check engine light FORD F650/750 2019 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2019, Model line: F650/750, Model: FORD F650/750 2019Pages: 387, PDF Size: 4.78 MB

Page 111 of 387

The information display shows a series of

messages about the amount of diesel

exhaust fluid available. A systems check

displays messages indicating the amount

of diesel exhaust fluid available or displays

a warning message indicating the

approximate distance remaining as the

fluid in the diesel exhaust fluid tank nears

empty. See Information Messages

(page 67). As the diesel exhaust fluid level

nears empty, the warning

symbol displays and a series of

tones and messages starting at

500 mi

(800 km) remaining before diesel exhaust

fluid is depleted. The warning symbol and

messages continue until you refill the

diesel exhaust fluid tank.

Continued driving without refilling results

in the following actions as required by the

California Air Resources Board (CARB) and

the U.S. Environmental Protection Agency

(EPA):

• Within a preset distance to empty,

speed is limited upon vehicle restart.

Prior to this occurring a message

appears in the information display.

• Further vehicle operation without

refilling the diesel exhaust fluid tank

causes the engine to enter an idle-only

condition. This only occurs upon vehicle

refueling or at an extended idle. A

message indicates the required actions

to resume normal operation. It is

required to add a minimum of

1.0 gal

(3.8 L) of diesel exhaust fluid to the

tank to exit the idle-only condition, but

your vehicle is still in the speed-limiting

mode until you refill the tank

completely.

Note: For either vehicle speed limiting or

idle-only condition, normal vehicle operation

resumes when you refill the diesel exhaust

fluid tank. Note:

When filling the diesel exhaust fluid

tank from empty, there may be a short delay

before detecting the increased level of fluid.

The increased level detection must occur

before your vehicle returns to full power.

Diesel Exhaust Fluid Guidelines

and Information

• Use only diesel exhaust fluid that

carries the American Petroleum

Institute (API) certified diesel exhaust

fluid trademark or ISO 22241.

• Do not put diesel exhaust fluid in the

diesel fuel tank. If this happens, do not

switch the ignition on. Drain the fuel

tank as soon as possible.

• Do not overfill the diesel exhaust fluid

tank.

• Diesel exhaust fluid is corrosive.

• Do not re-use the diesel exhaust fluid

container once it is emptied.

• Avoid spilling diesel exhaust fluid on

painted surfaces, carpeting or plastic

components. Immediately wipe away

any diesel exhaust fluid that has spilled

with a damp cloth and water. If it has

already crystallized, use warm water

and a sponge.

• Store diesel exhaust fluid out of direct

sunlight and in temperatures between

23°F (-5°C)

and 68°F (20°C).

• Diesel exhaust fluid freezes below 12°F

(-11°C)

.

• Do not store the diesel exhaust fluid

bottle in your vehicle. If it leaks it could

cause damage to interior components

or release an ammonia odor inside your

vehicle.

• Diesel exhaust fluid is non-flammable,

non-toxic, colorless and water-soluble

liquid.

108

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission ControlE163176

Page 115 of 387

Before you start operator commanded

regeneration, do the following:

•

Shift into park (P) or if you have an

RNDM selector shift into neutral (N)

and apply the parking and or air brake,

on stable, level ground.

• Park your vehicle outside of any

structure.

• Park your vehicle 10– 15 ft (3–5 m)

away from any obstructions and away

from materials that can easily combust

or melt, for example paper, leaves,

petroleum products, fuels, plastics and

other dry organic material.

• Make sure there is a minimum of 1/8

tank of fuel.

• Make sure all fluids are at proper levels.

How to Start Operator Commanded

Regeneration WARNING:

Stay clear of the

exhaust tailpipe during regeneration. Hot

exhaust gases can burn you badly.

Note: You cannot use the operator

commanded regeneration until the diesel

particulate filter load percentage has

reached 100%. The diesel particulate filter

load percentage fluctuates up and down

when driving your vehicle due to active and

passive regenerations.

Note: During the use of operator

commanded regeneration, you may observe

a light amount of white smoke. This is

normal. You may not be able to use

operator commanded

regeneration if the service engine

soon warning lamp appears in the

information display Information Display Procedure

Start your vehicle engine and when it has

reached the normal operating temperature,

press the information display control

button on the steering wheel until Exhaust

Filter XX%/FULL is displays. Operator

commanded regeneration can only be

initiated when FULL

See Information

Display Control (page 47). If a message

advising that the exhaust filter is full

appears in the information display, press

the down arrow button to set the display

to

Y. Answer yes to this prompt and then

follow the next prompts regarding exhaust

position required to initiate operator

commanded regeneration. Be sure to

understand each prompt. If you are not

sure what is being asked by each prompt,

contact an authorized dealer. The display

confirms the operation has started and

when it has finished.

If the diesel particulate filter is near or at

saturation, a message requesting

permission to initiate filter cleaning

appears in the information display only if

viewing the Exhaust Filter Status message.

See

Information Messages (page 67).

Answer yes to this prompt and then follow

the next prompts regarding exhaust

position required to initiate operator

commanded regeneration. Be sure to

understand each prompt. If you are not

sure what is being asked by each prompt,

contact an authorized dealer. The display

confirms the operation has started and

when it has finished. You can also drive to

clean the filter. When the system is at the point

of oversaturation, the service

engine warning lamp illuminates

and a message appears in the information

display. You cannot initiate filter cleaning.

You must have your vehicle checked as

soon as possible.

112

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 116 of 387

Once operator commanded regeneration

starts, engine speed increases to

approximately 2000 rpm and the cooling

fan speed increases. You will hear a

change in audible sound due to engine

speed and cooling fan speed increases.

It is not necessary to open the hood on the

engine compartment. Once operator

commanded regeneration completes, the

engine speed returns to normal idling. The

exhaust system remains very hot for

several minutes even after regeneration is

complete. Do not reposition the vehicle

over materials that could burn until the

exhaust system has had sufficient time to

cool. Depending on the amount of soot

collected by the diesel particulate filter,

ambient temperature and altitude,

operator commanded regeneration lasts

approximately 30 minutes.

Operator Commanded Regeneration

with Automatic Regeneration Control

(If Equipped)

If your vehicle is operated with significant

stationary operation, low speed drive

cycles less than 25 mph (40 km/h), short

drive cycles, drive time less than 15 minutes

or the vehicle does not fully warm up,

passive and active regeneration may not

sufficiently clean the diesel particulate

filter system. You can switch off automatic

regeneration until better driving conditions

are available, for example steady high

speed driving. You can then switch

automatic regeneration back on to clean

the diesel particulate filter.

Switching Automatic Regeneration

Control On and Off

To switch operator commanded

regeneration on and off, use the

information display control on the steering

wheel. See Information Display Control

(page

47). Scroll to the exhaust cleaning

message and then select Y or N to switch

it On or Off. How to Interrupt or Cancel Operator

Commanded Regeneration

If you need to cancel the operator

commanded regeneration, pressing the

brake, accelerator or switching the engine

off stops the procedure. Depending on the

amount of time you allowed the operator

commanded regeneration to operate, soot

may not have had sufficient time to be fully

eliminated, but the exhaust system and

exhaust gas may still be hot. If you shut

your vehicle off during operator

commanded regeneration, you may notice

turbo flutter. This is a normal consequence

caused by shutting off a diesel engine

during boosted operation and is considered

normal.

Filter Service and Maintenance

Over time, a slight amount of ash builds

up in the diesel particulate filter, which is

not removed during the regeneration

process. The filter may need to be replaced

with a new or remanufactured part at

approximately 250,000 mi (400,000 km).

Actual mileage varies depending on engine

and vehicle operating conditions.

If filter service is required, the

engine control system warning

lamp illuminates in the

information display. If there are any issues with the

diesel particulate filter system,

the engine control system

warning lamp and a service

engine soon warning lamp

illuminate to inform you that

your vehicle requires service. Have your

vehicle checked as soon as possible.

113

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 125 of 387

GENERAL INFORMATION

WARNING: Do not apply the brake

pedal and accelerator pedal

simultaneously. Applying both pedals

simultaneously for more than a few

seconds will limit engine performance,

which may result in difficulty maintaining

speed in traffic and could lead to serious

injury.

Note: Occasional brake noise is normal. If

a metal-to-metal, continuous grinding or

continuous squeal sound is present, the

brake linings may be worn-out. Have the

system checked as soon as possible. If your

vehicle has continuous vibration or shudder

in the steering wheel while braking, have it

checked by an authorized dealer.

All standard equipment brakes are

self-adjusting. Automatic adjustment,

when required, occurs whenever you apply

and release the brakes during forward or

reverse operation.

Know the required stopping distances for

all driving conditions you may encounter.

For longer brake lining life, take full

advantage of engine braking power when

coming to a stop.

Wet brakes result in reduced braking

efficiency. Gently press the brake pedal a

few times when driving from a car wash or

standing water to dry the brakes.

If the brakes do not grip well:

• Check brake adjustment.

• Check the brake linings for excessive

wear.

• Check the system air pressure on

vehicles with air brakes. •

Let the brakes cool if you have been

using them excessively, as in mountain

driving or after several fast, high-speed

stops.

• If you have been driving through deep

water, gently apply the brakes several

times while your vehicle is moving

slowly.

Brake Over Accelerator

In the event the accelerator pedal

becomes stuck or entrapped, apply steady

and firm pressure to the brake pedal to

slow the vehicle and reduce engine power.

If you experience this condition, apply the

brakes and bring your vehicle to a safe

stop. Move the transmission to park (P),

switch the engine off and apply the parking

brake. Inspect the accelerator pedal for

any interference. If none are found and the

condition persists, have your vehicle towed

to the nearest authorized dealer

Anti-lock Brake System

This system helps you maintain steering

control during emergency stops by keeping

the brakes from locking. This lamp momentarily

illuminates when you switch the

ignition on. If the light does not

illuminate during start up, remains on or

flashes, the system may be disabled. Have

the system checked by an authorized

dealer. If you connect a PLC trailer with

the ignition on, the trailer ABS

light also illuminates. If the light

fails to illuminate, if it remains on after you

start the vehicle or continues to flash, have

the system serviced immediately.

See

Warning Lamps and Indicators

(page 60).

122

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Brakes E210335

Page 129 of 387

5. Tighten the nut until the spring is fully

caged and brakes released. Do not

loosen or remove the release stud and

nut unless you completely assemble

and securely clamp the brake chamber.

6. After restoring the air pressure, unscrew and remove the release stud

and install in the carrying pocket. Install

the access plug.

AIR BRAKES (IF EQUIPPED) WARNING:

Do not drive or

continue to drive if the low air pressure

buzzer is sounding or the brake warning

light is lit. These warnings indicate that

air pressure is not to normal operating

level. Continued use of the vehicle could

result in loss of braking ability. WARNING:

Avoid repeated light

application of the brake pedal. This

depletes air pressure faster and could

result in loss of braking capability. WARNING:

Do not move the

vehicle when the air pressure is

insufficient because the brake system

may be inoperative.

After starting the engine, give the air

compressor time to build up the air

pressure to

60 psi (414 kPa) before moving

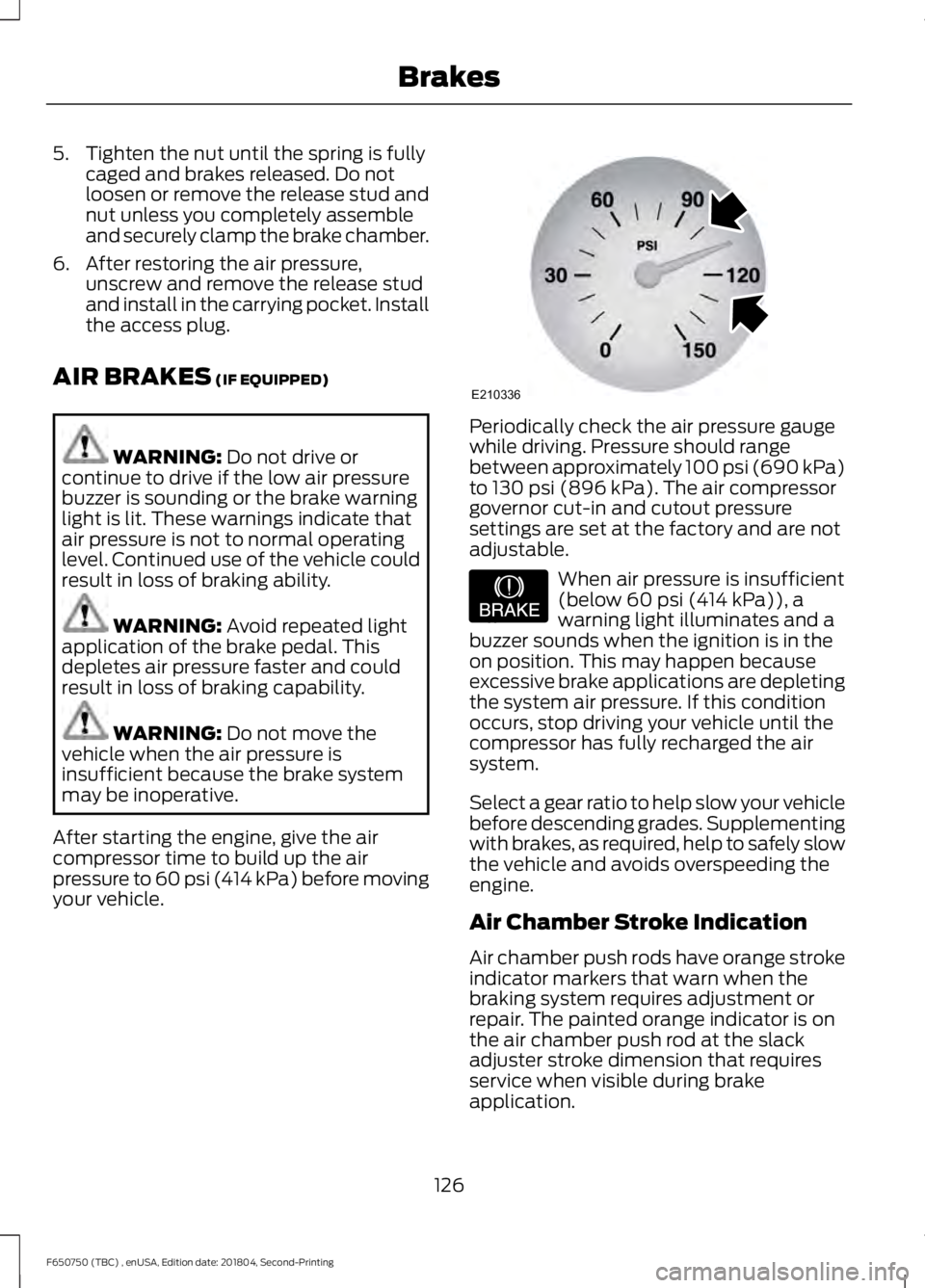

your vehicle. Periodically check the air pressure gauge

while driving. Pressure should range

between approximately 100 psi (690 kPa)

to

130 psi (896 kPa). The air compressor

governor cut-in and cutout pressure

settings are set at the factory and are not

adjustable. When air pressure is insufficient

(below

60 psi (414 kPa)), a

warning light illuminates and a

buzzer sounds when the ignition is in the

on position. This may happen because

excessive brake applications are depleting

the system air pressure. If this condition

occurs, stop driving your vehicle until the

compressor has fully recharged the air

system.

Select a gear ratio to help slow your vehicle

before descending grades. Supplementing

with brakes, as required, help to safely slow

the vehicle and avoids overspeeding the

engine.

Air Chamber Stroke Indication

Air chamber push rods have orange stroke

indicator markers that warn when the

braking system requires adjustment or

repair. The painted orange indicator is on

the air chamber push rod at the slack

adjuster stroke dimension that requires

service when visible during brake

application.

126

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing BrakesE210336 E206772

Page 149 of 387

ESSENTIAL TOWING CHECKS

See Load limits in the Load Carrying

chapter for load specification terms found

on the tire label and Safety Compliance

label and instructions on calculating your

vehicle's load.

Remember to account for the trailer

tongue weight as part of your vehicle load

when calculating the total vehicle weight.

Hitches

Do not use a hitch that either clamps onto

the bumper or attaches to the axle. You

must distribute the load in your trailer so

that 10-15% of the total weight of the

trailer is on the tongue.

Safety Chains

Note: Do not attach safety chains to the

bumper.

Always connect the safety chains to the

frame or hook retainers of your vehicle

hitch.

To connect the safety chains, cross the

chains under the trailer tongue and allow

enough slack for turning tight corners. Do

not allow the chains to drag on the ground.

Trailer Brakes WARNING:

Do not connect a

trailer's hydraulic brake system directly

to your vehicle's brake system. Your

vehicle may not have enough braking

power and your chances of having a

collision greatly increase.

Electric brakes and manual, automatic or

surge-type trailer brakes are safe if you

install them properly and adjust them to

the manufacturer's specifications. The

trailer brakes must meet local and federal

regulations. The rating for the tow vehicle's braking

system operation is at the gross vehicle

weight rating, not the gross combined

weight rating.

Trailer Lamps

WARNING:

Never connect any

trailer lamp wiring to the vehicle's tail

lamp wiring; this may damage the

electrical system resulting in fire. Contact

your authorized dealer as soon as

possible for assistance in proper trailer

tow wiring installation. Additional

electrical equipment may be required.

Trailer lamps are required on most towed

vehicles. Make sure all running lights, brake

lights, turn signals and hazard lights are

working.

Before Towing a Trailer

Practice turning, stopping and backing up

to get the feel of your vehicle-trailer

combination before starting on a trip.

When turning, make wider turns so the

trailer wheels clear curbs and other

obstacles.

When Towing a Trailer

• Check your hitch, electrical connections

and trailer wheel lug nuts thoroughly

after you have traveled

50 mph

(80 km/h).

• When stopped in congested or heavy

traffic during hot weather, place the

transmission in park (P) or neutral (N)

to aid engine and transmission cooling

and to help air conditioning

performance.

• Turn off the speed control with heavy

loads or in hilly terrain. The speed

control may turn off automatically

when you are towing on long, steep

grades.

146

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Towing

Page 150 of 387

•

Shift to a lower gear when driving down

a long or steep hill. Do not apply the

brakes continuously, as they may

overheat and become less effective.

• If your transmission is equipped with

the Tow/Haul feature, use this feature

when towing. This provides engine

braking and helps eliminate excessive

transmission shifting for optimum fuel

economy and transmission cooling.

• Allow more distance for stopping with

a trailer attached. Anticipate stops and

brake gradually.

FIFTH WHEEL OPERATION WARNING: Failure to follow the

fifth wheel manufacturer ’s instructions

for hooking and unhooking as well as

sliding the fifth wheel could result in an

accident, personal injury or death. WARNING:

When the tractor and

trailer are parked unattended, the trailer

brake hand control should never be used

to apply the brake, since air may leak

from the system, allowing vehicle

movement, resulting in possible property

damage, personal injury or death.

Before hook-up, make sure:

• The fifth wheel jaws are fully open.

• The fifth wheel is fully tilted back to

prevent body damage when the tractor

is backed under a trailer.

• You block the trailer wheels and adjust

and apply the trailer spring brakes.

Never chase a trailer.

• The brake hoses and light cords are

clear of the fifth wheel. Hook-up

1. Back the tractor squarely under the

trailer, engaging the fifth-wheel jaws

on the kingpin. Always back up slowly;

make sure the trailer is neither too high

nor too low. Avoid backing under the

trailer from an angle.

2. Connect the service and emergency brake hoses and trailer light connector.

3. Inspect the jaws of the fifth wheel to be sure they have fully closed on the

trailer kingpin and the trailer plate is

resting securely on the fifth wheel.

4. Make sure the coupler release lever is in the locked position.

5. Charge the trailer brake system. Set the trailer brakes, with either the hand

valve or tractor protection valve. Pull

against the trailer for an extra check of

proper hook-up. Do not pull hard

enough to damage or strain the

equipment.

6. Set the tractor parking brakes and fully

raise the trailer landing gear.

7. Check the operation of all trailer lights

and correct any lights that may be

faulty.

Un-hook

1. Try to keep the tractor and trailer in a straight line.

2. Apply the parking brakes.

3. Lower the trailer landing gear, making sure it is on solid, level ground. The

weight of the trailer is to be on the

landing gear.

4. Block the trailer wheels.

5. Disconnect the brake hoses and light cords. Be sure hoses and cords are

clear.

6. Pull coupler release lever to disengage

the fifth wheel jaws.

147

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Towing

Page 156 of 387

Operation in Snow and Rain

Vehicle operation in heavy snowfall or

extreme rain conditions may feed

excessive amounts of snow or water into

the air intake system. This could plug the

air filter with snow and may cause the

engine to lose power and possibly shut

down.

We recommend the following actions after

operating your vehicle up to 199 mi

(320 km) in snowfall or extreme rain:

• Snow: At the earliest opportunity, open

the hood and clear all the snow and ice

from the air filter housing inlet (do not

remove the foam filter) and reset the

air filter restriction gauge.

Note: Removal of the foam filter degrades

your vehicle performance during snow and

hot weather conditions.

• Extreme rain: The air filter dries after

about 15– 30 minutes at highway

speeds. At the earliest opportunity,

open the hood and reset the air filter

restriction gauge.

DRIVING THROUGH WATER WARNING:

Do not drive through

flowing or deep water as you may lose

control of your vehicle.

Note: Driving through standing water can

cause vehicle damage.

Note: Engine damage can occur if water

enters the air filter.

Before driving through standing water,

check the depth. Never drive through water

that is higher than the bottom of the wheel

hubs. When driving through standing water, drive

very slowly and do not stop your vehicle.

Your brake performance and traction may

be limited. After driving through water and

as soon as it is safe to do so:

•

Lightly press the brake pedal to dry the

brakes and to check that they work.

• Check that the horn works.

• Check that the exterior lights work.

• Turn the steering wheel to check that

the steering power assist works.

Operation in Standing Water

Ingestion of water into the diesel engine

can result in immediate and severe

damage to the engine. If driving through

water, slow down to avoid splashing water

into the intake. If the engine stalls, and you

suspect ingestion of water into the engine,

do not try to restart the engine. Consult

your dealer for service immediately.

Your fuel tank vents to the atmosphere by

valves on top of the tank and through the

fuel cap. If water reaches the top of the

tank, the valves may pull water into the

fuel tank. Water in the fuel can cause

performance issues and damage the fuel

injection system.

153

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Driving HintsE176913

Page 183 of 387

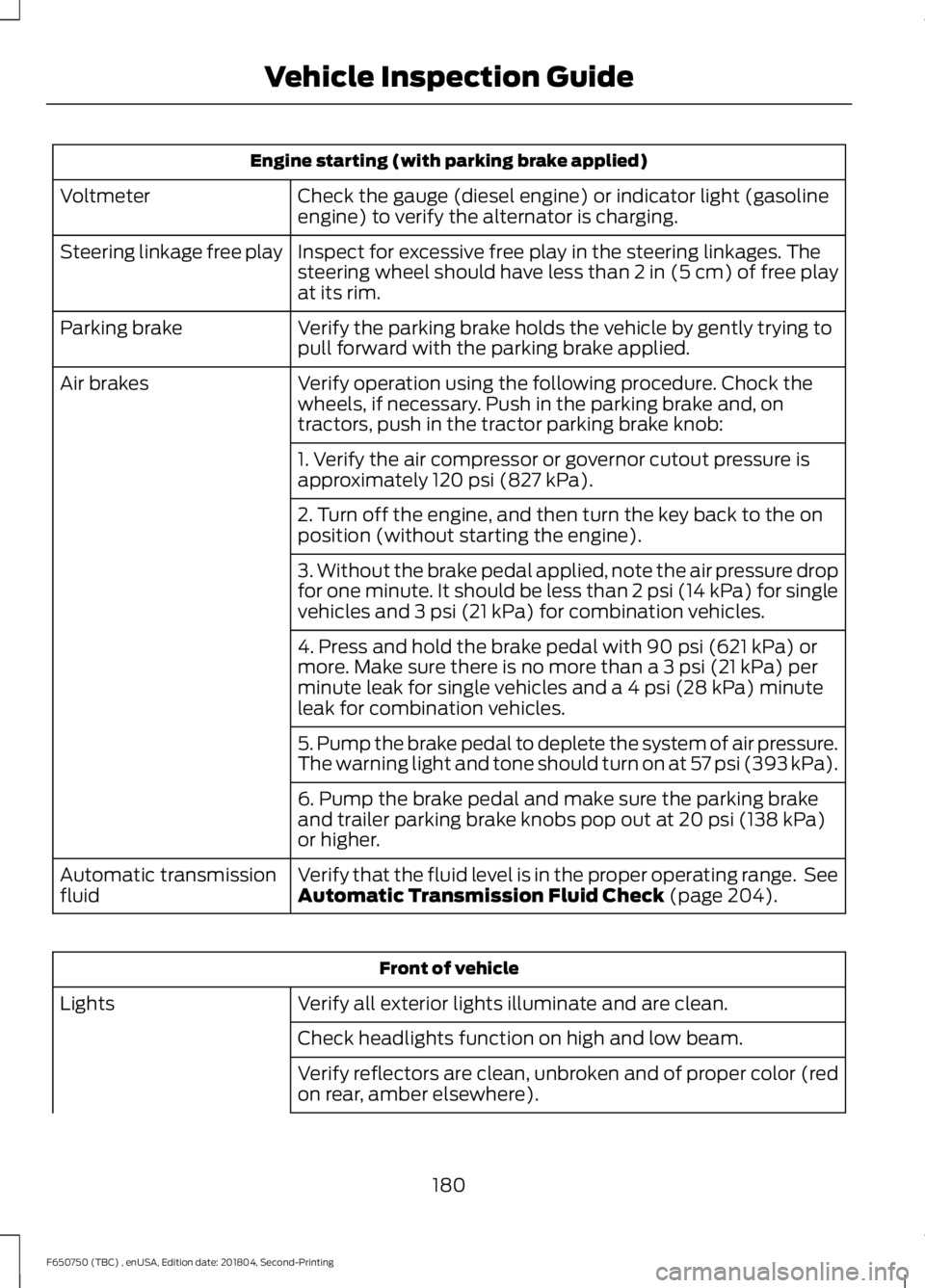

Engine starting (with parking brake applied)

Check the gauge (diesel engine) or indicator light (gasoline

engine) to verify the alternator is charging.

Voltmeter

Inspect for excessive free play in the steering linkages. The

steering wheel should have less than 2 in (5 cm) of free play

at its rim.

Steering linkage free play

Verify the parking brake holds the vehicle by gently trying to

pull forward with the parking brake applied.

Parking brake

Verify operation using the following procedure. Chock the

wheels, if necessary. Push in the parking brake and, on

tractors, push in the tractor parking brake knob:

Air brakes

1. Verify the air compressor or governor cutout pressure is

approximately 120 psi (827 kPa).

2. Turn off the engine, and then turn the key back to the on

position (without starting the engine).

3. Without the brake pedal applied, note the air pressure drop

for one minute. It should be less than 2 psi (14 kPa) for single

vehicles and

3 psi (21 kPa) for combination vehicles.

4. Press and hold the brake pedal with

90 psi (621 kPa) or

more. Make sure there is no more than a 3 psi (21 kPa) per

minute leak for single vehicles and a 4 psi (28 kPa) minute

leak for combination vehicles.

5. Pump the brake pedal to deplete the system of air pressure.

The warning light and tone should turn on at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the parking brake

and trailer parking brake knobs pop out at

20 psi (138 kPa)

or higher.

Verify that the fluid level is in the proper operating range. See

Automatic Transmission Fluid Check

(page 204).

Automatic transmission

fluid Front of vehicle

Verify all exterior lights illuminate and are clean.

Lights

Check headlights function on high and low beam.

Verify reflectors are clean, unbroken and of proper color (red

on rear, amber elsewhere).

180

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Vehicle Inspection Guide

Page 188 of 387

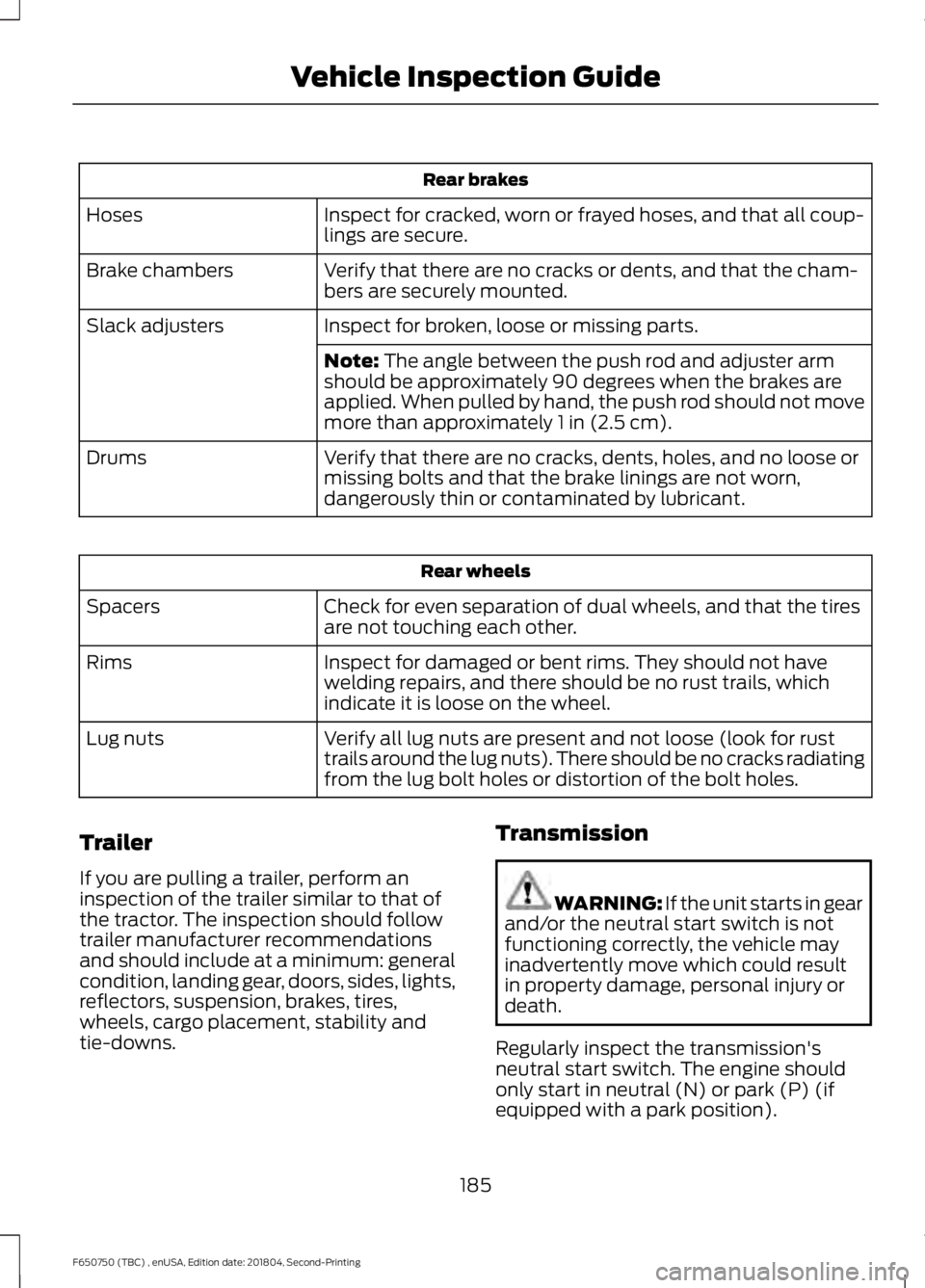

Rear brakes

Inspect for cracked, worn or frayed hoses, and that all coup-

lings are secure.

Hoses

Verify that there are no cracks or dents, and that the cham-

bers are securely mounted.

Brake chambers

Inspect for broken, loose or missing parts.

Slack adjusters

Note: The angle between the push rod and adjuster arm

should be approximately 90 degrees when the brakes are

applied. When pulled by hand, the push rod should not move

more than approximately

1 in (2.5 cm).

Verify that there are no cracks, dents, holes, and no loose or

missing bolts and that the brake linings are not worn,

dangerously thin or contaminated by lubricant.

Drums Rear wheels

Check for even separation of dual wheels, and that the tires

are not touching each other.

Spacers

Inspect for damaged or bent rims. They should not have

welding repairs, and there should be no rust trails, which

indicate it is loose on the wheel.

Rims

Verify all lug nuts are present and not loose (look for rust

trails around the lug nuts). There should be no cracks radiating

from the lug bolt holes or distortion of the bolt holes.

Lug nuts

Trailer

If you are pulling a trailer, perform an

inspection of the trailer similar to that of

the tractor. The inspection should follow

trailer manufacturer recommendations

and should include at a minimum: general

condition, landing gear, doors, sides, lights,

reflectors, suspension, brakes, tires,

wheels, cargo placement, stability and

tie-downs. Transmission WARNING: If the unit starts in gear

and/or the neutral start switch is not

functioning correctly, the vehicle may

inadvertently move which could result

in property damage, personal injury or

death.

Regularly inspect the transmission's

neutral start switch. The engine should

only start in neutral (N) or park (P) (if

equipped with a park position).

185

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Vehicle Inspection Guide