FORD F650/750 2024 Owners Manual

Manufacturer: FORD, Model Year: 2024, Model line: F650/750, Model: FORD F650/750 2024Pages: 386, PDF Size: 8.7 MB

Page 211 of 386

Protected ComponentRatingItem

Not used.—81

Upfitter switch (factorylocation for ignition power).5 A82

Upfitter switch (optionallocation for power at alltimes).

5 A83

Not used.—84

Not used.—85

Not used.—86

Not used.—87

Cargo lamps.10 A88

Urea tank heater.20 A89

Upfitter - B-pillar.40 A91

Not used.—93

Not used.—94

Stoplamps.20 A95Trailer tow stoplamps.

Urea line heater.20 A96

Not used.—97

Trailer tow battery charge.30 A98

Upfitter relay 2.40 A99

Urea valves.20 A100

Not used.—101

Not used.—102

Not used.—103

Not used.—104

Trailer tow stoplamp andturn relay.15 A105

Note:Spare fuse amperage may vary.

207

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingFuses

Page 212 of 386

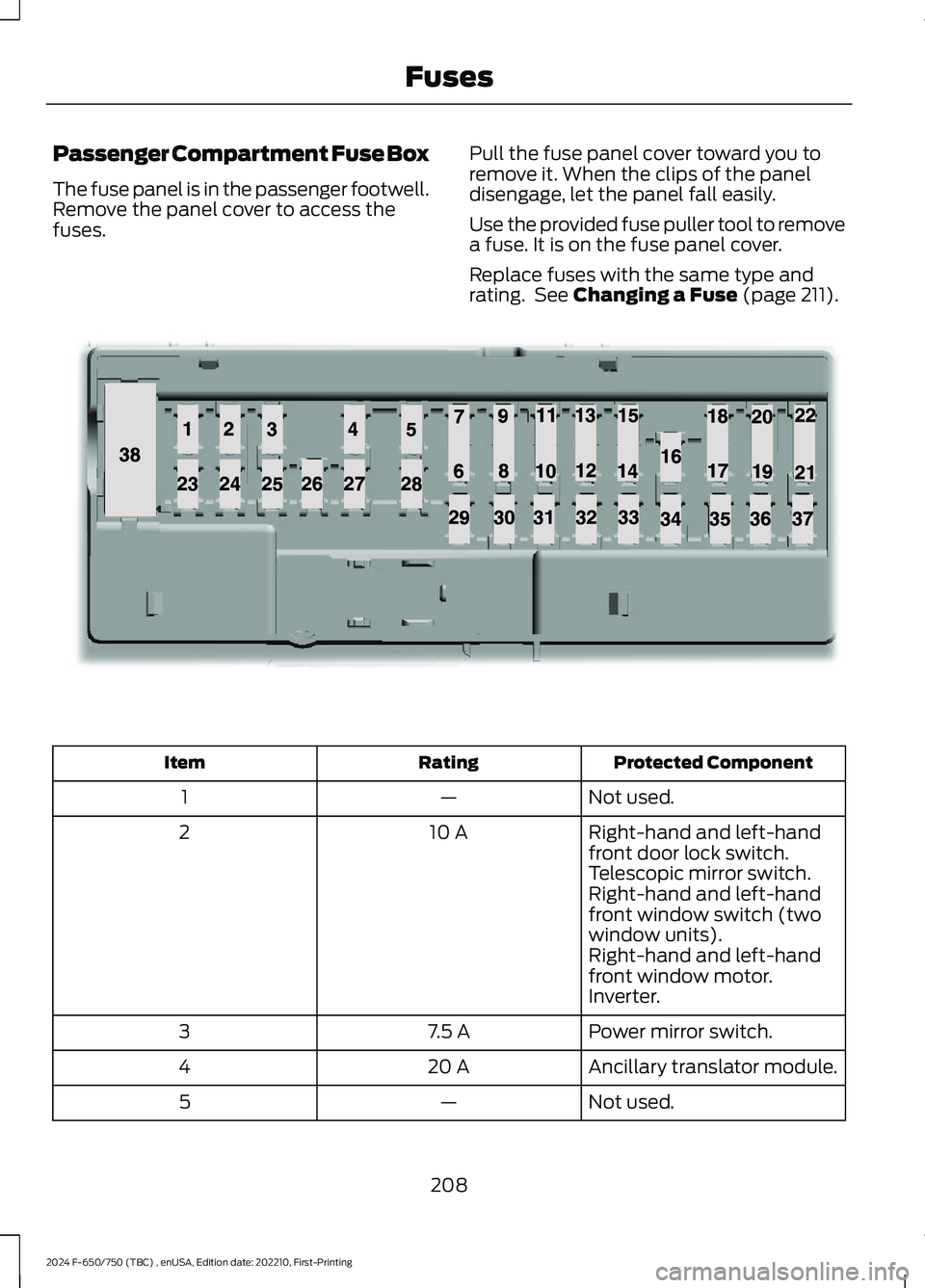

Passenger Compartment Fuse Box

The fuse panel is in the passenger footwell.Remove the panel cover to access thefuses.

Pull the fuse panel cover toward you toremove it. When the clips of the paneldisengage, let the panel fall easily.

Use the provided fuse puller tool to removea fuse. It is on the fuse panel cover.

Replace fuses with the same type andrating. See Changing a Fuse (page 211).

Protected ComponentRatingItem

Not used.—1

Right-hand and left-handfront door lock switch.10 A2

Telescopic mirror switch.Right-hand and left-handfront window switch (twowindow units).Right-hand and left-handfront window motor.Inverter.

Power mirror switch.7.5 A3

Ancillary translator module.20 A4

Not used.—5

208

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingFusesE145984

Page 213 of 386

Protected ComponentRatingItem

Not used.—6

Smart data link connectorpower.10 A7

Air brake diagnosticconnector.

Not used.—8

Not used.—9

Not used.—10

Not used.—11

Smart data link connector.7.5 A12

Instrument Cluster.7.5 A13Steering column controlmodule.

Not used.—14

Climate control module.15 A15

Not used.—16

Not used.—17

Yaw sensor.7.5 A18Electronic stability controland non-electronic stabilitycontrol.

Telematics control unitmodule.5 A19

Ignition switch.5 A20

Not used.—21

Not used.—22

Left-hand front windowmotor.30 A23

Not used.—24

Not used.—25

209

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingFuses

Page 214 of 386

Protected ComponentRatingItem

Right-hand front windowmotor.30 A26

Not used.—27

Not used.—28

Relay folding mirror.15 A29

Brake signal for air brake.5 A30Customer access stoplampsignal.Brake on-off isolation relay.Trailer tow stoplamp relay.

Upfitter interface module.10 A31Remote radio frequencyreceiver.

Radio.20 A32

Not used.—33

Not used.—34

Tow haul switch.5 A35

Lane departure warningcamera.15 A36

Mirror display.

Not used.—37

Left-hand front powerwindow switch (fourwindow units).

30 A38

Note:Spare fuse amperage may vary.

210

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingFuses

Page 215 of 386

CHANGING A FUSE

Fuses

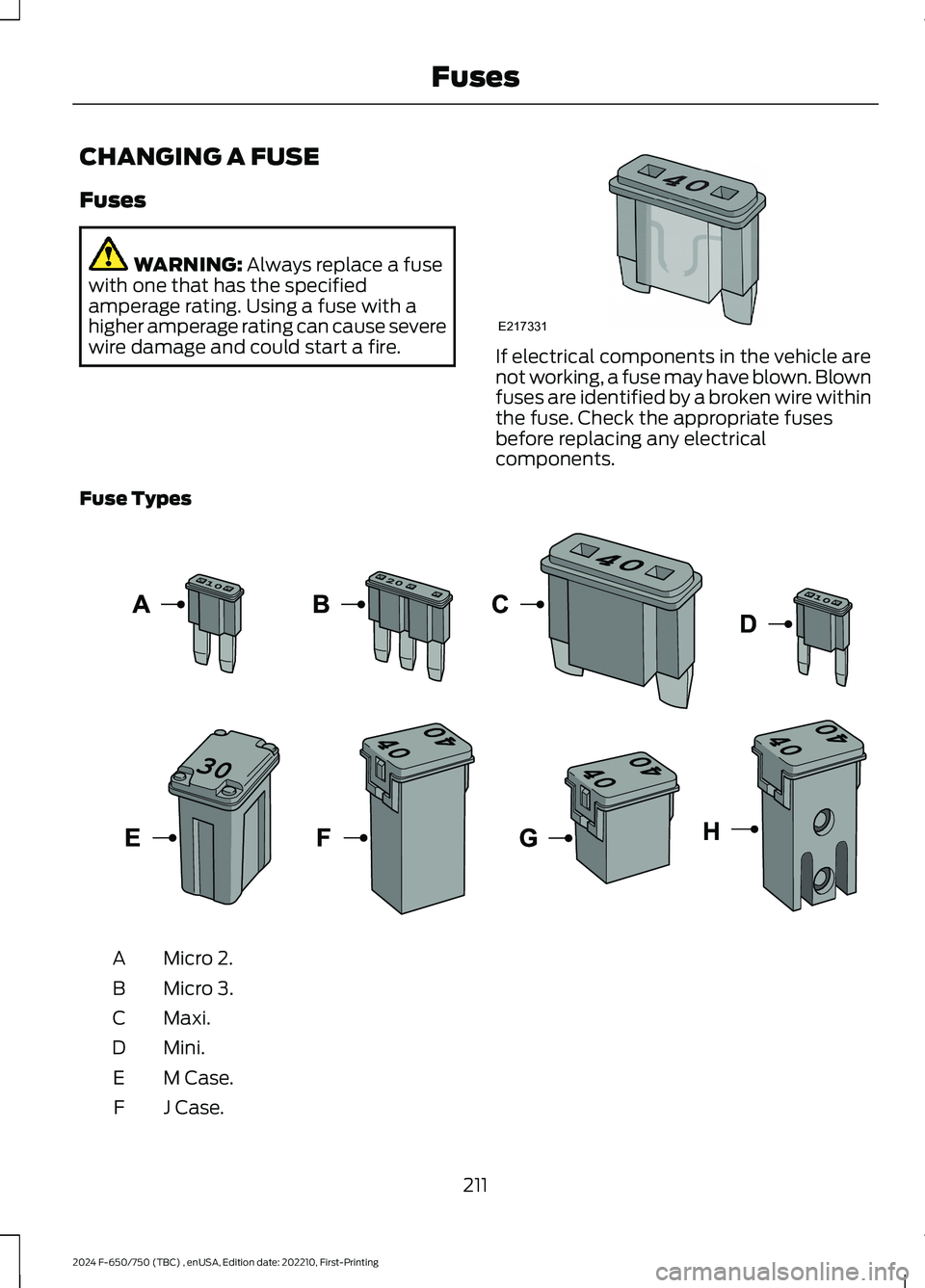

WARNING: Always replace a fusewith one that has the specifiedamperage rating. Using a fuse with ahigher amperage rating can cause severewire damage and could start a fire.If electrical components in the vehicle arenot working, a fuse may have blown. Blownfuses are identified by a broken wire withinthe fuse. Check the appropriate fusesbefore replacing any electricalcomponents.

Fuse Types

Micro 2.A

Micro 3.B

Maxi.C

Mini.D

M Case.E

J Case.F

211

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingFusesE217331 E267379

Page 216 of 386

J Case Low Profile.G

Slotted M Case.H

212

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingFuses

Page 217 of 386

VEHICLE INSPECTION

INFORMATION

To make sure your vehicle is ready tooperate, conduct a pre-trip inspection atthe beginning of each work period. Followthe steps listed in this section to verify aproper vehicle inspection procedure.

WARNING: Exercise great cautionwhen working on a vehicle equipped withan automatic fan clutch. The fan startsin motion only after the engine coolantreaches a predetermined temperatureor the refrigerant pressure (if equippedwith air conditioning) reaches apredetermined setting. The fan starts atthis point with no advance warning.Never reach near, or permit objects toprotrude into, the fan blade radius whilethe engine is running as this could resultin vehicle damage, personal injury ordeath.

WARNING: Do not operate thevehicle if any suspension conditionslisted in the following charts are evident.Loss of steering or suspension couldresult in property damage, personal injuryor death.

WARNING: If a wheel must bechanged, obtain expert tire service help.Mounting and un-mounting of tiresshould only be performed by a qualifiedtechnician using necessary safetyprocedures and equipment, otherwisethe result could be property damage,personal injury or death.

Note:Always make sure you apply theparking brake before starting the engine.

Engine compartment (with engine off)

Use the dipstick to verify the oil level is in the proper operatingrange. See Engine Oil Dipstick (page 227).Engine oil

Look through the plastic reservoir and verify the coolant levelis within the proper operating range. Do not remove thepressure cap until the coolant has cooled. See EngineCoolant Check (page 238).

Engine coolant

Verify that the fluid level is in the proper operating range. SeePower Steering Fluid Check (page 246).Power steering fluid

Remove the master cylinder caps and inspect the fluid level.See Brake Fluid Check (page 245).Brake fluid

213

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide

Page 218 of 386

Engine compartment (with engine off)

Inspect for glazing, fraying or cracking. There should be nomore than 5-7 cracks per rib, per 1 in (2.5 cm)Belts (fan, alternator,water pump and airconditioningcompressor)

Inspect for signs of fluid puddles or dripping fluid on theground under the engine, or the underside of the engine.Fluid leaks

Inspect for debris that may have collected on the HVAC airinlet grille or inside the exterior module as this may reducesystem performance.

HVAC air inlet

Engine starting (with parking brake applied)

Before entering the cab, verify that the vehicle is equippedwith spare electrical fuses (if used), three red reflectivetriangles, a properly charged and rated fire extinguisher andwheel chocks.

Safety and emergencyequipment

Walk around the vehicle and verify all steps and grab handles,inside and out (as well as behind), are tight and clean. Useextreme caution and a three-point stance at all times.

Inspect door latches for proper closing, latching and locking.

Set the parking brake. Make sure the gearshift lever is inneutral (N) or park (P) (if equipped with a park position).Starting the engine

Diesel engine: Turn the key to the on position. Turn the keyto start when the wait to start indicator light in the instrumentcluster turns off.

Gasoline engine: Turn the key to start, and then release itas soon as the engine starts.

Verify pressure builds to normal operating range.Engine oil pressure

A tone indicating low air pressure should sound immediatelyafter the engine starts but before the compressor has built-up pressure. The tone should stop when the air pressurereaches 70 psi (483 kPa). Let the air pressure build togoverned cutout pressure, which should occur between115–130 psi (793–896 kPa).

Low air pressure warningtone (if equipped with anair compressor)

Press the accelerator and verify that it operates smoothly,without any binding or irregular feel. Release the pedal andverify the engine returns to idle speed immediately.

Accelerator

214

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide

Page 219 of 386

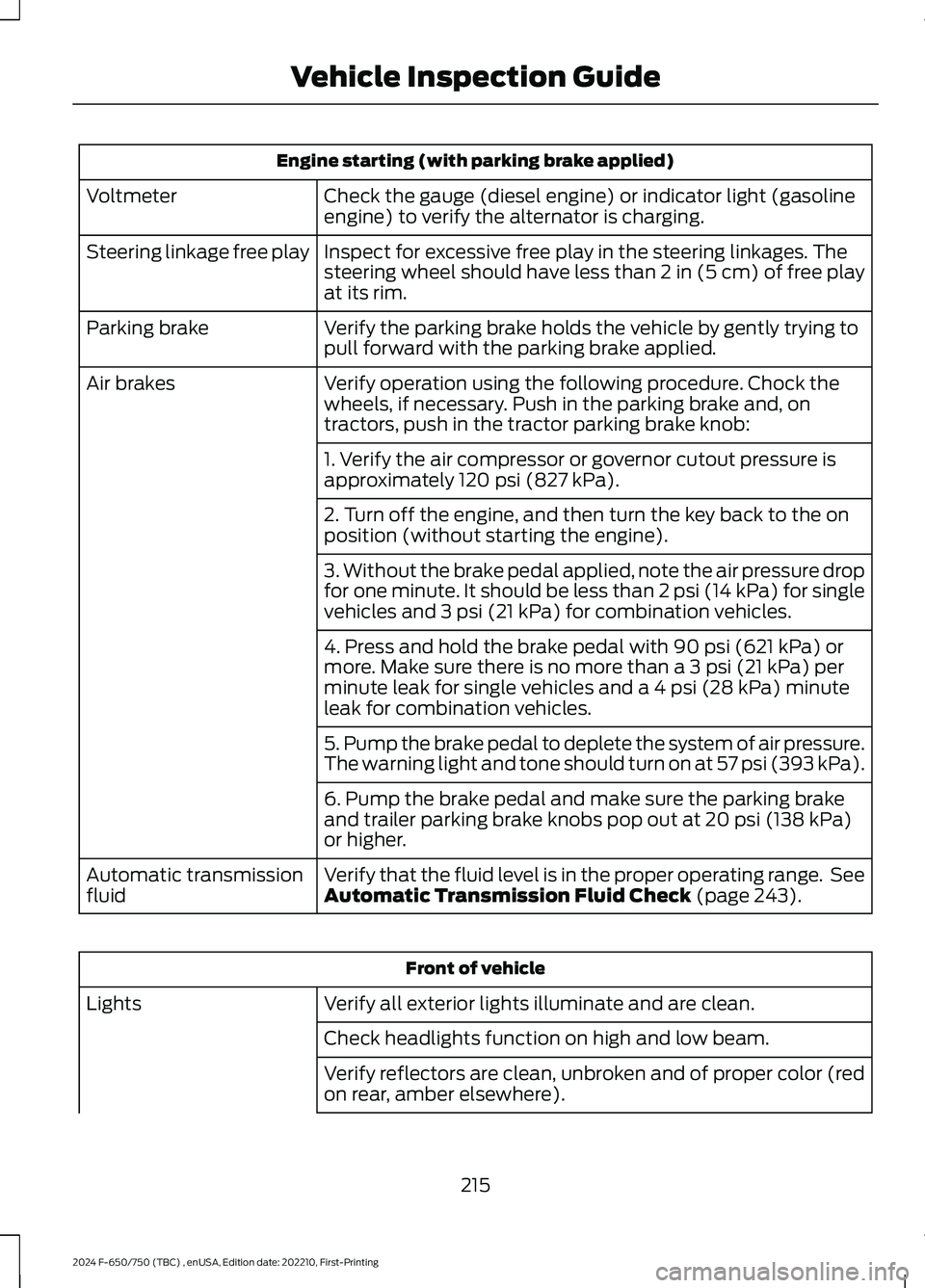

Engine starting (with parking brake applied)

Check the gauge (diesel engine) or indicator light (gasolineengine) to verify the alternator is charging.Voltmeter

Inspect for excessive free play in the steering linkages. Thesteering wheel should have less than 2 in (5 cm) of free playat its rim.

Steering linkage free play

Verify the parking brake holds the vehicle by gently trying topull forward with the parking brake applied.Parking brake

Verify operation using the following procedure. Chock thewheels, if necessary. Push in the parking brake and, ontractors, push in the tractor parking brake knob:

Air brakes

1. Verify the air compressor or governor cutout pressure isapproximately 120 psi (827 kPa).

2. Turn off the engine, and then turn the key back to the onposition (without starting the engine).

3. Without the brake pedal applied, note the air pressure dropfor one minute. It should be less than 2 psi (14 kPa) for singlevehicles and 3 psi (21 kPa) for combination vehicles.

4. Press and hold the brake pedal with 90 psi (621 kPa) ormore. Make sure there is no more than a 3 psi (21 kPa) perminute leak for single vehicles and a 4 psi (28 kPa) minuteleak for combination vehicles.

5. Pump the brake pedal to deplete the system of air pressure.The warning light and tone should turn on at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the parking brakeand trailer parking brake knobs pop out at 20 psi (138 kPa)or higher.

Verify that the fluid level is in the proper operating range. SeeAutomatic Transmission Fluid Check (page 243).Automatic transmissionfluid

Front of vehicle

Verify all exterior lights illuminate and are clean.Lights

Check headlights function on high and low beam.

Verify reflectors are clean, unbroken and of proper color (redon rear, amber elsewhere).

215

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide

Page 220 of 386

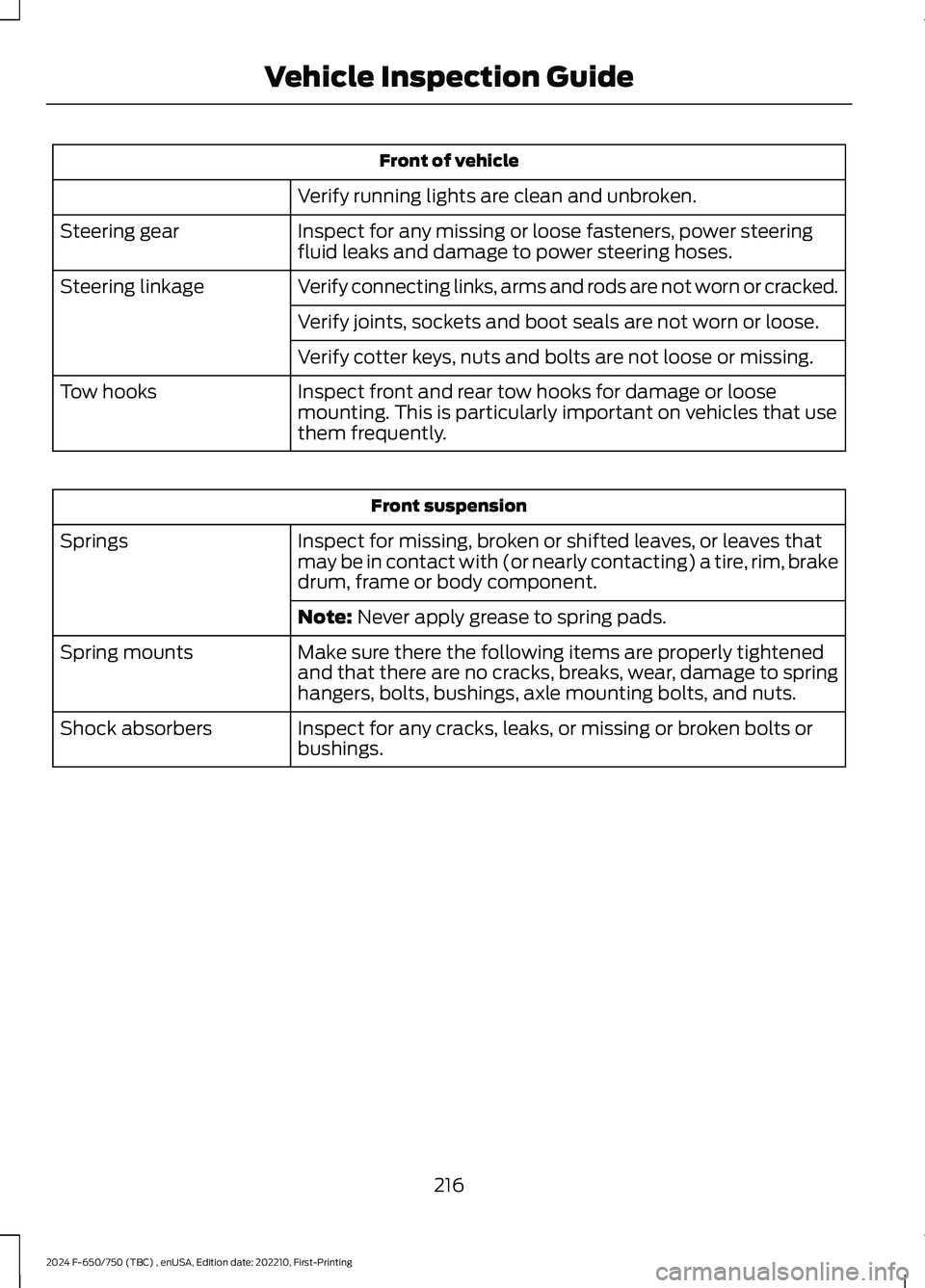

Front of vehicle

Verify running lights are clean and unbroken.

Inspect for any missing or loose fasteners, power steeringfluid leaks and damage to power steering hoses.Steering gear

Verify connecting links, arms and rods are not worn or cracked.Steering linkage

Verify joints, sockets and boot seals are not worn or loose.

Verify cotter keys, nuts and bolts are not loose or missing.

Inspect front and rear tow hooks for damage or loosemounting. This is particularly important on vehicles that usethem frequently.

Tow hooks

Front suspension

Inspect for missing, broken or shifted leaves, or leaves thatmay be in contact with (or nearly contacting) a tire, rim, brakedrum, frame or body component.

Springs

Note: Never apply grease to spring pads.

Make sure there the following items are properly tightenedand that there are no cracks, breaks, wear, damage to springhangers, bolts, bushings, axle mounting bolts, and nuts.

Spring mounts

Inspect for any cracks, leaks, or missing or broken bolts orbushings.Shock absorbers

216

2024 F-650/750 (TBC) , enUSA, Edition date: 202210, First-PrintingVehicle Inspection Guide