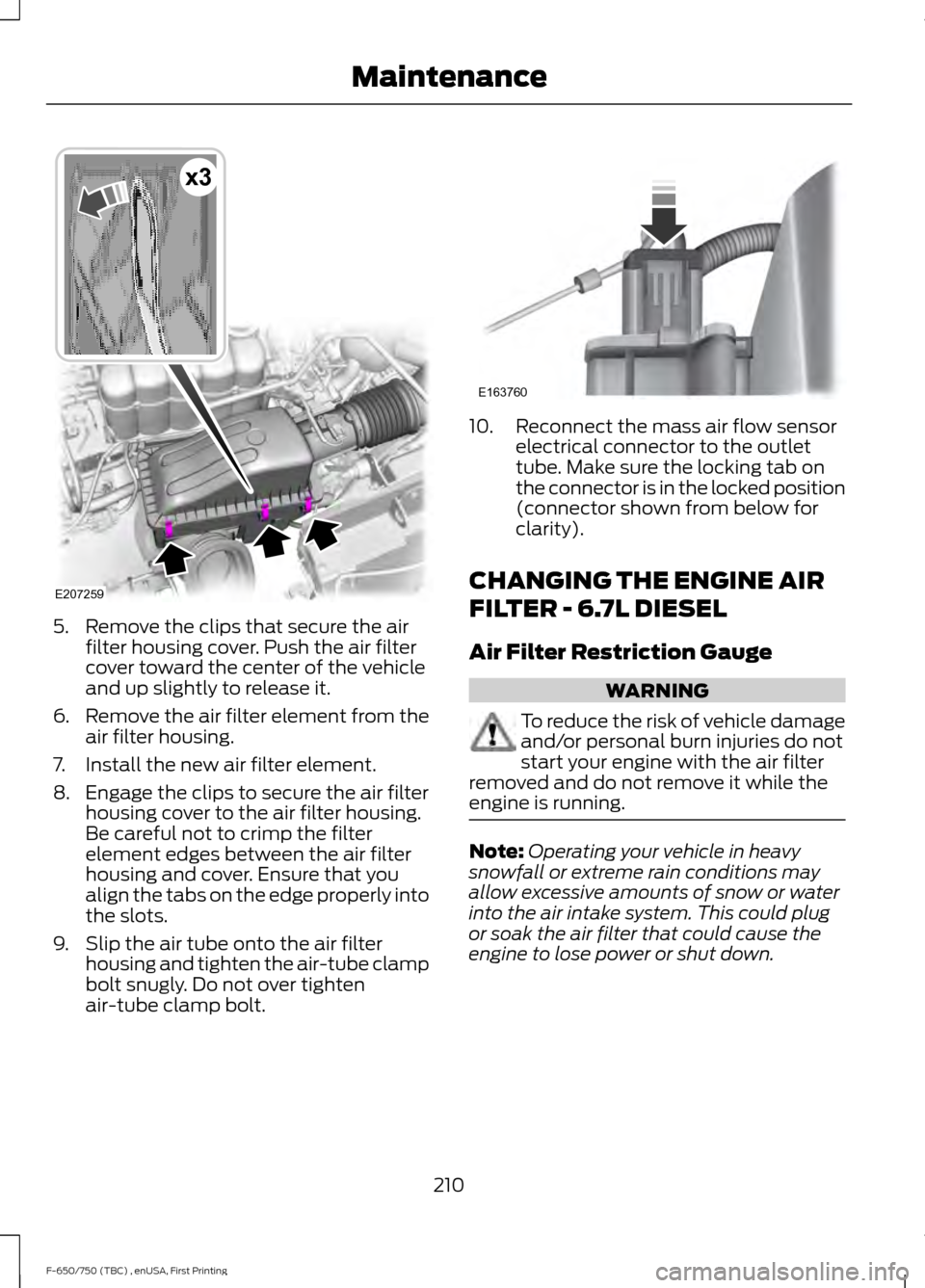

5. Remove the clips that secure the air

filter housing cover. Push the air filter

cover toward the center of the vehicle

and up slightly to release it.

6. Remove the air filter element from the

air filter housing.

7. Install the new air filter element.

8. Engage the clips to secure the air filter housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

9. Slip the air tube onto the air filter housing and tighten the air-tube clamp

bolt snugly. Do not over tighten

air-tube clamp bolt. 10. Reconnect the mass air flow sensor

electrical connector to the outlet

tube. Make sure the locking tab on

the connector is in the locked position

(connector shown from below for

clarity).

CHANGING THE ENGINE AIR

FILTER - 6.7L DIESEL

Air Filter Restriction Gauge WARNING

To reduce the risk of vehicle damage

and/or personal burn injuries do not

start your engine with the air filter

removed and do not remove it while the

engine is running. Note:

Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter that could cause the

engine to lose power or shut down.

210

F-650/750 (TBC) , enUSA, First Printing MaintenanceE207259

x3 E163760

Page 215 of 382

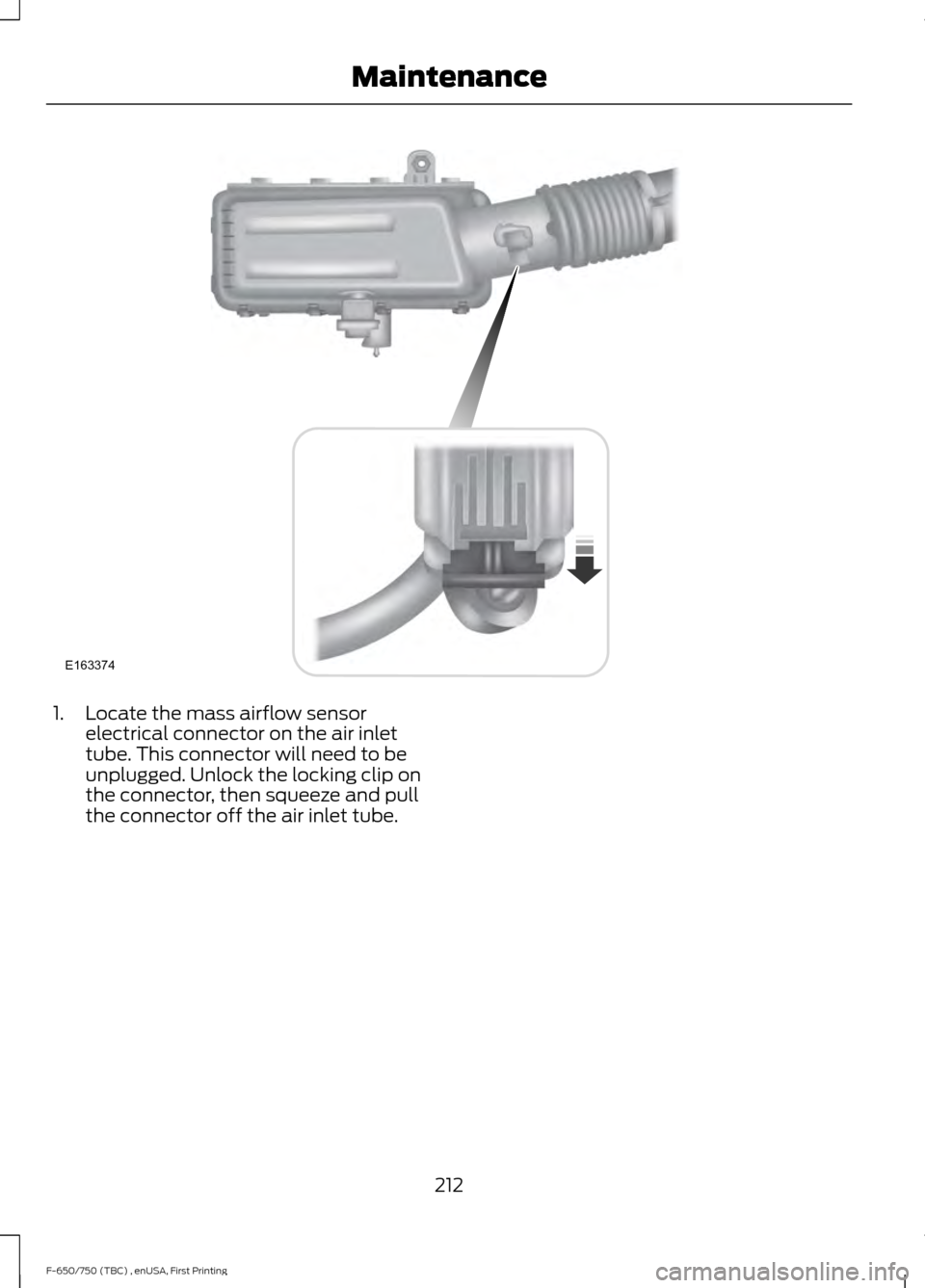

1. Locate the mass airflow sensor

electrical connector on the air inlet

tube. This connector will need to be

unplugged. Unlock the locking clip on

the connector, then squeeze and pull

the connector off the air inlet tube.

212

F-650/750 (TBC) , enUSA, First Printing MaintenanceE163374

Page 216 of 382

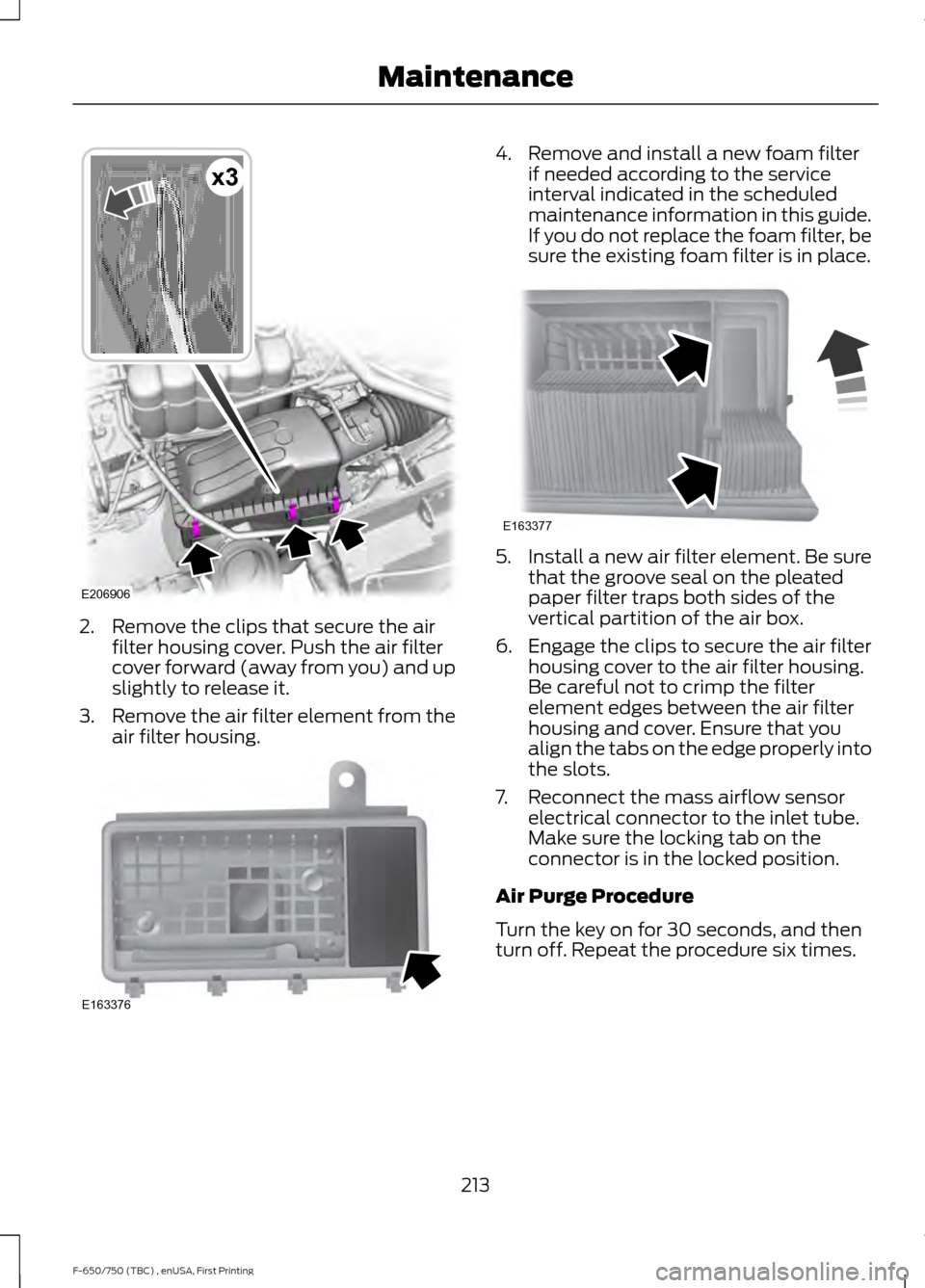

2. Remove the clips that secure the air

filter housing cover. Push the air filter

cover forward (away from you) and up

slightly to release it.

3. Remove the air filter element from the

air filter housing. 4. Remove and install a new foam filter

if needed according to the service

interval indicated in the scheduled

maintenance information in this guide.

If you do not replace the foam filter, be

sure the existing foam filter is in place. 5. Install a new air filter element. Be sure

that the groove seal on the pleated

paper filter traps both sides of the

vertical partition of the air box.

6. Engage the clips to secure the air filter housing cover to the air filter housing.

Be careful not to crimp the filter

element edges between the air filter

housing and cover. Ensure that you

align the tabs on the edge properly into

the slots.

7. Reconnect the mass airflow sensor electrical connector to the inlet tube.

Make sure the locking tab on the

connector is in the locked position.

Air Purge Procedure

Turn the key on for 30 seconds, and then

turn off. Repeat the procedure six times.

213

F-650/750 (TBC) , enUSA, First Printing MaintenanceE206906

x3 E163376 E163377

Page 322 of 382

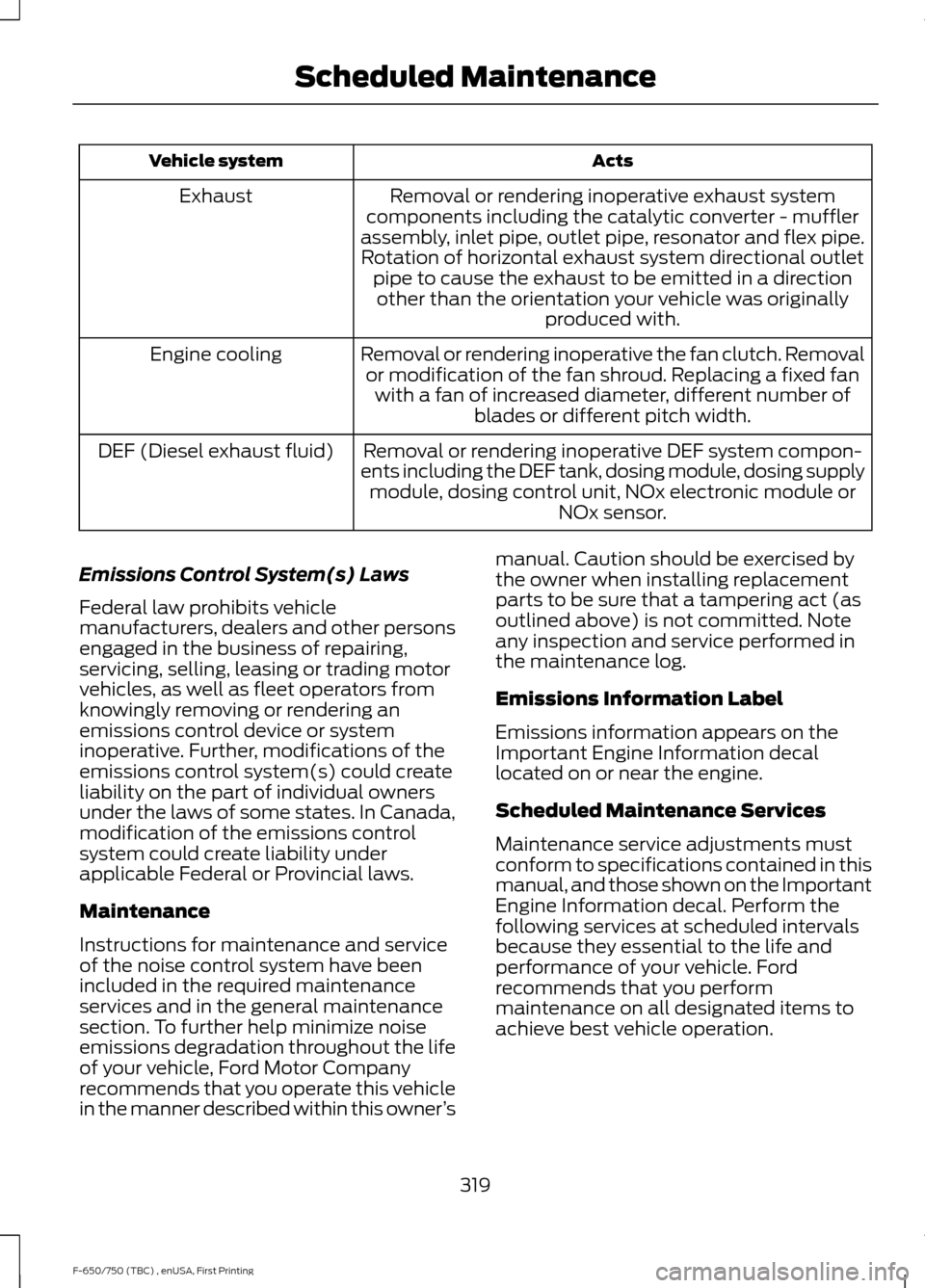

Acts

Vehicle system

Removal or rendering inoperative exhaust system

components including the catalytic converter - muffler

assembly, inlet pipe, outlet pipe, resonator and flex pipe. Rotation of horizontal exhaust system directional outlet pipe to cause the exhaust to be emitted in a directionother than the orientation your vehicle was originally produced with.

Exhaust

Removal or rendering inoperative the fan clutch. Removalor modification of the fan shroud. Replacing a fixed fan with a fan of increased diameter, different number of blades or different pitch width.

Engine cooling

Removal or rendering inoperative DEF system compon-

ents including the DEF tank, dosing module, dosing supply module, dosing control unit, NOx electronic module or NOx sensor.

DEF (Diesel exhaust fluid)

Emissions Control System(s) Laws

Federal law prohibits vehicle

manufacturers, dealers and other persons

engaged in the business of repairing,

servicing, selling, leasing or trading motor

vehicles, as well as fleet operators from

knowingly removing or rendering an

emissions control device or system

inoperative. Further, modifications of the

emissions control system(s) could create

liability on the part of individual owners

under the laws of some states. In Canada,

modification of the emissions control

system could create liability under

applicable Federal or Provincial laws.

Maintenance

Instructions for maintenance and service

of the noise control system have been

included in the required maintenance

services and in the general maintenance

section. To further help minimize noise

emissions degradation throughout the life

of your vehicle, Ford Motor Company

recommends that you operate this vehicle

in the manner described within this owner ’s manual. Caution should be exercised by

the owner when installing replacement

parts to be sure that a tampering act (as

outlined above) is not committed. Note

any inspection and service performed in

the maintenance log.

Emissions Information Label

Emissions information appears on the

Important Engine Information decal

located on or near the engine.

Scheduled Maintenance Services

Maintenance service adjustments must

conform to specifications contained in this

manual, and those shown on the Important

Engine Information decal. Perform the

following services at scheduled intervals

because they essential to the life and

performance of your vehicle. Ford

recommends that you perform

maintenance on all designated items to

achieve best vehicle operation.

319

F-650/750 (TBC) , enUSA, First Printing Scheduled Maintenance