FORD F650/750 2024 Owners Manual

Manufacturer: FORD, Model Year: 2024, Model line: F650/750, Model: FORD F650/750 2024Pages: 386, PDF Size: 8.7 MB

Page 221 of 386

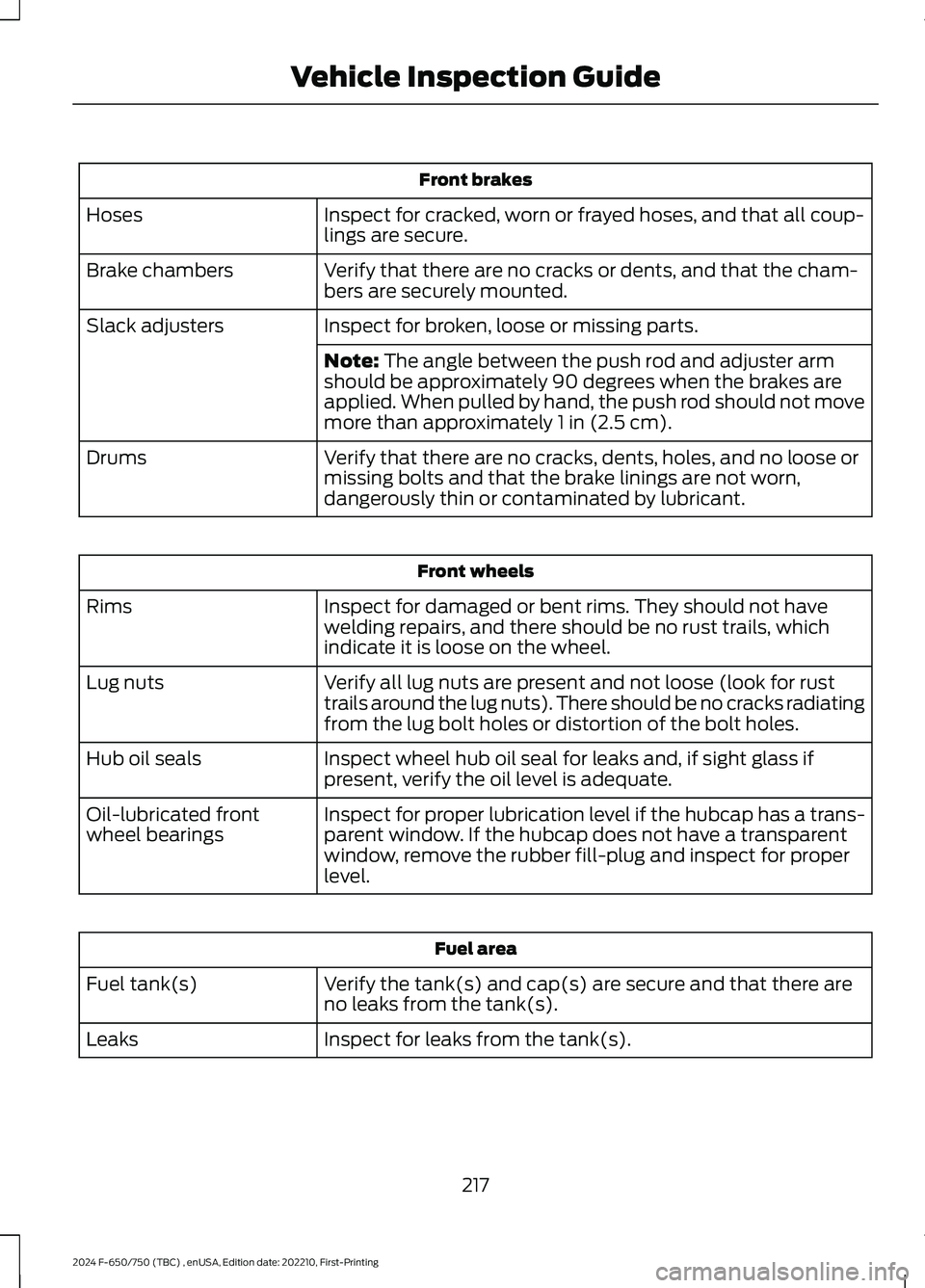

Front brakes

Inspect for cracked, worn or frayed hoses, and that all coup-lings are secure.Hoses

Verify that there are no cracks or dents, and that the cham-bers are securely mounted.Brake chambers

Inspect for broken, loose or missing parts.Slack adjusters

Note: The angle between the push rod and adjuster armshould be approximately 90 degrees when the brakes areapplied. When pulled by hand, the push rod should not movemore than approximately 1 in (2.5 cm).

Verify that there are no cracks, dents, holes, and no loose ormissing bolts and that the brake linings are not worn,dangerously thin or contaminated by lubricant.

Drums

Front wheels

Inspect for damaged or bent rims. They should not havewelding repairs, and there should be no rust trails, whichindicate it is loose on the wheel.

Rims

Verify all lug nuts are present and not loose (look for rusttrails around the lug nuts). There should be no cracks radiatingfrom the lug bolt holes or distortion of the bolt holes.

Lug nuts

Inspect wheel hub oil seal for leaks and, if sight glass ifpresent, verify the oil level is adequate.Hub oil seals

Inspect for proper lubrication level if the hubcap has a trans-parent window. If the hubcap does not have a transparentwindow, remove the rubber fill-plug and inspect for properlevel.

Oil-lubricated frontwheel bearings

Fuel area

Verify the tank(s) and cap(s) are secure and that there areno leaks from the tank(s).Fuel tank(s)

Inspect for leaks from the tank(s).Leaks

217

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide

Page 222 of 386

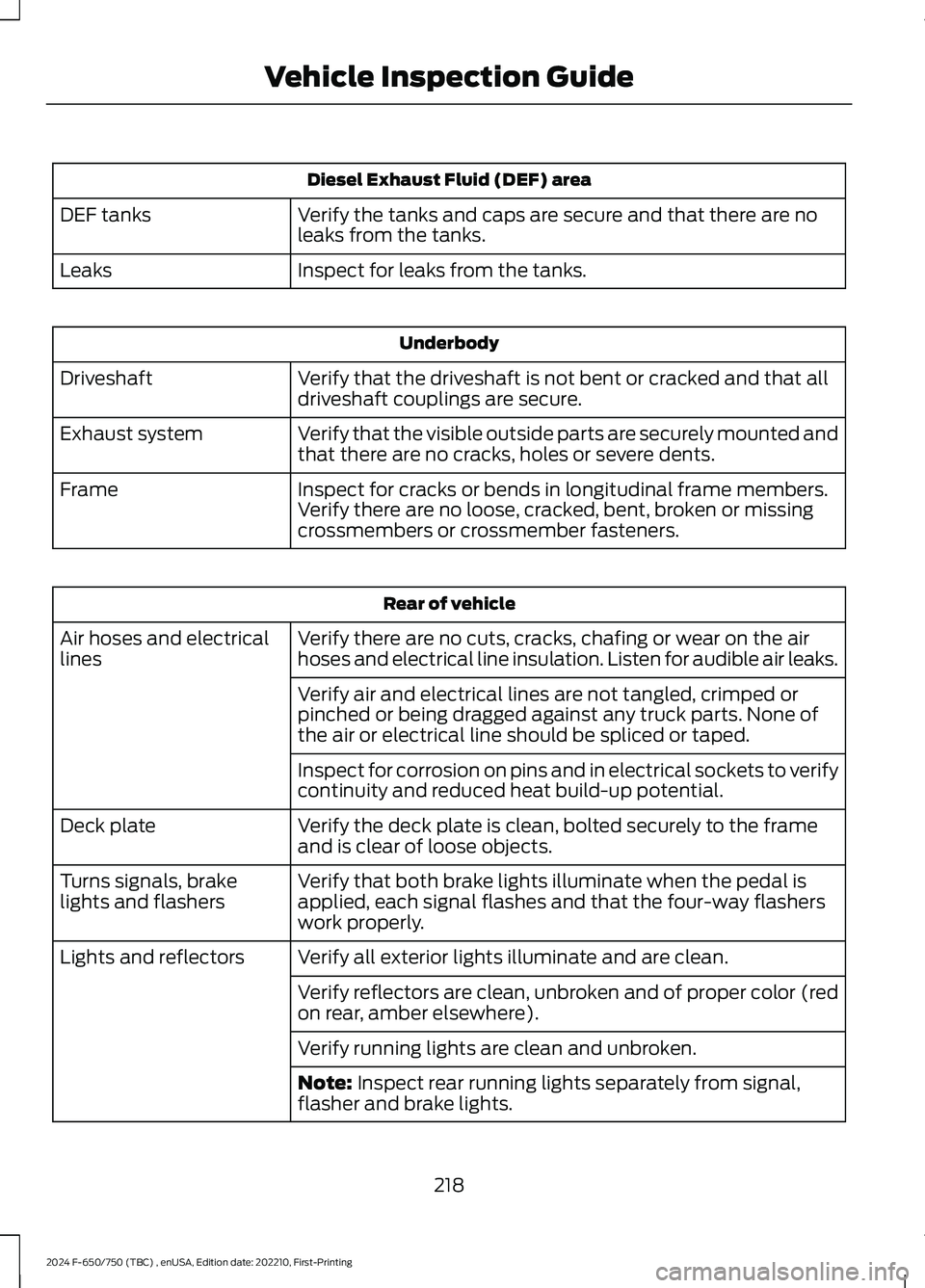

Diesel Exhaust Fluid (DEF) area

Verify the tanks and caps are secure and that there are noleaks from the tanks.DEF tanks

Inspect for leaks from the tanks.Leaks

Underbody

Verify that the driveshaft is not bent or cracked and that alldriveshaft couplings are secure.Driveshaft

Verify that the visible outside parts are securely mounted andthat there are no cracks, holes or severe dents.Exhaust system

Inspect for cracks or bends in longitudinal frame members.Verify there are no loose, cracked, bent, broken or missingcrossmembers or crossmember fasteners.

Frame

Rear of vehicle

Verify there are no cuts, cracks, chafing or wear on the airhoses and electrical line insulation. Listen for audible air leaks.Air hoses and electricallines

Verify air and electrical lines are not tangled, crimped orpinched or being dragged against any truck parts. None ofthe air or electrical line should be spliced or taped.

Inspect for corrosion on pins and in electrical sockets to verifycontinuity and reduced heat build-up potential.

Verify the deck plate is clean, bolted securely to the frameand is clear of loose objects.Deck plate

Verify that both brake lights illuminate when the pedal isapplied, each signal flashes and that the four-way flasherswork properly.

Turns signals, brakelights and flashers

Verify all exterior lights illuminate and are clean.Lights and reflectors

Verify reflectors are clean, unbroken and of proper color (redon rear, amber elsewhere).

Verify running lights are clean and unbroken.

Note: Inspect rear running lights separately from signal,flasher and brake lights.

218

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide

Page 223 of 386

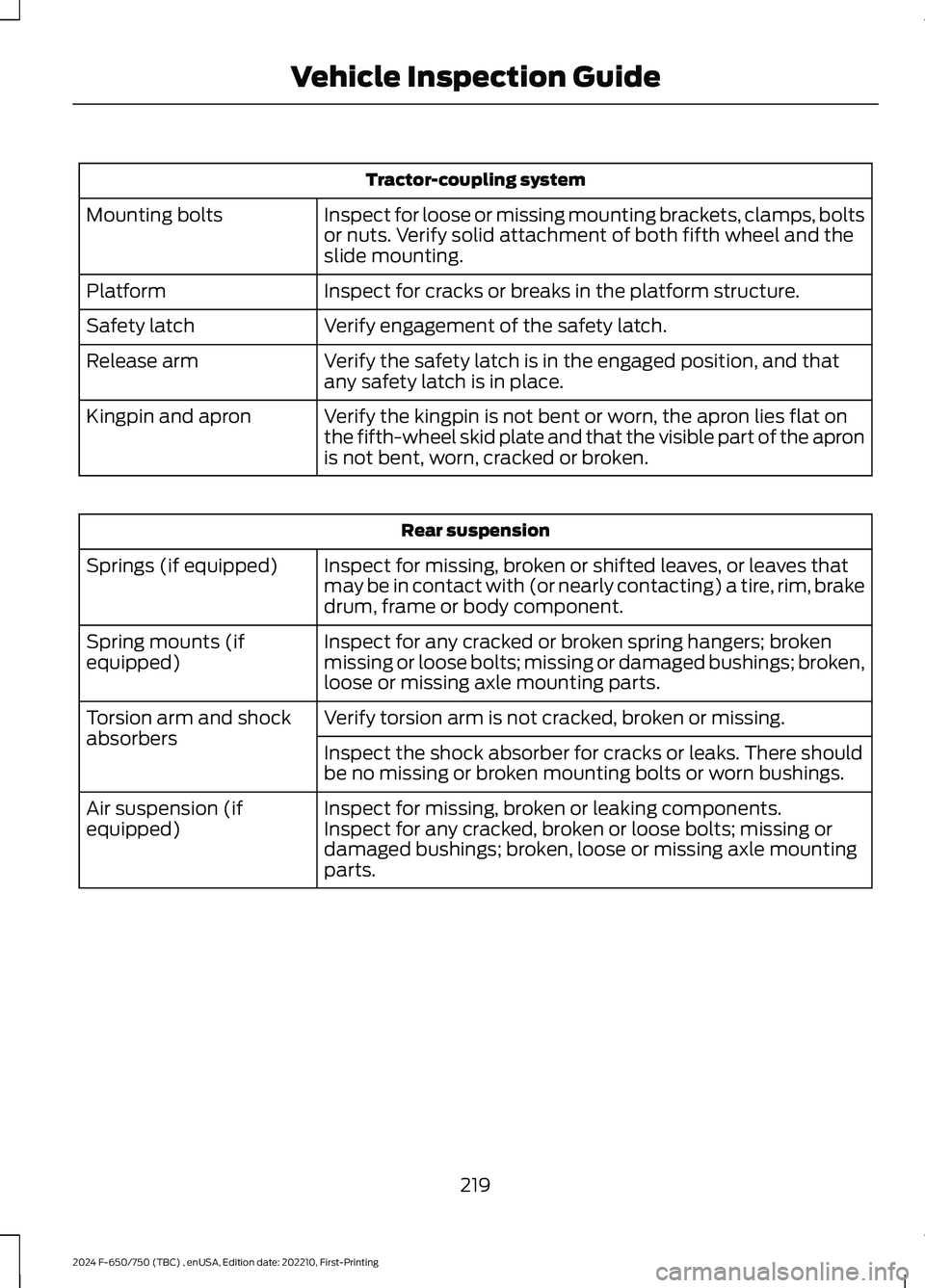

Tractor-coupling system

Inspect for loose or missing mounting brackets, clamps, boltsor nuts. Verify solid attachment of both fifth wheel and theslide mounting.

Mounting bolts

Inspect for cracks or breaks in the platform structure.Platform

Verify engagement of the safety latch.Safety latch

Verify the safety latch is in the engaged position, and thatany safety latch is in place.Release arm

Verify the kingpin is not bent or worn, the apron lies flat onthe fifth-wheel skid plate and that the visible part of the apronis not bent, worn, cracked or broken.

Kingpin and apron

Rear suspension

Inspect for missing, broken or shifted leaves, or leaves thatmay be in contact with (or nearly contacting) a tire, rim, brakedrum, frame or body component.

Springs (if equipped)

Inspect for any cracked or broken spring hangers; brokenmissing or loose bolts; missing or damaged bushings; broken,loose or missing axle mounting parts.

Spring mounts (ifequipped)

Verify torsion arm is not cracked, broken or missing.Torsion arm and shockabsorbersInspect the shock absorber for cracks or leaks. There shouldbe no missing or broken mounting bolts or worn bushings.

Inspect for missing, broken or leaking components.Air suspension (ifequipped)Inspect for any cracked, broken or loose bolts; missing ordamaged bushings; broken, loose or missing axle mountingparts.

219

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide

Page 224 of 386

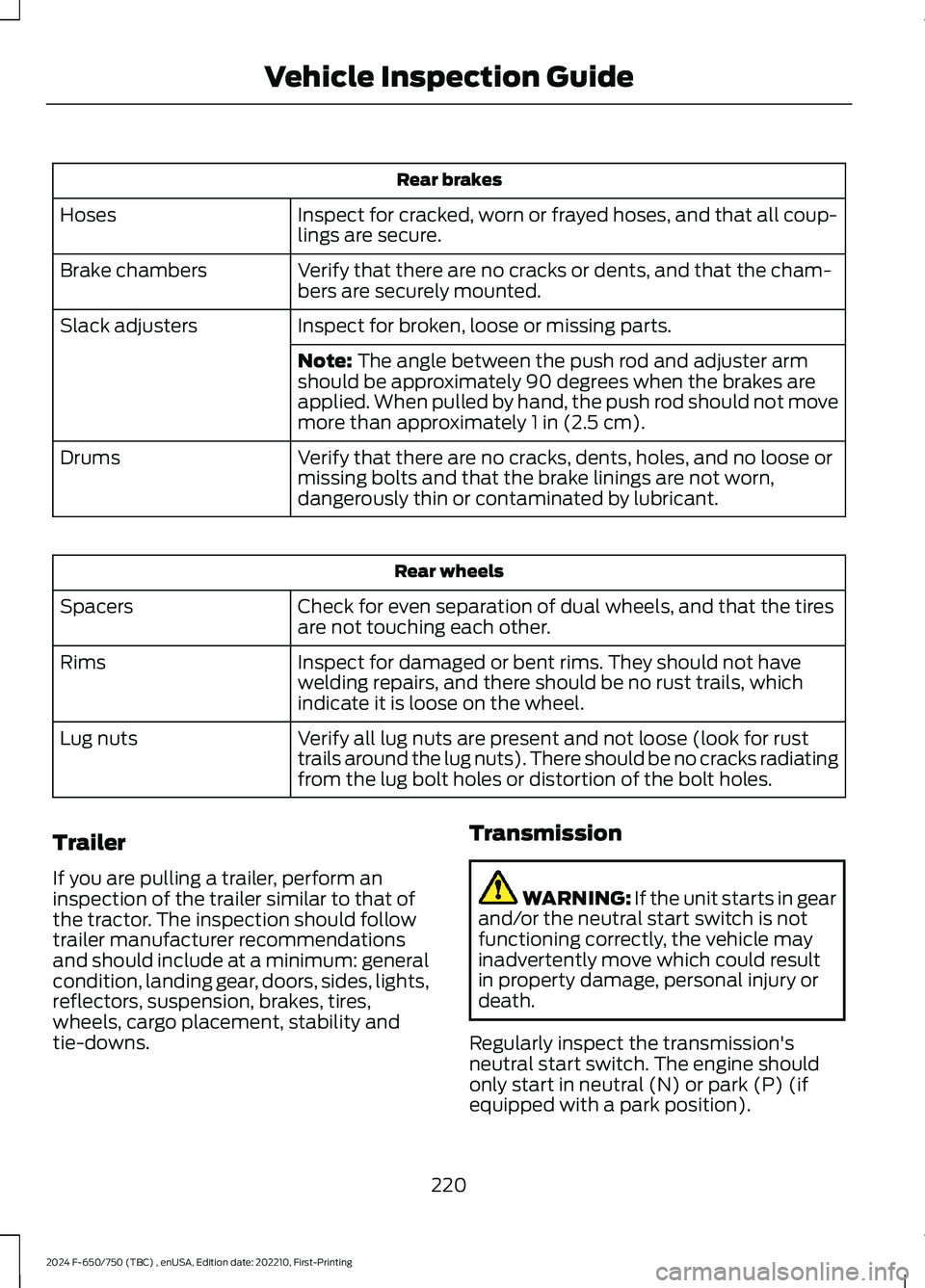

Rear brakes

Inspect for cracked, worn or frayed hoses, and that all coup-lings are secure.Hoses

Verify that there are no cracks or dents, and that the cham-bers are securely mounted.Brake chambers

Inspect for broken, loose or missing parts.Slack adjusters

Note: The angle between the push rod and adjuster armshould be approximately 90 degrees when the brakes areapplied. When pulled by hand, the push rod should not movemore than approximately 1 in (2.5 cm).

Verify that there are no cracks, dents, holes, and no loose ormissing bolts and that the brake linings are not worn,dangerously thin or contaminated by lubricant.

Drums

Rear wheels

Check for even separation of dual wheels, and that the tiresare not touching each other.Spacers

Inspect for damaged or bent rims. They should not havewelding repairs, and there should be no rust trails, whichindicate it is loose on the wheel.

Rims

Verify all lug nuts are present and not loose (look for rusttrails around the lug nuts). There should be no cracks radiatingfrom the lug bolt holes or distortion of the bolt holes.

Lug nuts

Trailer

If you are pulling a trailer, perform aninspection of the trailer similar to that ofthe tractor. The inspection should followtrailer manufacturer recommendationsand should include at a minimum: generalcondition, landing gear, doors, sides, lights,reflectors, suspension, brakes, tires,wheels, cargo placement, stability andtie-downs.

Transmission

WARNING: If the unit starts in gearand/or the neutral start switch is notfunctioning correctly, the vehicle mayinadvertently move which could resultin property damage, personal injury ordeath.

Regularly inspect the transmission'sneutral start switch. The engine shouldonly start in neutral (N) or park (P) (ifequipped with a park position).

220

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide

Page 225 of 386

Inspect the transmission fluid level andshift linkage for proper operation.

221

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide

Page 226 of 386

GENERAL INFORMATION

WARNING: Making modificationsto various parts, components andsystems of the vehicle, such as brake andsteering systems, can adversely affectthe quality, reliability and operation ofyour vehicle and could result in propertydamage, personal injury or death. Suchmodifications must be avoided.

WARNING: Failure to properlyperform maintenance and servicingprocedures could result in vehicledamage, personal injury or death.

WARNING: Take care whenperforming any maintenance, systemcheck or service on your vehicle. Someof the materials may also be hazardousif used, serviced or handled improperlyand could result in property damage,personal injury or death.

If the owner or operator of the vehicle is askilled technician and intends onperforming the vehicle maintenance andservice, he is strongly urged to purchase aservice manual.

Always use care when performing vehiclemaintenance, repairs or system checks.Improper or incomplete service could resultin your vehicle not working properly whichmay result in personal injury or damage toyour vehicle or equipment. It is theoperator’s responsibility to see that yourvehicle receives proper care andmaintenance. If you have any questionsabout performing service, have the servicedone by a qualified technician.

To help you service your vehicle, weprovide scheduled maintenanceinformation which makes tracking routineservice easy. See ScheduledMaintenance (page 325).

If your vehicle requires professional service,an authorized dealer can provide thenecessary parts and service. Check yourwarranty information to find out whichparts and services are covered.

Use only recommended fuels, lubricants,fluids and service parts conforming tospecifications. Motorcraft® parts aredesigned and built to provide the bestperformance in your vehicle.

Servicing Guidelines

WARNING: The use of inferior partscan adversely affect the quality andreliability of your vehicle and could resultin property damage, personal injury ordeath.

When servicing your vehicle:

•Always wear safety glasses for eyeprotection.

•Always set the parking brake or chockthe wheels.

•Always use support stands, not a jack,when working under a raised vehicle.

•Always turn off the ignition unless aprocedure requires the engine to berunning.

•Always avoid contact with hot metalparts. Allow the components to coolbefore working with, or around, them.

•Always operate the engine in awell-ventilated area.

•Do not wear loose-fitting clothing,hanging jewelry, watches or rings.

•Do not smoke.

•Do not work on the brakes or the clutchunless you take the proper precautionsto avoid inhaling friction material dust.

222

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingMaintenance

Page 227 of 386

Quality service parts are available throughan authorized dealer. If dealer parts are notused, make sure the replacement parts areof equivalent quality.

Working with the Engine Off

1.Set the parking brake and shift toneutral (N) or park (P).

2.Switch off the engine.

3.Block the wheels.

Working with the Engine On

WARNING: To reduce the risk ofvehicle damage and/or personal burninjuries, do not start your engine with theair cleaner removed and do not removeit while the engine is running.

1.Set the parking brake and shift toneutral (N) or park (P).

2.Block the wheels

Supporting Your Vehicle forService

WARNING: Do not use a jack whenworking under a vehicle. It may give way,causing the vehicle to fall and result inproperty damage, personal injury ordeath. Always use floor stands tosupport the vehicle.

Prepare your vehicle for service repairs bydoing the following:

1.Park your vehicle on a level, concretefloor.

2.Set the parking brake and block thewheels to prevent your vehicle frommoving.

3.Select a jack with a rated capacitysufficient to lift and hold up yourvehicle.

4.Raise your vehicle with the jack appliedto the axle(s). Do not use the bumperas a lifting point.

5.Support your vehicle with floor standsunder the axle(s). When servicing theaxle or the suspension, support yourvehicle with floor stands under theframe side-members, preferablybetween the axles.

OPENING AND CLOSING THE

HOOD

WARNING: Before opening thehood, fully apply the parking brake, shiftinto park (P) or neutral (N) and switchthe ignition off.

WARNING: Do not stand under thehood when you raise or lower it. Failureto follow this warning could result inserious personal injury or death.

WARNING: If the engine is runningwhile the hood is open, stay clear ofmoving engine components. Failure tofollow this warning could result in seriouspersonal injury or death.

223

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingMaintenance

Page 228 of 386

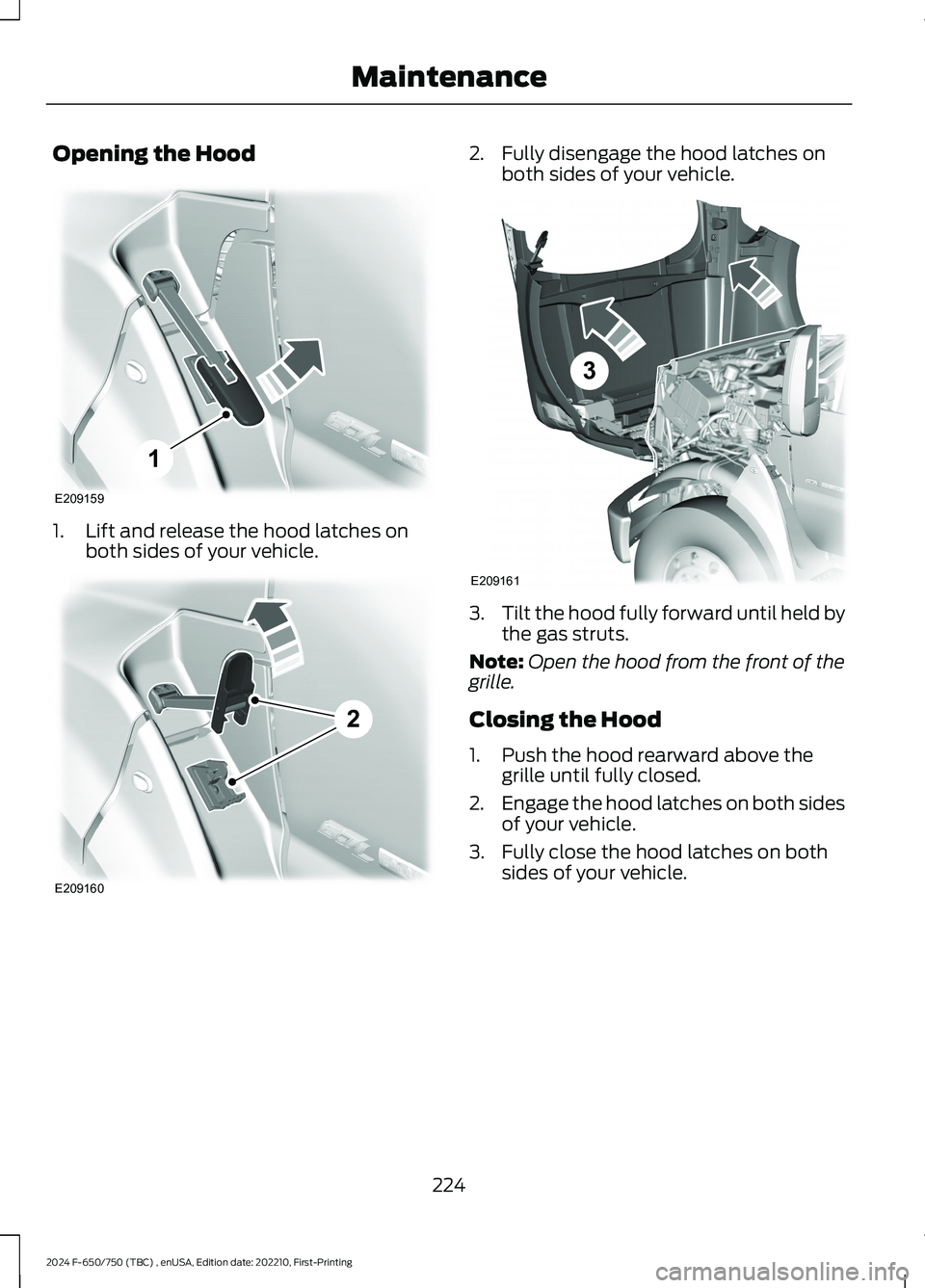

Opening the Hood

1.Lift and release the hood latches onboth sides of your vehicle.

2.Fully disengage the hood latches onboth sides of your vehicle.

3.Tilt the hood fully forward until held bythe gas struts.

Note:Open the hood from the front of thegrille.

Closing the Hood

1.Push the hood rearward above thegrille until fully closed.

2.Engage the hood latches on both sidesof your vehicle.

3.Fully close the hood latches on bothsides of your vehicle.

224

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingMaintenanceE2091591 E2091602 E2091613

Page 229 of 386

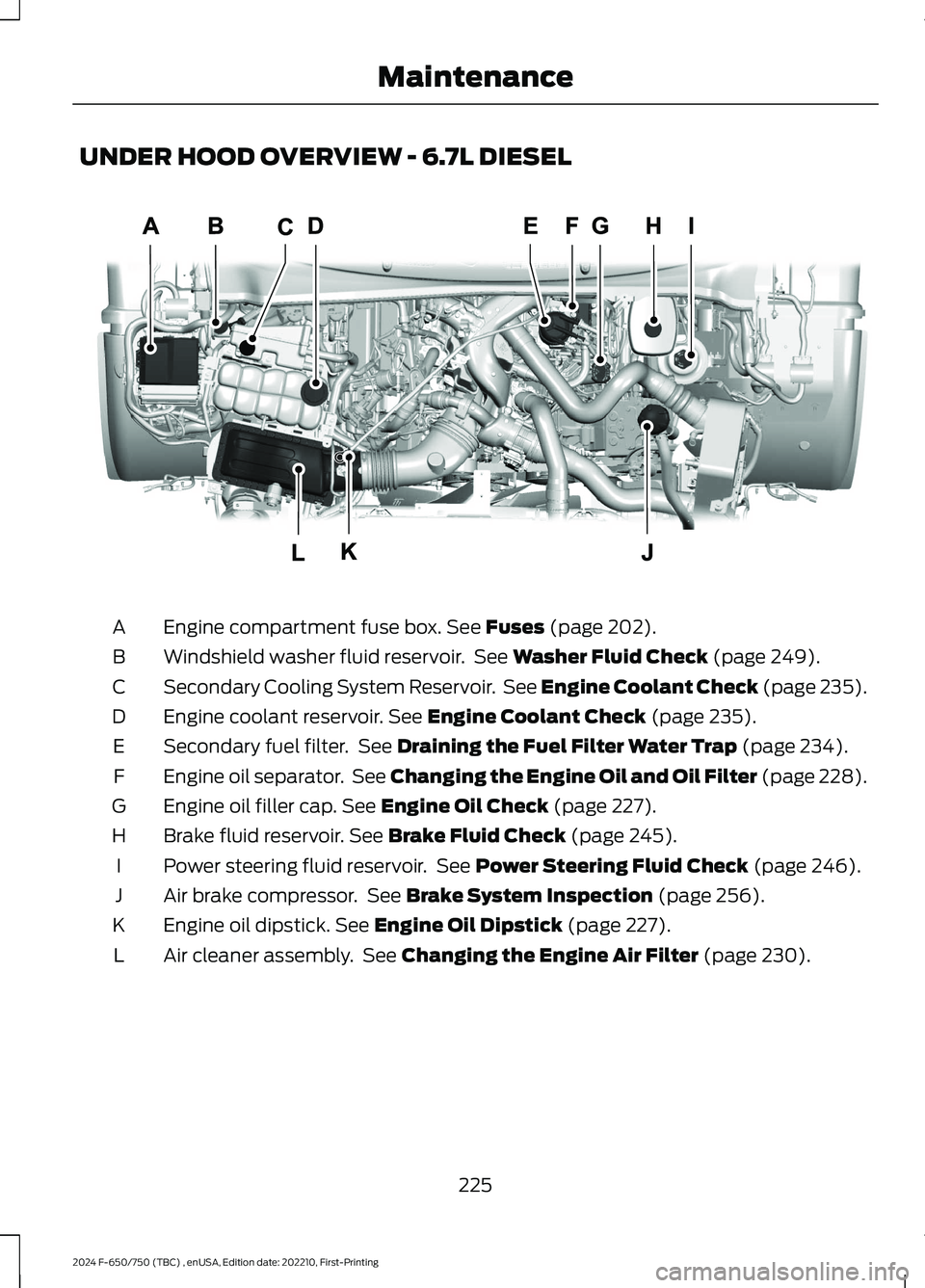

UNDER HOOD OVERVIEW - 6.7L DIESEL

Engine compartment fuse box. See Fuses (page 202).A

Windshield washer fluid reservoir. See Washer Fluid Check (page 249).B

Secondary Cooling System Reservoir. See Engine Coolant Check (page 235).C

Engine coolant reservoir. See Engine Coolant Check (page 235).D

Secondary fuel filter. See Draining the Fuel Filter Water Trap (page 234).E

Engine oil separator. See Changing the Engine Oil and Oil Filter (page 228).F

Engine oil filler cap. See Engine Oil Check (page 227).G

Brake fluid reservoir. See Brake Fluid Check (page 245).H

Power steering fluid reservoir. See Power Steering Fluid Check (page 246).I

Air brake compressor. See Brake System Inspection (page 256).J

Engine oil dipstick. See Engine Oil Dipstick (page 227).K

Air cleaner assembly. See Changing the Engine Air Filter (page 230).L

225

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingMaintenanceE389955

Page 230 of 386

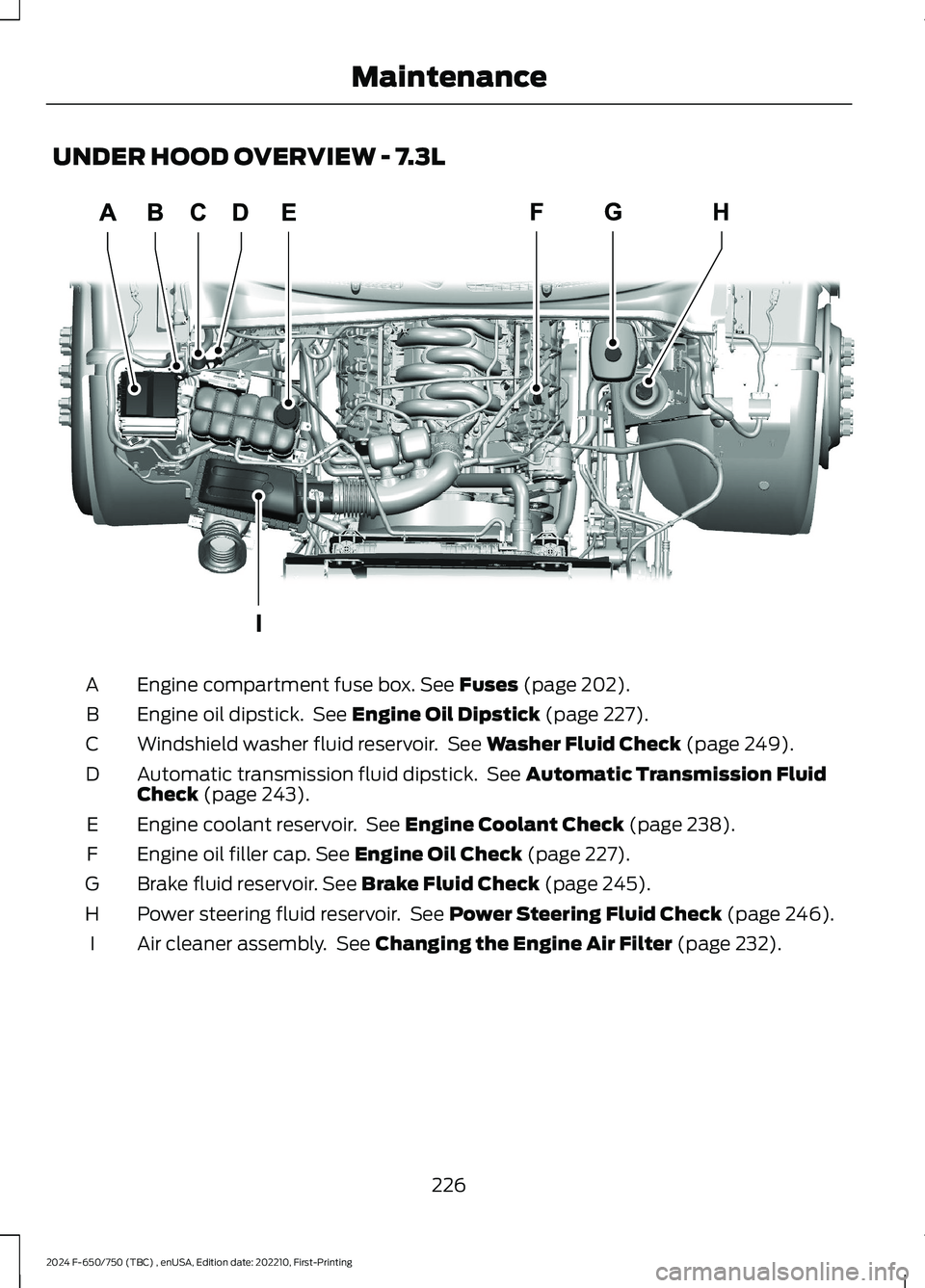

UNDER HOOD OVERVIEW - 7.3L

Engine compartment fuse box. See Fuses (page 202).A

Engine oil dipstick. See Engine Oil Dipstick (page 227).B

Windshield washer fluid reservoir. See Washer Fluid Check (page 249).C

Automatic transmission fluid dipstick. See Automatic Transmission FluidCheck (page 243).D

Engine coolant reservoir. See Engine Coolant Check (page 238).E

Engine oil filler cap. See Engine Oil Check (page 227).F

Brake fluid reservoir. See Brake Fluid Check (page 245).G

Power steering fluid reservoir. See Power Steering Fluid Check (page 246).H

Air cleaner assembly. See Changing the Engine Air Filter (page 232).I

226

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingMaintenanceE330964