brakes FORD F750 2009 12.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: F750, Model: FORD F750 2009 12.GPages: 276, PDF Size: 1.75 MB

Page 2 of 276

Driving 92

Starting 92

Brakes 100

Air suspension 121

Transmission operation 123

Vehicle loading 136

Roadside Emergencies 143

Hazard flasher switch 144

Fuses and relays 144

Jump starting 153

Wrecker towing 157

Customer Assistance 161

Getting assistance outside the U.S. and Canada 163

Ordering additional owner’s literature 164

Reporting safety defects (U.S. only) 164

Reporting safety defects (Canada only) 165

Cleaning 166

Cleaning your vehicle 166

Repairing paint chips 166

Underbody preservation 169

Table of Contents

2

2009 F-650/750(f67)

Supplement

USA(fus)

Page 15 of 276

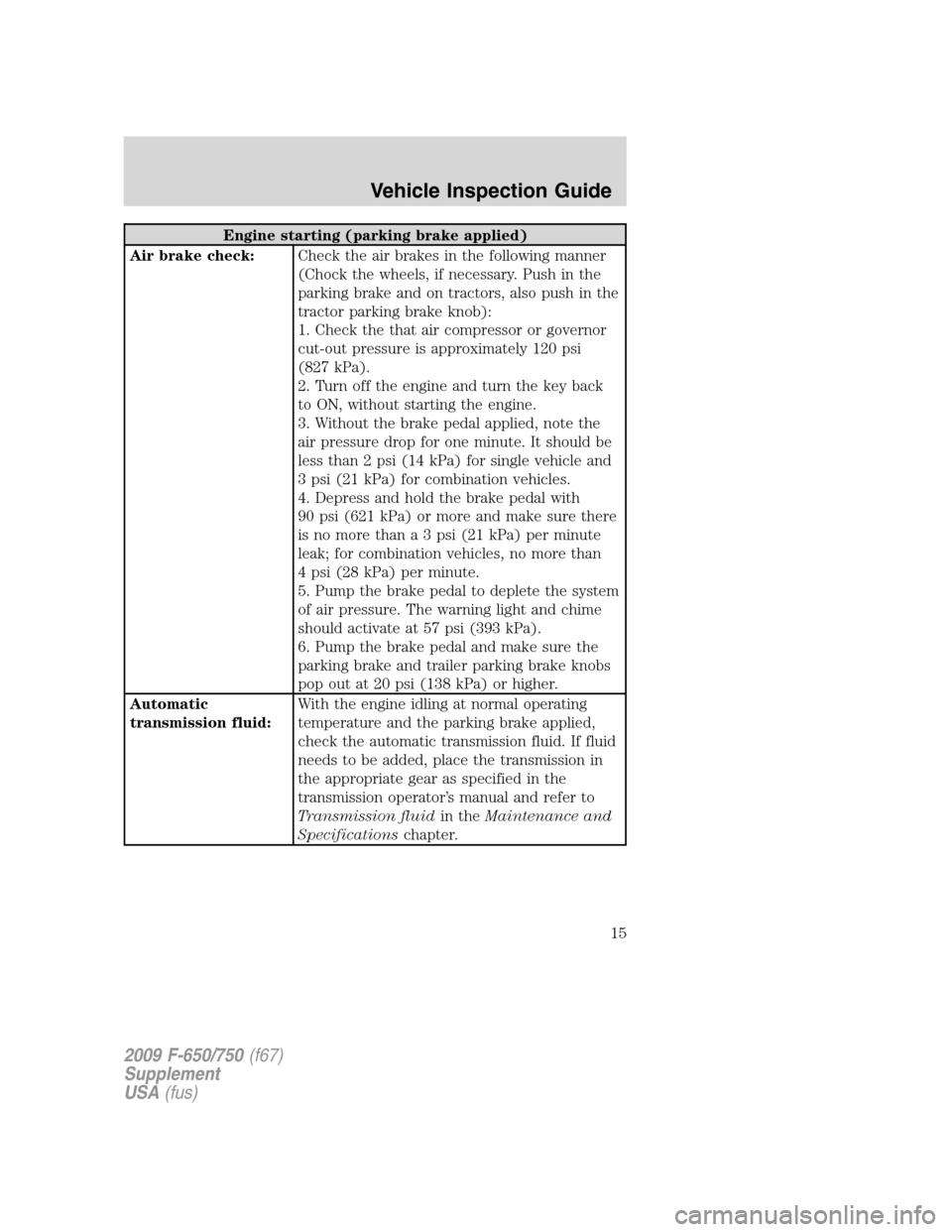

Engine starting (parking brake applied)

Air brake check:Check the air brakes in the following manner

(Chock the wheels, if necessary. Push in the

parking brake and on tractors, also push in the

tractor parking brake knob):

1. Check the that air compressor or governor

cut-out pressure is approximately 120 psi

(827 kPa).

2. Turn off the engine and turn the key back

to ON, without starting the engine.

3. Without the brake pedal applied, note the

air pressure drop for one minute. It should be

less than 2 psi (14 kPa) for single vehicle and

3 psi (21 kPa) for combination vehicles.

4. Depress and hold the brake pedal with

90 psi (621 kPa) or more and make sure there

is no more than a 3 psi (21 kPa) per minute

leak; for combination vehicles, no more than

4 psi (28 kPa) per minute.

5. Pump the brake pedal to deplete the system

of air pressure. The warning light and chime

should activate at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the

parking brake and trailer parking brake knobs

pop out at 20 psi (138 kPa) or higher.

Automatic

transmission fluid:With the engine idling at normal operating

temperature and the parking brake applied,

check the automatic transmission fluid. If fluid

needs to be added, place the transmission in

the appropriate gear as specified in the

transmission operator’s manual and refer to

Transmission fluidin theMaintenance and

Specificationschapter.

2009 F-650/750(f67)

Supplement

USA(fus)

Vehicle Inspection Guide

15

Page 17 of 276

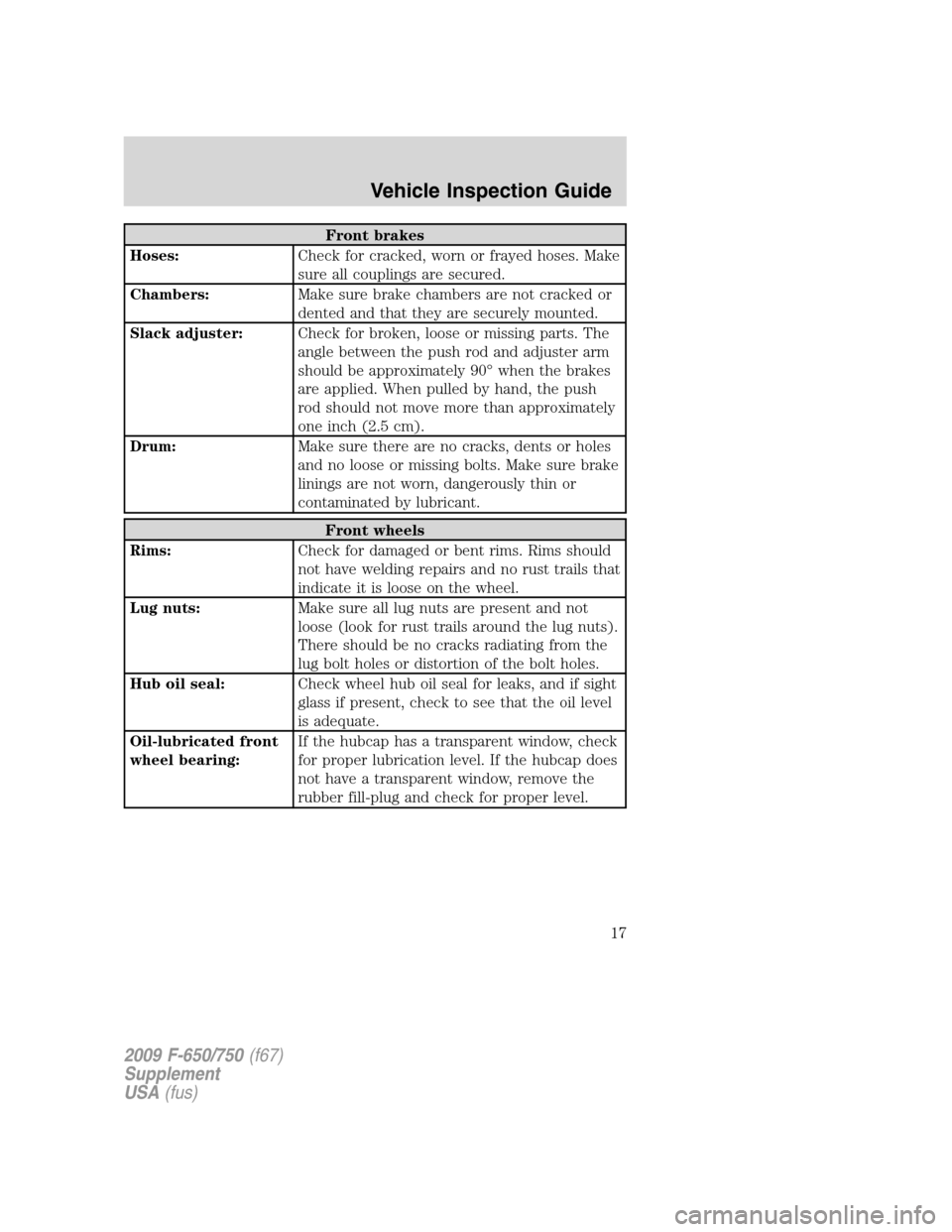

Front brakes

Hoses:Check for cracked, worn or frayed hoses. Make

sure all couplings are secured.

Chambers:Make sure brake chambers are not cracked or

dented and that they are securely mounted.

Slack adjuster:Check for broken, loose or missing parts. The

angle between the push rod and adjuster arm

should be approximately 90° when the brakes

are applied. When pulled by hand, the push

rod should not move more than approximately

one inch (2.5 cm).

Drum:Make sure there are no cracks, dents or holes

and no loose or missing bolts. Make sure brake

linings are not worn, dangerously thin or

contaminated by lubricant.

Front wheels

Rims:Check for damaged or bent rims. Rims should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nuts:Make sure all lug nuts are present and not

loose (look for rust trails around the lug nuts).

There should be no cracks radiating from the

lug bolt holes or distortion of the bolt holes.

Hub oil seal:Check wheel hub oil seal for leaks, and if sight

glass if present, check to see that the oil level

is adequate.

Oil-lubricated front

wheel bearing:If the hubcap has a transparent window, check

for proper lubrication level. If the hubcap does

not have a transparent window, remove the

rubber fill-plug and check for proper level.

2009 F-650/750(f67)

Supplement

USA(fus)

Vehicle Inspection Guide

17

Page 20 of 276

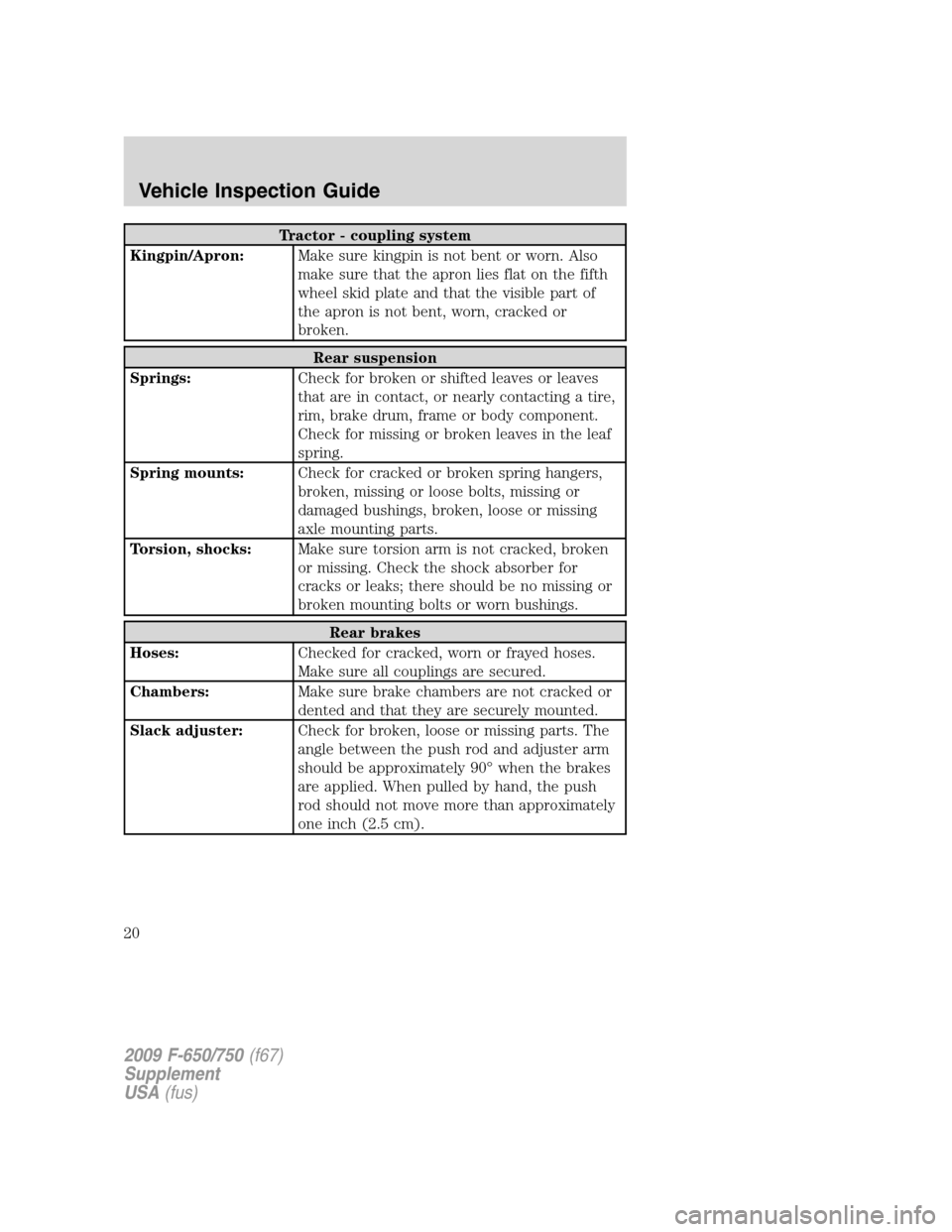

Tractor - coupling system

Kingpin/Apron:Make sure kingpin is not bent or worn. Also

make sure that the apron lies flat on the fifth

wheel skid plate and that the visible part of

the apron is not bent, worn, cracked or

broken.

Rear suspension

Springs:Check for broken or shifted leaves or leaves

that are in contact, or nearly contacting a tire,

rim, brake drum, frame or body component.

Check for missing or broken leaves in the leaf

spring.

Spring mounts:Check for cracked or broken spring hangers,

broken, missing or loose bolts, missing or

damaged bushings, broken, loose or missing

axle mounting parts.

Torsion, shocks:Make sure torsion arm is not cracked, broken

or missing. Check the shock absorber for

cracks or leaks; there should be no missing or

broken mounting bolts or worn bushings.

Rear brakes

Hoses:Checked for cracked, worn or frayed hoses.

Make sure all couplings are secured.

Chambers:Make sure brake chambers are not cracked or

dented and that they are securely mounted.

Slack adjuster:Check for broken, loose or missing parts. The

angle between the push rod and adjuster arm

should be approximately 90° when the brakes

are applied. When pulled by hand, the push

rod should not move more than approximately

one inch (2.5 cm).

2009 F-650/750(f67)

Supplement

USA(fus)

Vehicle Inspection Guide

20

Page 21 of 276

Rear brakes

Drum:Make sure there are no cracks, dents or holes

and no loose or missing bolts. Make sure brake

linings are not worn, dangerously thin or

contaminated by lubricant.

Rear wheels

Spacers:Make sure dual wheels are evenly separated

and that tires are not touching one another.

Rims:Check for damaged or bent rims. Rims should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nuts:Make sure all lug nuts are present and not

loose (look for rust trails around the lug nuts).

There should be no cracks radiating from the

lug bolt holes or distortion of the bolt holes.

Trailer

If you are pulling a trailer, an inspection of the trailer similar to that of

the tractor should be done. Such an inspection should follow trailer

manufacturer recommendations and should include at a minimum:

general condition, landing gear, doors, sides, lights, reflectors,

suspension, brakes, tires, wheels, cargo placement, stability and

tie-downs.

Transmission

If your vehicle is equipped with an automatic transmission, regularly

check the transmission’s neutral start switch. The engine should only

start in the N (Neutral) or P (Park) positions.

WARNING:If the unit starts in gear and/or the neutral start

switch is not functioning correctly, the vehicle may inadvertently

move which could result in property damage, personal injury or death.

Check the transmission fluid level and shift linkage for proper operation.

2009 F-650/750(f67)

Supplement

USA(fus)

Vehicle Inspection Guide

21

Page 32 of 276

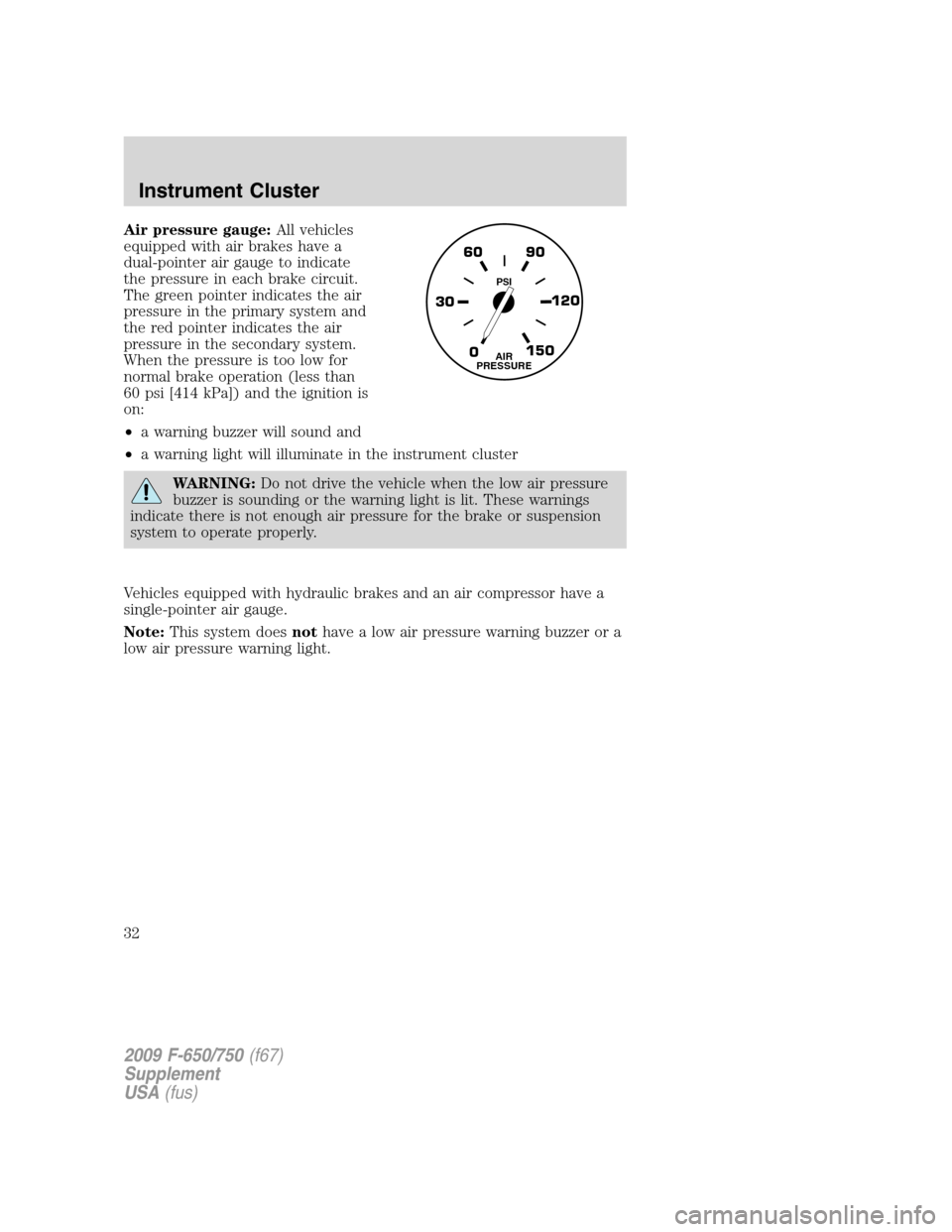

Air pressure gauge:All vehicles

equipped with air brakes have a

dual-pointer air gauge to indicate

the pressure in each brake circuit.

The green pointer indicates the air

pressure in the primary system and

the red pointer indicates the air

pressure in the secondary system.

When the pressure is too low for

normal brake operation (less than

60 psi [414 kPa]) and the ignition is

on:

•a warning buzzer will sound and

•a warning light will illuminate in the instrument cluster

WARNING:Do not drive the vehicle when the low air pressure

buzzer is sounding or the warning light is lit. These warnings

indicate there is not enough air pressure for the brake or suspension

system to operate properly.

Vehicles equipped with hydraulic brakes and an air compressor have a

single-pointer air gauge.

Note:This system doesnothave a low air pressure warning buzzer or a

low air pressure warning light.

0 30120 90 60

150AIR

PRESSURE

PSI

2009 F-650/750(f67)

Supplement

USA(fus)

Instrument Cluster

32

Page 60 of 276

To turn speed control off

Press OFF or turn off the ignition.

Once speed control is switched off,

the previously programmed engine

RPM will be erased.

WARNING:Do not use the speed control in heavy traffic or on

roads that are winding, slippery, or unpaved.

To set a speed

Press SET +. If the vehicle is

moving, this will set the vehicle

speed. If the vehicle is stationary,

this will set the vehicle idle RPM.

If you drive up or down a steep hill, your vehicle speed may vary

momentarily slower or faster than the set speed; this is normal.

Speed control cannot reduce the vehicle speed if it increases above the

set speed on a downhill. If your vehicle speed is faster than the set

speed while driving on a downhill, you may want to shift to the next

lower gear or apply the brakes to reduce your vehicle speed.

If the vehicle speed falls below 30 mph (48 km/h) or engine RPM falls

below 1,000 RPM, your speed control will disengage; this is normal.

Pressing RESUME - will re-engage it.

WARNING:Do not use the speed control in heavy traffic or on

roads that are winding, slippery, or unpaved.

CRUISE

RPM

OFF

2009 F-650/750(f67)

Supplement

USA(fus)

Driver Controls

60

Page 72 of 276

Vehicle sensitive mode

The vehicle sensitive retractor allows free shoulder belt length

adjustment to your movements and locks in response to vehicle

movement. For example, if the driver brakes suddenly or turns a corner

sharply, or the vehicle receives an impact of approximately 5 mph

(8 km/h) or more, the combination safety belts will lock to help reduce

forward movement of the driver and passengers.

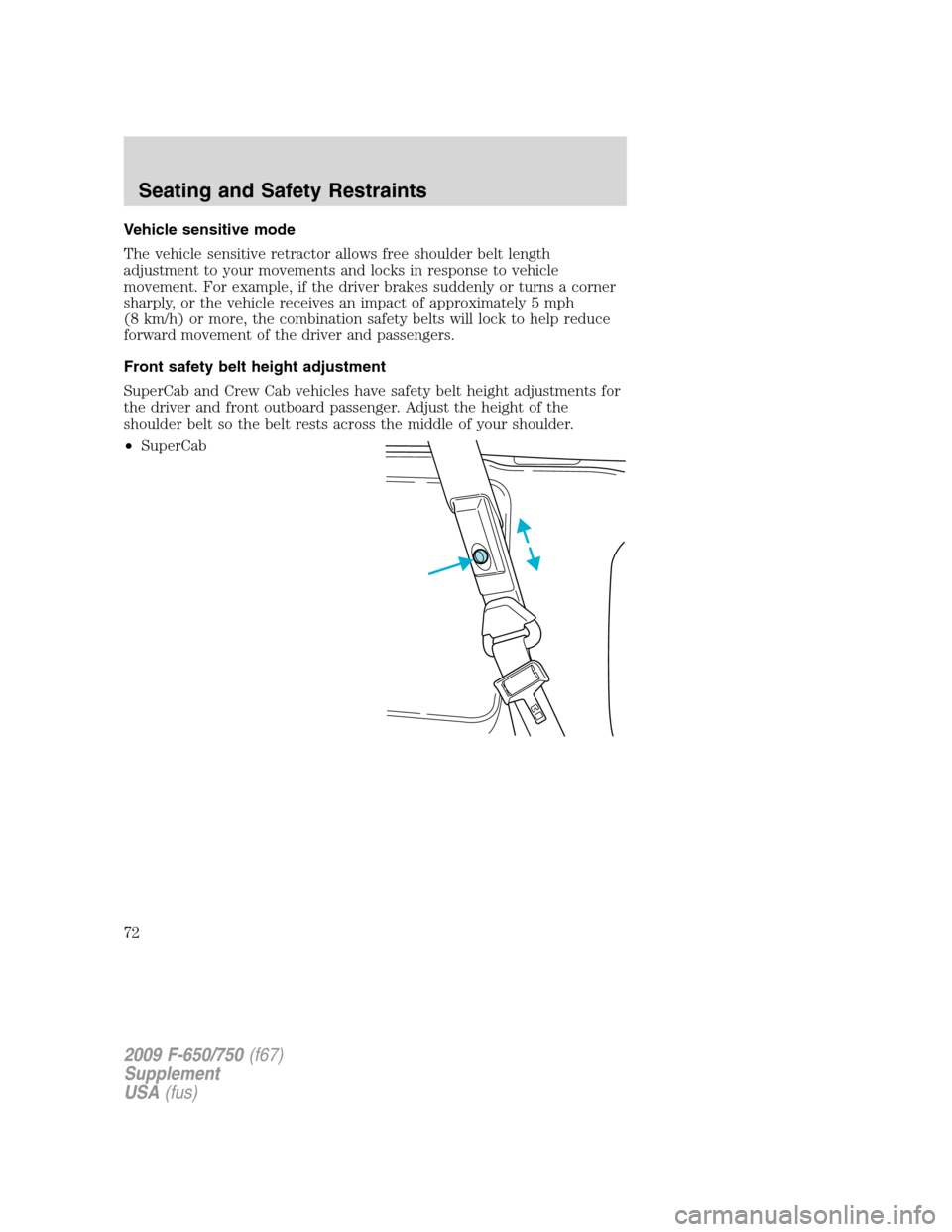

Front safety belt height adjustment

SuperCab and Crew Cab vehicles have safety belt height adjustments for

the driver and front outboard passenger. Adjust the height of the

shoulder belt so the belt rests across the middle of your shoulder.

•SuperCab

2009 F-650/750(f67)

Supplement

USA(fus)

Seating and Safety Restraints

72

Page 97 of 276

Although OSHA or some governmental regulations may require the use

of an electrical or mechanical back-up alarm to warn bystanders, such an

alarm does not ensure that the intended path is clear. When in doubt,

get out of the vehicle and visually check the intended path is clear;

back-up slowly as to allow others time to move, if necessary.

If an electrical back-up alarm is installed, it should be connected to the

back-up lamp circuit.

Parking your vehicle

Always use the parking brake. When parking on a grade, block the

wheels and turn the front wheels to one side so that if the vehicle rolls,

the front tires will act against the curb to stop the vehicle. The front

wheels will be more effective at stopping a rolling vehicle than the rear

wheels.

WARNING:When parking your vehicle, do not leave the

transmission in gear; if the key is in the ON position and the

vehicle rolls, the engine could start. Failure to follow these instructions

could result in an unattended vehicle moving, possibly causing personal

injury or property damage.

Driving through water

If driving through deep or standing water is unavoidable, proceed very

slowly especially if the depth is not known. Never drive through water

that is higher than the bottom of the hubs. Traction or brake capability

may be limited and your vehicle may stall. Water may also enter your

engine’s air intake and severely damage your engine, drive axles or the

transmission (through the breather ports).

Once through the water, always dry the brakes by moving your vehicle

slowly while applying light pressure on the brake pedal. Wet brakes do

not stop the vehicle as quickly as dry brakes.

ENGINE IDLE SHUTDOWN (IF EQUIPPED)

Your vehicle may be equipped with an Engine Idle Shutdown system.

This system will automatically shut down your engine when it has been

idling in P (Park) or N (Neutral) for five minutes (parking brake set) or

15 minutes (parking brake not set). During the engine idle shutdown

process:

•TheService Engine Soonlight will flash, once per second, for the

final 30 seconds just prior to shutdown.

2009 F-650/750(f67)

Supplement

USA(fus)

Driving

97

Page 98 of 276

•Within the final 30 seconds, the timer can be reset by:

1. changing the position of the accelerator pedal, or

2. changing the brake pedal, clutch pedal, or park brake from engaged

to disengaged or from disengaged to engaged.

•When the timer reaches zero, the engine will shut down.

•In this event, the key remains in the ON (Run) position, and power

continues to be supplied to the accessories.

Battery power may be drained if the key is left in the ON (Run)

position without the engine running.

Note:The engine idle shutdown timer will not start if:

•The engine is operating in power take-off (PTO) mode.

•The engine coolant temperature is below 60° F (16° C).

•The exhaust emission control system is regenerating the diesel

particulate filter (DPF).

ENGINE AUTOMATIC SHUTDOWN WARNING LIGHT OR CHIME

(IF EQUIPPED)

Your vehicle may be equipped with an automatic shutdown feature that

stops the engine in the event of high coolant temperature, low engine oil

pressure, high diesel particulate filter soot loading or low engine coolant

level. A warning light in the instrument cluster and a warning chime will

indicate high engine coolant temperature, low engine oil pressure or the

need to have the diesel particulate filter cleaned or serviced. If the

engine coolant temperature becomes too high, engine oil pressure too

low or the diesel particulate filter too restricted, the engine will

automatically shut down.

If the engine shuts down, it can be restarted and operated for

30 seconds at a time or until the problem is corrected. Do not attempt to

use this restarting feature to drive the vehicle very far as serious engine

damage could result.

WARNING:In the event of engine shutdown, make sure the

vehicle is safely off the road and the problem is remedied prior

to returning to the road. Failure to remove the vehicle from the road

could result in an accident, causing serious injury or death.

GENERAL BRAKE INFORMATION

All standard equipment brakes are designed to be self-adjusting.

Automatic adjustment, when required, occurs whenever the brakes are

applied and released during forward or reverse operation. Refer to the

Scheduled Maintenance Guidechapter for scheduled maintenance.

2009 F-650/750(f67)

Supplement

USA(fus)

Driving

98