FORD F750 2004 11.G Owners Manual

Manufacturer: FORD, Model Year: 2004, Model line: F750, Model: FORD F750 2004 11.GPages: 264, PDF Size: 1.47 MB

Page 141 of 264

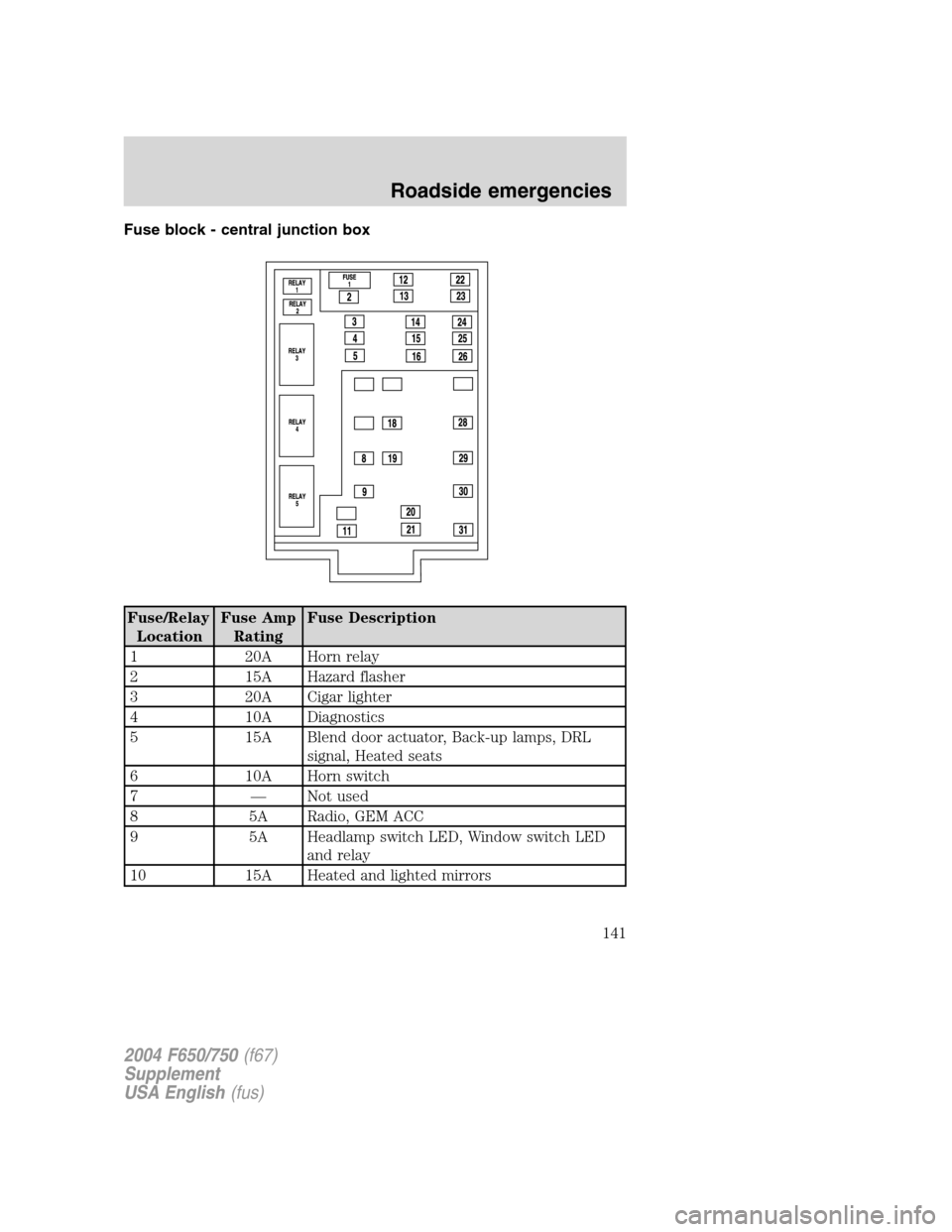

Fuse block - central junction box

Fuse/Relay

LocationFuse Amp

RatingFuse Description

1 20A Horn relay

2 15A Hazard flasher

3 20A Cigar lighter

4 10A Diagnostics

5 15A Blend door actuator, Back-up lamps, DRL

signal, Heated seats

6 10A Horn switch

7—Not used

8 5A Radio, GEM ACC

9 5A Headlamp switch LED, Window switch LED

and relay

10 15A Heated and lighted mirrors

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

141

Page 142 of 264

Fuse/Relay

LocationFuse Amp

RatingFuse Description

11 30A Wiper motor, Washer pump relay

12 10A Stop lamp switch (Hydraulic brake vehicles)

13 20A Cluster, Radio

14 10A Interior lamp relay

15 10A Interior lamp relay

16 15A Headlamp high beam, High beam indicator

17—Not used

18 5A Headlamp switch interior lighting

19 15A Engine control (all engines), Accelerator

pedal (6.0L Power Stroke engine)

20 15A Starting system

21 10A DRL resistor

22 15A Speed control feed (6.0L Power Stroke

engine), Air solenoid, Fuel transfer pump

23 10A Hazard flasher (Run)

24 15A ABS, Air dryer, Vacuum pump, Fuel heater

relay

25 10A Function selector switch

26 10A RH headlamp low beam

27—Not used

28 10A LH headlamp low beam

29 10A Cluster warning lamps, Gauges GEM,

Hydraulic brake ABS

30—Not used

31 15A Allison transmission or ABS event

Relay 1 1/2 ISO Interior lamp relay

Relay 2 1/2 ISO Not used

Relay 3 Full ISO Horn relay

Relay 4 Full ISO One-touch window down relay

Relay 5 Full ISO Not used

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

142

Page 143 of 264

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; doing so may

damage the catalytic converter.

Jump starting your vehicle

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

143

Page 144 of 264

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle’s engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

+–+–

+–+–

+–+–

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

144

Page 145 of 264

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

+–+–

+–+–

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

145

Page 146 of 264

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

WRECKER TOWING INSTRUCTIONS

Before moving the towed vehicle, check for adequate road clearance of

vehicle components. It is recommended the towed vehicle be unloaded

prior to being towed to reduce any abnormal load to the vehicle

components resulting from the towing procedures. Before towing, be

sure to fully release the parking brake. The spring-actuated type parking

brake can be reset by recharging the air system with at least 441 kPa (64

psi) of air. If the brake system will not retain air pressure, then the

spring brakes must be released manually. Refer toParking brakein the

Drivingchapter

Note:For towing, make sure the vehicle is securely connected to the

tow vehicle and the tow vehicle parking brakes are applied before

releasing the disabled vehicle’s spring brakes.

+–+–

+–+–

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

146

Page 147 of 264

To reduce the risk of personal injury or property damage when

manually releasing the spring brakes, be sure to block the wheels

so the vehicle cannot move once the brakes are released.

Towing the vehicle with the front wheels suspended

When it is necessary to tow a vehicle with the front wheels suspended,

extra precautions must be taken to avoid transmission or differential

damage. Proceed as follows:

•Remove the axle shafts from the axle assembly to prevent the wheels

from driving the differential and the transmission.

•The wheel hub ends must be covered to prevent loss of axle lubricant

and entrance of other contaminants. If the axle shafts are not

removed, removal of the propeller shafts is required.

Note:To avoid transmission damage, vehicles should not be towed even

a short distance without suspending rear wheels or removing the axle

shaft or propeller shaft.

Note:In the event the chassis is equipped with a tandem axle and the

vehicle is to be towed from the front, the forward rear axle may be

raised to clear the road surface and secured to the frame by chains or

U-bolts, allowing only the rear rear axle to contact the road surface. Axle

shafts must be removed from the rear rear axle assembly. The wheel hub

ends must be covered to prevent loss of axle lubricant and entrance of

contaminants. Use extreme care in securing the chains or U-bolts to

avoid possible damage to the brake lines, hoses or other components.

Towing vehicles equipped with a driver-controlled differential lock

Note:If the vehicle must be towed to a service facility with the drive

axle wheels on the ground, it is necessary to remove the axle shafts

before the vehicle is towed.

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

147

Page 148 of 264

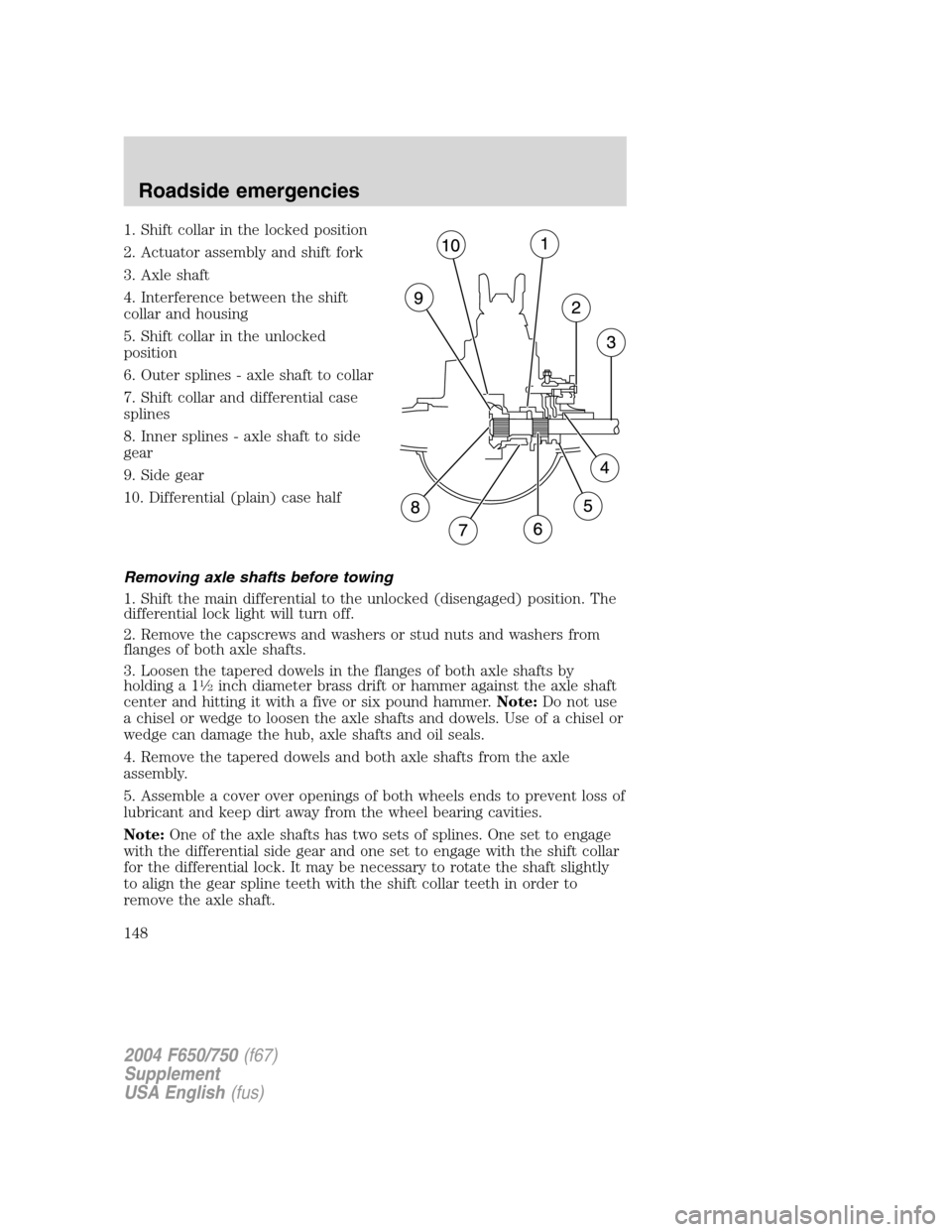

1. Shift collar in the locked position

2. Actuator assembly and shift fork

3. Axle shaft

4. Interference between the shift

collar and housing

5. Shift collar in the unlocked

position

6. Outer splines - axle shaft to collar

7. Shift collar and differential case

splines

8. Inner splines - axle shaft to side

gear

9. Side gear

10. Differential (plain) case half

Removing axle shafts before towing

1. Shift the main differential to the unlocked (disengaged) position. The

differential lock light will turn off.

2. Remove the capscrews and washers or stud nuts and washers from

flanges of both axle shafts.

3. Loosen the tapered dowels in the flanges of both axle shafts by

holding a 1

1⁄2inch diameter brass drift or hammer against the axle shaft

center and hitting it with a five or six pound hammer.Note:Do not use

a chisel or wedge to loosen the axle shafts and dowels. Use of a chisel or

wedge can damage the hub, axle shafts and oil seals.

4. Remove the tapered dowels and both axle shafts from the axle

assembly.

5. Assemble a cover over openings of both wheels ends to prevent loss of

lubricant and keep dirt away from the wheel bearing cavities.

Note:One of the axle shafts has two sets of splines. One set to engage

with the differential side gear and one set to engage with the shift collar

for the differential lock. It may be necessary to rotate the shaft slightly

to align the gear spline teeth with the shift collar teeth in order to

remove the axle shaft.

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

148

Page 149 of 264

Installing the axle shafts

1. Remove the covers from the wheel ends

2. Shift the differential lock to the unlocked position (disengaged)

position.

3. Install the axle shafts

•Place the gaskets on the wheel hub studs.

•Push the right-hand axle shaft and gasket in to the wheel end and

housing until the shaft stops against the differential shift collar.

•Push down and in on the axle shaft flange and rotate the shaft until

the splines of the shaft and shift collar are engaged.

•Push the axle shaft further into the housing until the shaft stops

against the differential side gear.

•Push down on the axle shaft flange and rotate the shaft until the

splines of the shaft and side gear are engaged.

•Push the axle shaft completely into the housing until the axle shaft

flange and the gasket are flush against the wheel hub.

•Install the left-hand axle shaft and gasket into the wheel end.

4. If tapered dowels are required, install them at each stud and into the

flange of the axle shaft. Use a punch or drift and hammer, if needed.

5. Install the fasteners and tighten to correct torque value. Refer to the

Service Manual section.

Towing the vehicle with the rear wheels suspended

Note:To avoid damage to the cab roof or air deflector when towing the

vehicle backward (rear wheels suspended) the air deflector must be

removed.

Whenever possible, it is preferable to tow a disabled vehicle from the

rear by raising the rear of the chassis. When towing a vehicle with the

rear of the chassis suspended the front wheels must be locked in the

straight-ahead position.

Vehicles equipped with a manual-shift transmission must have at least

one (1) pint of transmission fluid drained from the case. This will

prevent the transmission fluid from entering the clutch housing and fluid

saturating the clutch discs. Make sure that the transmission fluid is

replaced before the vehicle is returned to service.

2004 F650/750(f67)

Supplement

USA English(fus)

Roadside emergencies

149

Page 150 of 264

GETTING THE SERVICES YOU NEED

At home

Ford Motor Company and Ford of Canada have authorized dealerships to

service your vehicle. It is preferred that you return to the authorized

dealer where your vehicle was purchased when warranty repairs are

needed. However, you may also take your vehicle to another Ford Motor

Company or Ford of Canada dealership authorized for warranty repairs.

Please note that certain warranty repairs require special training and/or

equipement, so not all dealers are authorized to perform all warranty

repairs. That means that depending on the warranty repair needed, the

vehicle may need to be taken to another dealer. If a particular dealership

cannot assist you, then contact the Commercial Vehicle Hotline.

If you have questions or concerns, or are unsatisfied with the service you

are receiving, follow these steps:

1. Contact your Sales Representative or Service Advisor at your

selling/servicing dealership.

2. If your inquiry or concern remains unresolved, contact the Sales

Manager or Service Manager at the dealership.

3. If the inquiry or concern cannot be resolved at the dealership level,

please contact the Ford Commercial Vehicle Hotline.

Away from home

If you own a F-650 or F-750 and need more help than the dealership can

provide after following the steps provided above call the Ford Fleet and

Commercial Vehicle Hotline.

In the United States:

Ford Motor Company

Commercial Vehicle Hotline

1655 Fairlane Circle

Allen Park, MI 48101

800-782-8627 (option #3)

(TDD for the hearing impaired: 1-800-232-5952)

www.fleet.ford.com

In Canada:

Customer Relationship Centre

Ford Motor Company of Canada, Limited

P.O. Box 2000

Oakville, Ontario L6J 5E4

1-800-565-3673 (FORD)

www.ford.ca

2004 F650/750(f67)

Supplement

USA English(fus)

Customer assistance

Customer assistance

150