FORD F750 2012 12.G Owners Manual

Manufacturer: FORD, Model Year: 2012, Model line: F750, Model: FORD F750 2012 12.GPages: 306, PDF Size: 1.74 MB

Page 121 of 306

EXHAUST BRAKE (IF EQUIPPED)

An exhaust brake is an auxiliary braking system that assists, but does

not replace, the primary service brake system. It is intended to help

control vehicle speed; it is not a vehicle stopping device.

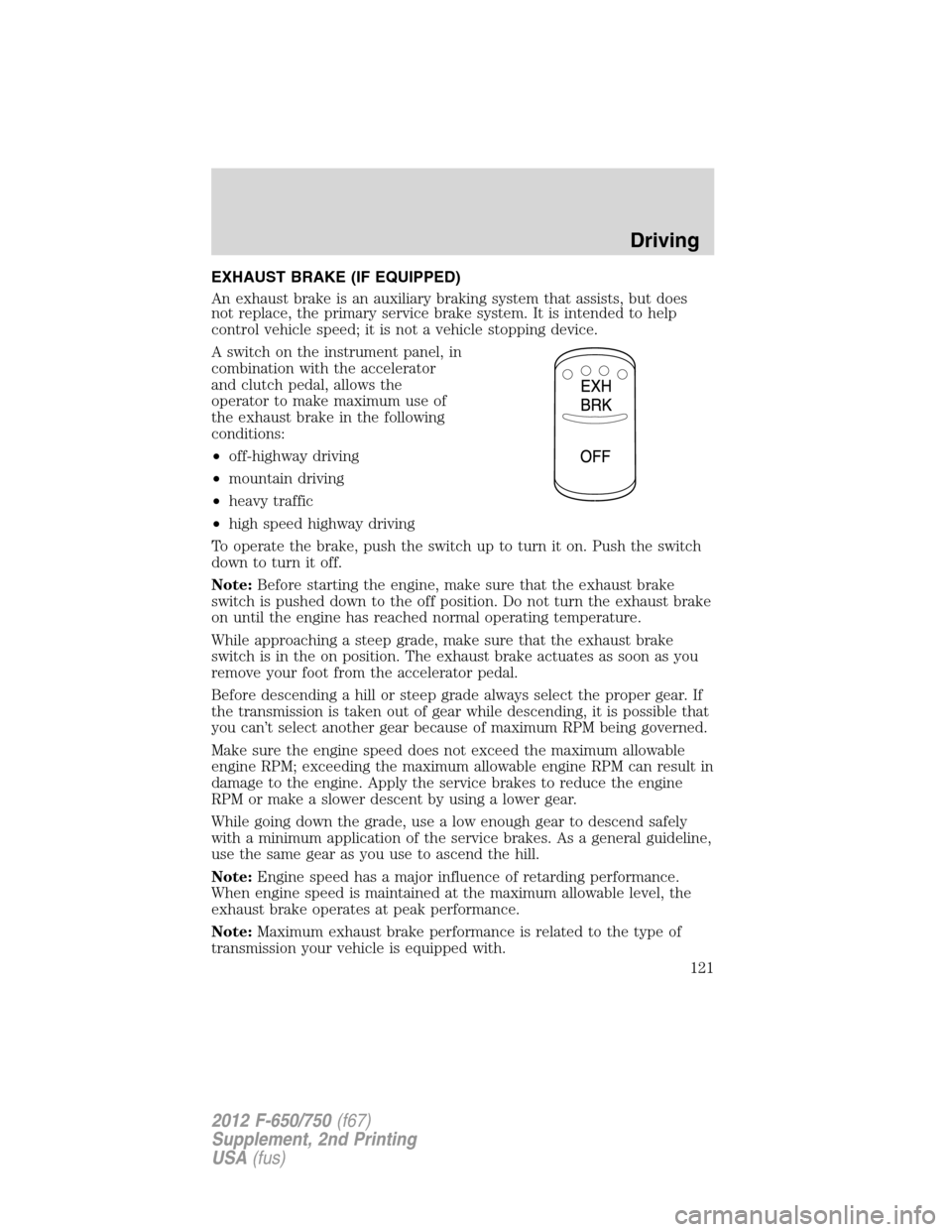

A switch on the instrument panel, in

combination with the accelerator

and clutch pedal, allows the

operator to make maximum use of

the exhaust brake in the following

conditions:

•off-highway driving

•mountain driving

•heavy traffic

•high speed highway driving

To operate the brake, push the switch up to turn it on. Push the switch

down to turn it off.

Note:Before starting the engine, make sure that the exhaust brake

switch is pushed down to the off position. Do not turn the exhaust brake

on until the engine has reached normal operating temperature.

While approaching a steep grade, make sure that the exhaust brake

switch is in the on position. The exhaust brake actuates as soon as you

remove your foot from the accelerator pedal.

Before descending a hill or steep grade always select the proper gear. If

the transmission is taken out of gear while descending, it is possible that

you can’t select another gear because of maximum RPM being governed.

Make sure the engine speed does not exceed the maximum allowable

engine RPM; exceeding the maximum allowable engine RPM can result in

damage to the engine. Apply the service brakes to reduce the engine

RPM or make a slower descent by using a lower gear.

While going down the grade, use a low enough gear to descend safely

with a minimum application of the service brakes. As a general guideline,

use the same gear as you use to ascend the hill.

Note:Engine speed has a major influence of retarding performance.

When engine speed is maintained at the maximum allowable level, the

exhaust brake operates at peak performance.

Note:Maximum exhaust brake performance is related to the type of

transmission your vehicle is equipped with.

Driving

121

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 122 of 306

Note:Manual transmissions should be downshifted to the lowest gear

possible, without exceeding the maximum RPM limit of the engine. This

maximizes the exhaust brake’s retarding effect.

Note:Exhaust brakes operate effectively with automatic transmissions,

but performance varies with engine speed and the gear selected by the

transmission.

Note:Installing an exhaust or auxiliary brake does not necessarily

protect the engine from exceeding maximum governed speed. The

primary brakes should be used to make sure the engine never exceeds

maximum governed speed under any conditions.

WARNING:The exhaust brake is not recommended for use on

slippery or low traction road surfaces. Under these conditions a

loss of vehicle control could occur.

Exhaust brake operating characteristics

When you remove your feet from both the accelerator and clutch pedals

and the exhaust brake switch is in the on position, the exhaust brake is

activated. The following conditions should exist if the brake is operating

properly:

•A slight change in the sound of the engine when the exhaust brake is

activated.

•A smooth braking effect; do not expect a retarding effect similar to

sudden, hard application of the service brakes.

•The retarding force possibly felt acting against your body when the

brake is applied, depending on the grade and vehicle load. The brake’s

retarding force is actually preventing the vehicle from going much

faster.

•Engine temperature remains in the normal operating range.

•During a descent, the tachometer usually shows a drop in engine RPM

depending on the grade and the vehicle load.

•Road speed usually decreases when the exhaust brake is applied

during a descent, except when the vehicle is carrying a heavy load or

the grade is extremely steep. In these instances, you may need to

apply the service brakes occasionally.

Driving

122

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 123 of 306

TRAILER BRAKE HAND CONTROL (IF EQUIPPED)

The hand control, located on the

right-hand side of the instrument

panel, is used to apply the trailer

service brakes which are

independent of the truck or tractor

service brakes.

WARNING:The hand control should never be used to apply the

brakes when the tractor and trailer are parked unattended. Air

may leak from the system and the vehicle could possibly move,

resulting in possible property damage, personal injury or death.

The hand control operates a valve that provides gradual control of air

pressure applied; when the valve is only partially applied, the trailer

brakes can be overridden by pressing fully on the brake pedal.

To apply the trailer brakes using the hand control, move the lever

downward. The further the lever is pushed down, the greater the air

pressure is applied to the brakes. The lever remains in place until

manually moved.

To release the trailer brakes, move the lever up completely.

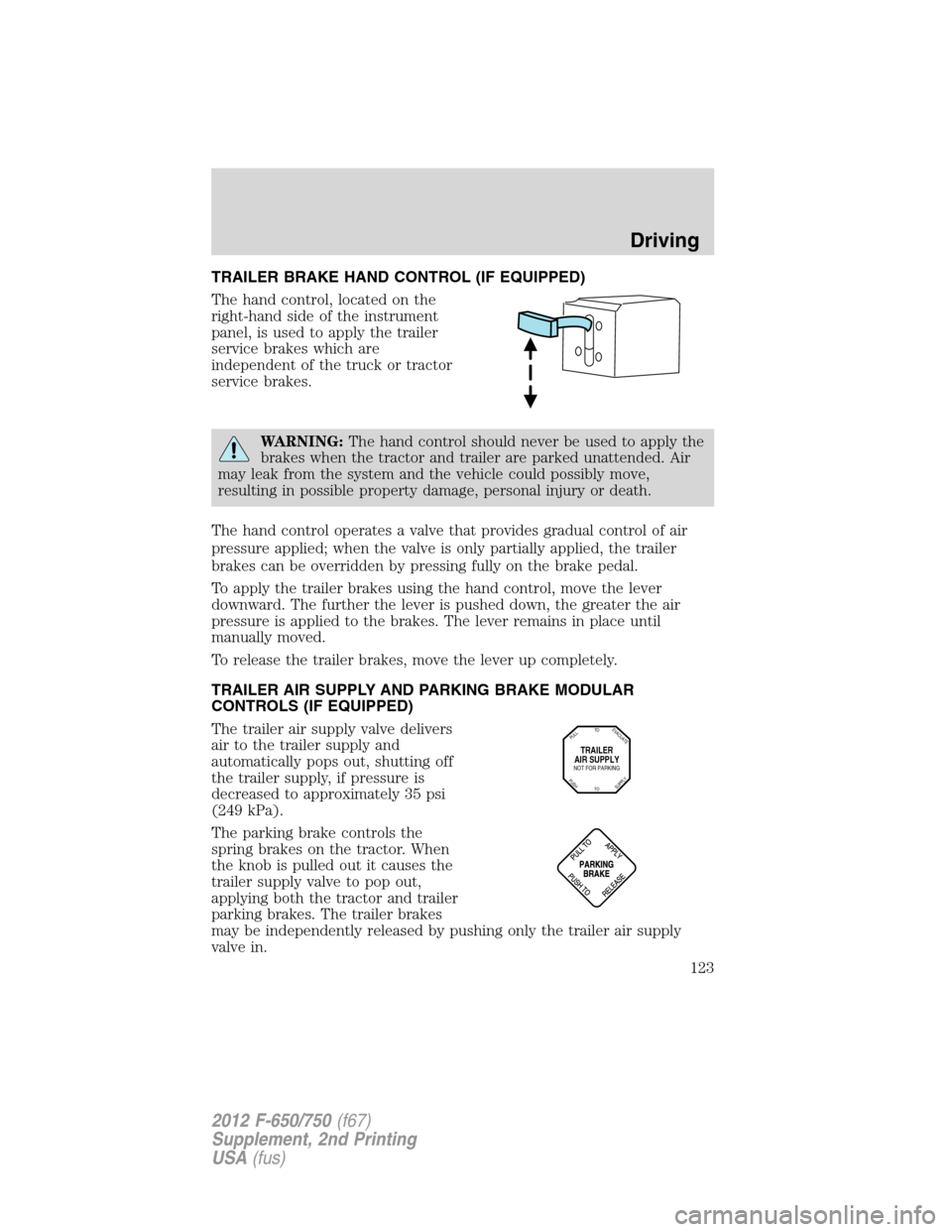

TRAILER AIR SUPPLY AND PARKING BRAKE MODULAR

CONTROLS (IF EQUIPPED)

The trailer air supply valve delivers

air to the trailer supply and

automatically pops out, shutting off

the trailer supply, if pressure is

decreased to approximately 35 psi

(249 kPa).

The parking brake controls the

spring brakes on the tractor. When

the knob is pulled out it causes the

trailer supply valve to pop out,

applying both the tractor and trailer

parking brakes. The trailer brakes

may be independently released by pushing only the trailer air supply

valve in.

TRAILER

AIR SUPPLY

NOT FOR PARKING

TO

TOPULL

SUPPLY

EVACUATE

PUSH

Driving

123

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 124 of 306

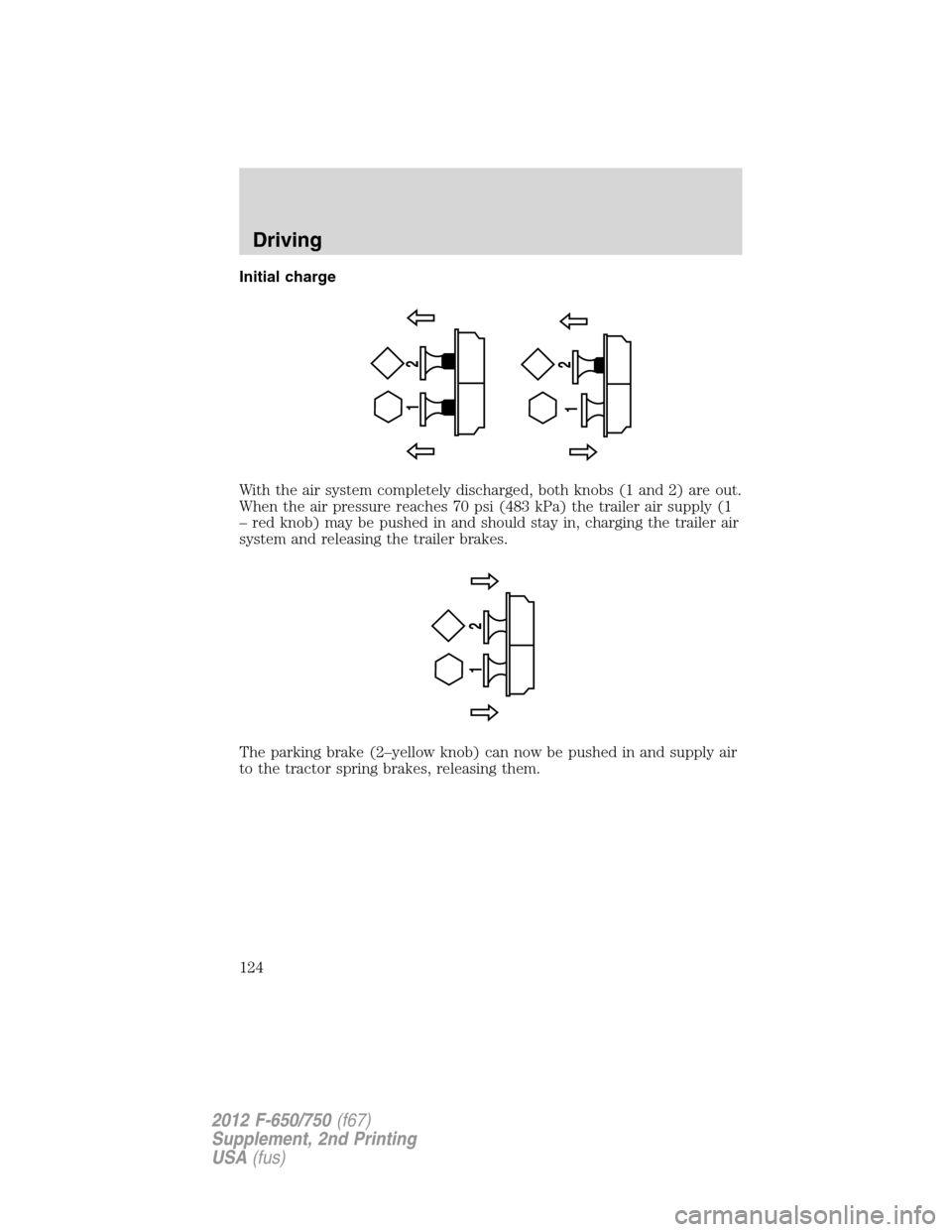

Initial charge

With the air system completely discharged, both knobs (1 and 2) are out.

When the air pressure reaches 70 psi (483 kPa) the trailer air supply (1

– red knob) may be pushed in and should stay in, charging the trailer air

system and releasing the trailer brakes.

The parking brake (2–yellow knob) can now be pushed in and supply air

to the tractor spring brakes, releasing them.

12 12

12

Driving

124

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 125 of 306

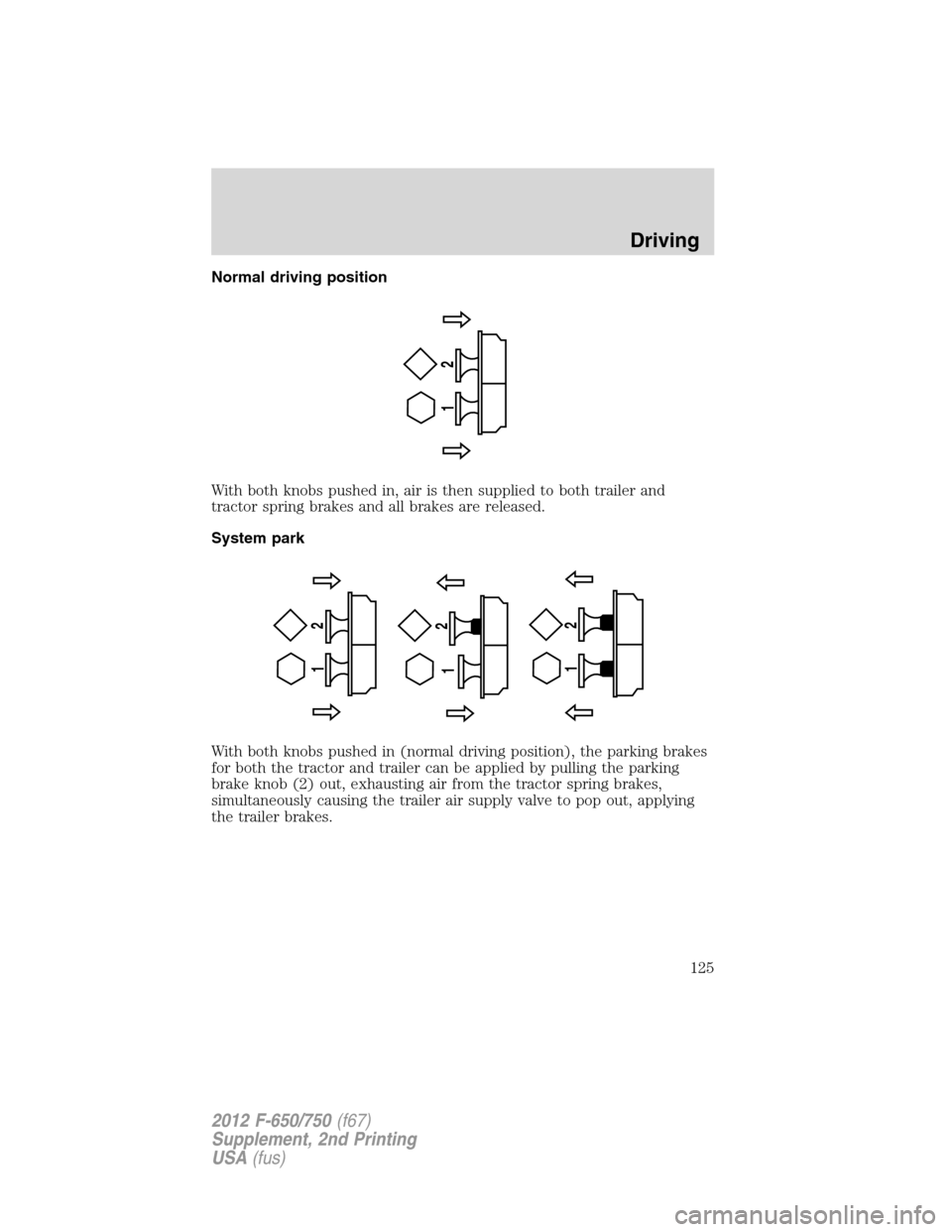

Normal driving position

With both knobs pushed in, air is then supplied to both trailer and

tractor spring brakes and all brakes are released.

System park

With both knobs pushed in (normal driving position), the parking brakes

for both the tractor and trailer can be applied by pulling the parking

brake knob (2) out, exhausting air from the tractor spring brakes,

simultaneously causing the trailer air supply valve to pop out, applying

the trailer brakes.

12

12

12

12

Driving

125

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 126 of 306

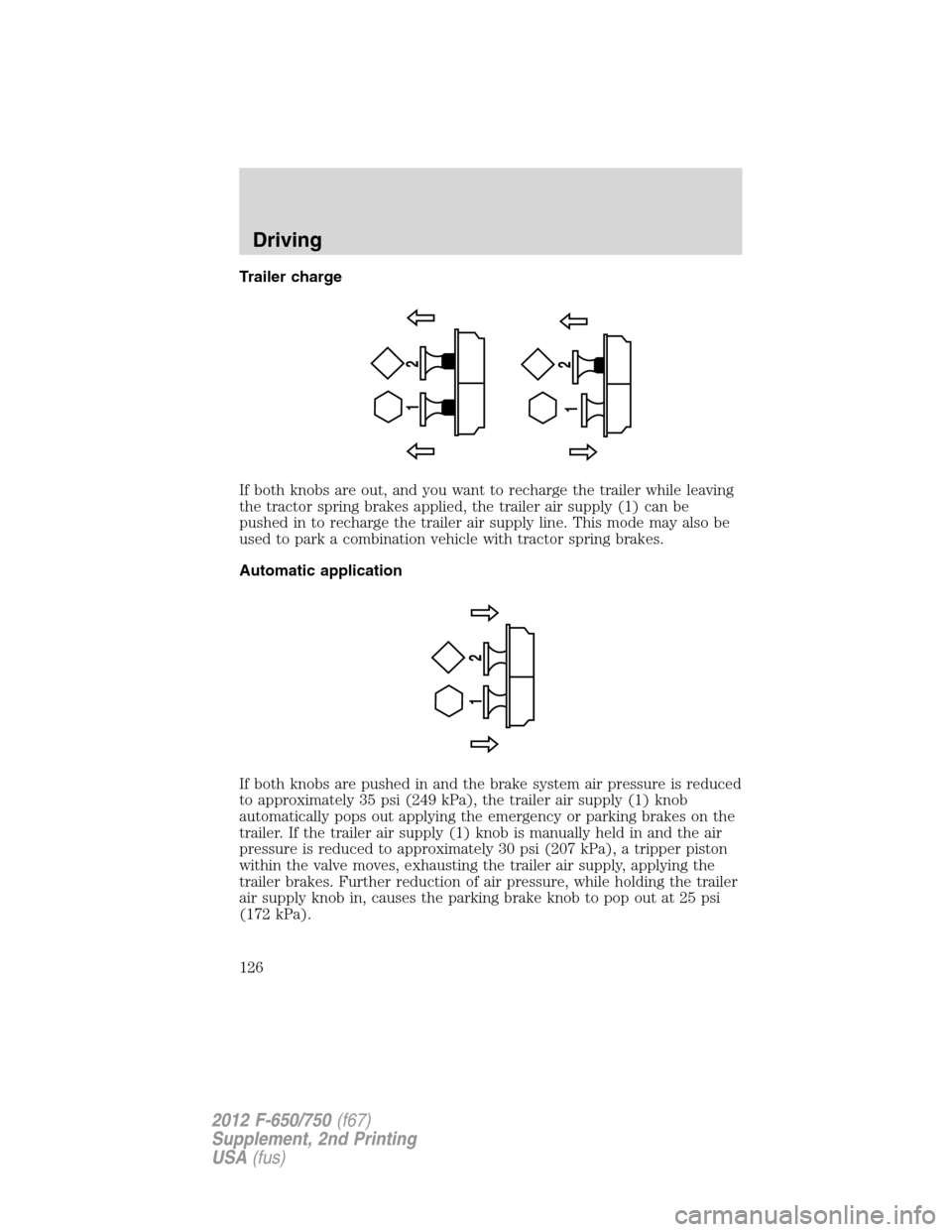

Trailer charge

If both knobs are out, and you want to recharge the trailer while leaving

the tractor spring brakes applied, the trailer air supply (1) can be

pushed in to recharge the trailer air supply line. This mode may also be

used to park a combination vehicle with tractor spring brakes.

Automatic application

If both knobs are pushed in and the brake system air pressure is reduced

to approximately 35 psi (249 kPa), the trailer air supply (1) knob

automatically pops out applying the emergency or parking brakes on the

trailer. If the trailer air supply (1) knob is manually held in and the air

pressure is reduced to approximately 30 psi (207 kPa), a tripper piston

within the valve moves, exhausting the trailer air supply, applying the

trailer brakes. Further reduction of air pressure, while holding the trailer

air supply knob in, causes the parking brake knob to pop out at 25 psi

(172 kPa).

12 12

12

Driving

126

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 127 of 306

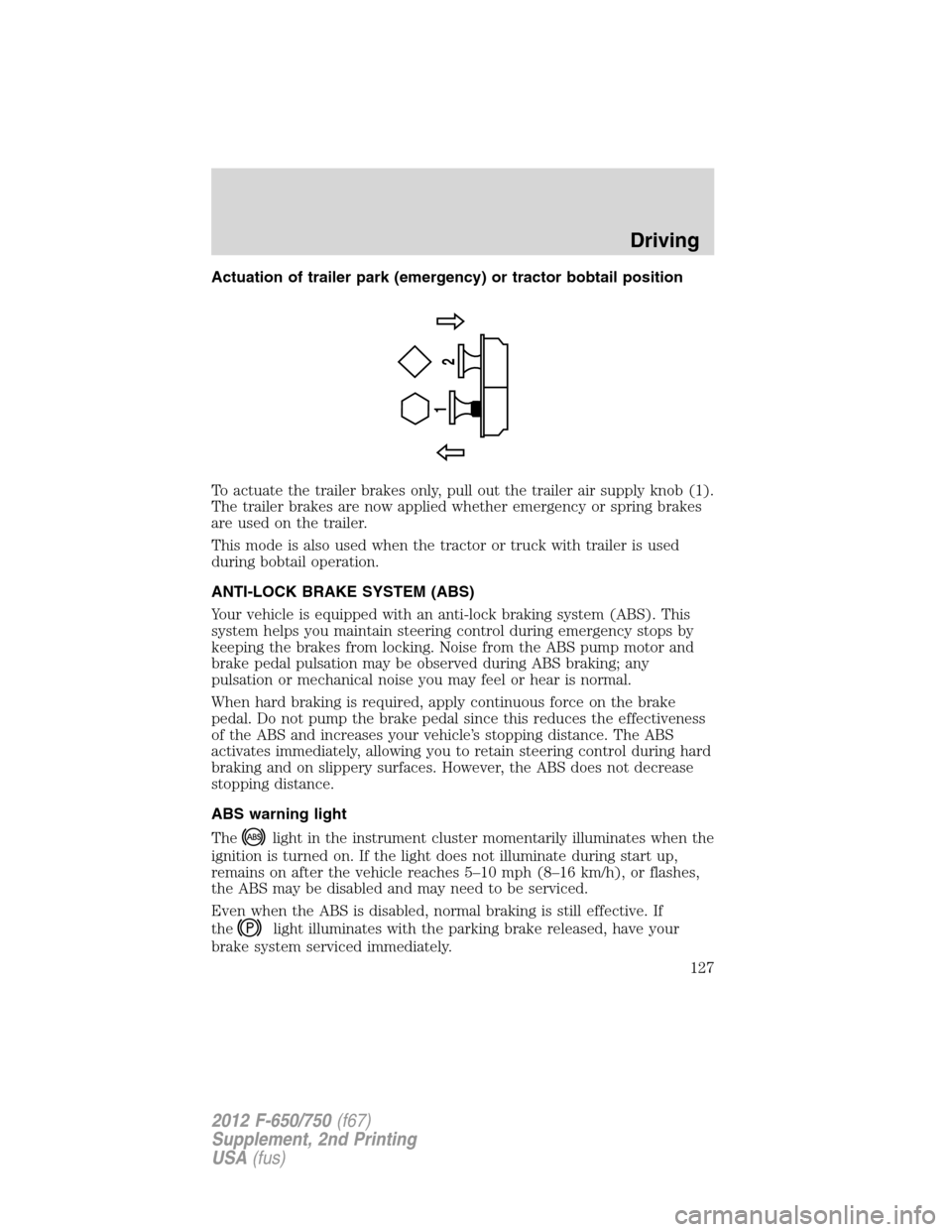

Actuation of trailer park (emergency) or tractor bobtail position

To actuate the trailer brakes only, pull out the trailer air supply knob (1).

The trailer brakes are now applied whether emergency or spring brakes

are used on the trailer.

This mode is also used when the tractor or truck with trailer is used

during bobtail operation.

ANTI-LOCK BRAKE SYSTEM (ABS)

Your vehicle is equipped with an anti-lock braking system (ABS). This

system helps you maintain steering control during emergency stops by

keeping the brakes from locking. Noise from the ABS pump motor and

brake pedal pulsation may be observed during ABS braking; any

pulsation or mechanical noise you may feel or hear is normal.

When hard braking is required, apply continuous force on the brake

pedal. Do not pump the brake pedal since this reduces the effectiveness

of the ABS and increases your vehicle’s stopping distance. The ABS

activates immediately, allowing you to retain steering control during hard

braking and on slippery surfaces. However, the ABS does not decrease

stopping distance.

ABS warning light

The

light in the instrument cluster momentarily illuminates when the

ignition is turned on. If the light does not illuminate during start up,

remains on after the vehicle reaches 5–10 mph (8–16 km/h), or flashes,

the ABS may be disabled and may need to be serviced.

Even when the ABS is disabled, normal braking is still effective. If

the

light illuminates with the parking brake released, have your

brake system serviced immediately.

1

2

Driving

127

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 128 of 306

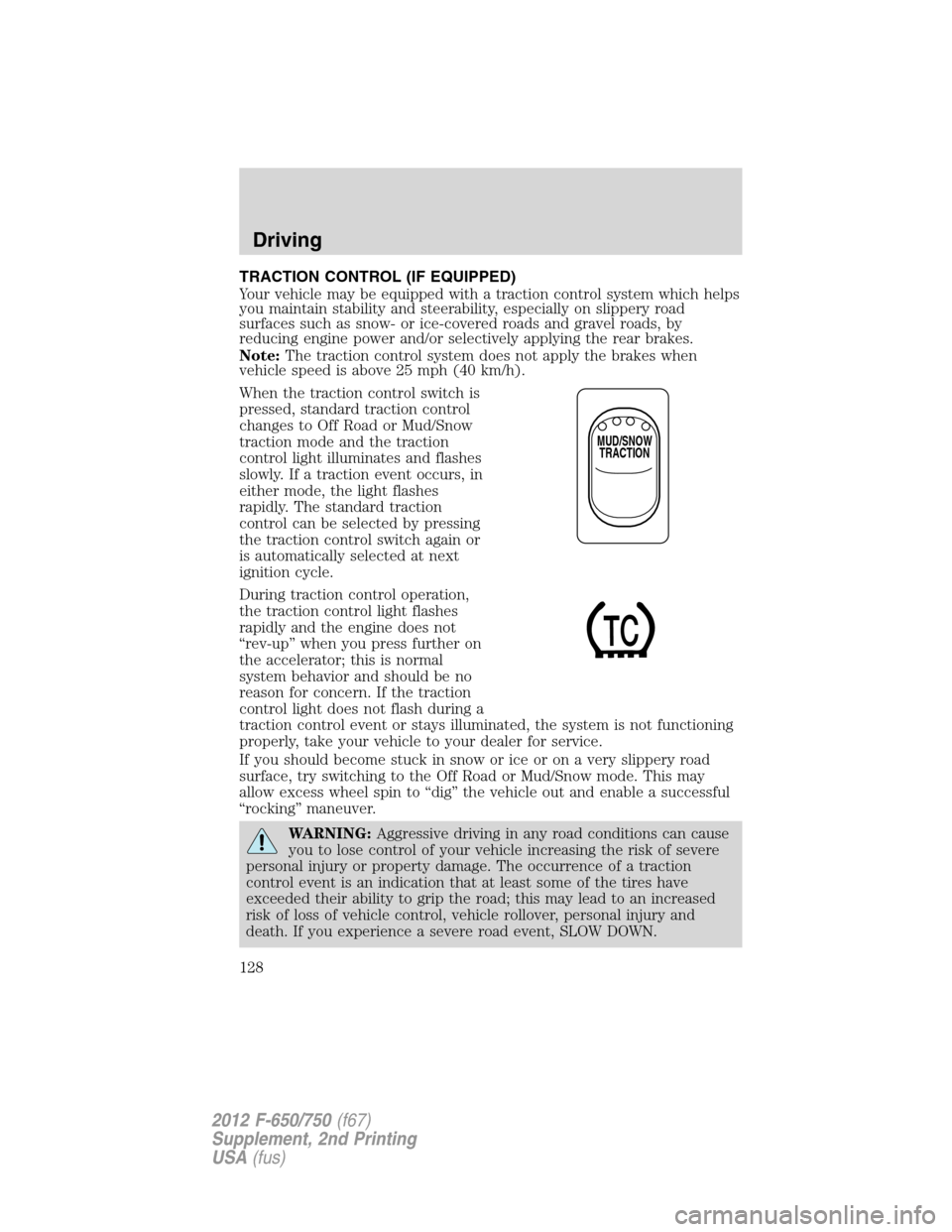

TRACTION CONTROL (IF EQUIPPED)

Your vehicle may be equipped with a traction control system which helps

you maintain stability and steerability, especially on slippery road

surfaces such as snow- or ice-covered roads and gravel roads, by

reducing engine power and/or selectively applying the rear brakes.

Note:The traction control system does not apply the brakes when

vehicle speed is above 25 mph (40 km/h).

When the traction control switch is

pressed, standard traction control

changes to Off Road or Mud/Snow

traction mode and the traction

control light illuminates and flashes

slowly. If a traction event occurs, in

either mode, the light flashes

rapidly. The standard traction

control can be selected by pressing

the traction control switch again or

is automatically selected at next

ignition cycle.

During traction control operation,

the traction control light flashes

rapidly and the engine does not

“rev-up” when you press further on

the accelerator; this is normal

system behavior and should be no

reason for concern. If the traction

control light does not flash during a

traction control event or stays illuminated, the system is not functioning

properly, take your vehicle to your dealer for service.

If you should become stuck in snow or ice or on a very slippery road

surface, try switching to the Off Road or Mud/Snow mode. This may

allow excess wheel spin to “dig” the vehicle out and enable a successful

“rocking” maneuver.

WARNING:Aggressive driving in any road conditions can cause

you to lose control of your vehicle increasing the risk of severe

personal injury or property damage. The occurrence of a traction

control event is an indication that at least some of the tires have

exceeded their ability to grip the road; this may lead to an increased

risk of loss of vehicle control, vehicle rollover, personal injury and

death. If you experience a severe road event, SLOW DOWN.

MUD/SNOW

TRACTION

Driving

128

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 129 of 306

AIR SUSPENSION (IF EQUIPPED)

The air suspension system automatically adjusts to different loads to

maintain a constant frame height, allows for ease of vehicle loading and

provides improved vehicle ride and increased driver comfort.

Note:The vehicle must not be operated without air in the suspension

springs. Operating the vehicle without air in the air suspension springs

damages the suspension, degrades ride performance and may cause

property damage.

Air suspension dump switch (if equipped)

The system is controlled by a switch

located in the overhead switch pack

which operates only when the

ignition is in the accessory or on

positions and the air tanks have

sufficient pressure to fill the air

springs. When the ignition is turned

off, the suspension remains in

whatever state it was last set.

Pressing the upper portion of the switch exhausts air from the air

springs, lowering the frame for loading. Pressing the lower portion of the

switch fills the air springs so the vehicle remains at normal ride height.

The air suspension warning lamp

illuminates when the switch has

been activated to release air

pressure in the rear air shocks.

Never drive the vehicle when the warning lamp is illuminated and there

is no (or low) air pressure in the shocks.

Note:The suspension dumps air when the ignition is in the accessory or

on position, but only fills when the ignition is in the on position.

Driving

129

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 130 of 306

Tractor-trailer connections

WARNING:To reduce the risk of personal injury, use extreme

caution when making brake and light connections. Inclement

weather and accumulated road contamination deposits on handhold

and stepping surfaces require extra care to avoid slip and falls. Provide

adequate lighting of working areas.

WARNING:Do not climb on the back of the tractor unless it

has been provided with a deck plate and handholds. Use a

three-point stance when climbing up and down from a deck plate. Do

not jump from the vehicle. Whenever possible, make all connections

while standing on the ground.

Connecting and disconnecting a trailer with air suspension and air

suspension dump switch (if equipped)

When connecting to a trailer:

•Press the lower portion of the dump switch to exhaust air from the air

suspension system.

•After making the connection to the trailer, press the upper portion of

the dump switch, then raise the landing gear.

When disconnecting the trailer:

•

Lower the landing gear, then press the lower portion of the dump switch.

•Disconnect the brake hoses, trailer-side and rear light connectors,

then pull the release lever on the fifth-wheel.

The upper portion of the dump switch must be pressed before operating

with a trailer or operating in the bobtail mode.

Suspension conversions

It is not recommended, or approved, that suspension conversions be

performed. However, it is understood that, on occasion, aftermarket add-on

suspensions are installed by others on the truck chassis which allow

operator control for weight transfer from other axles (i.e., air lift axles).

WARNING:When operating a loaded vehicle, the driver must

keep all adjustable axles on the ground at all times, supporting

their share of the vehicle’s load. Failure to do so can overload other

axles, tires, wheels, springs, steering components, brakes and frames,

resulting in early component failure, loss of vehicle control, possible

property damage and personal injury.

Driving

130

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)