FORD F750 2000 10.G Owners Manual

Manufacturer: FORD, Model Year: 2000, Model line: F750, Model: FORD F750 2000 10.GPages: 208, PDF Size: 1.08 MB

Page 121 of 208

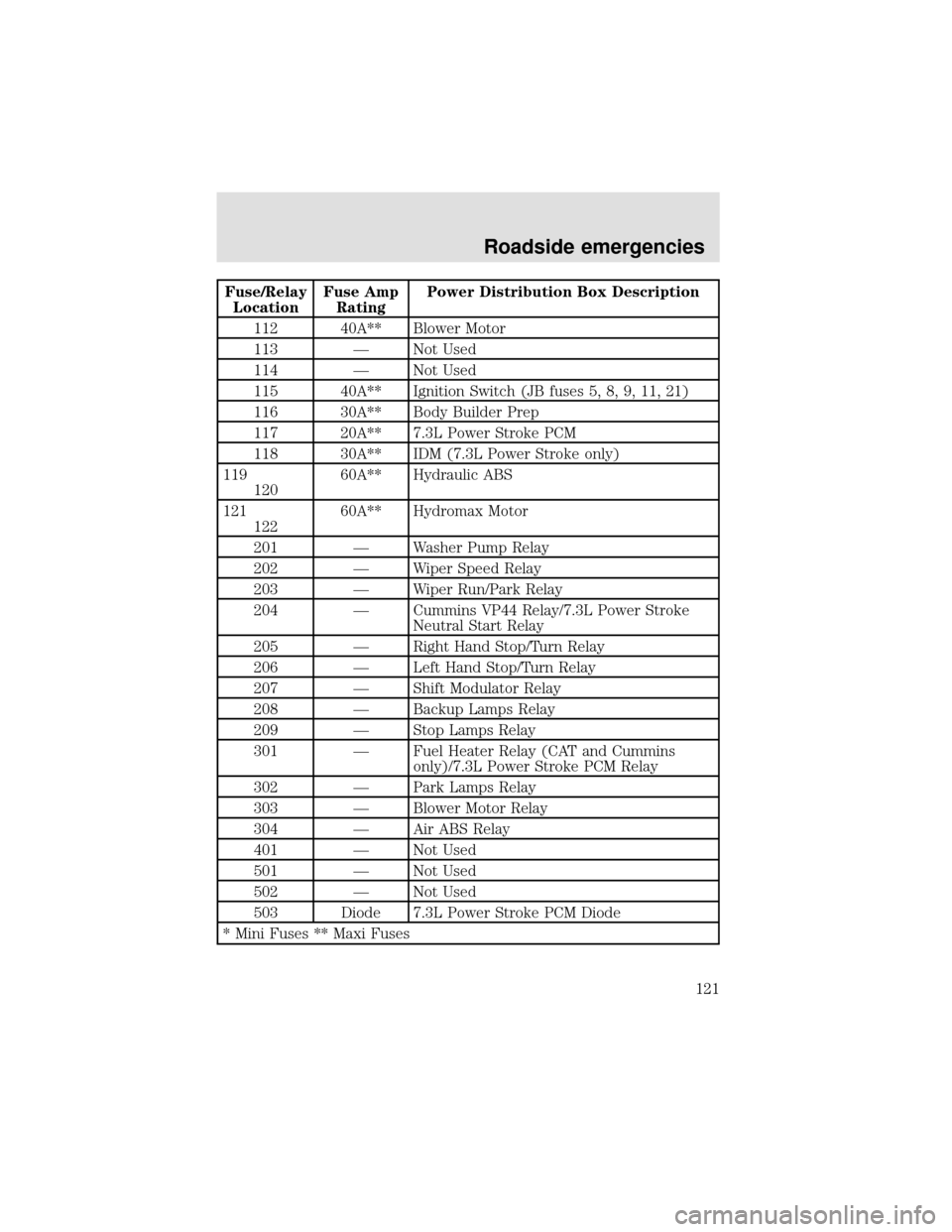

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box Description

112 40A** Blower Motor

113—Not Used

114—Not Used

115 40A** Ignition Switch (JB fuses 5, 8, 9, 11, 21)

116 30A** Body Builder Prep

117 20A** 7.3L Power Stroke PCM

118 30A** IDM (7.3L Power Stroke only)

119

12060A** Hydraulic ABS

121

12260A** Hydromax Motor

201—Washer Pump Relay

202—Wiper Speed Relay

203—Wiper Run/Park Relay

204—Cummins VP44 Relay/7.3L Power Stroke

Neutral Start Relay

205—Right Hand Stop/Turn Relay

206—Left Hand Stop/Turn Relay

207—Shift Modulator Relay

208—Backup Lamps Relay

209—Stop Lamps Relay

301—Fuel Heater Relay (CAT and Cummins

only)/7.3L Power Stroke PCM Relay

302—Park Lamps Relay

303—Blower Motor Relay

304—Air ABS Relay

401—Not Used

501—Not Used

502—Not Used

503 Diode 7.3L Power Stroke PCM Diode

* Mini Fuses ** Maxi Fuses

Roadside emergencies

121

Page 122 of 208

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Do not push start your vehicle. You could damage the catalytic

converter.

Batteries contain sulfuric acid which burns skin, eyes, and

clothing.

Preparing your vehicle

Also see the label on the battery.

1. Use only a 12–volt supply to start your vehicle. If you connect your

battery to a 24–volt power supply you can damage your starter, ignition

system and other electrical components. Do not attach the jumper cables

to the glow plug relay as this could severely damage the glow plugs,

injector driver module and PCM.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the disabled vehicle making sure

theydo nottouch. Set the parking brake on both vehicles and stay clear

of the engine cooling fan and other moving parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Roadside emergencies

122

Page 123 of 208

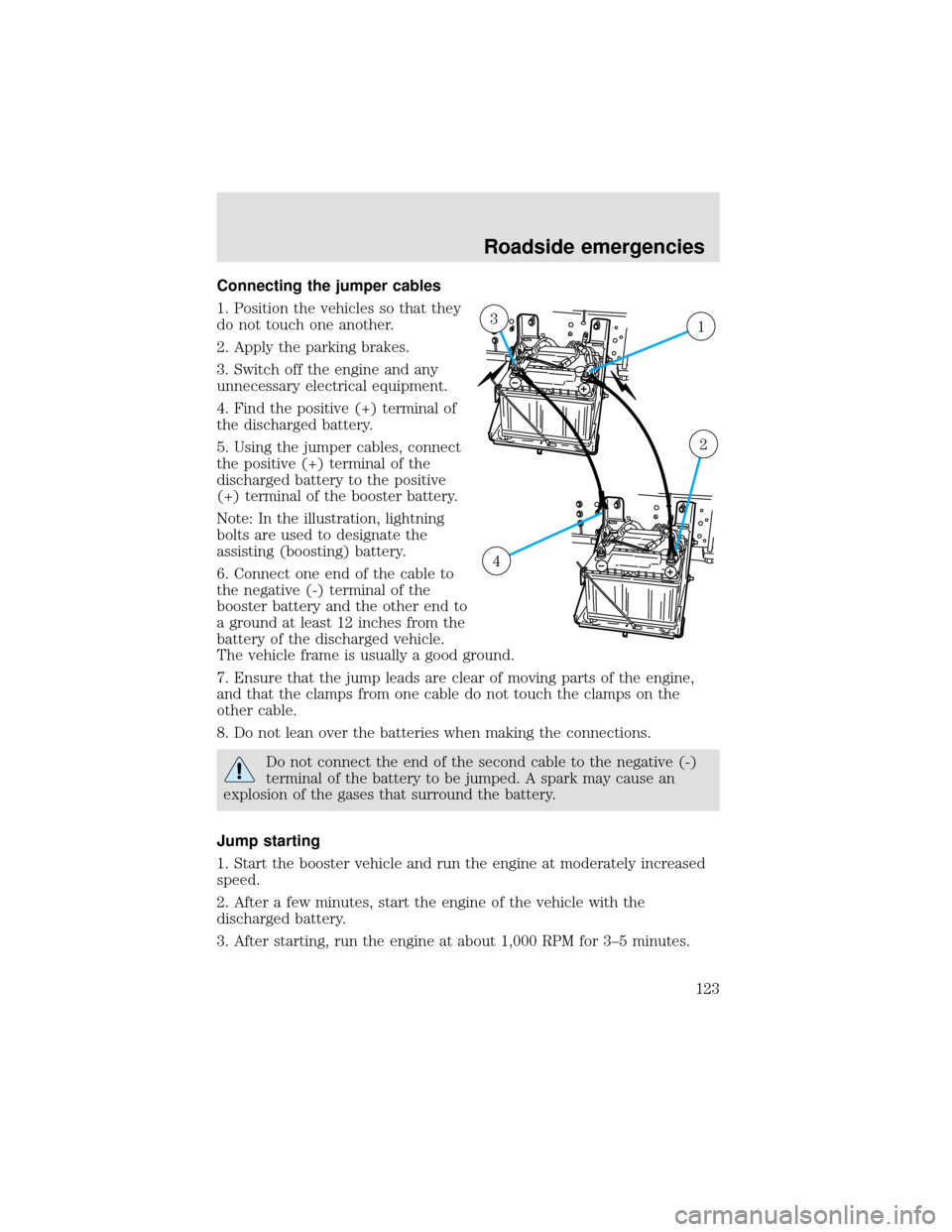

Connecting the jumper cables

1. Position the vehicles so that they

do not touch one another.

2. Apply the parking brakes.

3. Switch off the engine and any

unnecessary electrical equipment.

4. Find the positive (+) terminal of

the discharged battery.

5. Using the jumper cables, connect

the positive (+) terminal of the

discharged battery to the positive

(+) terminal of the booster battery.

Note: In the illustration, lightning

bolts are used to designate the

assisting (boosting) battery.

6. Connect one end of the cable to

the negative (-) terminal of the

booster battery and the other end to

a ground at least 12 inches from the

battery of the discharged vehicle.

The vehicle frame is usually a good ground.

7. Ensure that the jump leads are clear of moving parts of the engine,

and that the clamps from one cable do not touch the clamps on the

other cable.

8. Do not lean over the batteries when making the connections.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

Jump starting

1. Start the booster vehicle and run the engine at moderately increased

speed.

2. After a few minutes, start the engine of the vehicle with the

discharged battery.

3. After starting, run the engine at about 1,000 RPM for 3–5 minutes.

13

2

4

Roadside emergencies

123

Page 124 of 208

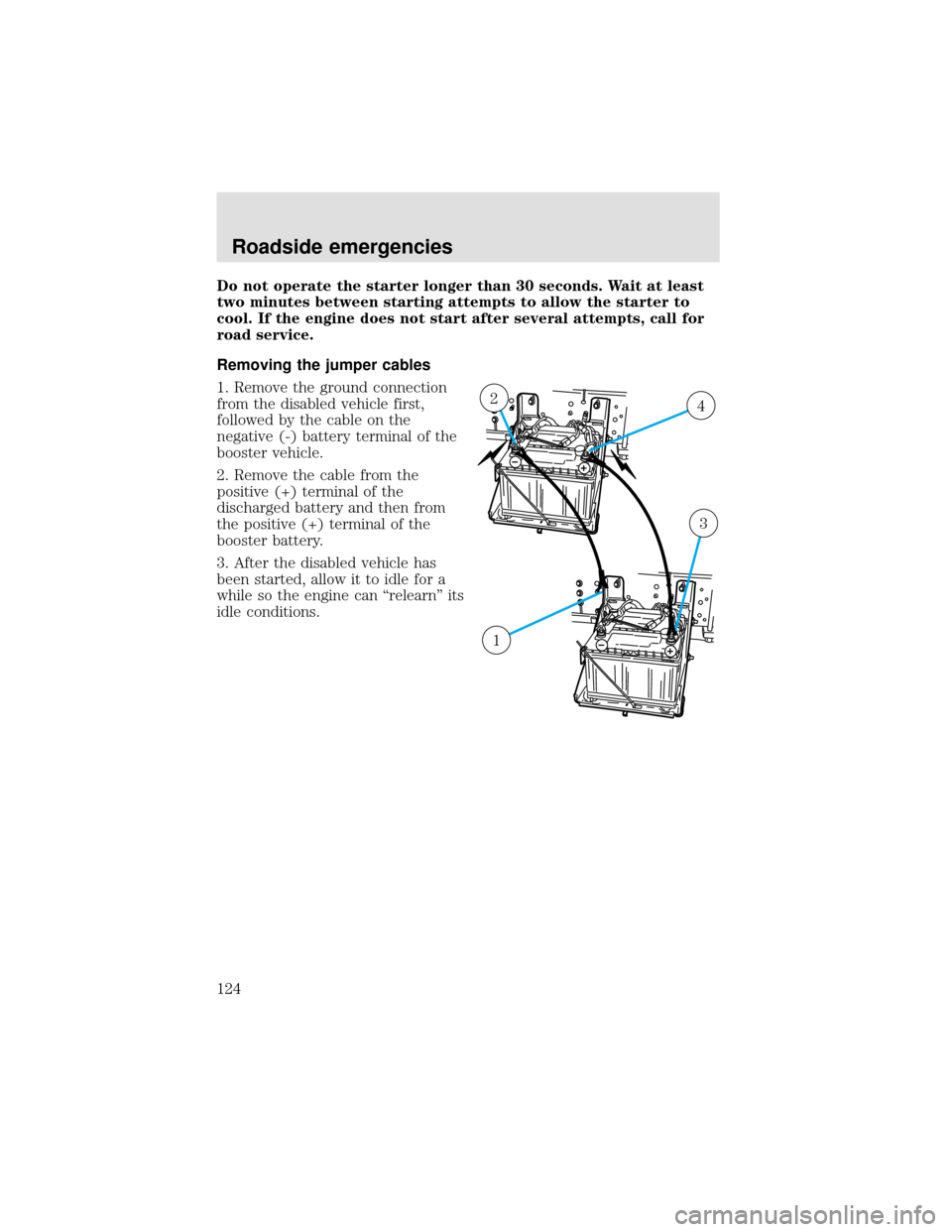

Do not operate the starter longer than 30 seconds. Wait at least

two minutes between starting attempts to allow the starter to

cool. If the engine does not start after several attempts, call for

road service.

Removing the jumper cables

1. Remove the ground connection

from the disabled vehicle first,

followed by the cable on the

negative (-) battery terminal of the

booster vehicle.

2. Remove the cable from the

positive (+) terminal of the

discharged battery and then from

the positive (+) terminal of the

booster battery.

3. After the disabled vehicle has

been started, allow it to idle for a

while so the engine can“relearn”its

idle conditions.

42

3

1

Roadside emergencies

124

Page 125 of 208

WRECKER TOWING

Always unload your vehicle before towing it. The recommended method

of towing is with the drive wheels off the ground.

Before towing, make sure:

•the parking brake is released.

•if air pressure has been lost, to release the brakes manually.

Improper towing of the vehicle will not allow sufficient lubrication of the

transmission which may cause serious damage to internal transmission

components. Always follow the outlined towing procedures.

•To tow a vehicle on the front wheels,the steering wheel must be

in the straight ahead position. Secure the steering wheel with a

holding device (such as provided by a towing company).

•To tow a vehicle on the rear wheels,it will be necessary to remove

the drive axles or disconnect the driveshaft. If the drive axles are

removed, the ends of the axle housing must be sealed to prevent the

loss of axle lubricant during towing.

•To tow a vehicle with an inoperative rear axle,the rear wheels

must be raised onto a dolly or tow the vehicle on the front wheels.

•If your vehicle is equipped with tow hooks,chains must be

fastened directly to the tow hooks on the vehicle.

•If your vehicle is not equipped with tow hooks,chains must be

routed under the bottom edge of the bumper with a protection bar to

protect the bumper, and attached to the vehicle chassis. Under no

circumstances is the vehicle to be lifted or towed by attaching chains

directly to the bumper.

RAISING THE VEHICLE

Never lift the vehicle by the bumper. When raising the vehicle, attach

chains to or place the jack(s) directly beneath the main structural

members of the vehicle.

PUSH-STARTING YOUR VEHICLE

Avoid attempting to start a vehicle by pushing. Instead, use jumper

cables as described underJump starting your vehiclein theRoadside

emergencieschapter. Vehicles with an automatic transmission cannot be

started by pushing.

Roadside emergencies

125

Page 126 of 208

CHECKING UNDER THE HOOD

Opening the hood

The hood and fenders are held in position by a latch located on each

fender.

The parking brake must be fully set before opening the hood or

possible personal injury may occur.

If you must leave the engine running while checking under the

hood, do not allow any loose clothing, jewelry, hair or other

items to get near moving engine components or possible personal

injury may occur.

To open the hood:

1. Set the parking brake, shift into N (Neutral) (automatic transmission)

or 1 (First) (manual transmission) and turn the engine off.

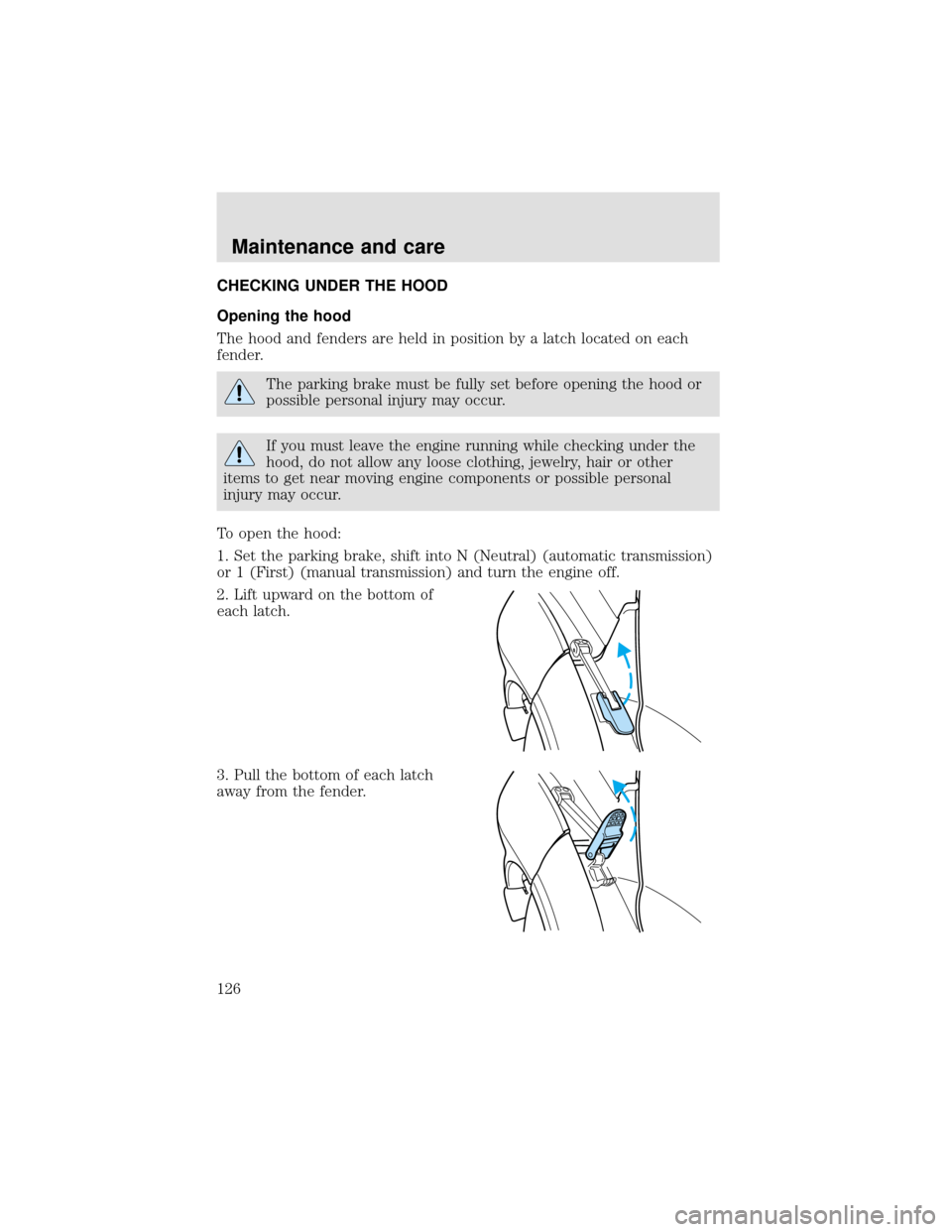

2. Lift upward on the bottom of

each latch.

3. Pull the bottom of each latch

away from the fender.

Maintenance and care

126

Page 127 of 208

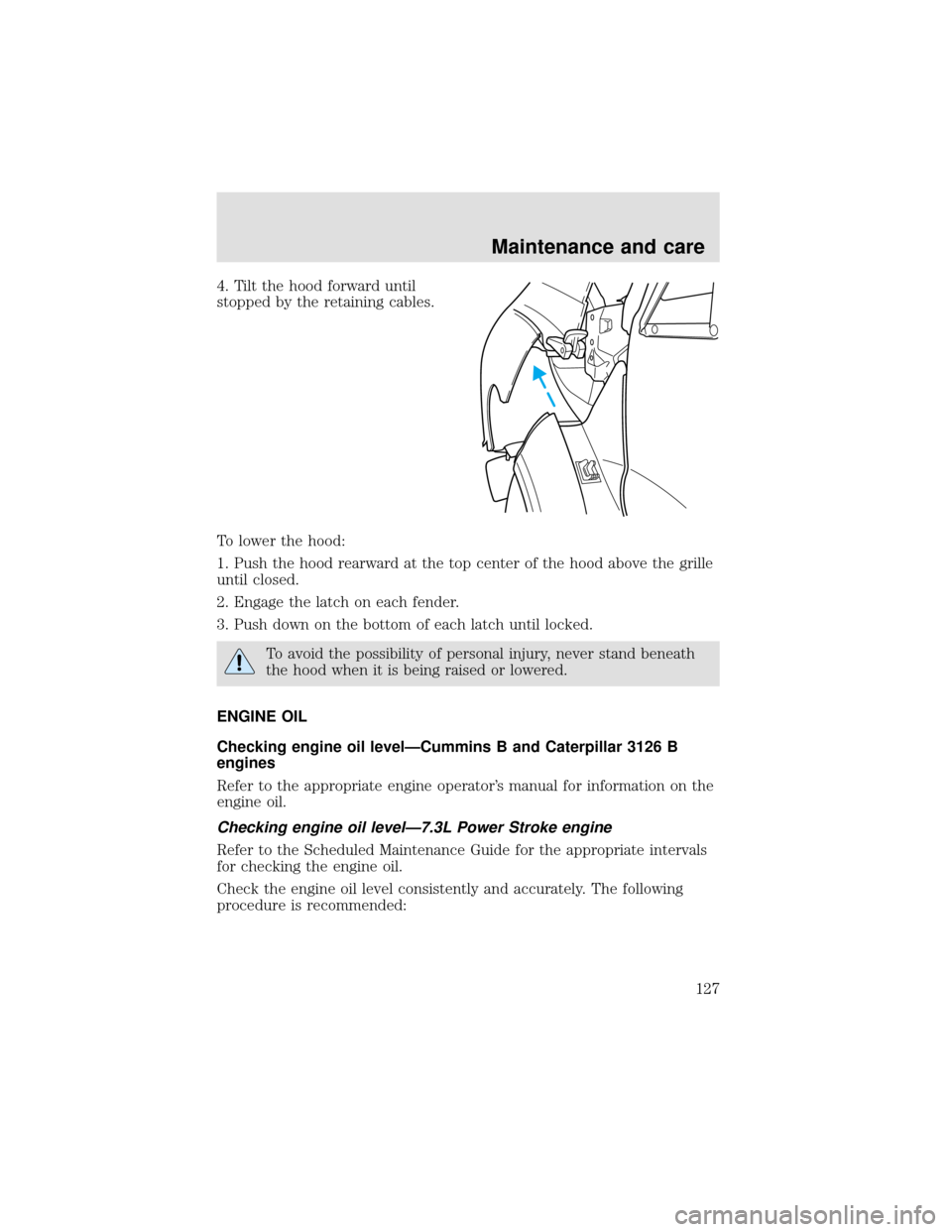

4. Tilt the hood forward until

stopped by the retaining cables.

To lower the hood:

1. Push the hood rearward at the top center of the hood above the grille

until closed.

2. Engage the latch on each fender.

3. Push down on the bottom of each latch until locked.

To avoid the possibility of personal injury, never stand beneath

the hood when it is being raised or lowered.

ENGINE OIL

Checking engine oil level—Cummins B and Caterpillar 3126 B

engines

Refer to the appropriate engine operator’s manual for information on the

engine oil.

Checking engine oil level—7.3L Power Stroke engine

Refer to the Scheduled Maintenance Guide for the appropriate intervals

for checking the engine oil.

Check the engine oil level consistently and accurately. The following

procedure is recommended:

Maintenance and care

127

Page 128 of 208

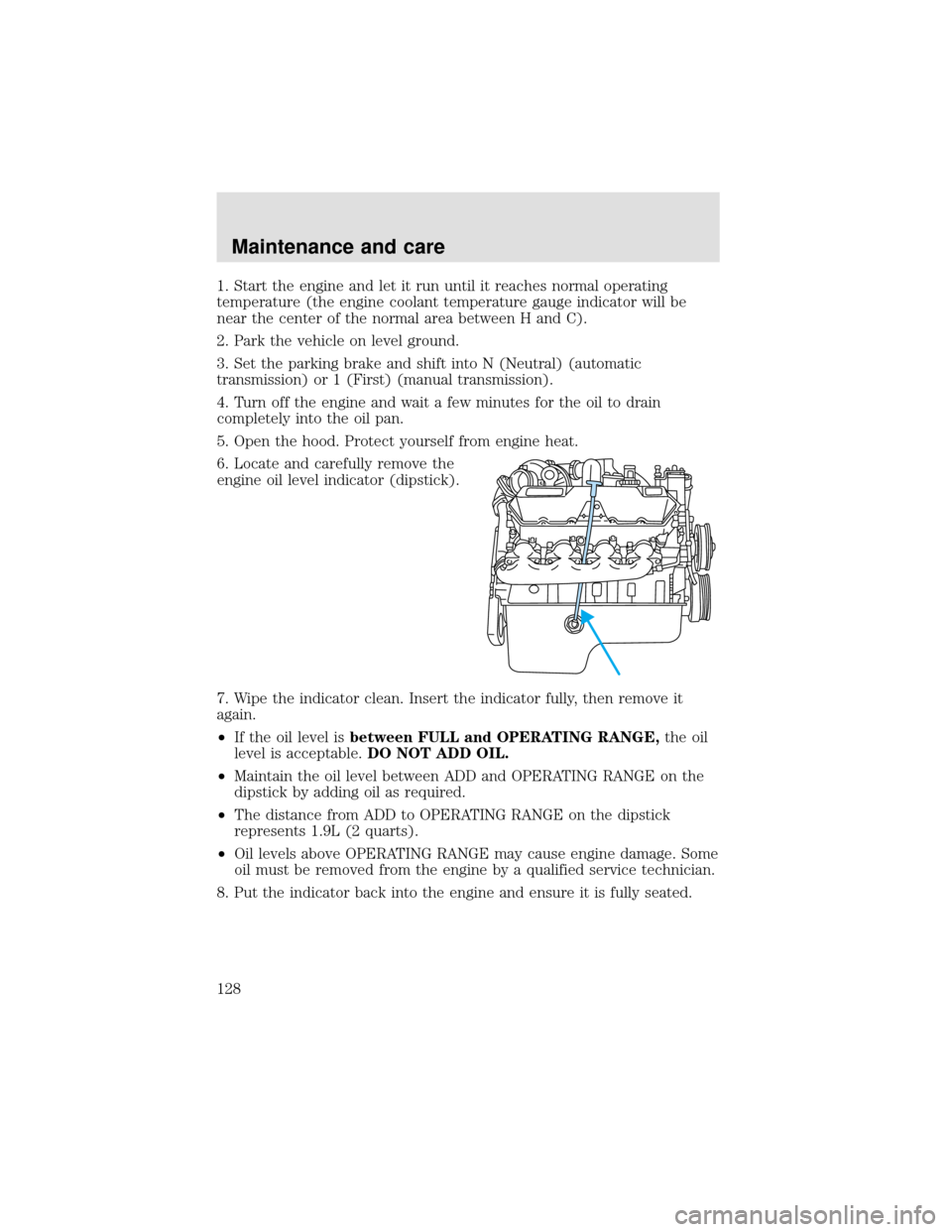

1. Start the engine and let it run until it reaches normal operating

temperature (the engine coolant temperature gauge indicator will be

near the center of the normal area between H and C).

2. Park the vehicle on level ground.

3. Set the parking brake and shift into N (Neutral) (automatic

transmission) or 1 (First) (manual transmission).

4. Turn off the engine and wait a few minutes for the oil to drain

completely into the oil pan.

5. Open the hood. Protect yourself from engine heat.

6. Locate and carefully remove the

engine oil level indicator (dipstick).

7. Wipe the indicator clean. Insert the indicator fully, then remove it

again.

•If the oil level isbetween FULL and OPERATING RANGE,the oil

level is acceptable.DO NOT ADD OIL.

•Maintain the oil level between ADD and OPERATING RANGE on the

dipstick by adding oil as required.

•The distance from ADD to OPERATING RANGE on the dipstick

represents 1.9L (2 quarts).

•Oil levels above OPERATING RANGE may cause engine damage. Some

oil must be removed from the engine by a qualified service technician.

8. Put the indicator back into the engine and ensure it is fully seated.

Maintenance and care

128

Page 129 of 208

Engine oil and filter recommendations—Cummins B and Caterpillar

3126 B engines

Refer to the appropriate engine operator’s manual for information on the

engine oil.

Engine oil and filter recommendations—7.3L Power Stroke engine

To help achieve proper engine performance and durability, it is important

that you:

•Use only engine lubricating oils and oil filters of the proper quality.

•Change the engine oil and filterno laterthan the recommended

service interval. Refer to the Scheduled Maintenance Guide for the

appropriate intervals for changing the engine oil and filter.

•Change your engine oil and filter more frequently if your vehicle

operation includes extended periods of idling or low-speed operation,

driving for a long time in cold temperatures or short driving distances.

Diesel engines require specially formulated oil to resist contamination.

Proper quality oils also provide maximum efficiency of the crankcase

ventilation system which reduces air pollution.

Use Motorcraft motor oil or an equivalent oil meeting Ford specification

WSS-M2C171–B or API service category designation CH-4/SJ. Do not use

oils labeled with only one of the category designations SG, SH, SJ, CE,

CF-4, CH-4 or CG-4, as they could cause engine damage.

Diesel engine oils with improved fuel economy properties (energy

conserving) are currently available. If you use an energy conserving oil,

be sure it meets Ford specification WSS-M2C171–B or API service

category designation CH-4/SJ and is of the proper viscosity grade for the

temperature range in which you expect to operate your vehicle. Some

energy conserving oils do not meet the requirements necessary for your

diesel engine.

Maintenance and care

129

Page 130 of 208

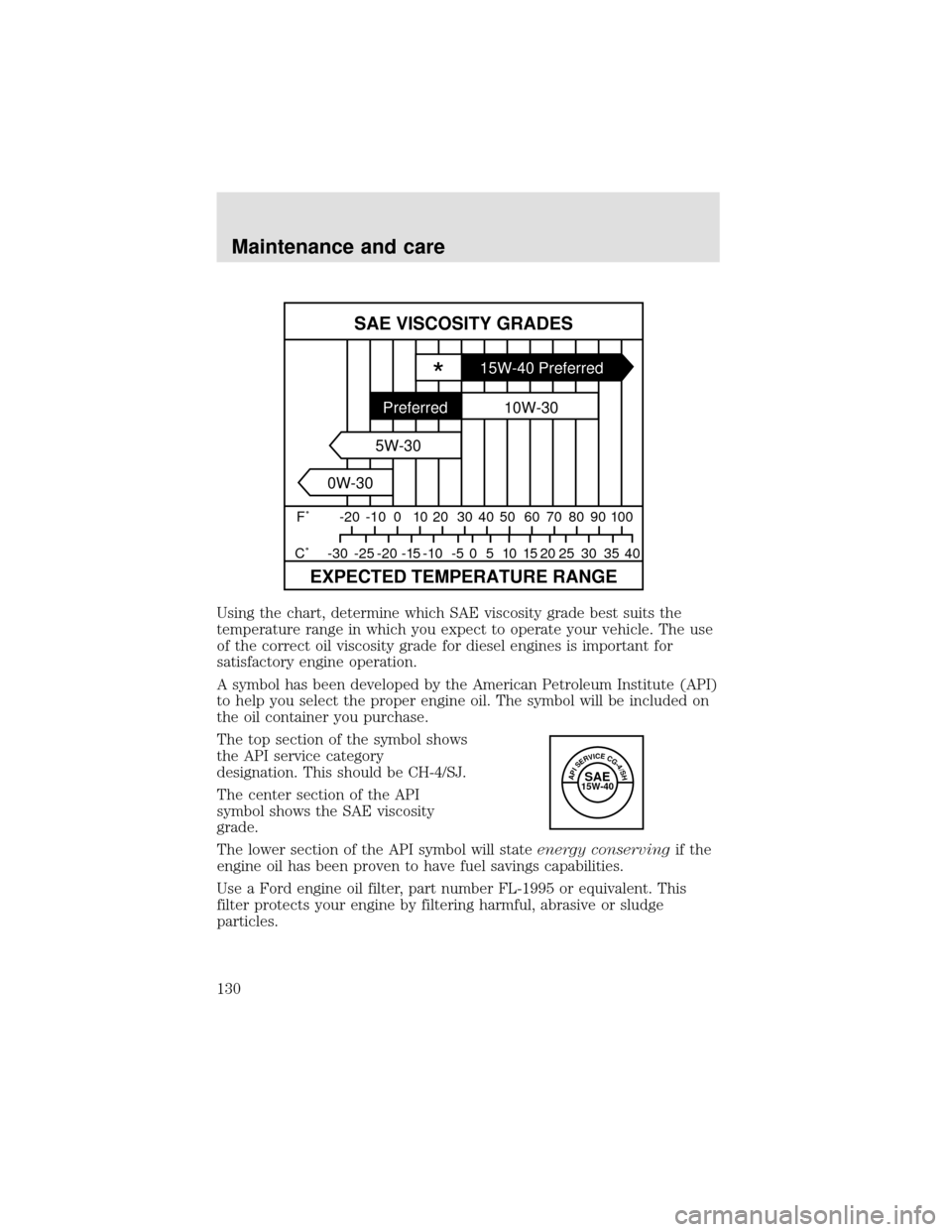

Using the chart, determine which SAE viscosity grade best suits the

temperature range in which you expect to operate your vehicle. The use

of the correct oil viscosity grade for diesel engines is important for

satisfactory engine operation.

A symbol has been developed by the American Petroleum Institute (API)

to help you select the proper engine oil. The symbol will be included on

the oil container you purchase.

The top section of the symbol shows

the API service category

designation. This should be CH-4/SJ.

The center section of the API

symbol shows the SAE viscosity

grade.

The lower section of the API symbol will stateenergy conservingif the

engine oil has been proven to have fuel savings capabilities.

Use a Ford engine oil filter, part number FL-1995 or equivalent. This

filter protects your engine by filtering harmful, abrasive or sludge

particles.

SAE VISCOSITY GRADES

EXPECTED TEMPERATURE RANGE

F˚ -20 -10 0 10 20 30 40

40 35 30 25 20 15 10 5 0 -5 -10 -15 -20 -25 -30 C˚50 60 70 80 90 100

*15W-40 Preferred

10W-30

5W-30

0W-30Preferred

APISERVICECG-4/SHSAE15W-40

Maintenance and care

130