FORD F750 2001 10.G Owners Manual

Manufacturer: FORD, Model Year: 2001, Model line: F750, Model: FORD F750 2001 10.GPages: 240, PDF Size: 1.3 MB

Page 101 of 240

Tether anchorage hardware

A tethered seat can be installed in the front seat. Put the tether strap

over the seatback and attach it to an anchor bracket.

An anchor bracket can be installed to the inside of the back panel of

your vehicle.

The anchor bracket must be installed using the instructions provided

with the tether anchorage hardware kit.

Tether anchorage hardware kits (part number 613D74) including

instructions, may be obtained at no charge from any Ford or

Lincoln/Mercury dealer.

If you have a Super Cab or Crew Cab, Ford recommends you attach

tether safety seats in the rear seating position (if possible) with the

tether strap attached to the tether anchorage bracket as shown in the

instructions provided with the tether anchor kit.

Tighten the anchor according to specifications. Otherwise, the

safety seat may not be properly secured and the child may be

injured in a sudden stop or collision.

Seating and safety restraints

101

Page 102 of 240

STARTING PROCEDURES

Operating precautions

²

Always shift to a lower gear at high altitudes to prevent engine smoking.

²Avoid extended and unnecessary idling.

Do not operate a diesel engine where the vapors can be

combustible. These vapors can be sucked through the air intake

system and cause engine acceleration and overspeeding, which may

result in bodily injury and extensive property damage. The equipment

owner and operator are responsible for safe operation in a hostile

environment.

STARTING THE ENGINE

1. Ensure headlamps and all accessories are turned off and the parking

brake is applied.

2.Automatic transmissions,ensure gearshift is in N (Neutral).

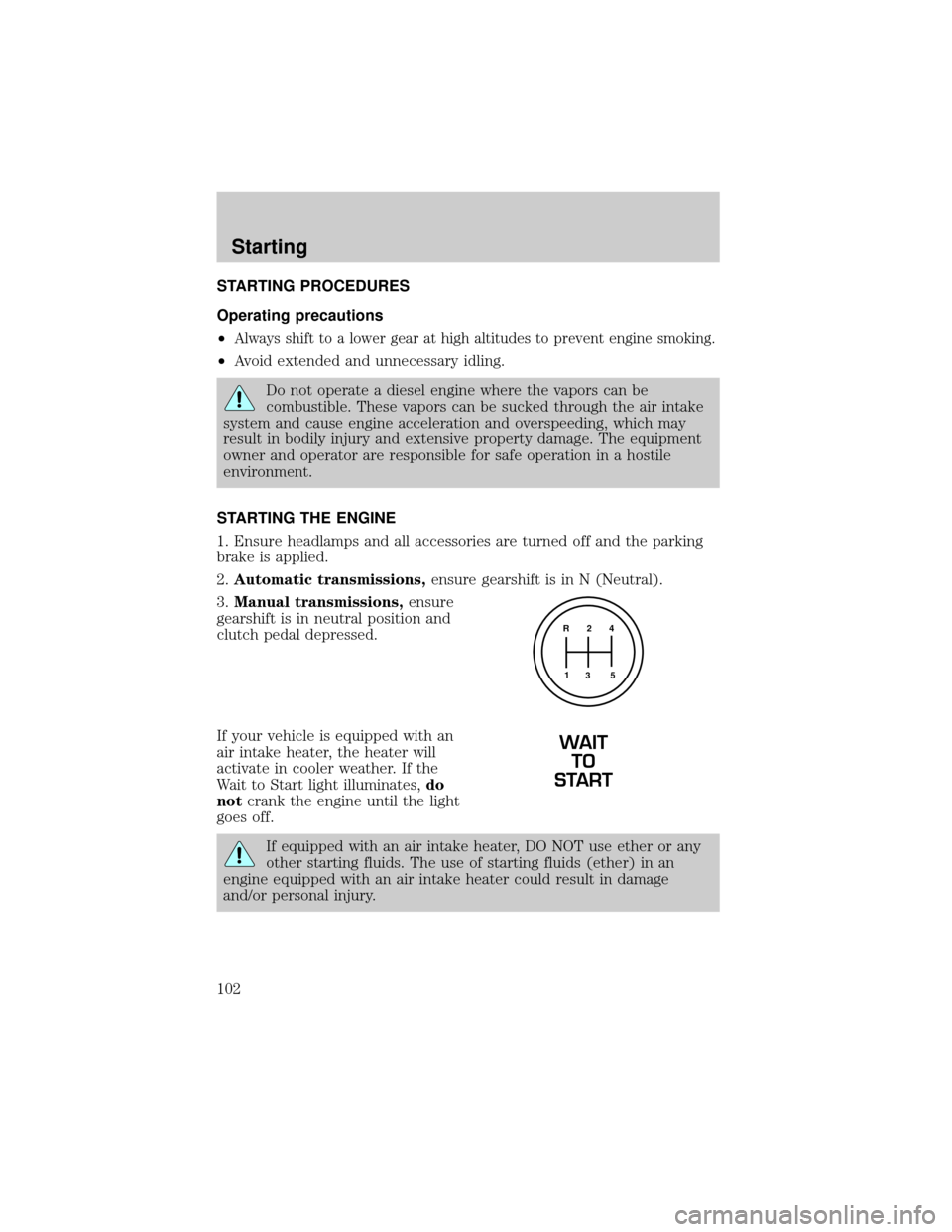

3.Manual transmissions,ensure

gearshift is in neutral position and

clutch pedal depressed.

If your vehicle is equipped with an

air intake heater, the heater will

activate in cooler weather. If the

Wait to Start light illuminates,do

notcrank the engine until the light

goes off.

If equipped with an air intake heater, DO NOT use ether or any

other starting fluids. The use of starting fluids (ether) in an

engine equipped with an air intake heater could result in damage

and/or personal injury.

R 2 4

3 5 1

WAIT

TO

START

Starting

102

Page 103 of 240

4. Do not depress the accelerator during starting the engine.

5. Start the engine.

If the engine does not start after 30 seconds of cranking, allow two

minutes for the starter to cool before trying again. Excessive cranking

may damage the starter.

After the engine starts:

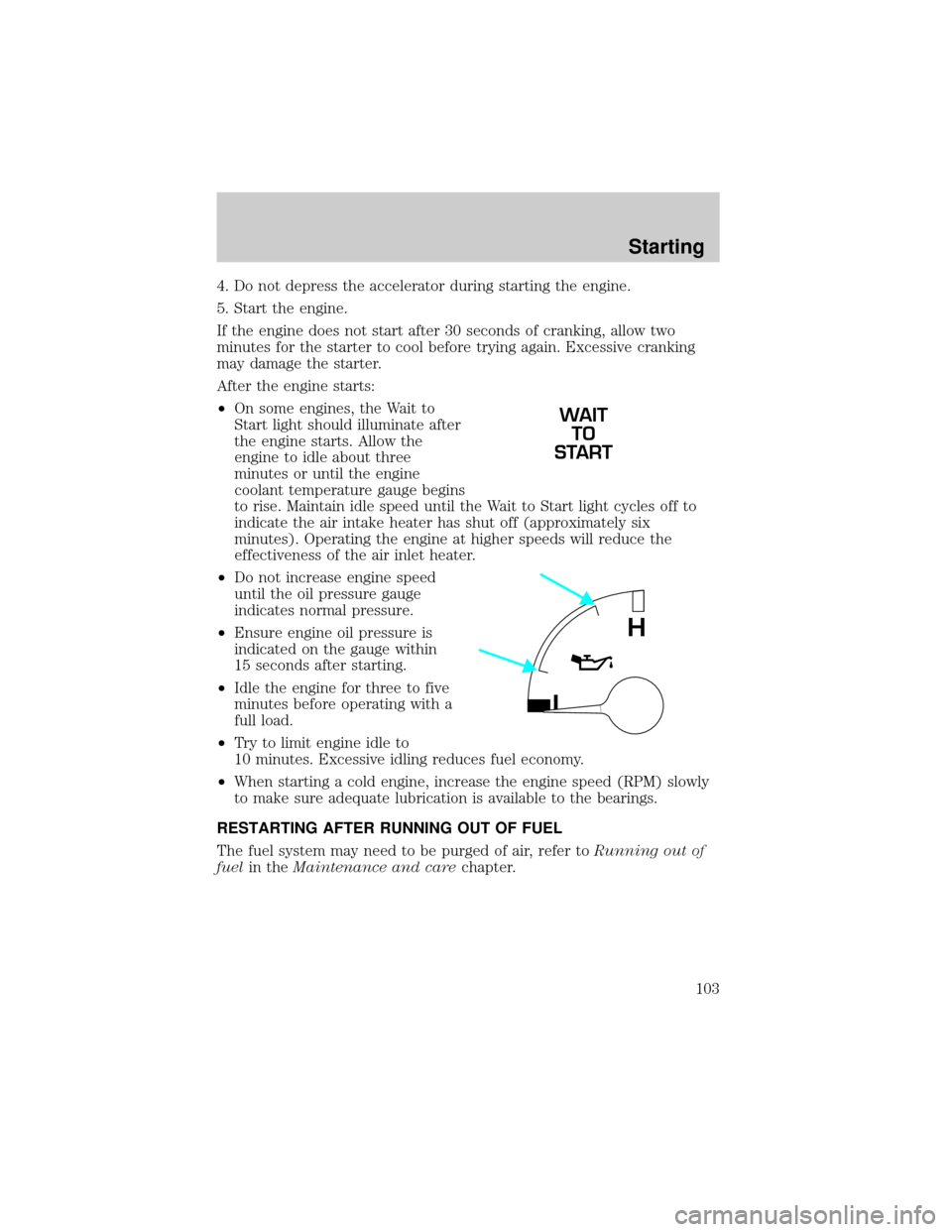

²On some engines, the Wait to

Start light should illuminate after

the engine starts. Allow the

engine to idle about three

minutes or until the engine

coolant temperature gauge begins

to rise. Maintain idle speed until the Wait to Start light cycles off to

indicate the air intake heater has shut off (approximately six

minutes). Operating the engine at higher speeds will reduce the

effectiveness of the air inlet heater.

²Do not increase engine speed

until the oil pressure gauge

indicates normal pressure.

²Ensure engine oil pressure is

indicated on the gauge within

15 seconds after starting.

²Idle the engine for three to five

minutes before operating with a

full load.

²Try to limit engine idle to

10 minutes. Excessive idling reduces fuel economy.

²When starting a cold engine, increase the engine speed (RPM) slowly

to make sure adequate lubrication is available to the bearings.

RESTARTING AFTER RUNNING OUT OF FUEL

The fuel system may need to be purged of air, refer toRunning out of

fuelin theMaintenance and carechapter.

WAIT

TO

START

L

H

Starting

103

Page 104 of 240

OPERATING THE ENGINE

Do not operate the engine at full throttle below peak torque engine

speed (RPM) for more than one minute at a time (peak torque RPM

varies from 1200-1500 RPM depending on engine rated speed).

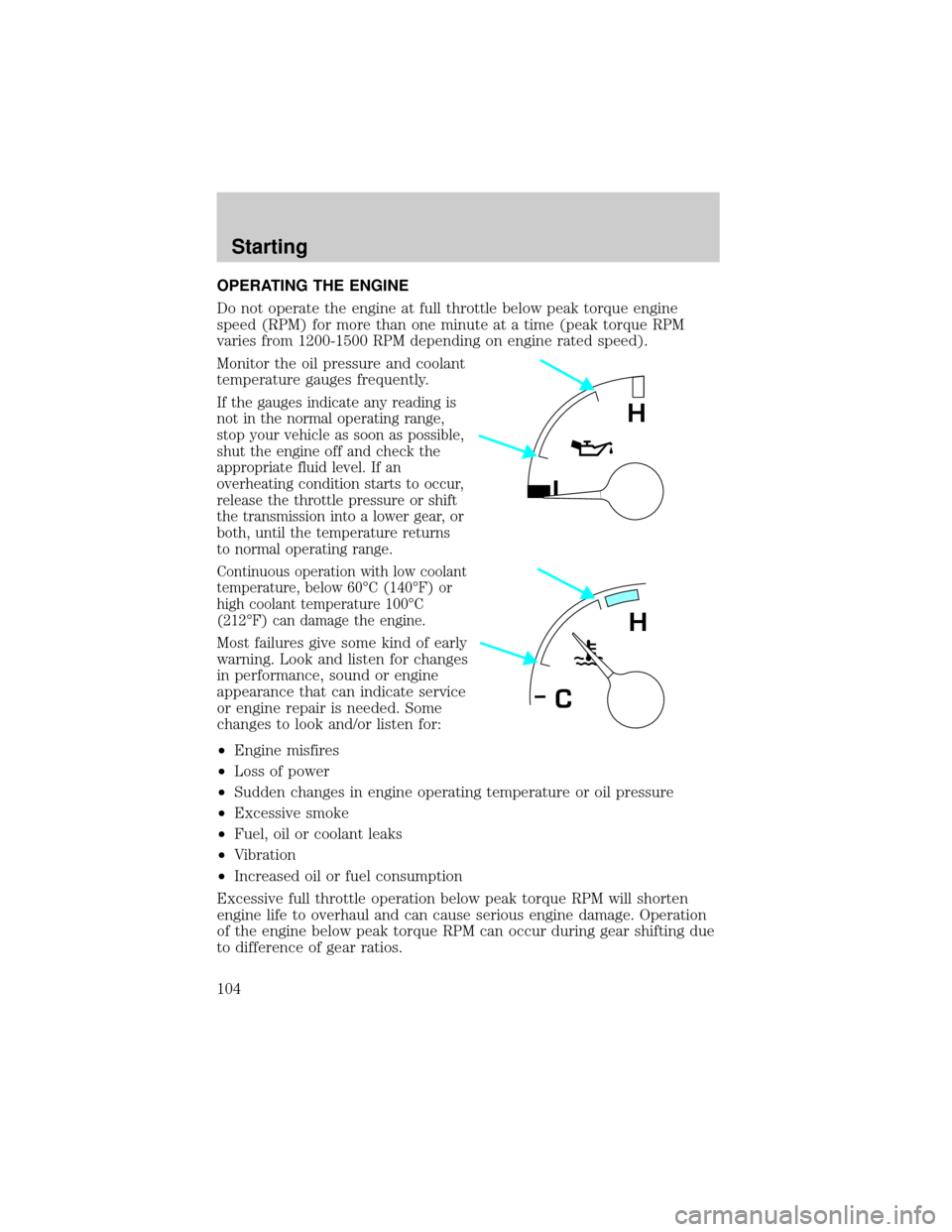

Monitor the oil pressure and coolant

temperature gauges frequently.

If the gauges indicate any reading is

not in the normal operating range,

stop your vehicle as soon as possible,

shut the engine off and check the

appropriate fluid level. If an

overheating condition starts to occur,

release the throttle pressure or shift

the transmission into a lower gear, or

both, until the temperature returns

to normal operating range.

Continuous operation with low coolant

temperature, below 60ÉC (140ÉF) or

high coolant temperature 100ÉC

(212ÉF) can damage the engine.

Most failures give some kind of early

warning. Look and listen for changes

in performance, sound or engine

appearance that can indicate service

or engine repair is needed. Some

changes to look and/or listen for:

²Engine misfires

²Loss of power

²Sudden changes in engine operating temperature or oil pressure

²Excessive smoke

²Fuel, oil or coolant leaks

²Vibration

²Increased oil or fuel consumption

Excessive full throttle operation below peak torque RPM will shorten

engine life to overhaul and can cause serious engine damage. Operation

of the engine below peak torque RPM can occur during gear shifting due

to difference of gear ratios.

L

H

H

C

Starting

104

Page 105 of 240

COLD WEATHER STARTING

Perform the following to assure efficient starting in cold weather:

²Use the proper grade oil for your climate. Refer to your engine

operator's manual for proper grade oil.

²Test the battery more frequently to assure ample power for starting.

²All electrical connections should be tight and in good condition to

prevent losses through loose or corroded connections.

USING THE ENGINE BLOCK HEATER (IF EQUIPPED)

An engine block heater warms the engine coolant, which improves

starting, warms up the engine faster and allows the heater-defroster

system to respond quickly. Use of an engine block heater is strongly

recommended if you live in a region where temperatures reach -23ÉC

(-10ÉF) or below.

For best results, plug the heater in at least three hours before starting

the vehicle. Using the heater for longer than three hours will not harm

the engine, so the heater can be plugged in the night before starting the

vehicle.

To prevent electrical shock, do not use your heater with

ungrounded electrical systems or two-pronged (cheater) adapters.

ENGINE SHUTDOWN SYSTEM (IF EQUIPPED)

This system is designed to help prevent engine damage that could result

from operating the engine during a prolonged period of low engine oil

pressure, high engine coolant temperature or low coolant level. If any of

these conditions occur, a warning light will illuminate and a chime will

sound warning the operator that the engine will shutdown in 30 seconds.

This is to allow time for the operator to move the vehicle off the road. If

additional time is required, the engine can be restarted and run each

time for approximately 30 seconds.

Do not attempt to use this restarting feature to drive the vehicle, serious

engine damage could result.

Starting

105

Page 106 of 240

EXHAUST FUMES

Never idle the engine in closed areas. Never sit in a parked or

stopped vehicle for any amount of time with engine running.

If you ever smell exhaust fumes of any kind inside your vehicle,

have your dealer inspect and fix your vehicle immediately. Do

not drive if you smell exhaust fumes. These fumes are harmful and

could kill you.

In order to guard against fumes entering your vehicle, the exhaust

system and body ventilation system should be checked by a qualified

technician:

²Each time the vehicle is raised for service.

²Whenever a change in exhaust system noise is noted.

²Whenever the vehicle has been damaged by impact from another

vehicle, object or road obstruction.

In order to afford proper operation, all air inlet vents should be kept

clear of snow, leaves and other debris.

If you run the engine while stopped (idled) in an unconfined area, open

the windows at least 2.5 cm (one inch) and adjust the heating or air

conditioning to draw outside air into the vehicle as follows:

²If your vehicle has outside air control vents, open them fully.

²Set fan speed on high with function control to any position except

OFF or MAX A/C and the temperature control on any desired position.

²Adjust air control system to force outside air into the vehicle.

BACKING UP

To avoid the possibility of personal injury while backing the

vehicle, always be sure your vehicle's path is clear.

Before backing your vehicle, be sure you can do so safely. If anything

behind the cab limits your view, do not rely on mirrors alone to assure

that your intended path is clear. If other persons are in the vicinity, have

someone standing well behind the vehicle and outside your intended

path - visible through an exterior mirror - guide you as you back up.

Driving

106

Page 107 of 240

Although OSHA or other governmental regulations may require use of an

electrical or mechanical back-up alarm to warn bystanders, such an

alarm does not assure that the intended path is clear.

An electrical back-up alarm, if installed, is connected to the back-up

lamp circuit.

HYDRAULIC BRAKES (IF EQUIPPED)

Your service brakes are self-adjusting. Refer to the Scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

If you are driving down a long or steep hill, shift to a lower gear.

Do not apply your brakes continuously, as they may overheat

and become less effective.

Four-wheel anti-lock brake system (ABS) (if equipped)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. If the vehicle has continuous vibration or shudder

in the steering wheel while braking, the vehicle should be inspected by a

qualified service technician.

Driving

107

Page 108 of 240

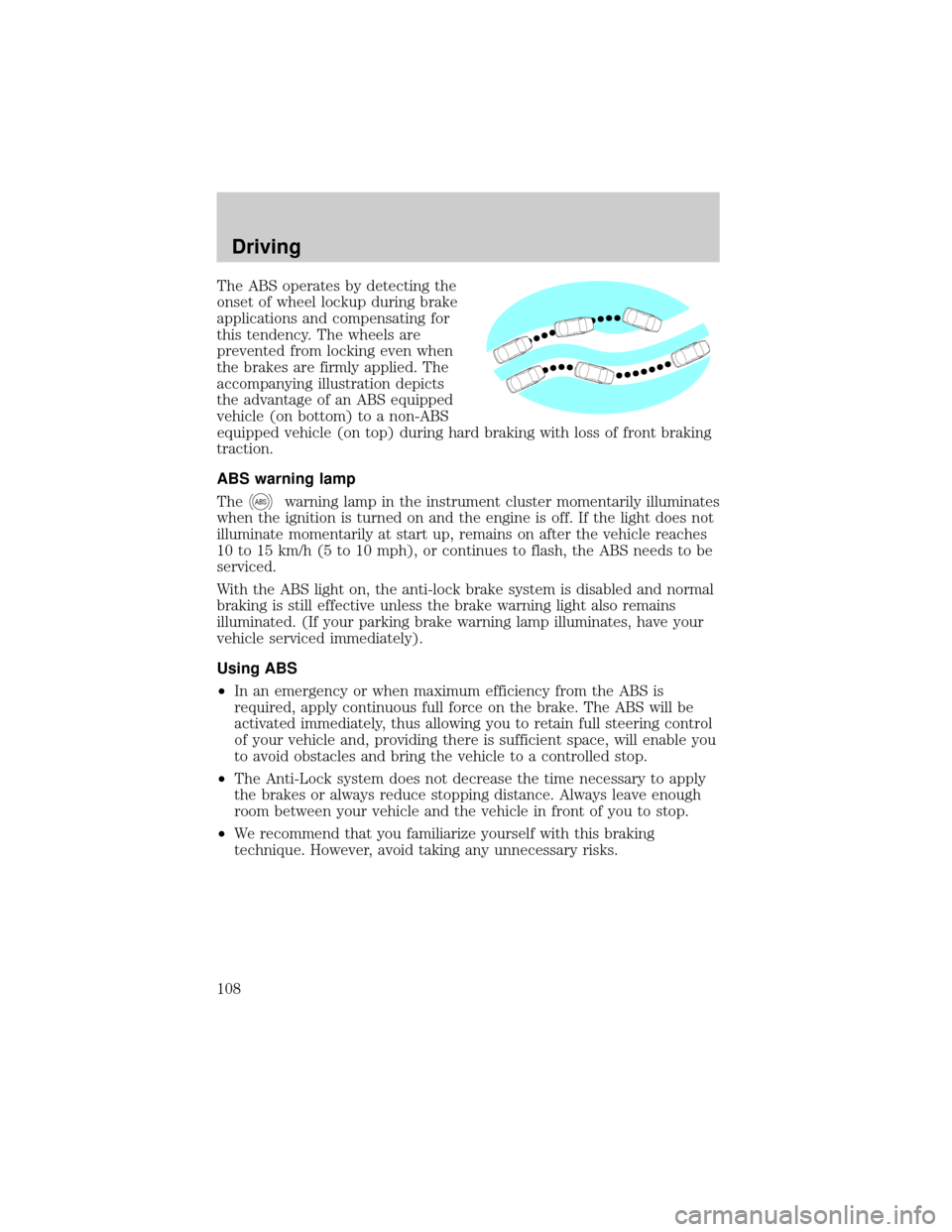

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensating for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

ABS warning lamp

The

ABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned on and the engine is off. If the light does not

illuminate momentarily at start up, remains on after the vehicle reaches

10 to 15 km/h (5 to 10 mph), or continues to flash, the ABS needs to be

serviced.

With the ABS light on, the anti-lock brake system is disabled and normal

braking is still effective unless the brake warning light also remains

illuminated. (If your parking brake warning lamp illuminates, have your

vehicle serviced immediately).

Using ABS

²In an emergency or when maximum efficiency from the ABS is

required, apply continuous full force on the brake. The ABS will be

activated immediately, thus allowing you to retain full steering control

of your vehicle and, providing there is sufficient space, will enable you

to avoid obstacles and bring the vehicle to a controlled stop.

²The Anti-Lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

Driving

108

Page 109 of 240

Hydraulic brake booster system (Hydromax)

The Hydromax systems receive fluid pressure from the power steering

pump to provide power assist during braking.

The Hydromax booster receives backup pressure from the reserve

system electric pump whenever the fluid in the power steering system is

not flowing. When the engine is OFF, the pump will turn on if the brake

pedal is applied, or if the ignition is turned to the ON position.

The sound of the pump operating may be heard by the driver, but this is

a normal characteristic of the system.

The reserve system provides reduced braking power, so the vehicle

should be operated under these conditions with caution, and only to seek

service repair and remove the vehicle from the roadway.

For Hydromax under normal operating conditions noise of the fluid

flowing through the booster may be heard whenever the brake is applied.

This condition is normal. Vehicle service is not required.

If braking performance or pedal response becomes very poor, even when

the pedal is strongly applied, this may indicate the presence of air in the

hydraulic system or fluid leakage. Stop the vehicle safely as soon as

possible and seek service immediately.

If the red BRAKE warning lamp in

the instrument cluster remains

illuminated after engine start up,

this indicates a system failure in the

master cylinder of the brake system.

Stop the vehicle safely as soon as possible and seek service immediately.

If the yellow BRAKE RESERVE

(E-motor) warning light remains on

while the engine is running, this

indicates inadequate hydraulic

booster pressure or reserve pump

system failure. Stop the vehicle safely as soon as possible and seek

service immediately.

!

BRAKE

BRAKE

Driving

109

Page 110 of 240

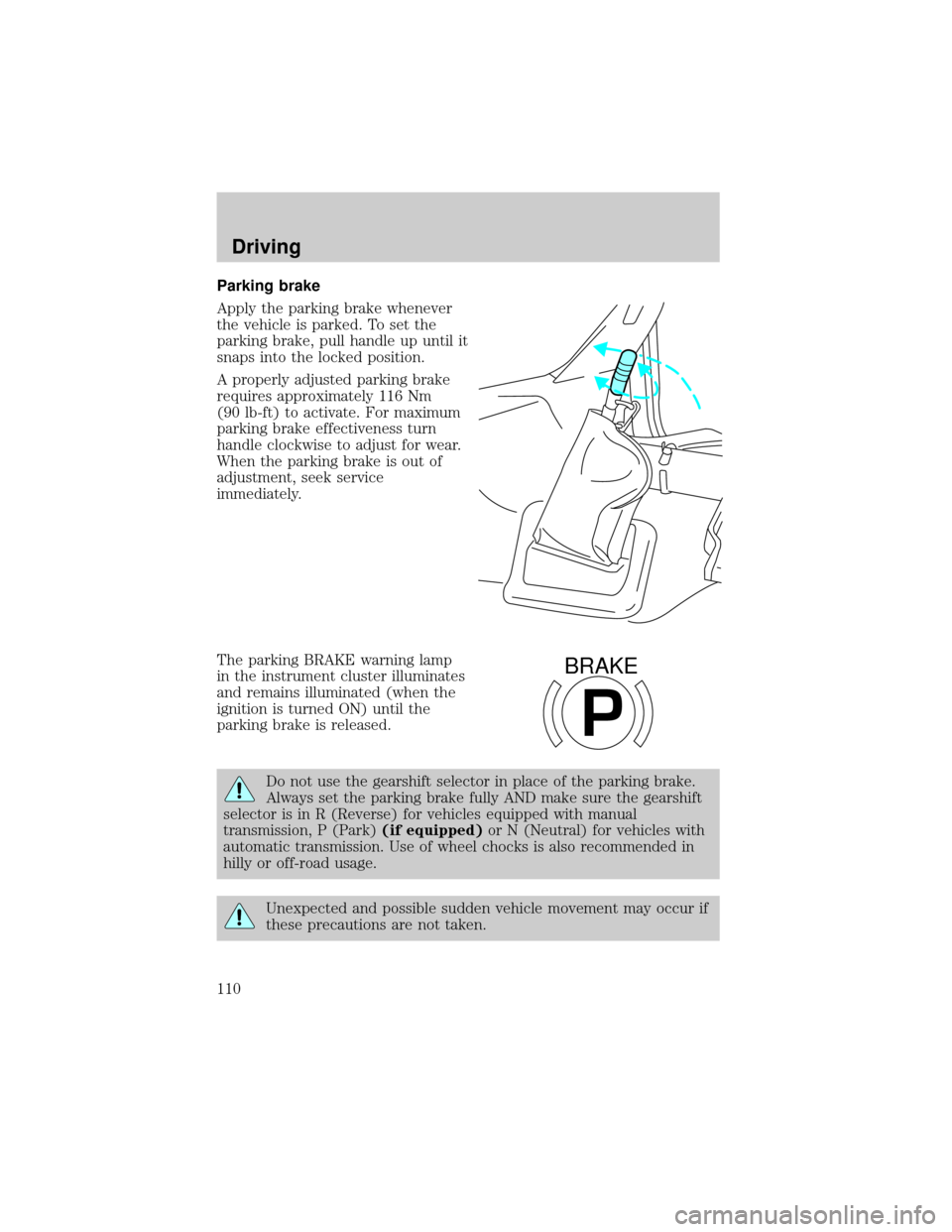

Parking brake

Apply the parking brake whenever

the vehicle is parked. To set the

parking brake, pull handle up until it

snaps into the locked position.

A properly adjusted parking brake

requires approximately 116 Nm

(90 lb-ft) to activate. For maximum

parking brake effectiveness turn

handle clockwise to adjust for wear.

When the parking brake is out of

adjustment, seek service

immediately.

The parking BRAKE warning lamp

in the instrument cluster illuminates

and remains illuminated (when the

ignition is turned ON) until the

parking brake is released.

Do not use the gearshift selector in place of the parking brake.

Always set the parking brake fully AND make sure the gearshift

selector is in R (Reverse) for vehicles equipped with manual

transmission, P (Park)(if equipped)or N (Neutral) for vehicles with

automatic transmission. Use of wheel chocks is also recommended in

hilly or off-road usage.

Unexpected and possible sudden vehicle movement may occur if

these precautions are not taken.

P

BRAKE

Driving

110