stop start FORD F750 2007 11.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: F750, Model: FORD F750 2007 11.GPages: 280, PDF Size: 1.93 MB

Page 146 of 280

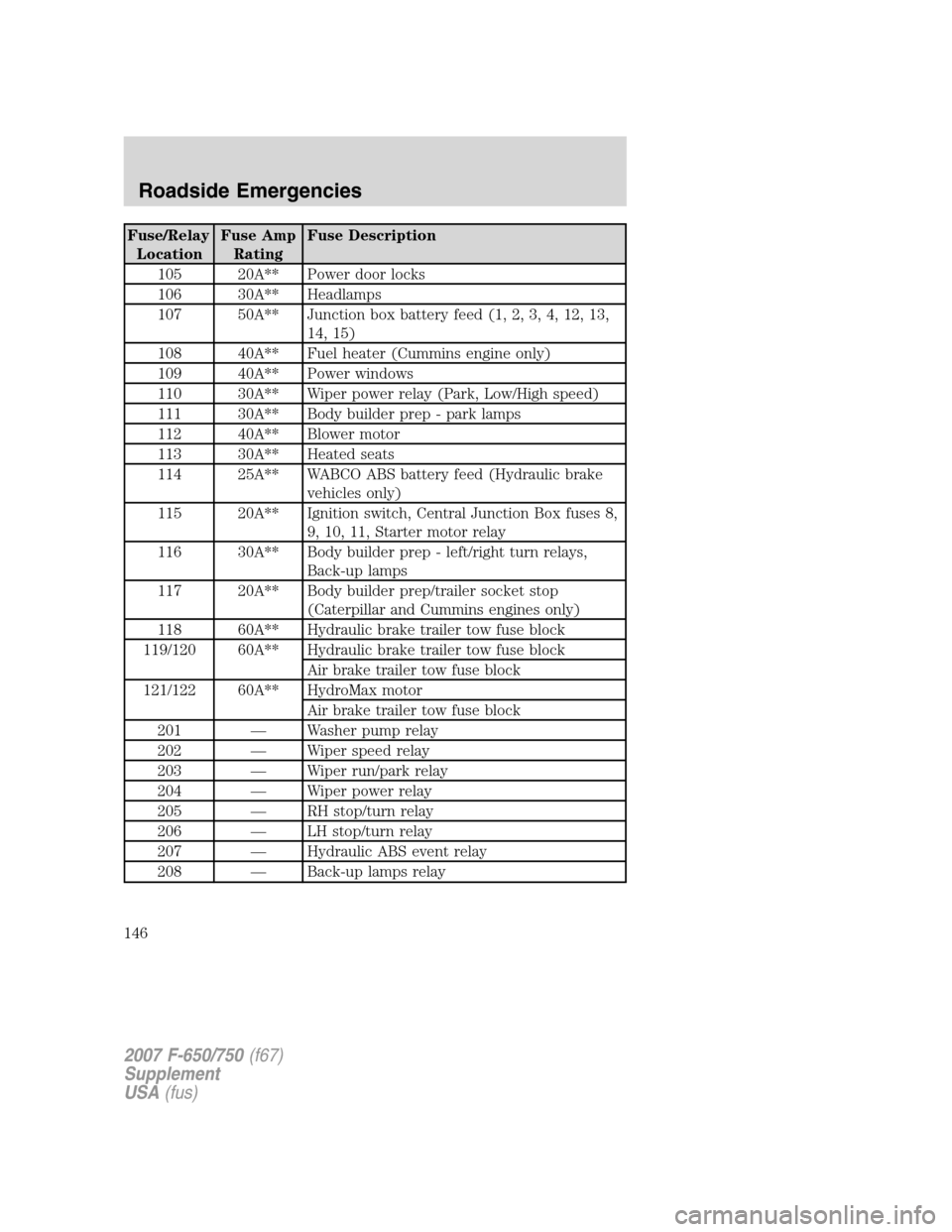

Fuse/Relay

LocationFuse Amp

RatingFuse Description

105 20A** Power door locks

106 30A** Headlamps

107 50A** Junction box battery feed (1, 2, 3, 4, 12, 13,

14, 15)

108 40A** Fuel heater (Cummins engine only)

109 40A** Power windows

110 30A** Wiper power relay (Park, Low/High speed)

111 30A** Body builder prep - park lamps

112 40A** Blower motor

113 30A** Heated seats

114 25A** WABCO ABS battery feed (Hydraulic brake

vehicles only)

115 20A** Ignition switch, Central Junction Box fuses 8,

9, 10, 11, Starter motor relay

116 30A** Body builder prep - left/right turn relays,

Back-up lamps

117 20A** Body builder prep/trailer socket stop

(Caterpillar and Cummins engines only)

118 60A** Hydraulic brake trailer tow fuse block

119/120 60A** Hydraulic brake trailer tow fuse block

Air brake trailer tow fuse block

121/122 60A** HydroMax motor

Air brake trailer tow fuse block

201 — Washer pump relay

202 — Wiper speed relay

203 — Wiper run/park relay

204 — Wiper power relay

205 — RH stop/turn relay

206 — LH stop/turn relay

207 — Hydraulic ABS event relay

208 — Back-up lamps relay

2007 F-650/750(f67)

Supplement

USA(fus)

Roadside Emergencies

146

Page 148 of 280

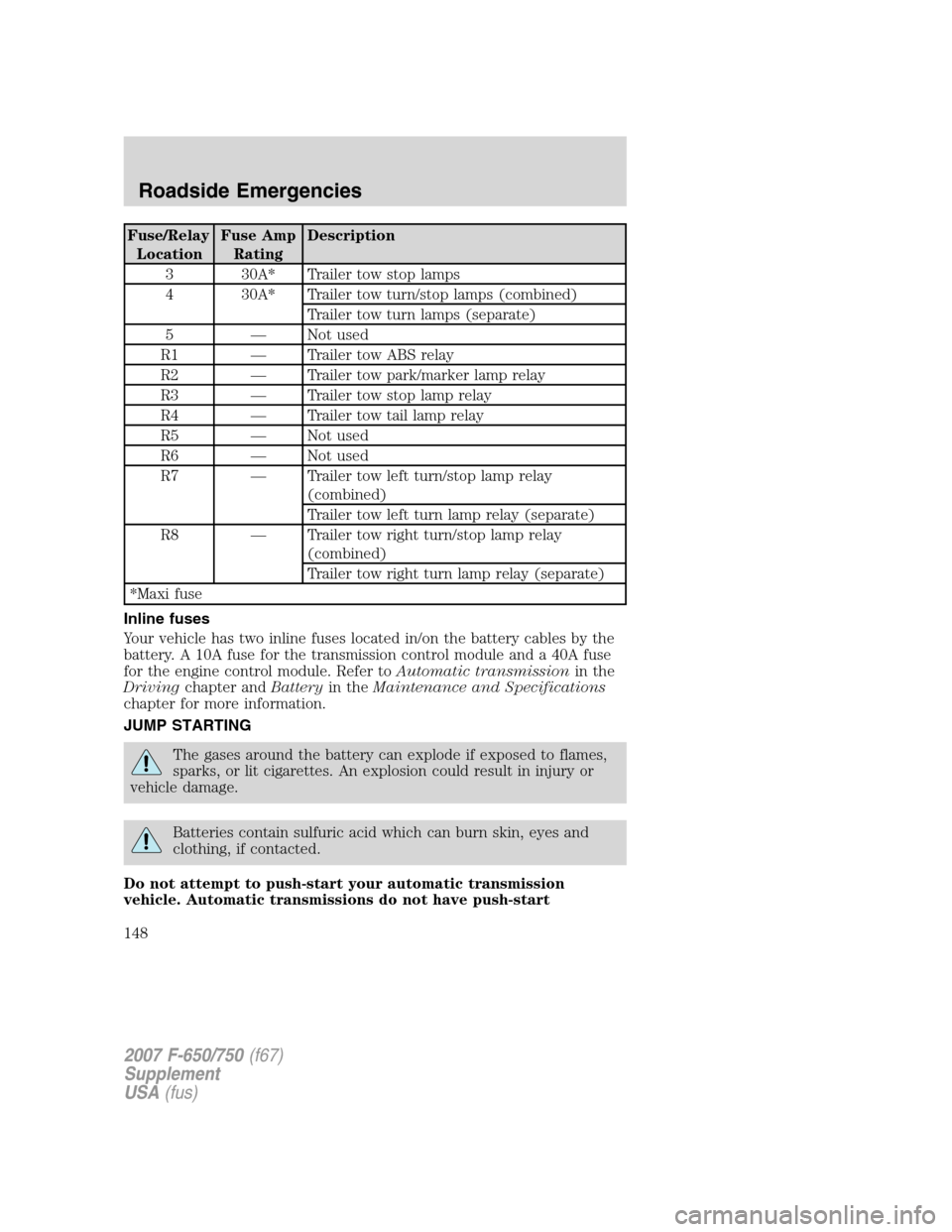

Fuse/Relay

LocationFuse Amp

RatingDescription

3 30A* Trailer tow stop lamps

4 30A* Trailer tow turn/stop lamps (combined)

Trailer tow turn lamps (separate)

5 — Not used

R1 — Trailer tow ABS relay

R2 — Trailer tow park/marker lamp relay

R3 — Trailer tow stop lamp relay

R4 — Trailer tow tail lamp relay

R5 — Not used

R6 — Not used

R7 — Trailer tow left turn/stop lamp relay

(combined)

Trailer tow left turn lamp relay (separate)

R8 — Trailer tow right turn/stop lamp relay

(combined)

Trailer tow right turn lamp relay (separate)

*Maxi fuse

Inline fuses

Your vehicle has two inline fuses located in/on the battery cables by the

battery. A 10A fuse for the transmission control module and a 40A fuse

for the engine control module. Refer toAutomatic transmissionin the

Drivingchapter andBatteryin theMaintenance and Specifications

chapter for more information.

JUMP STARTING

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your automatic transmission

vehicle. Automatic transmissions do not have push-start

2007 F-650/750(f67)

Supplement

USA(fus)

Roadside Emergencies

148

Page 182 of 280

If the engine coolant has not been checked at the recommended interval,

the engine coolant reservoir may become low or empty. If the reservoir is

low or empty, add engine coolant to the reservoir. Refer toAdding

engine coolantin this chapter.

Note:Automotive fluids are not interchangeable; do not use engine

coolant, antifreeze or windshield washer fluid outside of its specified

function and vehicle location.

Adding engine coolant - 6.0L Power Stroke

Note:The engine coolant reservoir requires air space for expansion

volume. The proper fill level is identified on the reservoir; do not overfill

the reservoir.

Note:If the coolant should get extremely low and the engine very hot,

let the engine cool for approximately 15 minutes before adding coolant.

After the engine has cooled, start the engine and add coolant slowly.

Adding coolant to a hot engine may crack the cylinder head or

crankcase. Never use only water to fill the cooling system.

When adding coolant, make sure it is a 50/50 mixture of engine coolant

and distilled water. Add the mixture to the coolant reservoir,when the

engine is cool, until the appropriate fill level is obtained.

Do not add engine coolant when the engine is hot. Steam and

scalding liquids released from a hot cooling system can burn you

badly. Also, you can be burned if you spill coolant on hot engine parts.

Do not put engine coolant in the windshield washer fluid

container. If sprayed on the windshield, engine coolant could

make it difficult to see through the windshield.

The cooling system in your vehicle is filled with yellow-colored

Motorcraft Premium Gold Engine Coolant meeting Ford Specification

WSS-M97B51–A1.

Note:Add the coolant type originally equipped in your vehicle.

•Add Motorcraft Premium Gold Engine Coolant, VC-7–B

(yellow-colored).

Note:Use of Motorcraft Cooling System Stop Leak Pellets, VC-6, may

darken the color of Motorcraft Premium Gold Engine Coolant from

yellow to golden tan.

2007 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

182

Page 186 of 280

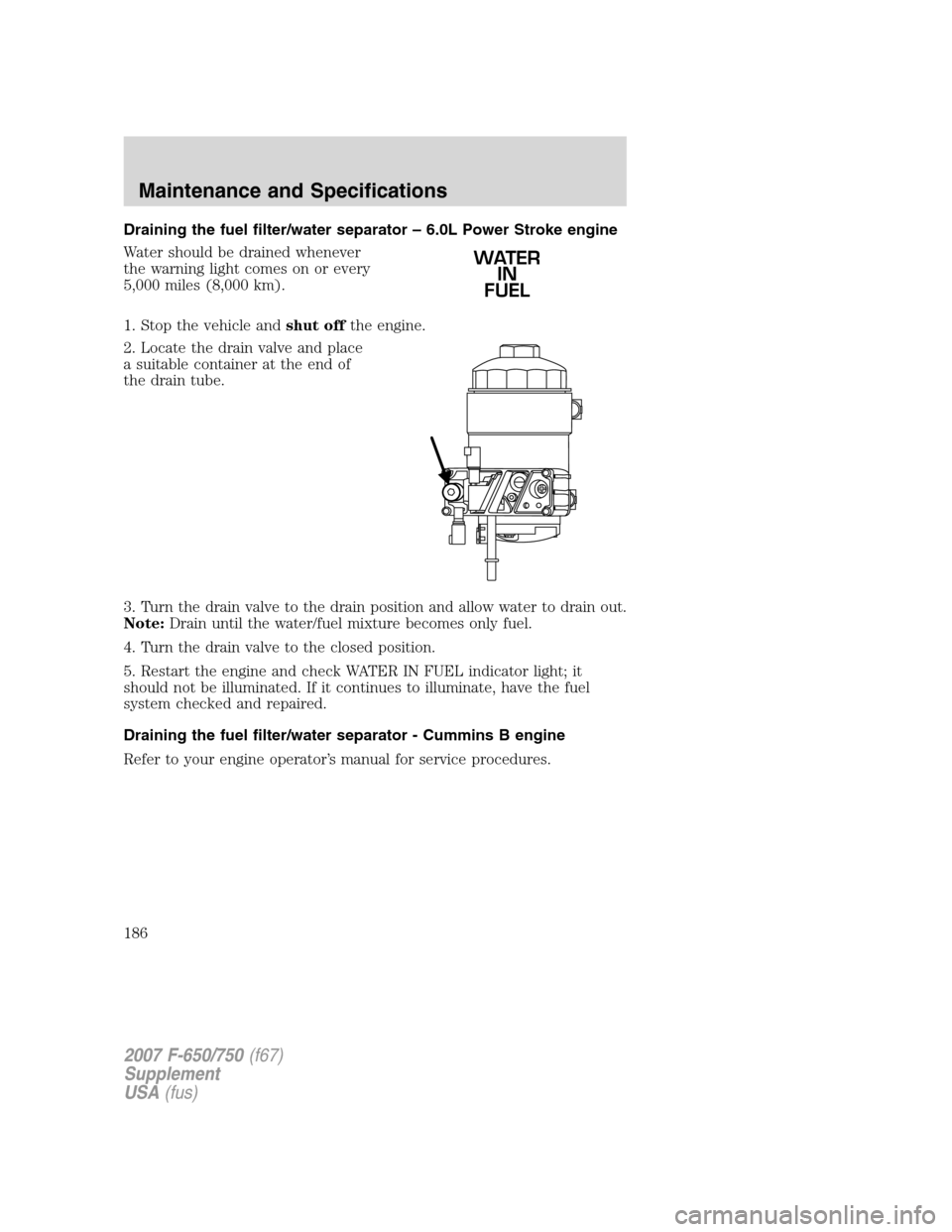

Draining the fuel filter/water separator – 6.0L Power Stroke engine

Water should be drained whenever

the warning light comes on or every

5,000 miles (8,000 km).

1. Stop the vehicle andshut offthe engine.

2. Locate the drain valve and place

a suitable container at the end of

the drain tube.

3. Turn the drain valve to the drain position and allow water to drain out.

Note:Drain until the water/fuel mixture becomes only fuel.

4. Turn the drain valve to the closed position.

5. Restart the engine and check WATER IN FUEL indicator light; it

should not be illuminated. If it continues to illuminate, have the fuel

system checked and repaired.

Draining the fuel filter/water separator - Cummins B engine

Refer to your engine operator’s manual for service procedures.

WATER

IN

FUEL

2007 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

186

Page 191 of 280

Many of the world’s automakers approved the World-wide Fuel Charter

that recommends diesel fuel specifications to provide improved

performance and emission control system protection for your vehicle.

Diesel fuel that meet the World-wide Fuel Charter should be used when

available. Ask your fuel supplier about fuel that meet the World-Wide

Fuel Charter.

Running out of fuel

Avoid running out of fuel as this will allow air to enter the fuel system,

which will make restarting the vehicle difficult.

If you have run out of fuel:

•If your vehicle is equipped with dual fuel tanks,add at least 4–5

gallons (15–19 liters) of fuel to each tank before attempting to restart

the engine.

•If your vehicle is equipped with a Caterpillar engine,the fuel

system must be primed before attempting to restart the engine. Refer

to the engine operator’s manual for instructions on priming the engine.

•Use caution not to overheat and damage the starterby cranking

the engine for an excessive period of time. You may need to crank the

engine for a longer time than normal. If the engine fails to start in 30

seconds, turn the ignition to the OFF position and wait for two

minutes before cranking the engine again.

•Any remaining trapped air will self-purge from the fuel system once

the engine starts running.

•The engine may run rough and produce white smoke while air is in

the fuel system. This is normal and should stop after a short period of

time.

FUEL CONSUMPTION IMPROVEMENT MEASURES

There are two important factors you can control to improve fuel

economy: the mechanical condition of your vehicle and how you drive it.

A properly maintained vehicle will deliver better performance than a

neglected vehicle. Always follow your maintenance schedule to keep your

vehicle in top operating condition.

Also, your driving habits have a significant influence on use of fuel. By

following these suggestions, you can stretch your fuel use:

•Avoid changes in speed as much as possible.

•Anticipate changing traffic conditions. Sudden stops and fast

acceleration waste fuel.

2007 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

191

Page 203 of 280

Air suspension U-bolt checks and re-torquing procedures

1. Inspect the threads of the U-bolt and nut for rust and debris. Clean

the threads if contaminated.

2. Using a torque wrench, determine if any nuts can be turned with a

force below the specified torque.

3. Using the lowest discovered torqued nut as a starting point, retighten

the nuts using the sequence listed underAir suspension U-bolt and

U-bolt nut installation.

Air suspension U-bolt and U-bolt nut installation

1. Inspect the threads of the U-bolt and nut for rust and debris. Clean

the threads if contaminated.

2. Install the U-bolts and nuts and torque the nuts to 15 ft. lb. (20 N•m),

using a diagonal pattern.

3. Re-torque the nuts to 100 ft. lb. (136 N•m), using a diagonal pattern.

4. Re-torque the nuts to 200 ft. lb. (271 N•m), using a diagonal pattern.

5. Re-torque the nuts to 400 ft. lb. (542 N•m), using a diagonal pattern.

(For vehicles equipped with 14ACC, 14 ADN and 14ADP axles, do not

use Step 6.)

6. Re-torque the nuts to 425 ft. lb (576 N•m), using a diagonal pattern.

(For vehicles equipped with 14ACC, 14 ADN and 14ADP axles.)

7. Use the same diagonal pattern with each U-bolt nut re-torque.

Spring U-bolt checks

Check U-bolt nuts and re-torque every 36,000 miles (58,000 km) after

initial 1,000 miles (1,600 km) re-torque. The U-bolt and nut threads and

seats should be cleaned and lubricated to ensure peak condition when

re-torqued.

PROPELLER SHAFT

At the regular lubrication interval, check the universal joints for any

evidence of wear or looseness. Should propeller shaft vibrations occur,

stop the vehicle immediately to avoid possible hazardous consequences

or damage to other components.

2007 F-650/750(f67)

Supplement

USA(fus)

Maintenance and Specifications

203

Page 242 of 280

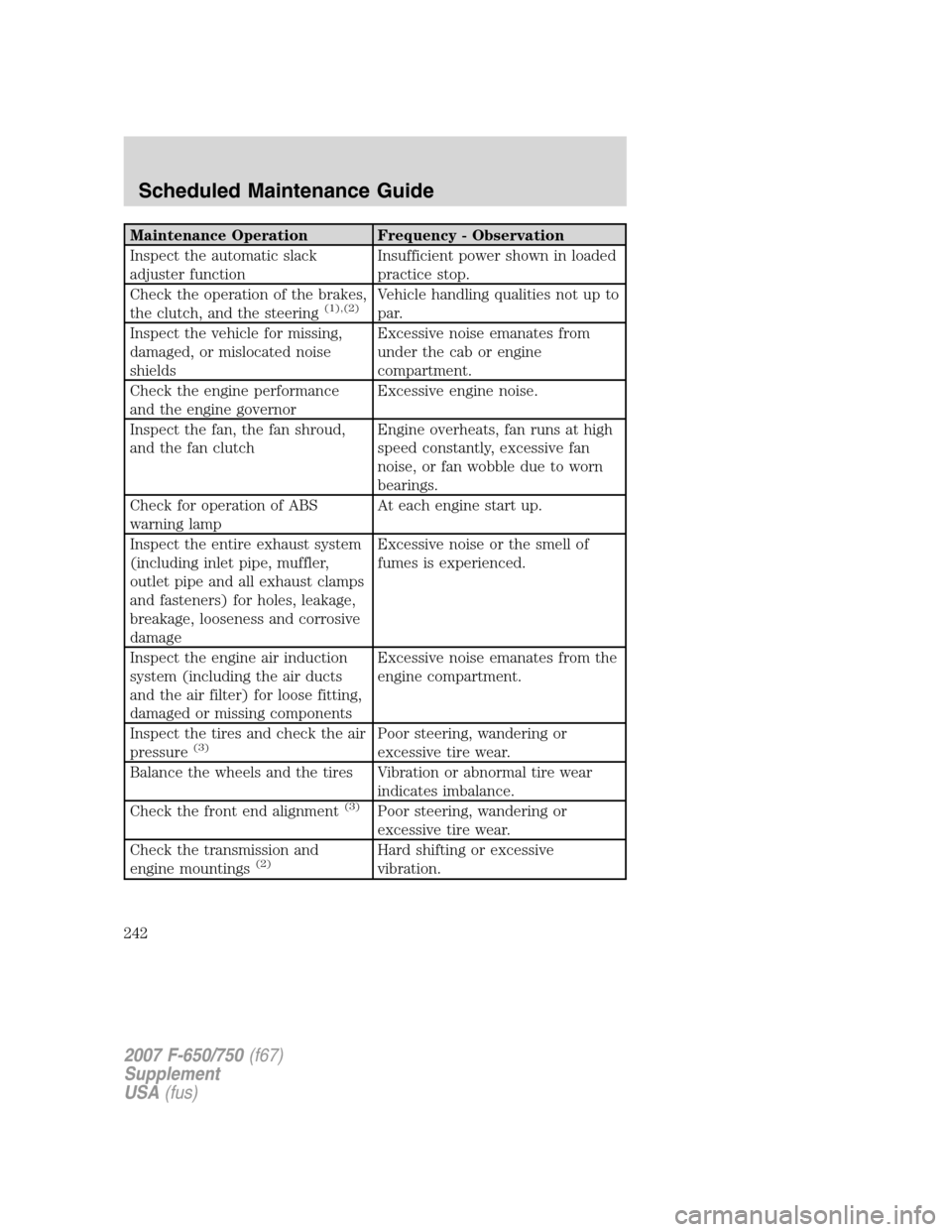

Maintenance Operation Frequency - Observation

Inspect the automatic slack

adjuster functionInsufficient power shown in loaded

practice stop.

Check the operation of the brakes,

the clutch, and the steering

(1),(2)Vehicle handling qualities not up to

par.

Inspect the vehicle for missing,

damaged, or mislocated noise

shieldsExcessive noise emanates from

under the cab or engine

compartment.

Check the engine performance

and the engine governorExcessive engine noise.

Inspect the fan, the fan shroud,

and the fan clutchEngine overheats, fan runs at high

speed constantly, excessive fan

noise, or fan wobble due to worn

bearings.

Check for operation of ABS

warning lampAt each engine start up.

Inspect the entire exhaust system

(including inlet pipe, muffler,

outlet pipe and all exhaust clamps

and fasteners) for holes, leakage,

breakage, looseness and corrosive

damageExcessive noise or the smell of

fumes is experienced.

Inspect the engine air induction

system (including the air ducts

and the air filter) for loose fitting,

damaged or missing componentsExcessive noise emanates from the

engine compartment.

Inspect the tires and check the air

pressure

(3)Poor steering, wandering or

excessive tire wear.

Balance the wheels and the tires Vibration or abnormal tire wear

indicates imbalance.

Check the front end alignment

(3)Poor steering, wandering or

excessive tire wear.

Check the transmission and

engine mountings

(2)Hard shifting or excessive

vibration.

2007 F-650/750(f67)

Supplement

USA(fus)

Scheduled Maintenance Guide

242