service interval FORD F650/750 2021 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2021, Model line: F650/750, Model: FORD F650/750 2021Pages: 390, PDF Size: 5.16 MB

Page 11 of 390

Right-hand side.

A

Left-hand side.

B

Warnings WARNING: Throughout this guide,

you will find warnings identified by the

warning symbol. Warnings remind you

to be especially careful to reduce the risk

of personal injury.

Diesel Engine Information

The diesel engine fuel system is a

pressurized two-stage filtration system

and consists of:

• A frame-mounted Fuel and Water

Separator primary filter with an electric

fuel pump and water drain

• An engine-mounted secondary fuel

filter

• A fuel injector for each cylinder (8

total)

• A high-pressure fuel pump

• A high-pressure fuel rail for each

cylinder bank (2 total)

• Numerous high-pressure pipes from

the high-pressure pump to the rails,

and rails to the injectors The fuel and water separator removes

both water and impurities from the fuel.

The engine-mounted filter filters finer

impurities from the diesel fuel. The

engine-mounted fuel filter and the

frame-mounted fuel filter should be

changed at the recommended service

interval or when indicated by the

information display LOW FUEL PRESSURE

message. See

Scheduled Maintenance

(page 319).

The fuel and water separator should be

drained at regular intervals (recommended

at every oil change) or when indicated by

the information display and water in fuel

indicator light. See

Fuel Quality (page

100).

Proper fuel filter maintenance and prompt

water draining when the water in fuel light

illuminates is essential to prevent injection

equipment damage. Ignoring the water in

fuel light or the information display

message WATER IN FUEL DRAIN FILTER

can cause your vehicle to go into a reduced

power mode.

A frame-mounted electric fuel pump

located inside the fuel and water separator

draws fuel from the fuel tank to provide

pressurized fuel to the engine. The fuel

pump contains a pressure relief valve for

overpressure protection in the event of

restricted flow.

The fuel injection system is controlled

through the powertrain control module.

Engine Protection Mode

Ford diesel engines are equipped with

engine protection and emission control

systems. These systems monitor critical

temperatures and pressures, and modify

engine operation accordingly. These

modified engine performance

characteristics are normal.

8

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing IntroductionE154903

Page 12 of 390

If these modified engine performance

characteristics persist for an extended

period and either the service engine soon

or powertrain malfunction, reduced power,

electronic throttle control light is

illuminated, have the system checked by

an authorized dealer.

Service engine soon

Powertrain malfunction, reduced

power, electronic throttle control

Diesel Lubrication System

It is important to change the engine oil at

the recommended service intervals or

when indicated by the information display

to maintain oil viscosity. Extending the oil

and filter change interval beyond the

recommended interval can negatively

affect engine performance, fuel economy

and engine life. See Engine Oil Check

(page 218).

Engine and secondary cooling system

The cooling system contains a primary

cooling loop to cool the engine and a

secondary cooling loop to cool the

transmission, charge air, and fuel. The

coolant serves three primary purposes: to

provide heat transfer, freeze point

protection, and corrosion protection using

additives.

Vehicles with diesel engines typically are

used to carry heavy loads and accumulate

mileage rapidly. These two factors may

cause the additives in the coolant to wear

out in a shorter time. You can find more

information about coolant additives and

coolant change intervals in the coolant

chapter. See

General Maintenance

Information (page 319). Operating the

engine with insufficient coolant or coolant

additive can cause severe engine damage. Selective catalytic reduction system

Your vehicle is equipped with a selective

catalytic reduction system designed to

reduce emission levels of nitrogen oxides

from the exhaust of your diesel engine. This

system relies on the use of Diesel Exhaust

Fluid (DEF) that you must replenish at

certain intervals. Failure to maintain proper

DEF levels or if the DEF becomes

contaminated will result in vehicle speed

limitations or result in your vehicle entering

an idle-only mode. See

Selective

Catalytic Reductant System (page 112).

Minor Troubleshooting Guide

If the engine won ’t crank WARNING:

Battery posts,

terminals and related accessories

contain lead and lead compounds. Wash

hands after handling.

Turn on the headlights. If the lights are dim,

do not go on at all or when the ignition is

turned to the start position, the lights

become dim or go out, the battery

connections may be loose or corroded, or

the battery may be discharged. If there is

a clicking or stuttering sound coming from

the engine compartment when you turn

the key to the start position, this may also

indicate a loose or corroded battery

connection.

Check the battery connections at the

battery posts, cable connection to the

engine grounding point and at the starter

connection.

If you suspect a discharged battery, have

it checked and corrected.

9

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Introduction

Page 105 of 390

To help achieve acceptable engine

performance and durability when using

biodiesel in your vehicle:

•

Confirm the biodiesel content of the

fuel to be 20% biodiesel or less, also

known as B20.

• Only use biodiesel fuel of good quality

that complies with industry standards.

• Follow the recommended service

maintenance intervals. See

Scheduled Maintenance (page 319).

• Do not store biodiesel fuel in the fuel

tank for more than 1 month.

• Consider changing brands or reducing

biodiesel content if you have cold

temperature fuel gelling issues or a

frequent LOW FUEL PRESSURE

message appearing.

Note: Do not use home heating oil,

agricultural fuel, raw fats and oils, waste

cooking greases, biodiesel fuels greater than

20% or any diesel fuel not intended for

highway use. Red dye is used to identify

fuels intended for agricultural and

non-highway use. Damage to the fuel

injection system, engine and exhaust

catalyst can occur if an improper fuel is

used.

Use of biodiesel in concentrations greater

than 20% could cause damage to your

vehicle, including engine and/or exhaust

catalyst and particulate filter failures.

Concentrations greater than 20% can also

cause fuel filter restrictions that could

result in a lack of power or damage to fuel

system components, including fuel pump

and fuel injector failures.

SAE 5W-40 or SAE 15W-40 oil is

recommended for fuels with greater than

5% biodiesel, also known as B5. Follow

the recommended oil change intervals and

other maintenance when operating on

biodiesel. See

Special Operating

Conditions Scheduled Maintenance

(page

329). Look for a label on the fuel pump to

confirm the amount of biodiesel contained

in a diesel fuel. Biodiesel content is often

indicated with the letter B followed by the

percent of biodiesel in the fuel. For

example, B20 indicates a fuel containing

20% biodiesel. Ask the service station

attendant to confirm the biodiesel content

of a diesel fuel if you do not see a label on

the fuel pump.

Note:

Biodiesel fuels degrade more easily

than diesel fuels not containing biodiesel.

Degraded or oxidized biodiesel can damage

fuel system seals and plastics and corrode

steel parts. If you plan to park or store your

vehicle for more than 1 month, empty your

vehicle fuel tank of biodiesel fuel. Fill the

tank with a pure petroleum-based diesel

fuel and run your vehicle for a minimum of

30 minutes.

During cold weather, if you have problems

operating on biodiesel, you may need to

use a diesel fuel with lower biodiesel

content, try another brand, or discontinue

the use of biodiesel.

Diesel Fuel Additives

It should not be necessary to add any

aftermarket additives to your fuel if you

use a high quality diesel fuel that conforms

to ASTM industry specifications.

Aftermarket additives can damage the fuel

injector system or engine.

Use Motorcraft® cetane booster or an

equivalent cetane booster additive if you

suspect fuel has low cetane. Use

Motorcraft® anti-gel & performance

improver or an equivalent additive if there

is fuel gelling.

Do not use alcohol-based additives to

improve cetane quality, to prevent fuel

gelling or any other use. The use of alcohol

additives may result in damage to the fuel

injectors and system. See Capacities and

Specifications (page 288).

102

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Fuel and Refueling

Page 139 of 390

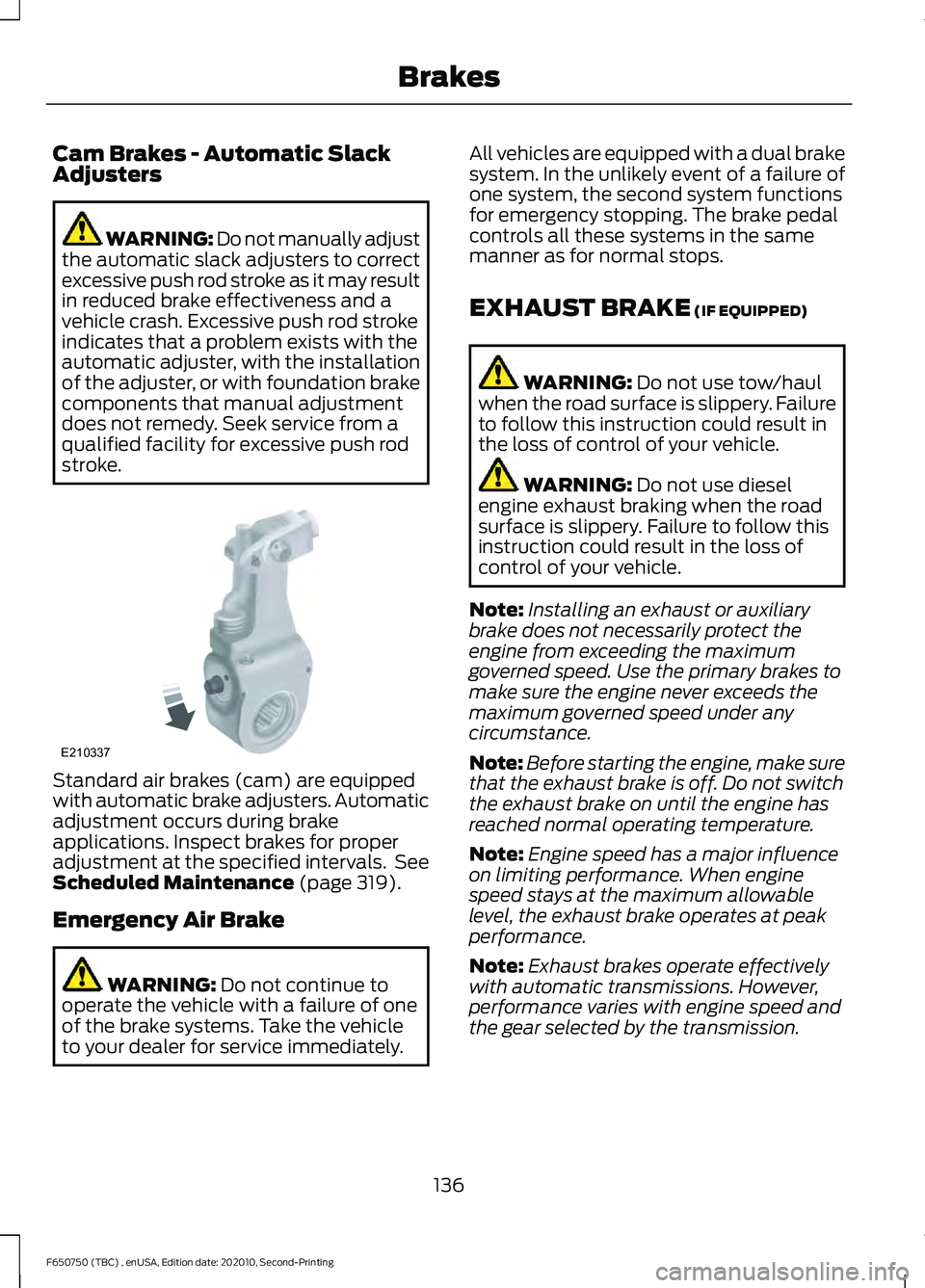

Cam Brakes - Automatic Slack

Adjusters

WARNING: Do not manually adjust

the automatic slack adjusters to correct

excessive push rod stroke as it may result

in reduced brake effectiveness and a

vehicle crash. Excessive push rod stroke

indicates that a problem exists with the

automatic adjuster, with the installation

of the adjuster, or with foundation brake

components that manual adjustment

does not remedy. Seek service from a

qualified facility for excessive push rod

stroke. Standard air brakes (cam) are equipped

with automatic brake adjusters. Automatic

adjustment occurs during brake

applications. Inspect brakes for proper

adjustment at the specified intervals. See

Scheduled Maintenance (page 319).

Emergency Air Brake WARNING:

Do not continue to

operate the vehicle with a failure of one

of the brake systems. Take the vehicle

to your dealer for service immediately. All vehicles are equipped with a dual brake

system. In the unlikely event of a failure of

one system, the second system functions

for emergency stopping. The brake pedal

controls all these systems in the same

manner as for normal stops.

EXHAUST BRAKE

(IF EQUIPPED)

WARNING:

Do not use tow/haul

when the road surface is slippery. Failure

to follow this instruction could result in

the loss of control of your vehicle. WARNING:

Do not use diesel

engine exhaust braking when the road

surface is slippery. Failure to follow this

instruction could result in the loss of

control of your vehicle.

Note: Installing an exhaust or auxiliary

brake does not necessarily protect the

engine from exceeding the maximum

governed speed. Use the primary brakes to

make sure the engine never exceeds the

maximum governed speed under any

circumstance.

Note: Before starting the engine, make sure

that the exhaust brake is off. Do not switch

the exhaust brake on until the engine has

reached normal operating temperature.

Note: Engine speed has a major influence

on limiting performance. When engine

speed stays at the maximum allowable

level, the exhaust brake operates at peak

performance.

Note: Exhaust brakes operate effectively

with automatic transmissions. However,

performance varies with engine speed and

the gear selected by the transmission.

136

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing BrakesE210337

Page 222 of 390

Adding Engine Oil

WARNING: Do not remove the filler

cap when the engine is running.

Do not use supplemental engine oil

additives because they are unnecessary

and could lead to engine damage that may

not be covered by the vehicle Warranty.

To top up the engine oil level do the

following:

1. Clean the area surrounding the engine oil filler cap before you remove it.

2. Remove the engine oil filler cap. See Under Hood Overview (page 215).

Turn it counterclockwise and remove

it.

3. Add engine oil of the proper viscosity and grade that meets Ford

specifications. See

Capacities and

Specifications (page 288). You may

have to use a funnel to pour the engine

oil into the opening.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap

correctly.

Note: Soak up any spillage with an

absorbent cloth immediately. Engine lubrication for severe

service operation

The following conditions define severe

operation for which engine operation with

SAE 5W-40 oil which meets Ford

specification, WSS-M2C171-F1, is

recommended. Oil and oil filter change

intervals will be determined by the

Intelligent Oil Life Monitor™ as noted

previously.

CHANGING THE ENGINE OIL

AND OIL FILTER

WARNING: Do not handle a hot oil

filter with bare hands. WARNING:

Continuous contact

with used motor oil has caused cancer

in laboratory mice. Protect your skin by

washing with soap and water.

If your vehicle is equipped with a diesel

engine, an Intelligent Oil Life Monitor™

calculates the proper oil change service

interval. When the information display

indicates: OIL CHANGE REQUIRED, change

the engine oil and oil filter. See

Information Displays

(page 70).

The engine oil filter protects your engine

by filtering harmful, abrasive or sludge

particles and particles significantly smaller

than most available will-fit filters. See

Motorcraft Parts

(page 283).

1. Unscrew the oil filter and oil pan drain plug and wait for the oil to drain.

2. Replace the filter.

3. Reinstall the oil pan drain plug.

4. Refill the engine with new oil. See Capacities and Specifications (page

288

).

219

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 223 of 390

5. For diesel engines, you need to reset

the Intelligent Oil Life Monitor™. See

Information Displays (page 70).

Engine lubrication for severe

service operation

The following conditions define severe

operation for which engine operation with

SAE 5W-40 API CJ-4 is recommended. Oil

and oil filter change intervals will be

determined by the Intelligent Oil Life

Monitor™ as noted previously.

• Frequent or extended idling (over 10

minutes per hour of normal driving).

• Low-speed operation/stationary use.

• If vehicle is operated in sustained

ambient temperatures below

-9°F

(-23°C) or above 100°F (38°C).

• Frequent low-speed operation,

consistent heavy traffic less than

25 mph (40 km/h)

.

• Operating in severe dust conditions.

• Operating the vehicle off road.

• Towing a trailer over

1,000 mi

(1,600 km).

• Sustained, high-speed driving at Gross

Vehicle Weight Rating (maximum

loaded weight for vehicle operation).

• Use of fuels with sulfur content other

than ultra-low sulfur diesel (ULSD).

• Use of high-sulfur diesel fuel.

OIL CHANGE INDICATOR

RESET

Base Cluster

Use the information display controls on

the steering wheel to reset the oil change

indicator. From the main menu scroll to: Action and Description

Message

Press the right arrow button,

then from this menu scroll

to the following message.

Settings

Press the down arrow

button, then from this menu

scroll to the following

message.

Vehicle

Press the right arrow button,

then from this menu scroll

to the following message.

Oil Life

Reset

Press and hold the

OK

button until the instrument

cluster displays the

following message.

Oil Life

Hold to

Reset

Press and hold the

OK

button until the instrument

cluster displays the

following message.

Oil Life

Hold OK

to Reset

Reset Complete

If the instrument cluster

displays the following

message, repeat the

process.

Reset Cancelled

High Series Cluster

Use the information display controls on

the steering wheel to reset the oil change

indicator.

220

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 229 of 390

2. Locate the diesel fuel conditioner

module and place an appropriate

container under the drain port. 3.

Rotate the drain counterclockwise until

the O-ring is visible. Allow the diesel

fuel conditioner module to drain for

approximately 25 seconds or until

clean fuel is observed. Rotate the drain

clockwise to tighten it. If no liquid

drains, there may be a clog in the drain.

Have the conditioner module serviced

by an authorized dealer.

4. Make sure that you fully tighten the drain valve and then remove the

container from under your vehicle.

5. Restart the engine. If the Water in Fuel

Drain Filter message and light

continues to illuminate, have the fuel

system checked and repaired. ENGINE COOLANT CHECK -

7.3L WARNING:

Do not remove the

coolant reservoir cap when the engine is

on or the cooling system is hot. Wait 10

minutes for the cooling system to cool

down. Cover the coolant reservoir cap

with a thick cloth to prevent the

possibility of scalding and slowly remove

the cap. Failure to follow this instruction

could result in personal injury. WARNING:

Do not put coolant in

the windshield washer reservoir. If

sprayed on the windshield, coolant could

make it difficult to see through the

windshield. WARNING:

To reduce the risk of

personal injury, make sure the engine is

cool before unscrewing the coolant

pressure relief cap. The cooling system

is under pressure. Steam and hot liquid

can come out forcefully when you loosen

the cap slightly. WARNING:

Do not add coolant

further than the MAX mark.

When the engine is cold, check the

concentration and level of the coolant at

the intervals listed in the scheduled

maintenance information. See Scheduled

Maintenance

(page 319).

Note: Make sure that the coolant level is

between the

MIN and MAX marks on the

coolant reservoir.

Note: Coolant expands when it is hot. The

level may extend beyond the

MAX mark.

226

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing MaintenanceE163360

Page 239 of 390

AUTOMATIC TRANSMISSION

FLUID CHECK

The transmission does not consume fluid.

However, check the fluid level if the

transmission is not working properly, for

example if the transmission slips, shifts

slowly or if there are signs of fluid loss.

Replace the transmission fluid and filter

on your vehicle at the specified service

interval. See Scheduled Maintenance

(page 319).

Automatic transmission fluid expands

when warmed. To check the fluid level

consistently and accurately, do the

following:

1. Drive the vehicle until it reaches normal

operating temperature. This may take

up to

20 mi (30 km). Make sure that

the transmission fluid temperature

gauge on the instrument cluster is

within normal operating temperature

196– 215°F (91– 102°C)

before

checking.

2. Make sure that your vehicle is on level ground.

3. With the engine running, parking brake

engaged and your foot on the brake

pedal, move the gearshift lever through

all of the gear ranges. Allow sufficient

time for each gear to engage.

4. Make sure the parking brake is on. Make

sure the transmission is in park (P) or

neutral (N) and leave the engine

running.

5. Open the hood. See

Opening and

Closing the Hood (page 213).

6. Remove the dipstick and wipe it with a clean, lint-free cloth. See

Under

Hood Overview (page 215).

7. Replace the dipstick and remove it again to check the fluid level. 8. If the fluid level is correct, replace the

dipstick and make sure it is fully seated.

Note: If the fluid level is between the

maximum and minimum marks, the fluid

level is acceptable. Do not add fluid.

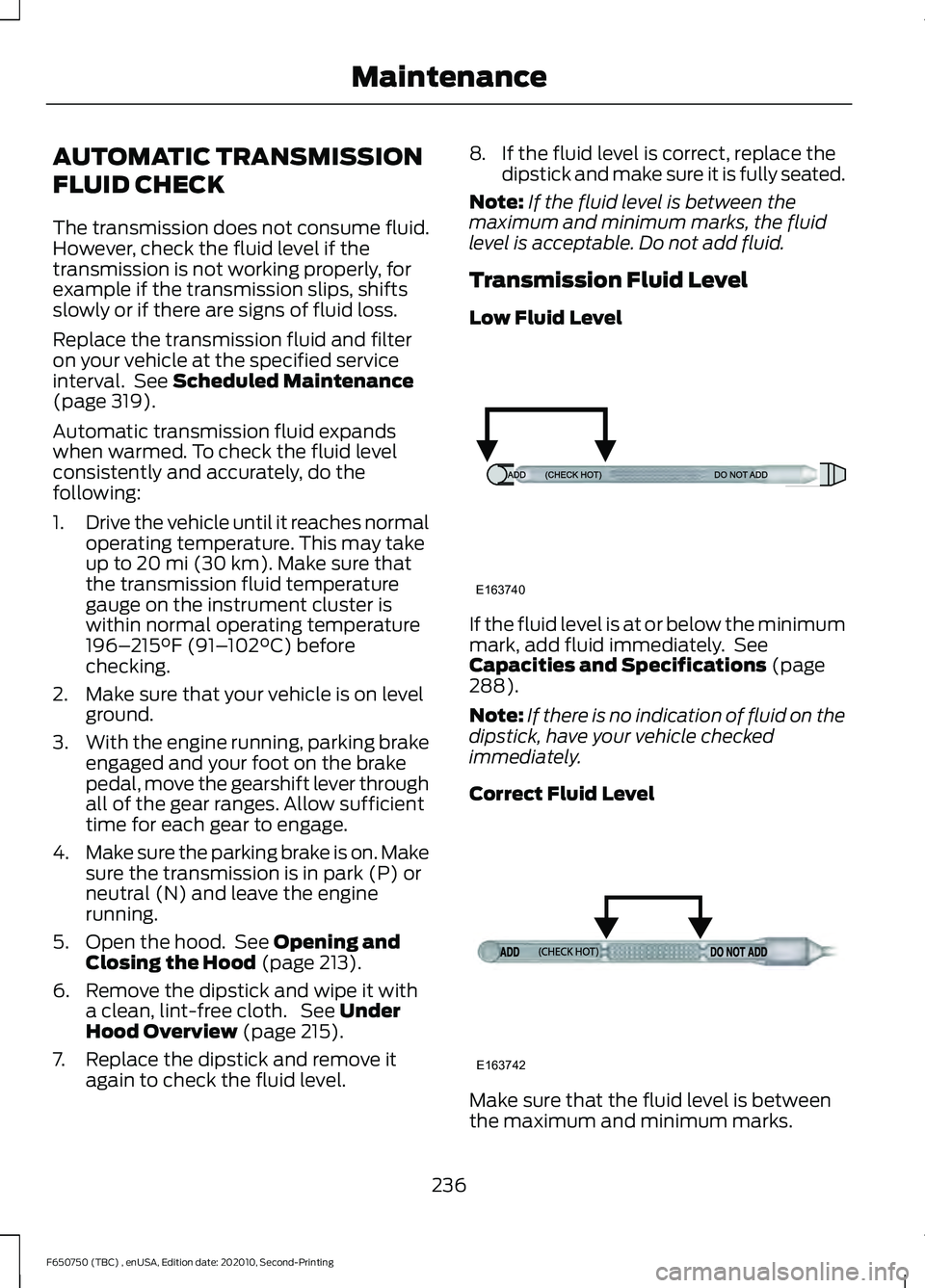

Transmission Fluid Level

Low Fluid Level If the fluid level is at or below the minimum

mark, add fluid immediately. See

Capacities and Specifications

(page

288).

Note: If there is no indication of fluid on the

dipstick, have your vehicle checked

immediately.

Correct Fluid Level Make sure that the fluid level is between

the maximum and minimum marks.

236

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing MaintenanceE163740 E163742

Page 241 of 390

1. Park your vehicle on a level surface.

2. Look at the brake fluid reservoir to see

where the brake fluid level is relative

to the MIN and the MAX marks on the

reservoir.

Note: If the brake fluid level is between the

MIN

and the MAX marks on the reservoir, it

is acceptable.

Note: If the brake fluid level is below the

MIN

mark or above the MAX mark, have

your vehicle checked as soon as possible.

Note: To avoid fluid contamination, the

reservoir cap must remain in place and fully

tight, unless you are adding fluid.

Only use fluid that meets our

specifications. See

Capacities and

Specifications (page 281).

Brake Fluid Service Interval

Brake fluid absorbs water over time which

degrades the effectiveness of the brake

fluid. Change the brake fluid at the

specified intervals to prevent degraded

braking performance. For detailed interval information, see

Scheduled Maintenance in your Owner's

Manual or your local maintenance guide.

POWER STEERING FLUID

CHECK

Check the power steering fluid. See

Scheduled Maintenance

(page 319). If

adding fluid is necessary, use only

MERCON LV ATF

Check the fluid level when it is at ambient

temperature.

1. Check the fluid level in the reservoir. It should be between the MIN and MAX

range. Do not add fluid if the level is

within this range.

2. If the fluid level is low, add fluid to bring

the fluid level up to between the MIN

and MAX range.

3. Switch the engine on.

4. While the engine idles, turn the steering

wheel left and right several times.

5. Switch the engine off.

6. Recheck the fluid level in the reservoir. Do not add fluid if the level is between

the MIN and MAX range.

7. If the fluid is low, add the proper type of fluid in small amounts, continuously

checking the level until it is between

the MIN and MAX range. See

Capacities and Specifications (page

288). Be sure to put the cap back on the

reservoir.

238

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing MaintenanceE170684

Page 247 of 390

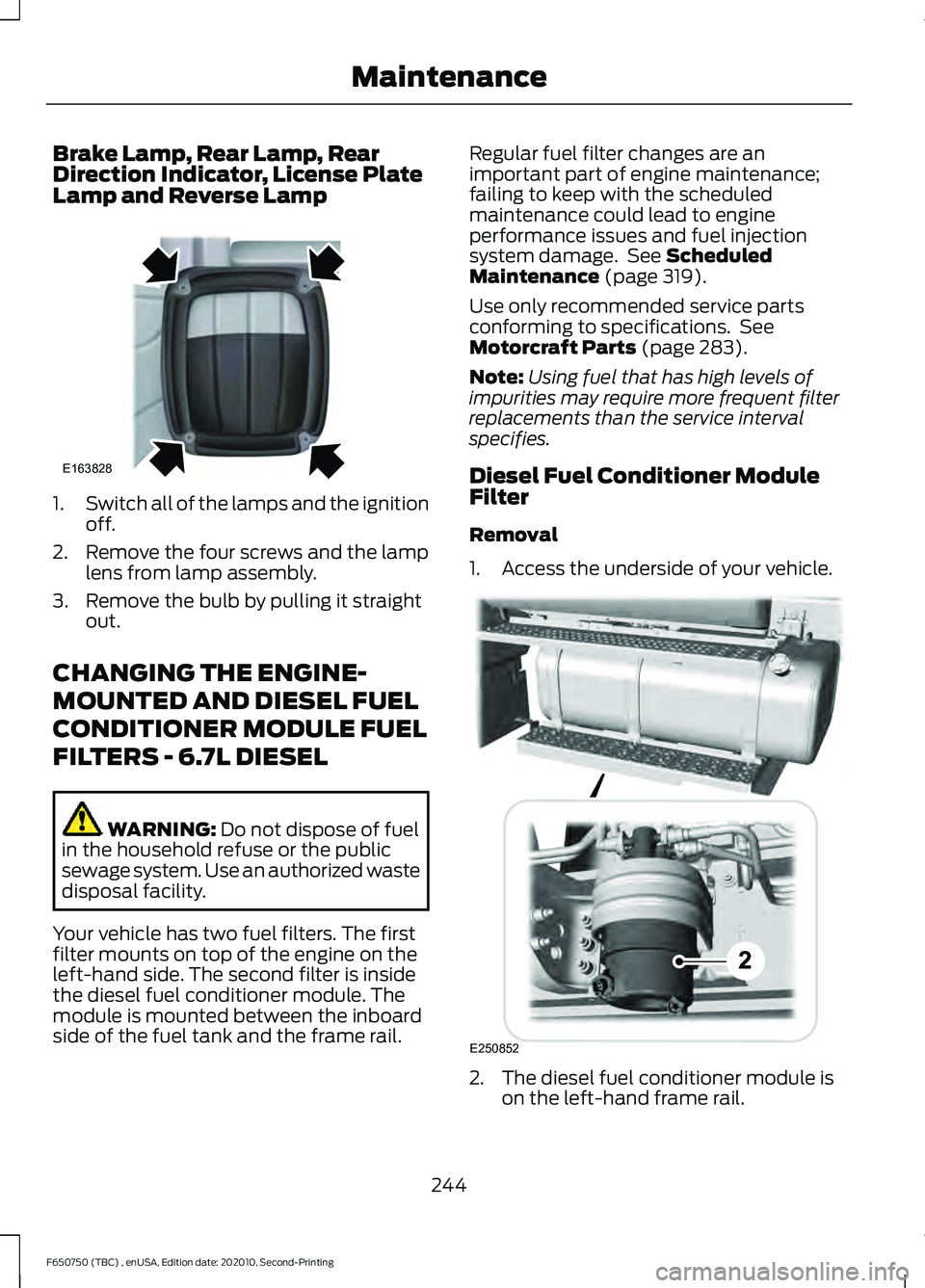

Brake Lamp, Rear Lamp, Rear

Direction Indicator, License Plate

Lamp and Reverse Lamp

1.

Switch all of the lamps and the ignition

off.

2. Remove the four screws and the lamp lens from lamp assembly.

3. Remove the bulb by pulling it straight out.

CHANGING THE ENGINE-

MOUNTED AND DIESEL FUEL

CONDITIONER MODULE FUEL

FILTERS - 6.7L DIESEL WARNING: Do not dispose of fuel

in the household refuse or the public

sewage system. Use an authorized waste

disposal facility.

Your vehicle has two fuel filters. The first

filter mounts on top of the engine on the

left-hand side. The second filter is inside

the diesel fuel conditioner module. The

module is mounted between the inboard

side of the fuel tank and the frame rail. Regular fuel filter changes are an

important part of engine maintenance;

failing to keep with the scheduled

maintenance could lead to engine

performance issues and fuel injection

system damage. See

Scheduled

Maintenance (page 319).

Use only recommended service parts

conforming to specifications. See

Motorcraft Parts

(page 283).

Note: Using fuel that has high levels of

impurities may require more frequent filter

replacements than the service interval

specifies.

Diesel Fuel Conditioner Module

Filter

Removal

1. Access the underside of your vehicle. 2. The diesel fuel conditioner module is

on the left-hand frame rail.

244

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing MaintenanceE163828 E250852