speed FORD F750 2000 10.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: F750, Model: FORD F750 2000 10.GPages: 208, PDF Size: 1.08 MB

Page 77 of 208

STARTING PROCEDURES

Operating precautions

•Always shift to a lower gear at high altitudes to prevent engine

smoking.

•Avoid extended and unnecessary idling.

Do not operate a diesel engine where the vapors can be

combustible. These vapors can be sucked through the air intake

system and cause engine acceleration and overspeeding, which may

result in bodily injury and extensive property damage. The equipment

owner and operator are responsible for safe operation in a hostile

environment.

STARTING THE ENGINE

1. Ensure headlamps and all accessories are turned off and the parking

brake is applied.

2.Automatic transmissions,ensure gearshift is in N (Neutral).

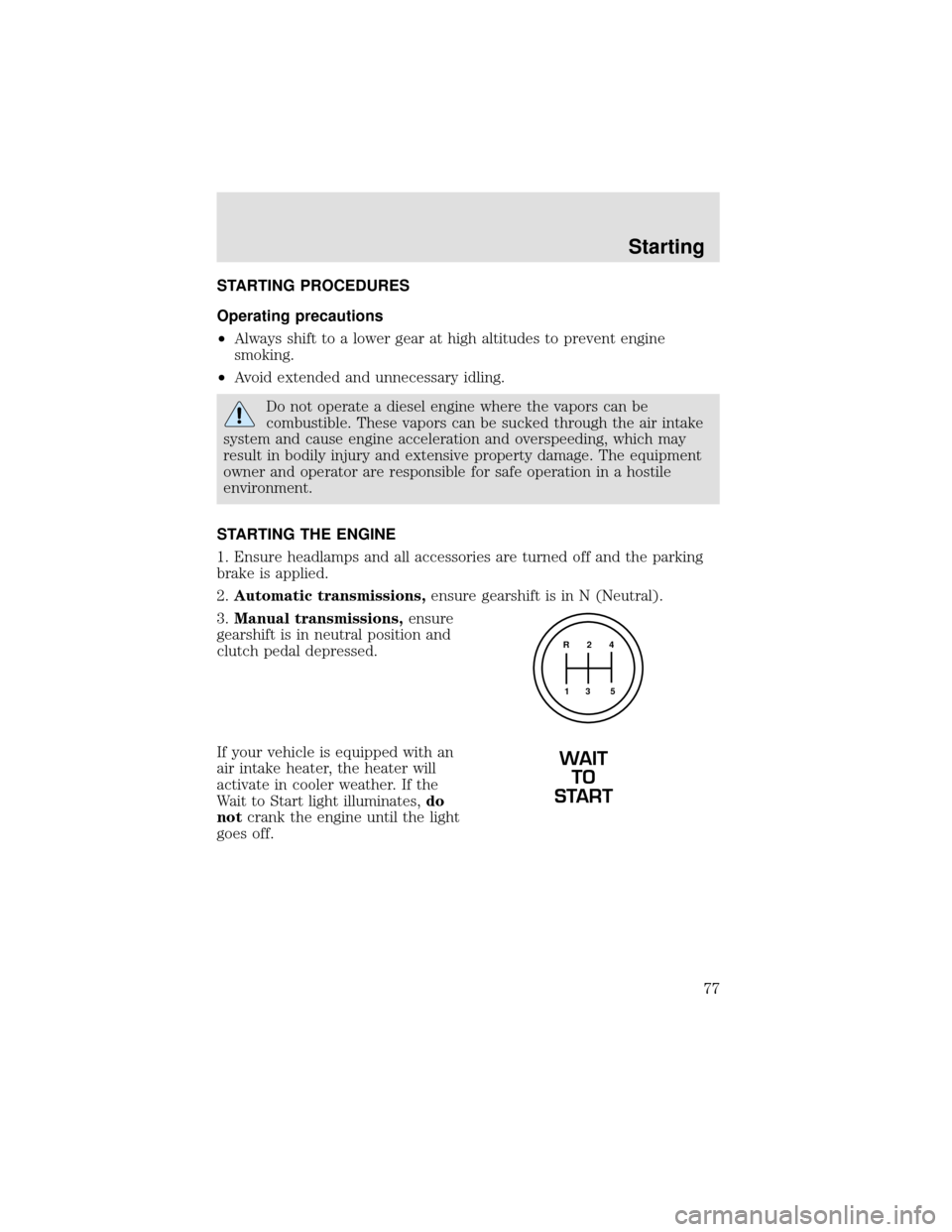

3.Manual transmissions,ensure

gearshift is in neutral position and

clutch pedal depressed.

If your vehicle is equipped with an

air intake heater, the heater will

activate in cooler weather. If the

Wait to Start light illuminates,do

notcrank the engine until the light

goes off.

R 2 4

3 5 1

WAIT

TO

START

Starting

77

Page 78 of 208

If equipped with an air intake heater, DO NOT use ether or any

other starting fluids. The use of starting fluids (ether) in an

engine equipped with an air intake heater could result in damage

and/or personal injury.

4. Do not depress the accelerator during starting the engine.

5. Start the engine.

If the engine does not start after 30 seconds of cranking, allow two

minutes for the starter to cool before trying again. Excessive cranking

may damage the starter.

After the engine starts:

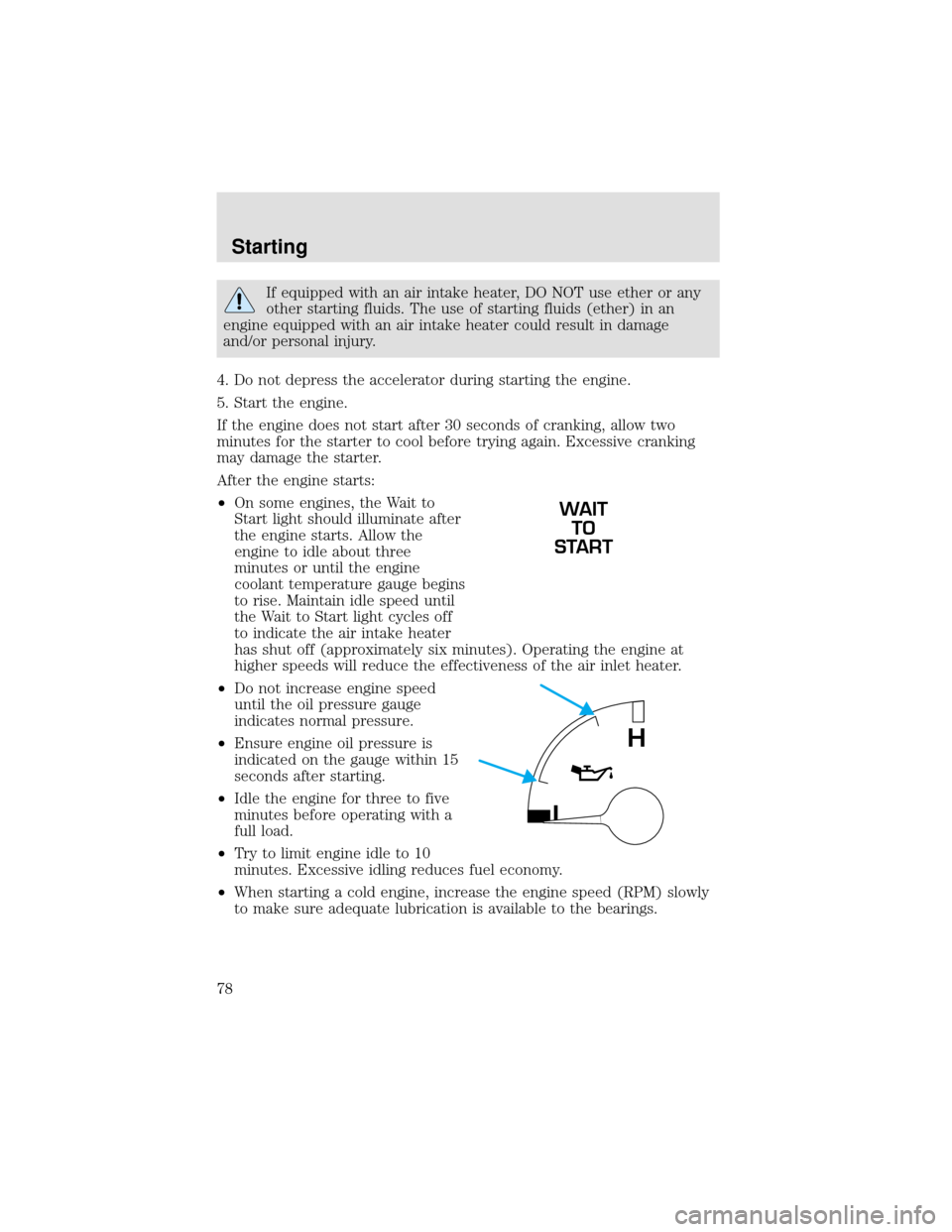

•On some engines, the Wait to

Start light should illuminate after

the engine starts. Allow the

engine to idle about three

minutes or until the engine

coolant temperature gauge begins

to rise. Maintain idle speed until

the Wait to Start light cycles off

to indicate the air intake heater

has shut off (approximately six minutes). Operating the engine at

higher speeds will reduce the effectiveness of the air inlet heater.

•Do not increase engine speed

until the oil pressure gauge

indicates normal pressure.

•Ensure engine oil pressure is

indicated on the gauge within 15

seconds after starting.

•Idle the engine for three to five

minutes before operating with a

full load.

•Try to limit engine idle to 10

minutes. Excessive idling reduces fuel economy.

•When starting a cold engine, increase the engine speed (RPM) slowly

to make sure adequate lubrication is available to the bearings.

WAIT

TO

START

L

H

Starting

78

Page 79 of 208

RESTARTING AFTER RUNNING OUT OF FUEL

The fuel system may need to be purged of air, refer toRunning out of

fuelin theMaintenance and carechapter.

OPERATING THE ENGINE

Do not operate the engine at full throttle below peak torque engine

speed (RPM) for more than one minute at a time (peak torque RPM

varies from 1200-1500 RPM depending on engine rated speed).

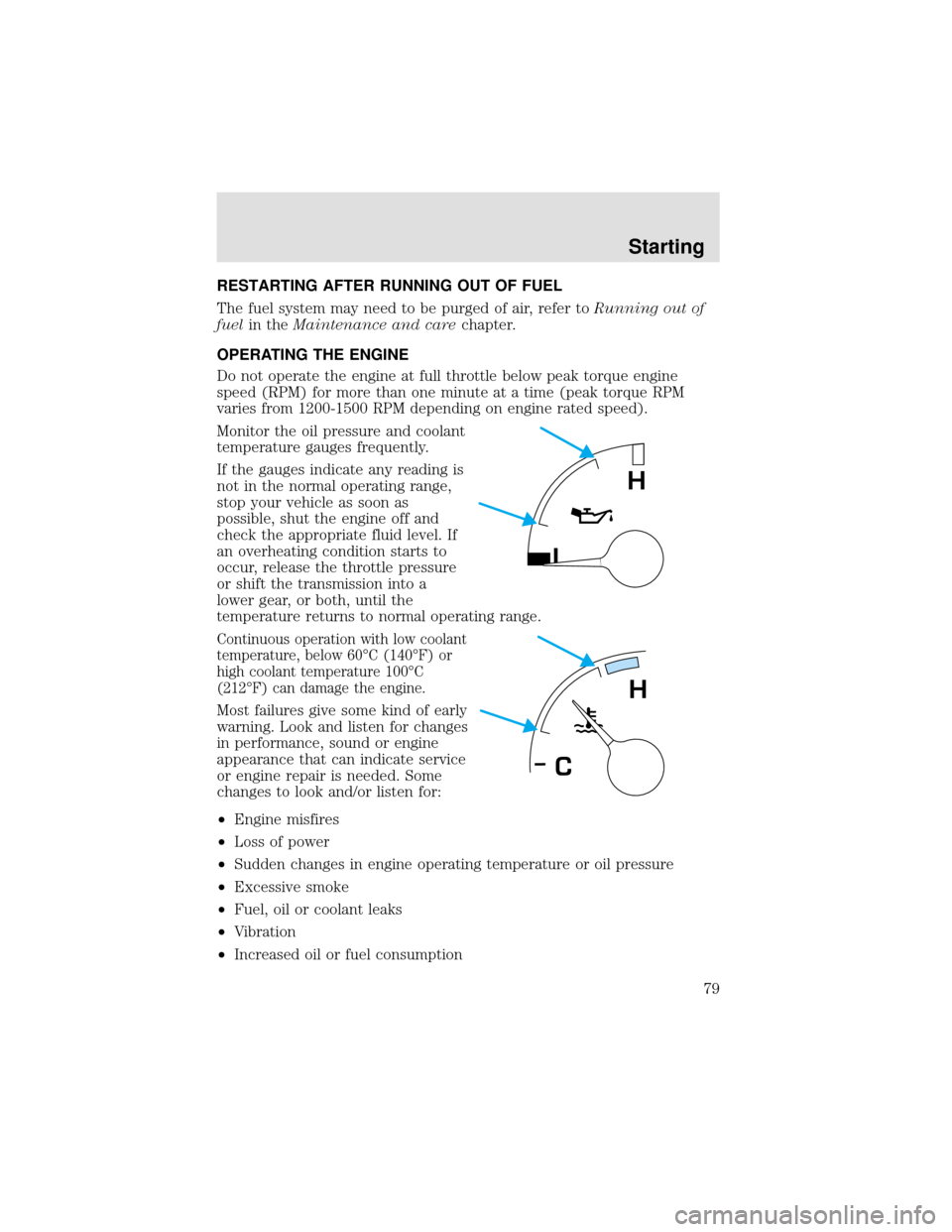

Monitor the oil pressure and coolant

temperature gauges frequently.

If the gauges indicate any reading is

not in the normal operating range,

stop your vehicle as soon as

possible, shut the engine off and

check the appropriate fluid level. If

an overheating condition starts to

occur, release the throttle pressure

or shift the transmission into a

lower gear, or both, until the

temperature returns to normal operating range.

Continuous operation with low coolant

temperature, below 60°C (140°F) or

high coolant temperature 100°C

(212°F) can damage the engine.

Most failures give some kind of early

warning. Look and listen for changes

in performance, sound or engine

appearance that can indicate service

or engine repair is needed. Some

changes to look and/or listen for:

•Engine misfires

•Loss of power

•Sudden changes in engine operating temperature or oil pressure

•Excessive smoke

•Fuel, oil or coolant leaks

•Vibration

•Increased oil or fuel consumption

L

H

H

C

Starting

79

Page 81 of 208

EXHAUST FUMES

Never idle the engine in closed areas. Never sit in a parked or

stopped vehicle for any amount of time with engine running.

If you ever smell exhaust fumes of any kind inside your vehicle,

have your dealer inspect and fix your vehicle immediately. Do

not drive if you smell exhaust fumes. These fumes are harmful and

could kill you.

In order to guard against fumes entering your vehicle, the exhaust

system and body ventilation system should be checked by a qualified

technician:

•Each time the vehicle is raised for service.

•Whenever a change in exhaust system noise is noted.

•Whenever the vehicle has been damaged by impact from another

vehicle, object or road obstruction.

In order to afford proper operation, all air inlet vents should be kept

clear of snow, leaves and other debris.

If you run the engine while stopped (idled) in an unconfined area, open

the windows at least 2.5 cm (one inch) and adjust the heating or air

conditioning to draw outside air into the vehicle as follows:

•If your vehicle has outside air control vents, open them fully.

•Set fan speed on high with function control to any position except

OFF or MAX A/C and the temperature control on any desired position.

•Adjust air control system to force outside air into the vehicle.

BACKING UP

To avoid the possibility of personal injury while backing the

vehicle, always be sure your vehicle’s path is clear.

Before backing your vehicle, be sure you can do so safely. If anything

behind the cab limits your view, do not rely on mirrors alone to assure

that your intended path is clear. If other persons are in the vicinity, have

someone standing well behind the vehicle and outside your intended

path - visible through an exterior mirror - guide you as you back up.

Driving

81

Page 88 of 208

not affect braking effectiveness. The brakes should be checked only if

squeal occurs continuously with every application.

If brakes do not grip well

•If you have been driving through deep water, gently apply the brakes

several times while the vehicle is moving slowly.

•Let the brakes cool if you have been using them excessively, as in

mountain driving or after several fast, high speed stops.

•Check brake adjustment.

•Check brake linings for excessive wear.

•Check system air pressure.

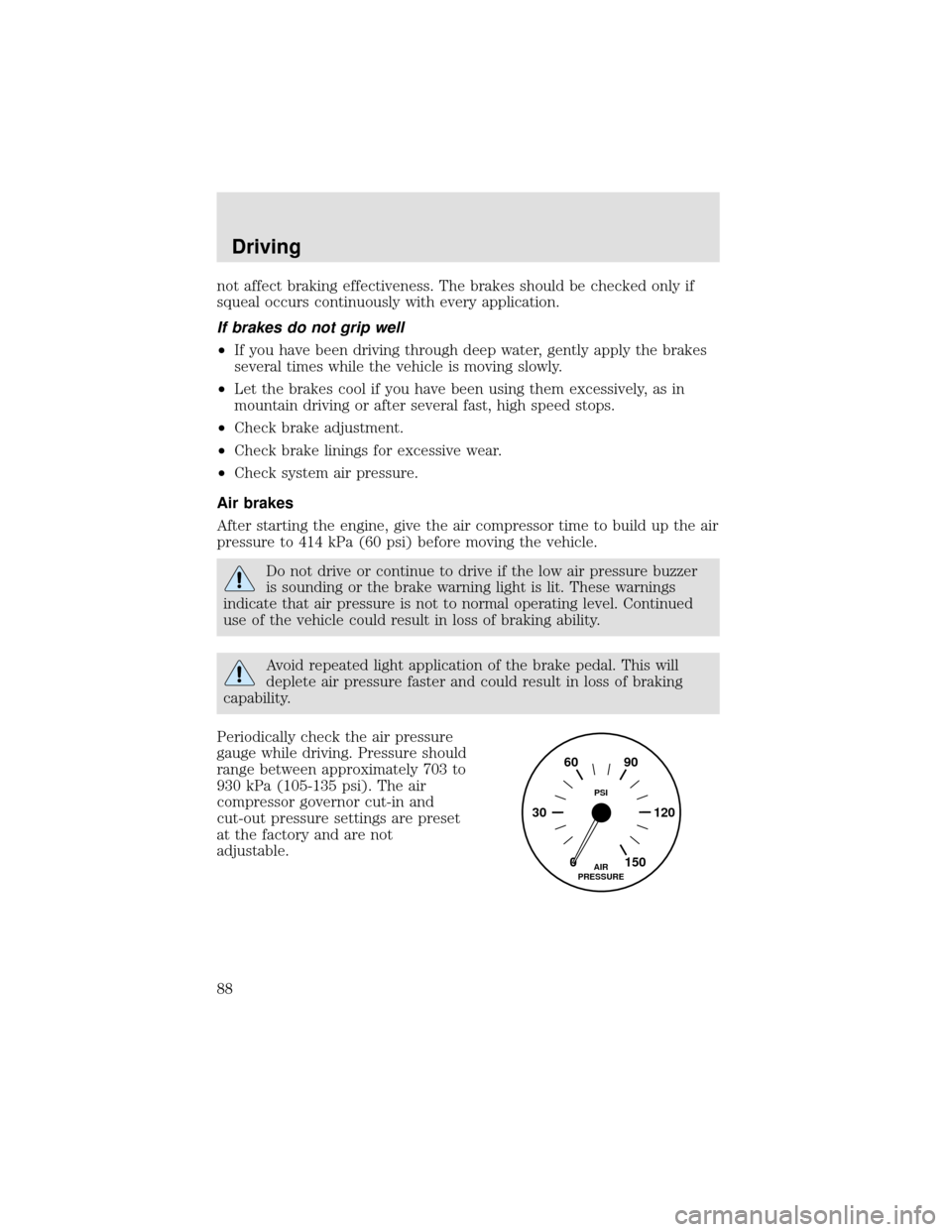

Air brakes

After starting the engine, give the air compressor time to build up the air

pressure to 414 kPa (60 psi) before moving the vehicle.

Do not drive or continue to drive if the low air pressure buzzer

is sounding or the brake warning light is lit. These warnings

indicate that air pressure is not to normal operating level. Continued

use of the vehicle could result in loss of braking ability.

Avoid repeated light application of the brake pedal. This will

deplete air pressure faster and could result in loss of braking

capability.

Periodically check the air pressure

gauge while driving. Pressure should

range between approximately 703 to

930 kPa (105-135 psi). The air

compressor governor cut-in and

cut-out pressure settings are preset

at the factory and are not

adjustable.

0 30 12090 60

150AIR

PRESSUREPSI

Driving

88

Page 89 of 208

![FORD F750 2000 10.G User Guide When air pressure is insufficient

(below 534 kPa [60 psi]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake app FORD F750 2000 10.G User Guide When air pressure is insufficient

(below 534 kPa [60 psi]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake app](/img/11/5066/w960_5066-88.png)

When air pressure is insufficient

(below 534 kPa [60 psi]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake applications depleting

the system air pressure. If this condition occurs, stop driving the vehicle

until the compressor has fully recharged the air system. Do not move the

vehicle in this condition because the brake system may be inoperative.

Select a gear ratio to help slow your vehicle before descending grades.

Supplement with brakes as required to safely slow the vehicle and avoid

overspeeding the engine.

Air chamber stroke indication

All Ford air chamber push rods have orange stroke indicator stripes that

alert the operator when the braking system requires adjustment or

repair. The orange stripe is painted on the air chamber push rod at the

slack adjuster readjustment stroke dimension.

Air brake inspection and adjustment should be performed by a qualified

service technician in accordance with the instructions in the Ford Truck

Service Manual.

Cam brakes—automatic slack adjusters

Standard air brakes (cam) are

equipped with automatic brake

adjusters. Automatic adjustment

occurs during forward and reverse

brake applications. Inspect brakes

for proper adjustment at the

intervals listed in the vehicle Service

Maintenance Guide.

!

BRAKE

Driving

89

Page 97 of 208

•Lack of lubricant in the front spindle bearings or linkage components

•Low oil level in the power steering system

•Broken or loose power steering pump direct drive connection

•Malfunctioning relief valve in power steering gear or steering pump

•Malfunctioning power steering pump

•Restriction in power steering lines

•Improperly set turn stops

•Air entrapped in power steering system fluid

DRIVING WITH A MANUAL TRANSMISSION, IF EQUIPPED

Continued use of a damaged or worn clutch, prolonged clutch

slippage or downshifting at excessive speeds can result in a

failure of the engine, transmission or clutch components.

To avoid premature clutch wear and failure, do not drive with

your foot resting on the clutch pedal or use it to hold the vehicle

at a standstill on an upgrade as when waiting for a traffic light.

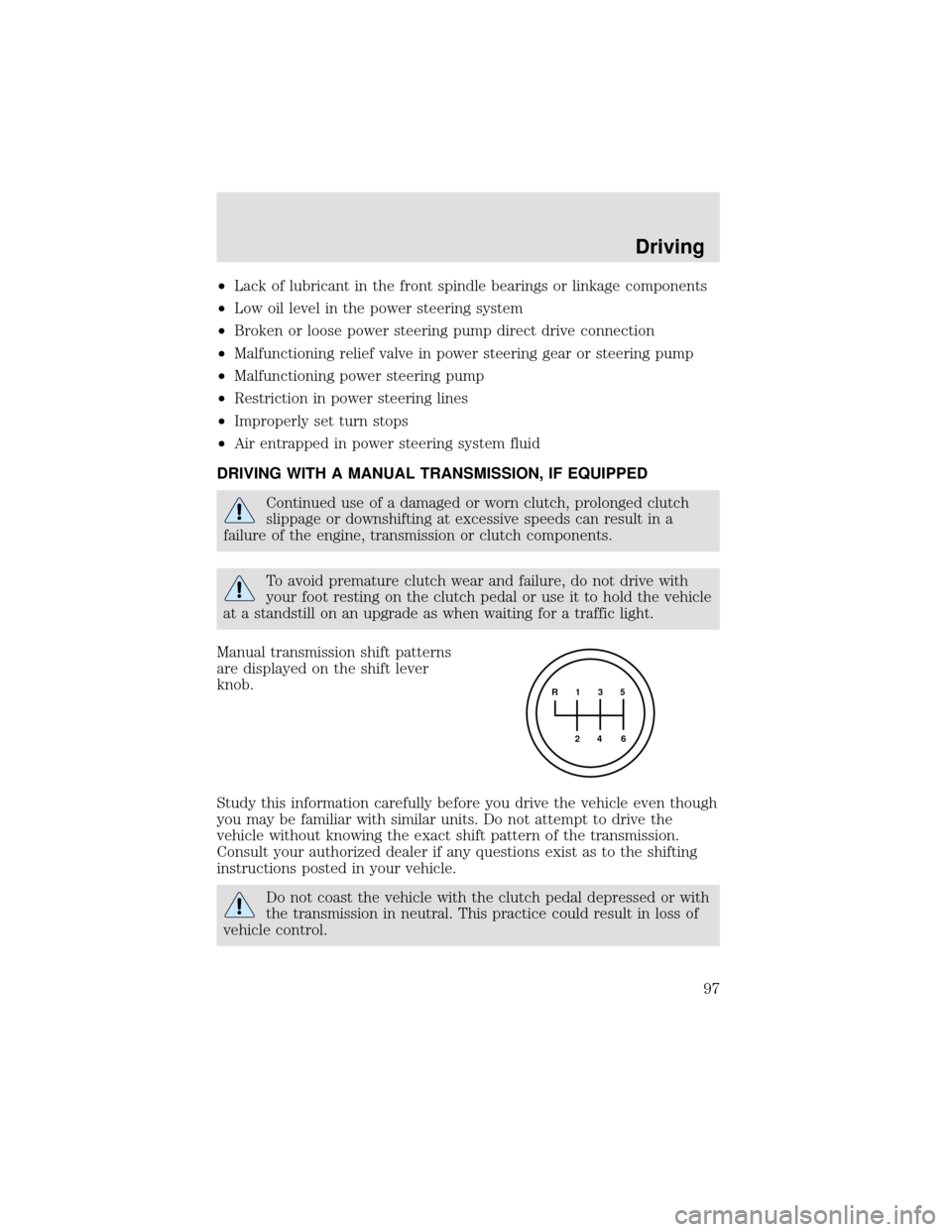

Manual transmission shift patterns

are displayed on the shift lever

knob.

Study this information carefully before you drive the vehicle even though

you may be familiar with similar units. Do not attempt to drive the

vehicle without knowing the exact shift pattern of the transmission.

Consult your authorized dealer if any questions exist as to the shifting

instructions posted in your vehicle.

Do not coast the vehicle with the clutch pedal depressed or with

the transmission in neutral. This practice could result in loss of

vehicle control.

R 1 3 5

4

6 2

Driving

97

Page 98 of 208

Always use a gear ratio low enough to allow the engine to operate above

the minimum engine operation speed range. Do not lug the engine. When

more power is required, shift to a lower gear and accelerate the engine

near the governed speed.

Driving hints

The following driving hints are provided as a brief, general guide in

operating the different manual transmissions used in your vehicle.

•Always use the lowest gear to start the vehicle.

•Do not slam or jerk lever into gear.

•When shifting into 1 (First) or R (Reverse) with vehicle standing still,

quickly release and depress the clutch pedal (if necessary to complete

gear engagement).

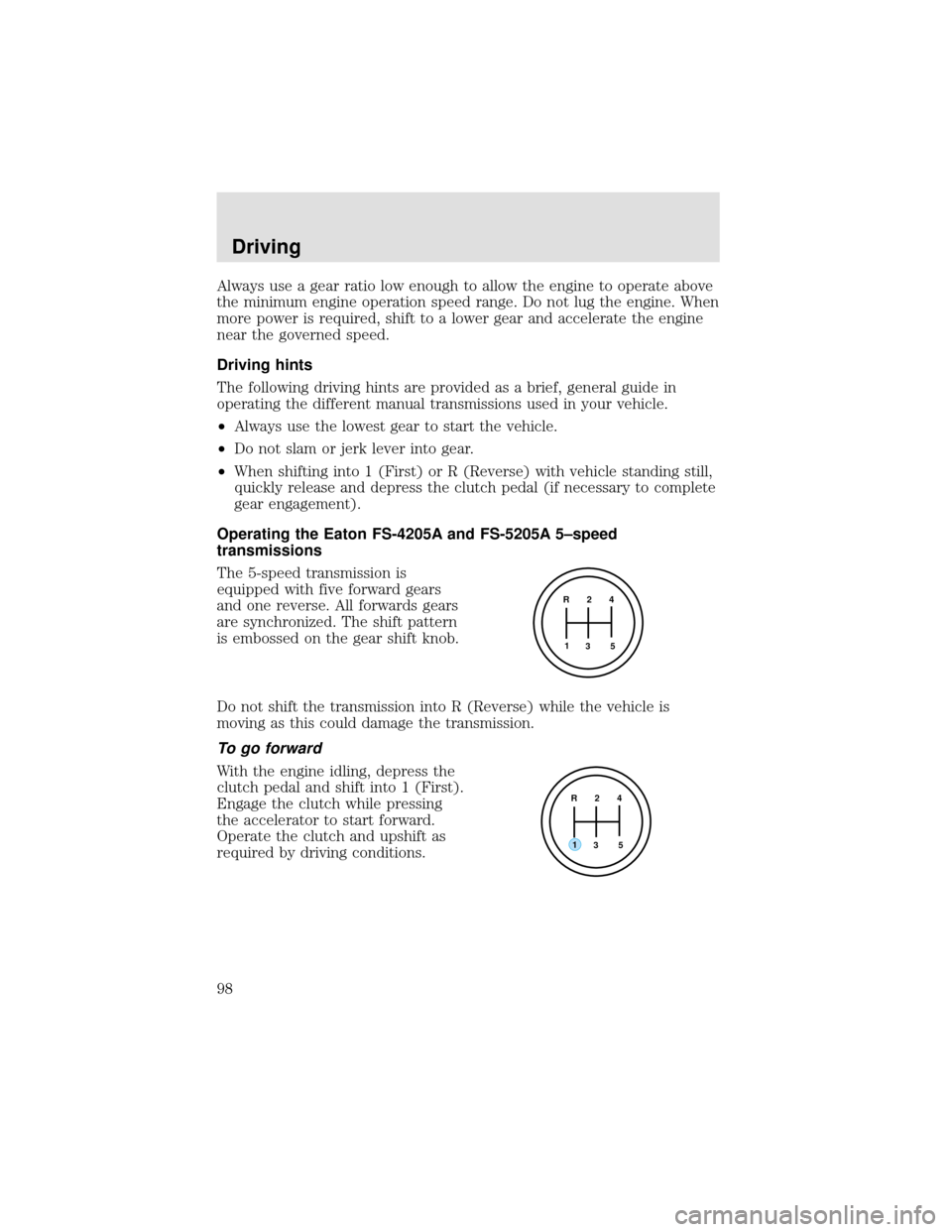

Operating the Eaton FS-4205A and FS-5205A 5–speed

transmissions

The 5-speed transmission is

equipped with five forward gears

and one reverse. All forwards gears

are synchronized. The shift pattern

is embossed on the gear shift knob.

Do not shift the transmission into R (Reverse) while the vehicle is

moving as this could damage the transmission.

To go forward

With the engine idling, depress the

clutch pedal and shift into 1 (First).

Engage the clutch while pressing

the accelerator to start forward.

Operate the clutch and upshift as

required by driving conditions.

R 2 4

3 5 1

R 2 4

3 5

1

Driving

98

Page 99 of 208

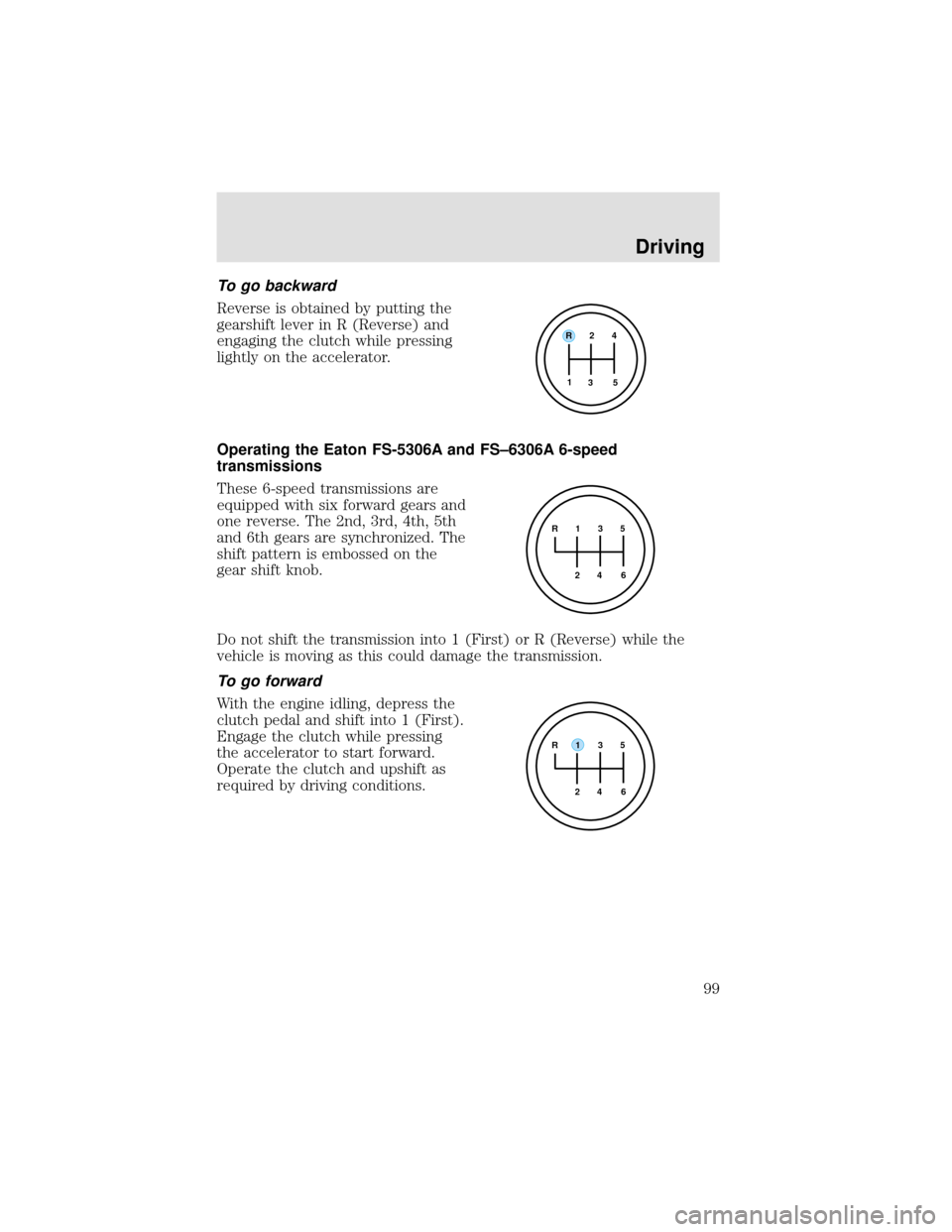

To go backward

Reverse is obtained by putting the

gearshift lever in R (Reverse) and

engaging the clutch while pressing

lightly on the accelerator.

Operating the Eaton FS-5306A and FS–6306A 6-speed

transmissions

These 6-speed transmissions are

equipped with six forward gears and

one reverse. The 2nd, 3rd, 4th, 5th

and 6th gears are synchronized. The

shift pattern is embossed on the

gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

To go forward

With the engine idling, depress the

clutch pedal and shift into 1 (First).

Engage the clutch while pressing

the accelerator to start forward.

Operate the clutch and upshift as

required by driving conditions.

R 2 4

3 5 1

R 1 3 5

4

6 2

R 1 3 5

4

6 2

Driving

99

Page 100 of 208

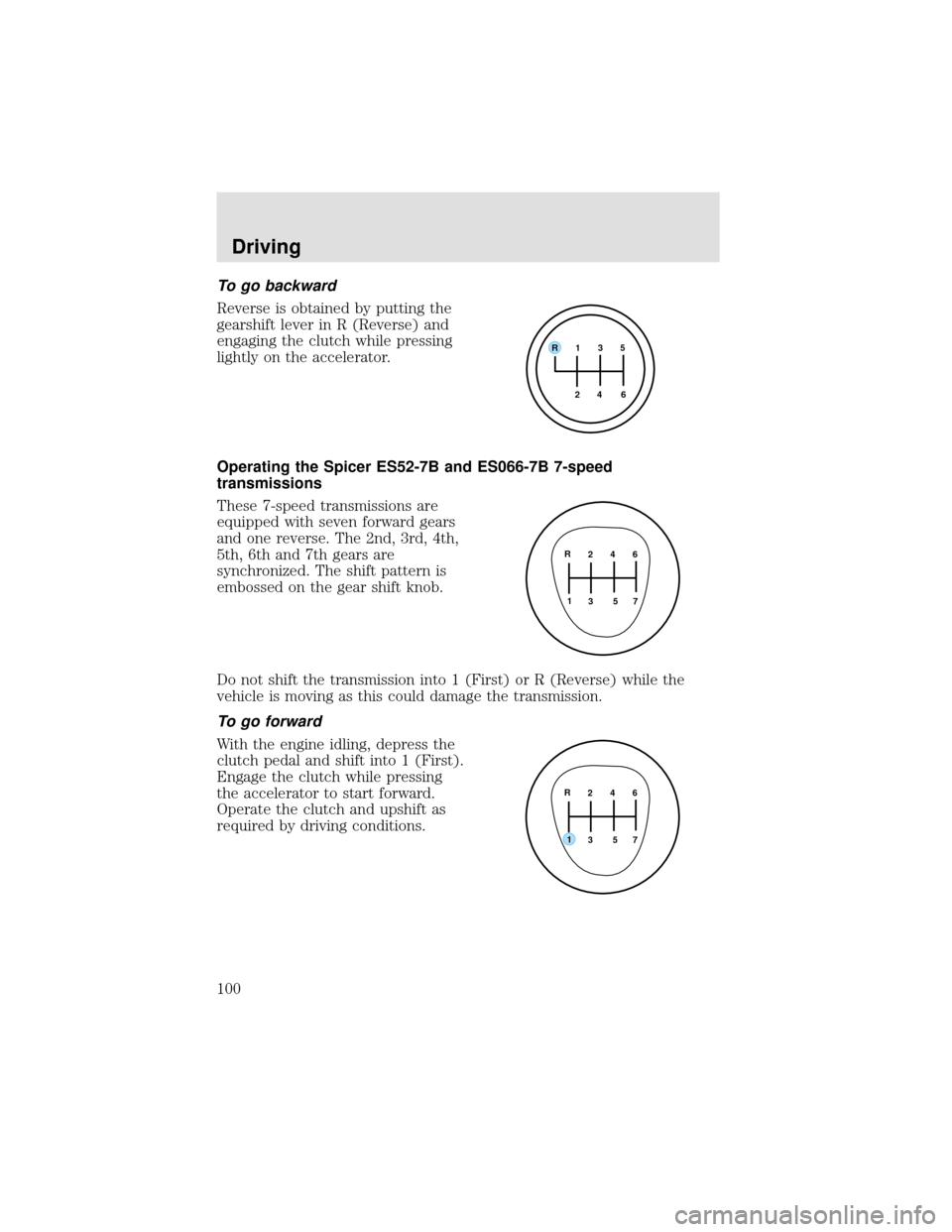

To go backward

Reverse is obtained by putting the

gearshift lever in R (Reverse) and

engaging the clutch while pressing

lightly on the accelerator.

Operating the Spicer ES52-7B and ES066-7B 7-speed

transmissions

These 7-speed transmissions are

equipped with seven forward gears

and one reverse. The 2nd, 3rd, 4th,

5th, 6th and 7th gears are

synchronized. The shift pattern is

embossed on the gear shift knob.

Do not shift the transmission into 1 (First) or R (Reverse) while the

vehicle is moving as this could damage the transmission.

To go forward

With the engine idling, depress the

clutch pedal and shift into 1 (First).

Engage the clutch while pressing

the accelerator to start forward.

Operate the clutch and upshift as

required by driving conditions.

R 1 3 5

4

6 2

2 4 6

3 5 71 R

2 4 6

3 5 7

1 R

Driving

100